Efficient engraving and milling machine

An engraving and milling machine and high-efficiency technology, applied in the mechanical field, can solve problems such as decreased work efficiency and impact on engraving accuracy, and achieve the effects of ensuring quality, improving production efficiency, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

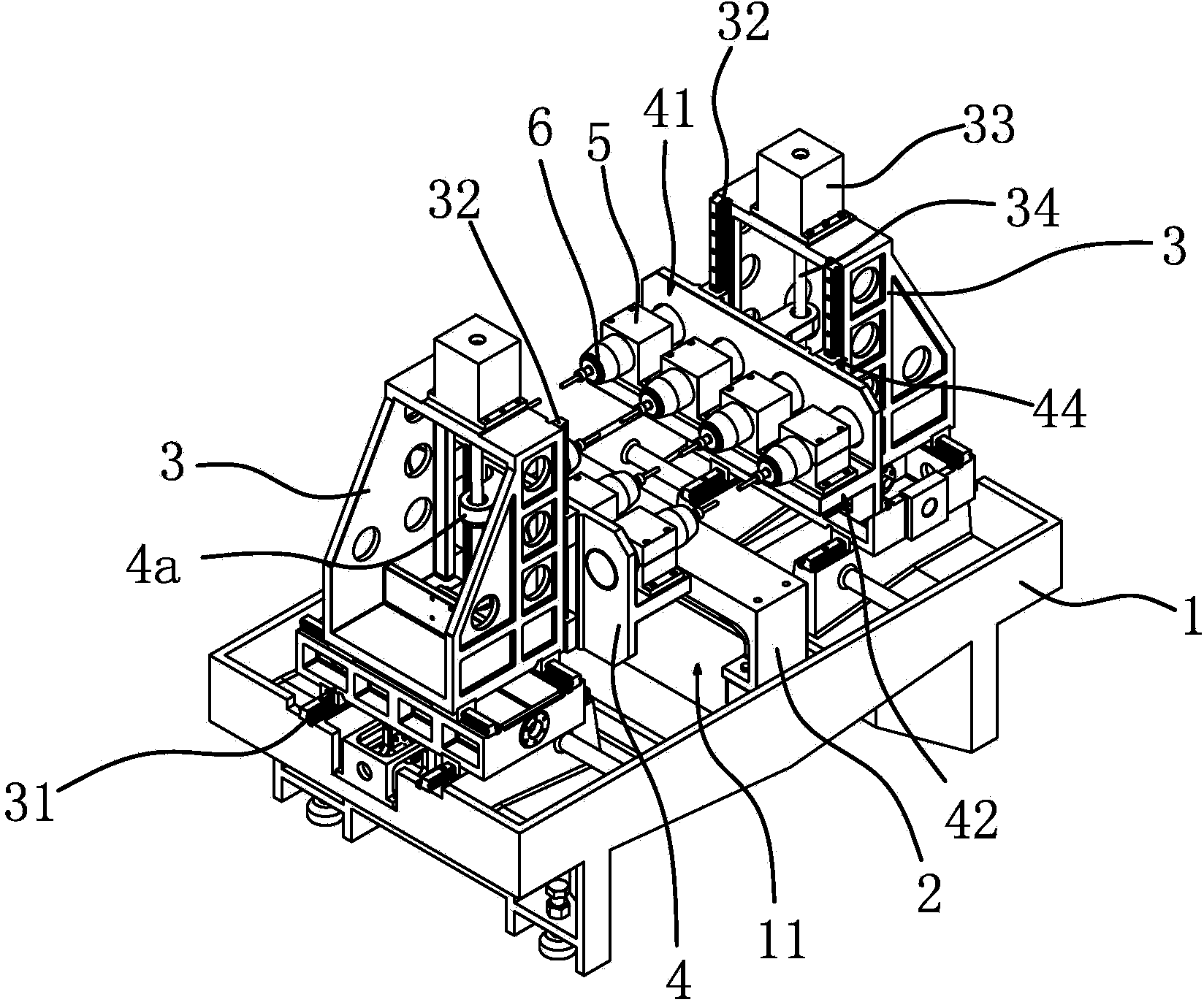

[0028] Such as figure 1 As shown, a high-efficiency engraving and milling machine includes a workbench 1, and the middle part of the workbench 1 is fixed with a fixed table 2 for fixing workpiece fixtures. The fixed table 2 is elongated, and several workpiece fixtures can be fixed on the fixed table 2. The processed workpiece is fixed on the fixed table 2 by the workpiece fixture. The workbench 1 is located below the fixed table 2 and has a recovery hole 11 for collecting debris. The recovery hole 11 is elongated; the width of the upper end port of the recovery hole 11 is greater than The width of the workbench, the fixed platform 2 is located directly above the middle part of the upper port of the recovery hole, the cross section of the fixed platform 2 is trapezoidal, and both sides of the fixed platform 2 have inclined surfaces 21, and debris slides to the recovery hole 11 through the guidance of the inclined surfaces 21, Prevent accumulation on the fixed table 2.

[0029]...

Embodiment 2

[0035] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference lies in that the mounting plate and the bracket are connected by cross guide rails, and guide rails are fixed on the workbench. The table is vertical, the bracket is slidably connected to the guide rail, and the drive source capable of driving the bracket to slide along the guide rail is fixed on the workbench. The driving source can be a motor or a cylinder. The bracket can drive the engraving and milling motor away from or close to the worktable. The driving source drives the engraving and milling motor to move freely on a plane perpendicular to its output shaft, realizing the movement of the engraving and milling motor along three degrees of freedom.

Embodiment 3

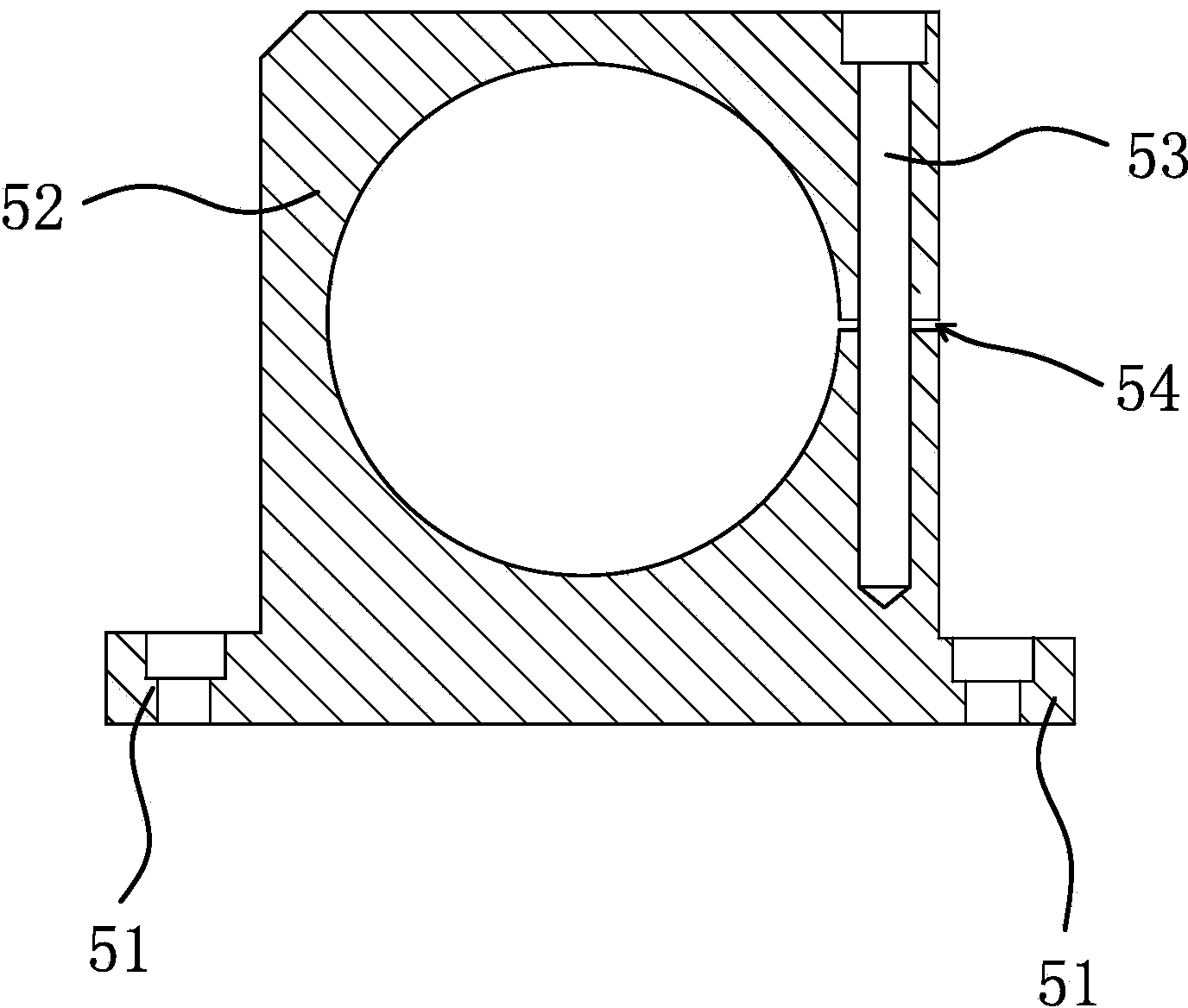

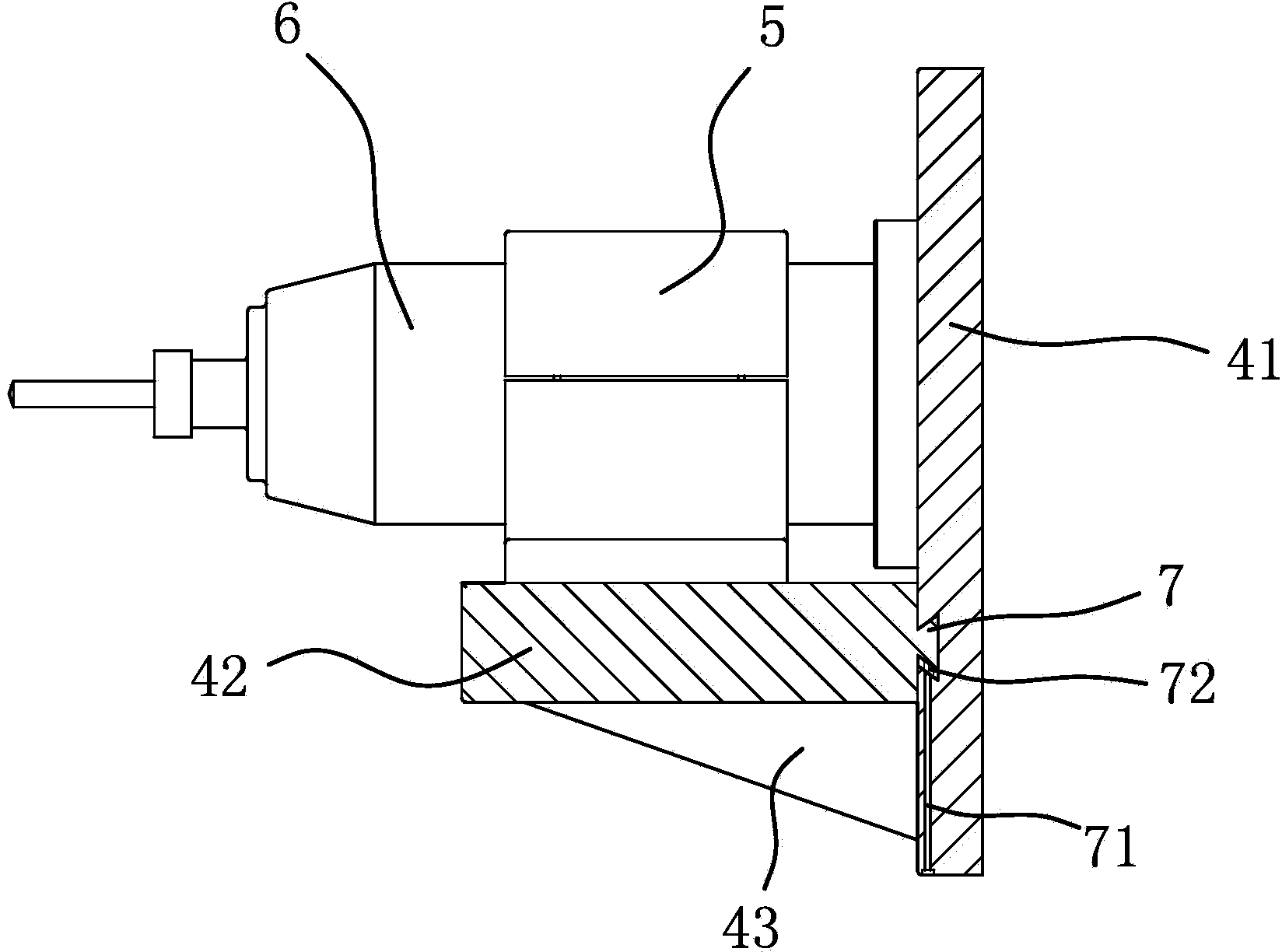

[0037] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: image 3 As shown, the mounting plate 4 includes a strip-shaped fixed plate 41 and several support plates 42, the fixed plate 41 is connected to the support 3, the fixed plate 41 is parallel to the table top of the workbench 1, and the fixed plate 41 is provided with an engraving and milling motor 6 There are positioning grooves distributed along the length direction of the fixing plate 41 on the side of the positioning groove, the width of the notch of the positioning groove is smaller than the width of the bottom surface of the positioning groove, the support plate 42 is arranged horizontally, and the support plates 42 are distributed sequentially along the length direction of the fixing plate 41, each The upper plate surface of the support plate 42 is fixed with the shaft center fixing seat 5, the engraving and milling motor 6 is positioned on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com