Fine-engraving machine capable of loading and unloading automatically

A technology of automatic loading and unloading, fine carving machine, applied in the field of fine carving machine, can solve the problems of work efficiency, reduce production cost, restrict the production efficiency of fine carving machine, no automatic loading and unloading, etc., achieve positioning accuracy and efficiency improvement, reduce production cost, efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

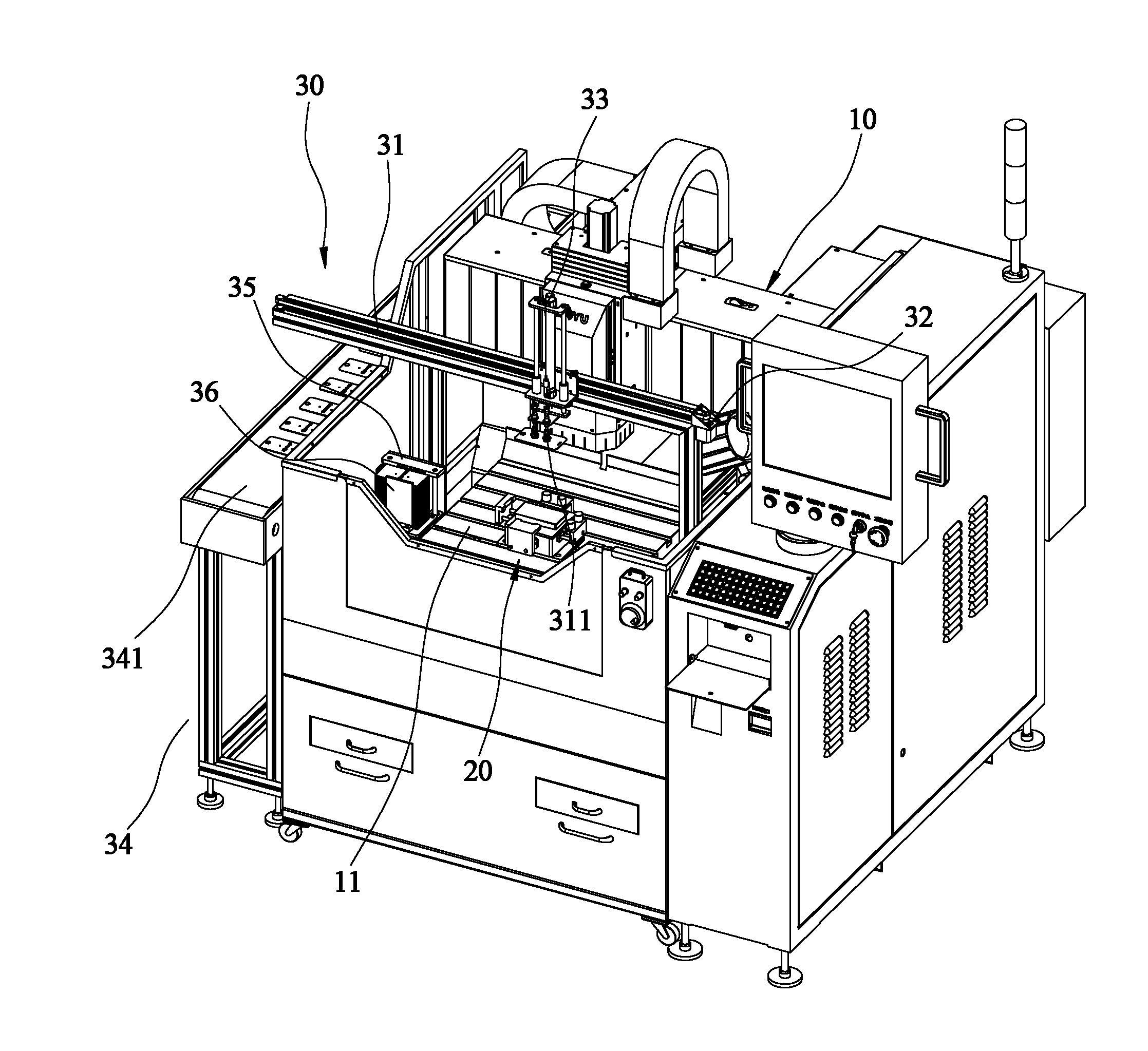

[0031] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, a fine carving machine with automatic loading and unloading, including a base 10, a fine carving operation component, a control component, a pneumatic positioning device 20 and an automatic loading and unloading device 30 ,in:

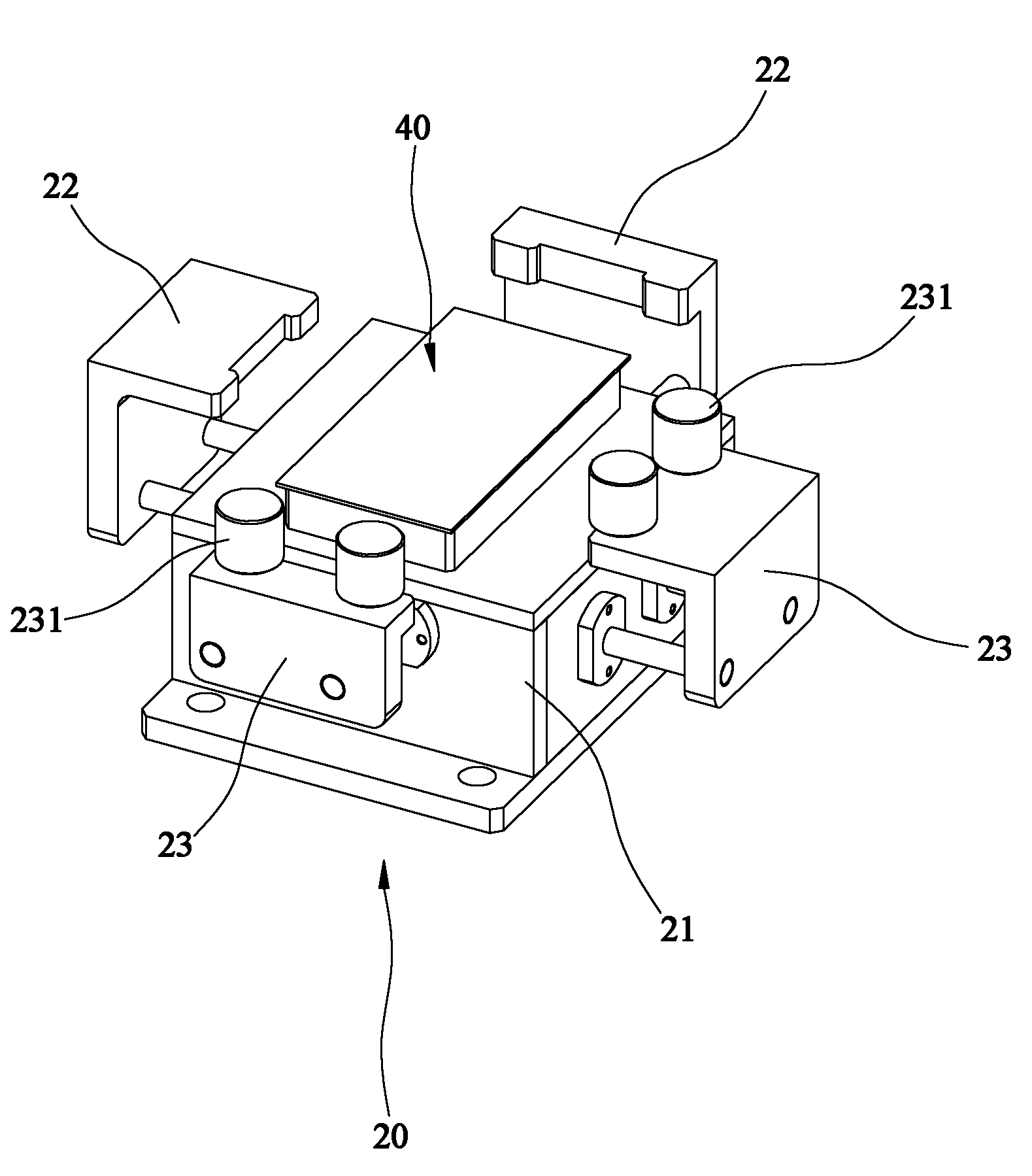

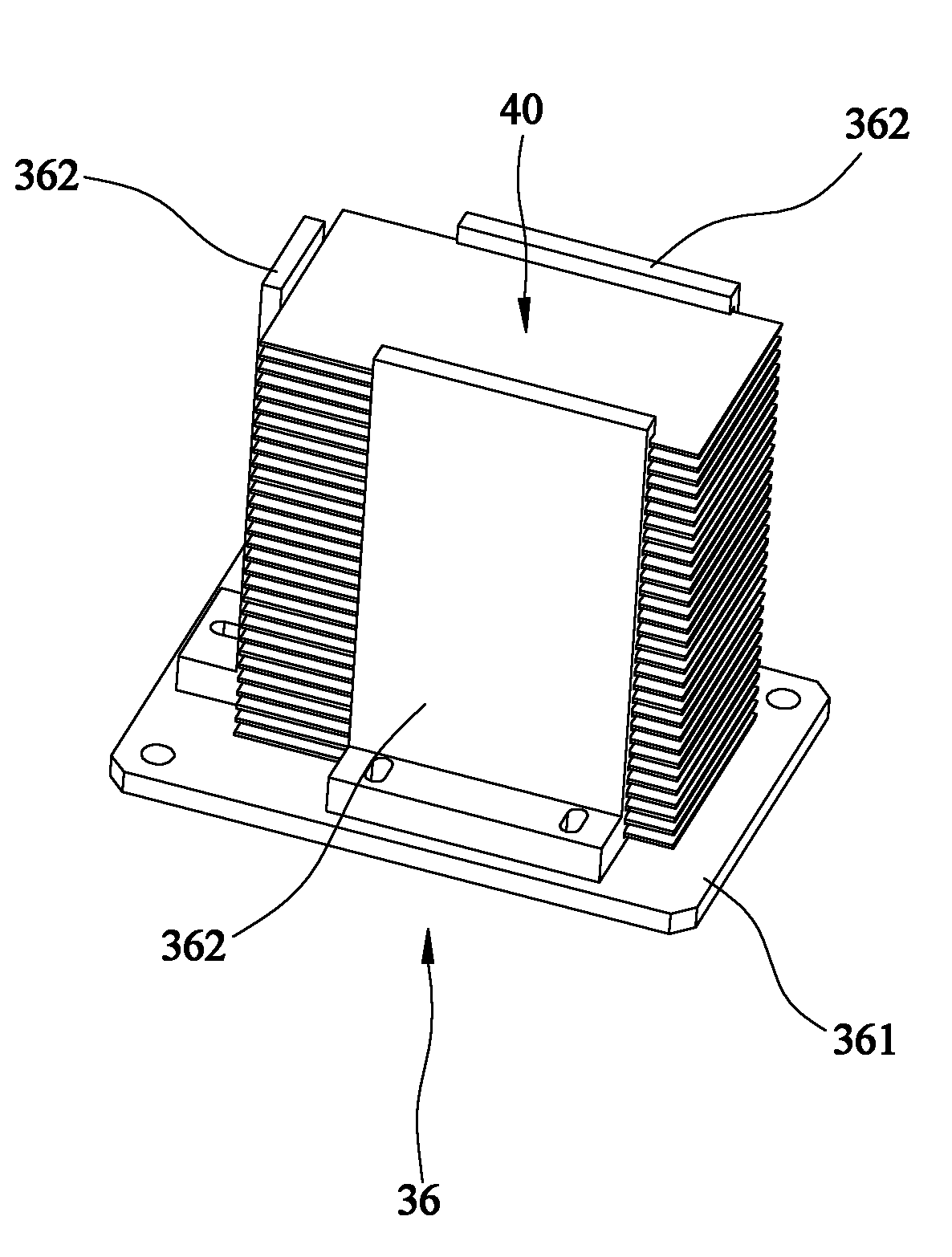

[0032] The base 10 has a working platform 11, and the pneumatic positioning device 20 is fixedly installed on the working platform 11 for absorbing and positioning the glass panel 40. The pneumatic positioning device 20 includes a seat body 21, a cylinder, and four positioning stops. side, the upper surface of the seat body 21 is provided with a vacuum suction port, the cylinder is installed in the seat body 21, and the four positioning ribs are located on the front, rear, left, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com