Engraving device for wood board processing

A technology of wood board and engraving machine, which is applied in the fields of engraving and decorative arts. It can solve the problems affecting the accuracy of wood board engraving and the surface finish of wood boards, so as to achieve the effect of ensuring smoothness, reducing labor intensity and high carving precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

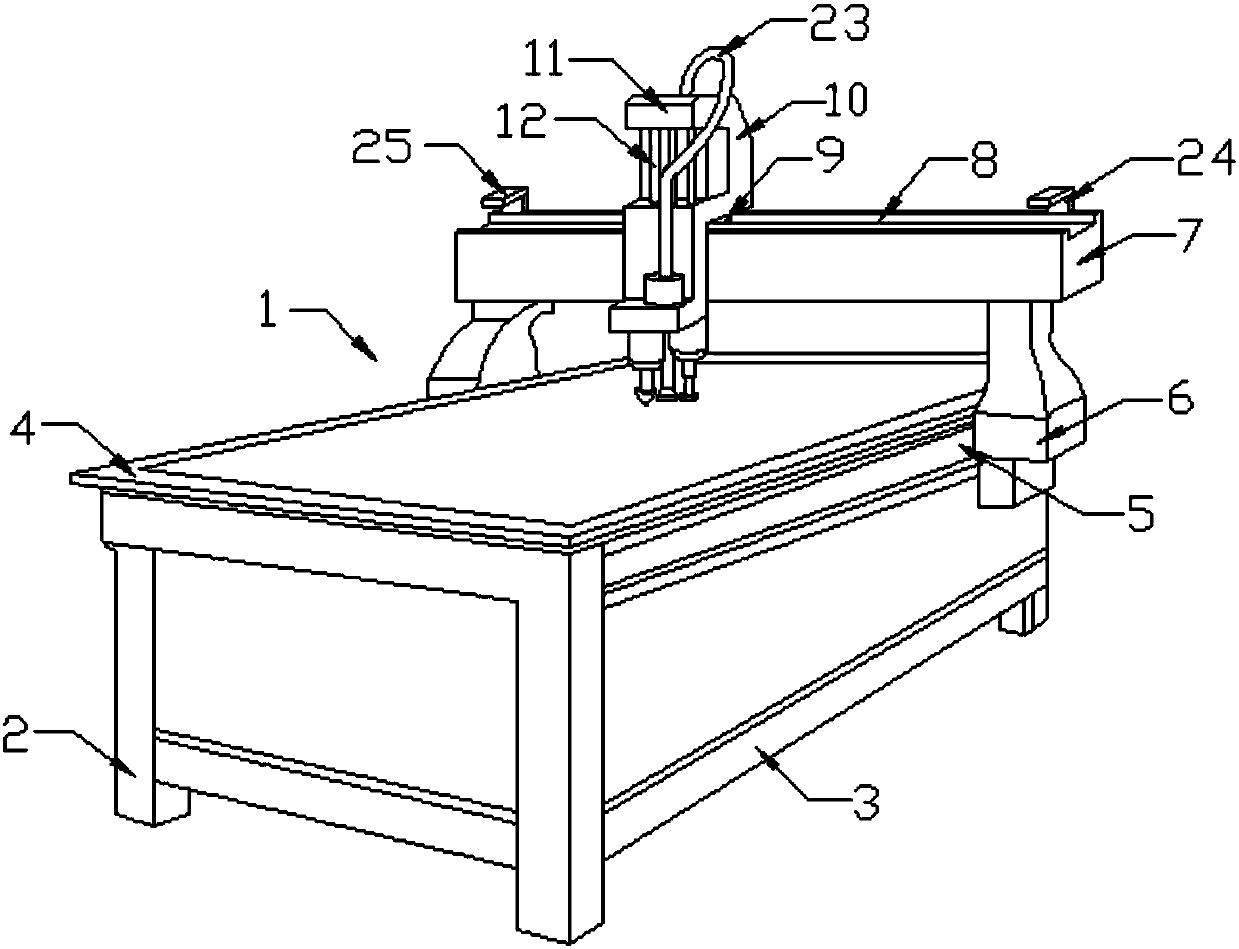

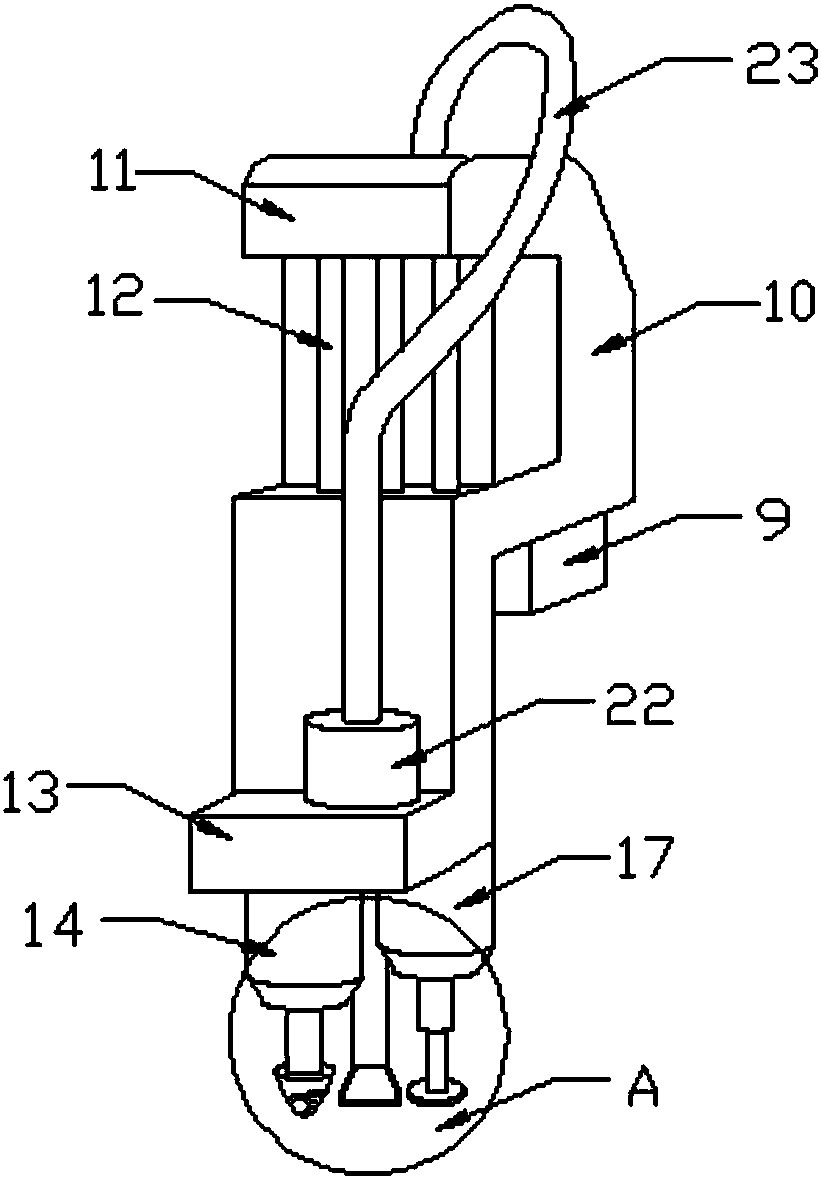

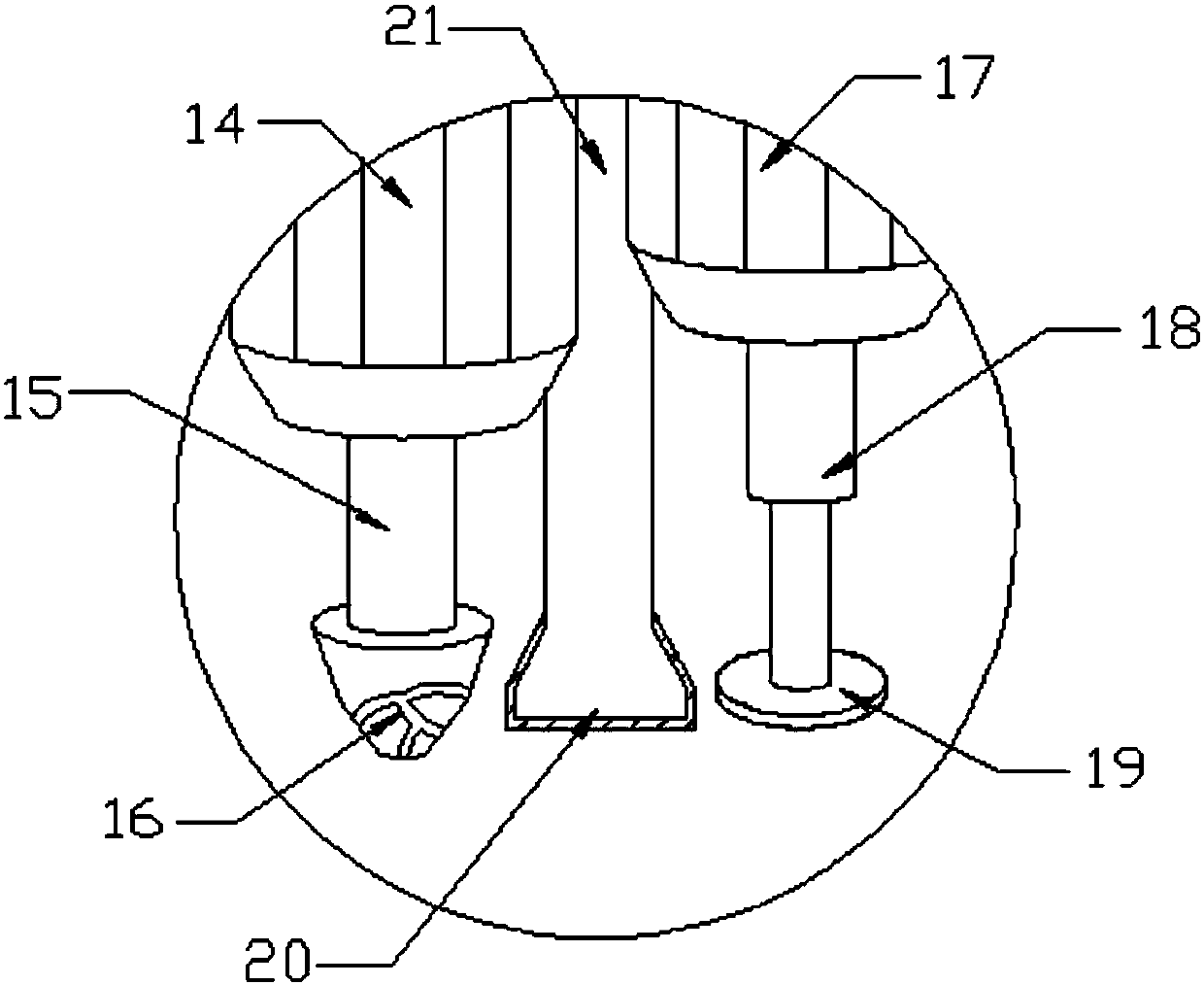

[0020] like Figure 1-Figure 3 As shown, this specific embodiment adopts the following technical solutions: an engraving device for wood processing, including an engraving machine main body 1 and a bracket 2, the bracket 2 is fixedly installed on the bottom of the engraving machine main body 1, and also includes a machine base 3 , engraving workbench 4, side guide rail 5, the first moving slide 6, moving beam 7, cross guide rail 8, the second moving slide 9 and column 10, the top of described support 2 is installed organic base 3, and described base The top of 3 is equipped with engraving workbench 4, and side guide rail 5 is all installed on opposite sides of described machine base 3, and first mobile slide seat 6 is slidably installed on described side guide rail 5, and described first mobile slide seat 6 A moving beam 7 is installed on the top of the moving beam 7, and a transverse guide rail 8 is installed on the top of the moving beam 7. A second mobile slide 9 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com