Multifunctional carving machine

An engraving machine, multi-functional technology, applied in the field of processing machinery, can solve the problems of single function, time-consuming and laborious, low degree of automation, etc., to achieve the effect of convenient and safe operation, wide range of uses, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

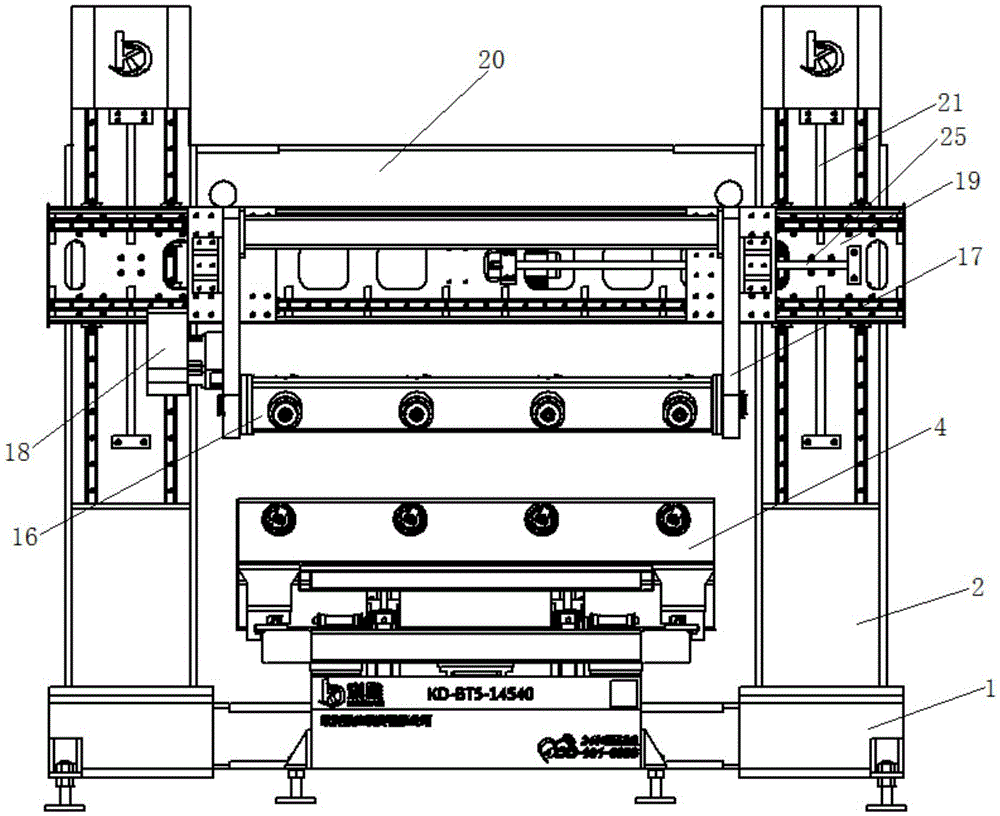

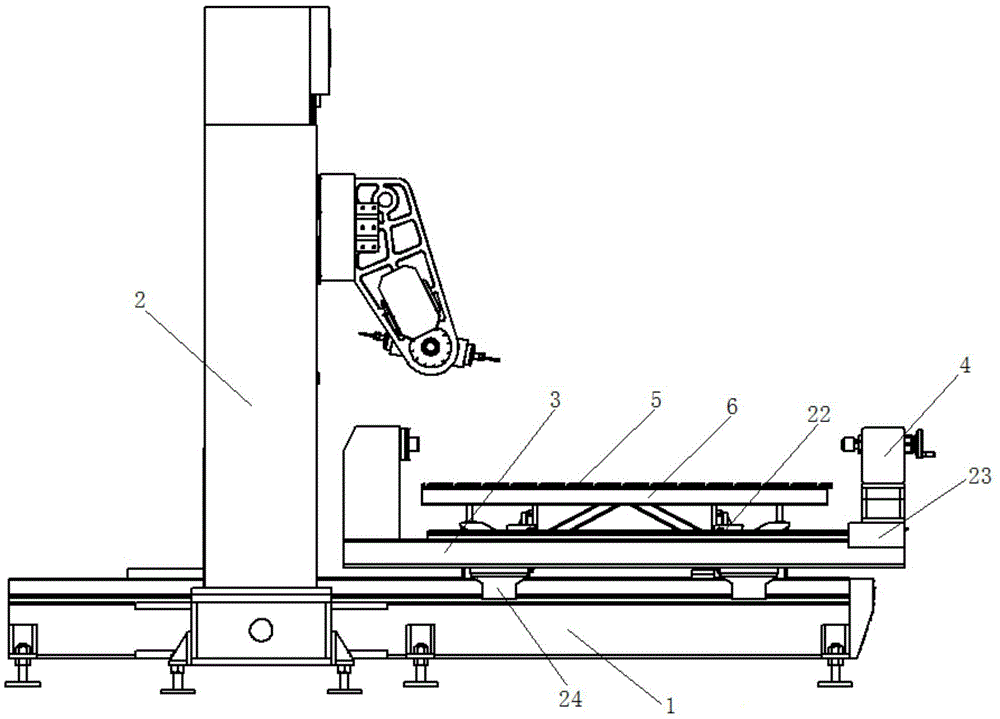

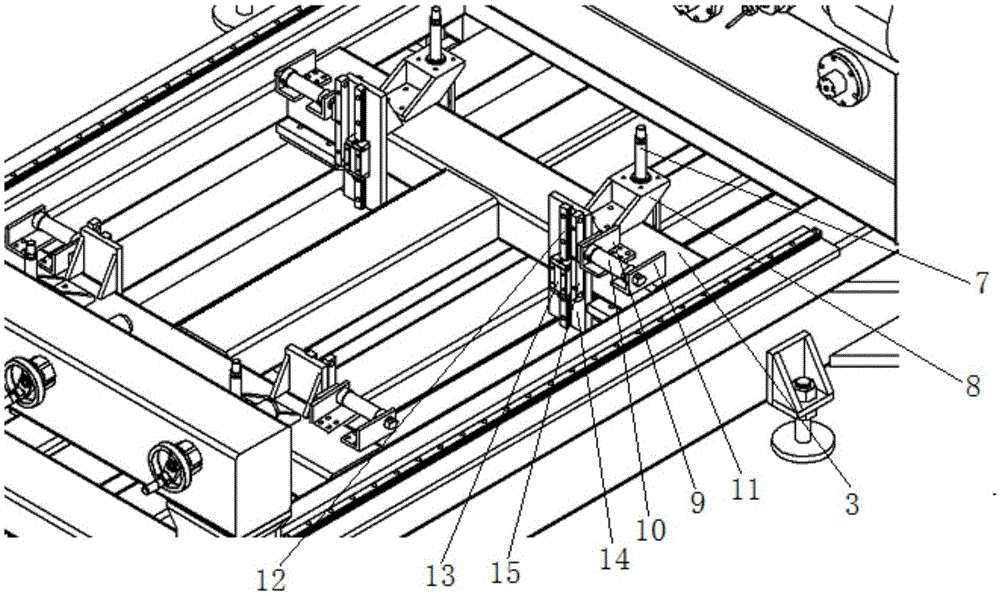

[0022] Example: such as Figure 1 to Figure 4 As shown, a multifunctional engraving machine of the present invention includes a base 1, a column 2, an engraving platform and a tool mechanism, the engraving platform includes a mobile platform 3 and a workpiece clamping device 4, and the mobile platform 3 is provided with an automatic lift Platform mechanism, the automatic lifting platform mechanism includes a table top 5, a table lifting frame 6 and an automatic table lifting mechanism, and the table automatic lifting mechanism includes a lifting cylinder 7, a cylinder seat I8, a limit cylinder 9, a cylinder seat II10, and a cylinder seat III11 , guide rail I12, slider I13, slide rail fixing plate 14 and limit bar 15, the cylinder seat I8 is fixed on the beam of the mobile platform 3, and the lifting cylinder 7 is placed vertically and fixed on the cylinder On the seat I8, the slide rail fixing plate 14 is provided with a card slot matching with the guide rail I12, the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com