Multi-station numerical controlled carving tool setting device

A tool setting device and multi-station technology, applied in the direction of automatic control device, engraving, feeding device, etc., to achieve the effect of low probability of knife stabbing, reliable performance, and consistent engraving depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

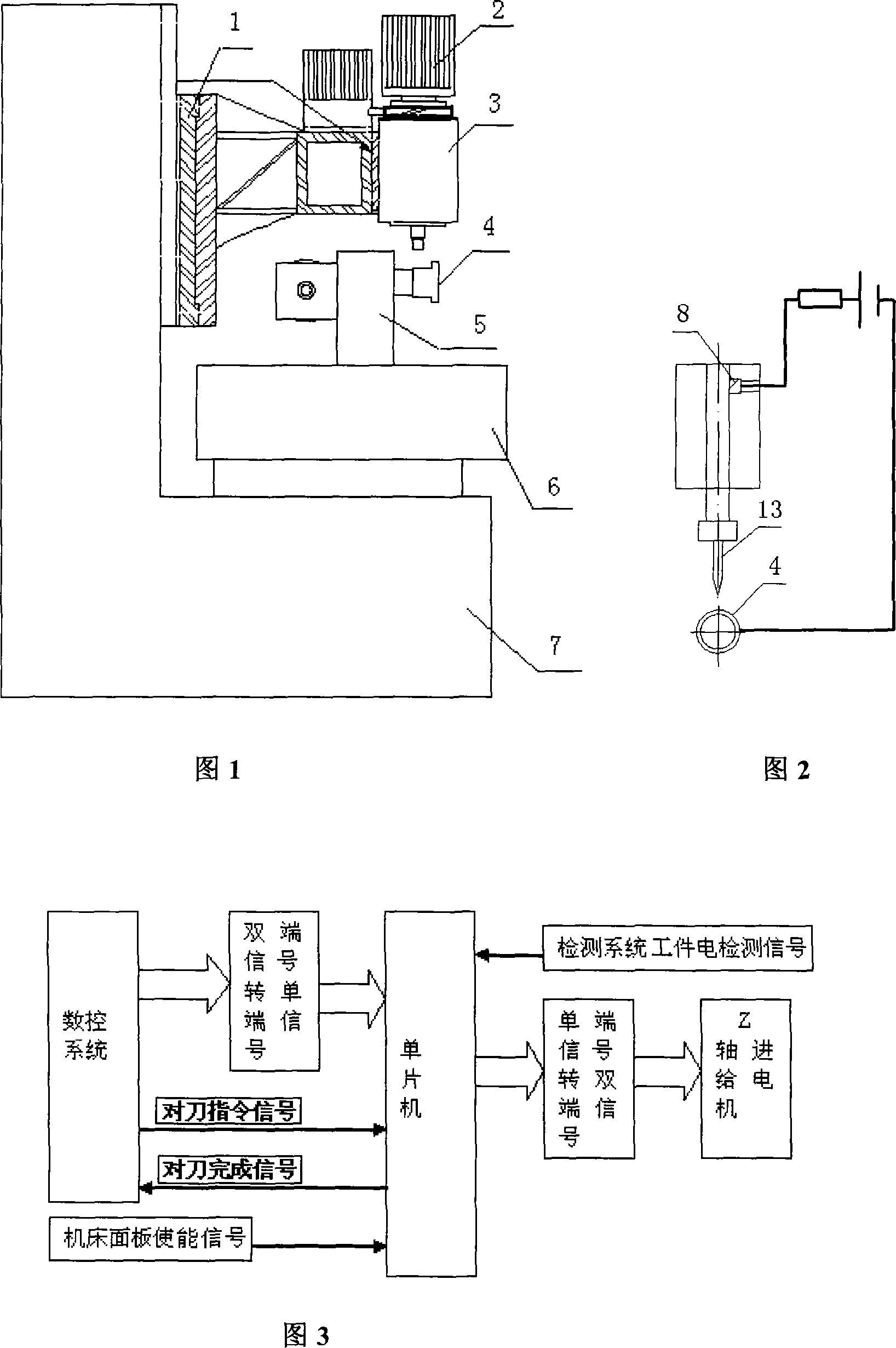

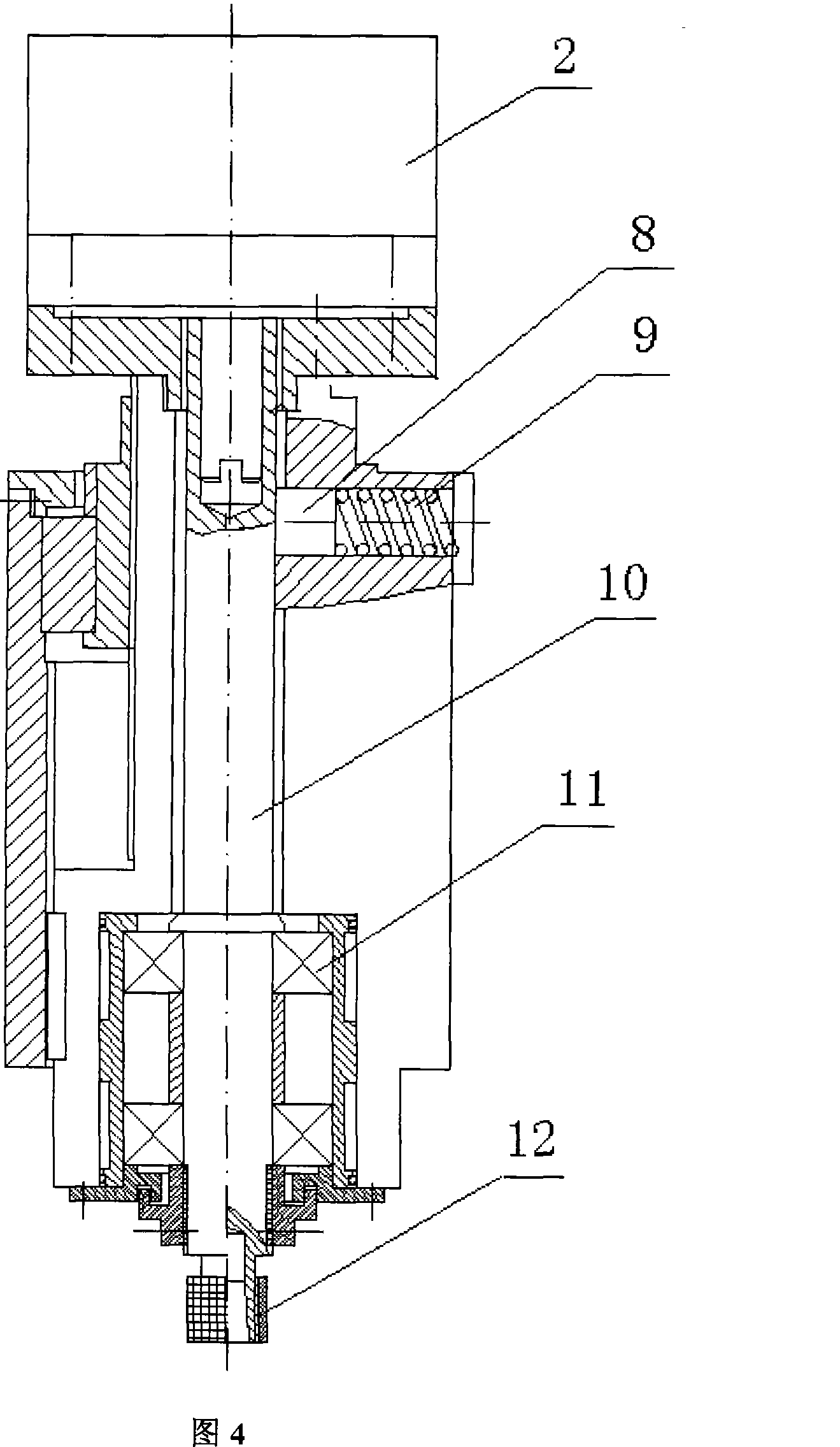

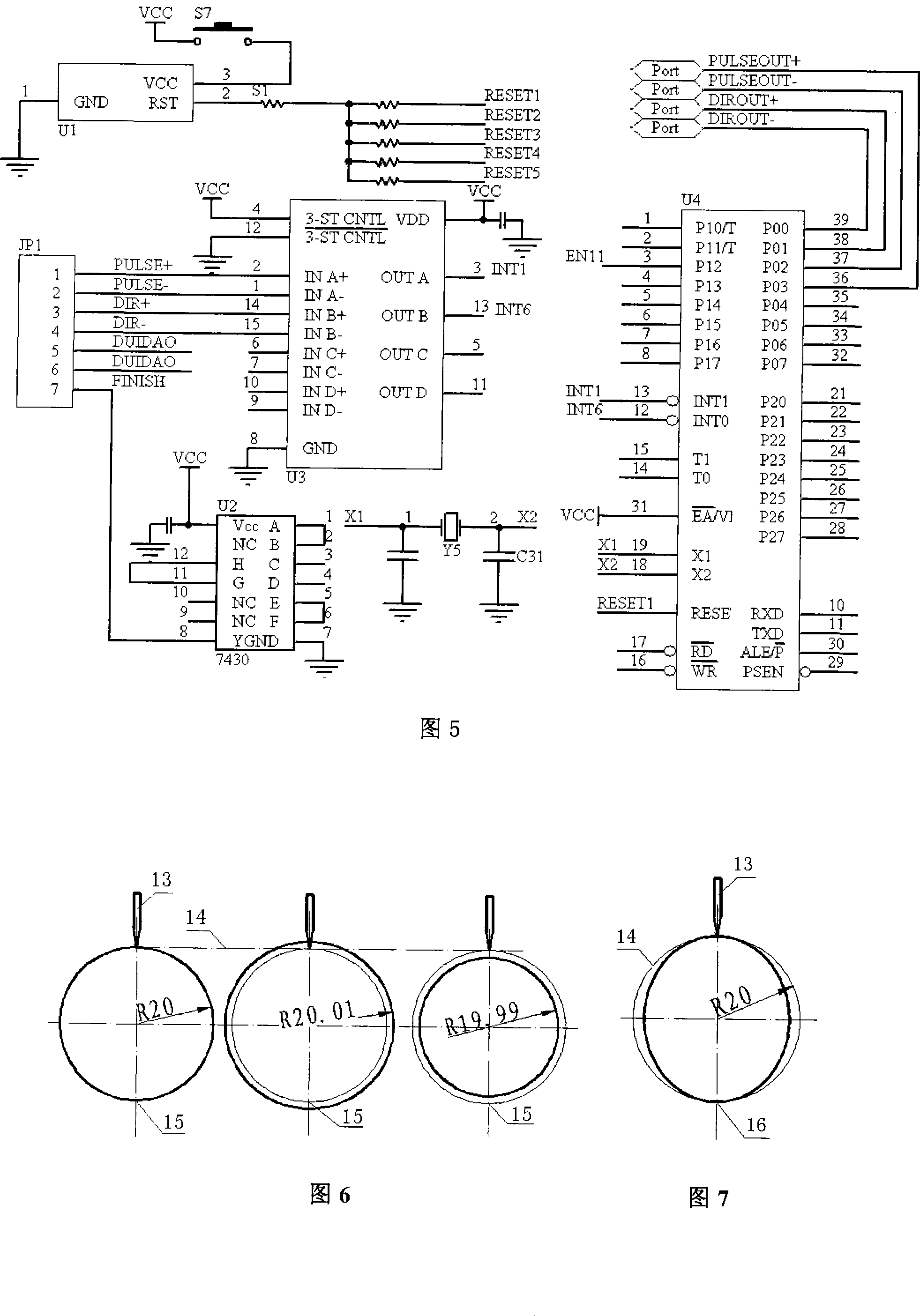

[0023] The multi-station CNC engraving tool setting device provided by the present invention is composed of a control system and an electric contact signal detection system. As shown in Figures 1 to 5: the control system includes four circuits: a single-chip microcomputer control group, signal input conversion, and signal output conversion. The single-chip microcomputer control group circuit is composed of multiple independent single-chip microcomputer U4 and its peripheral circuits. It transmits the signal input conversion circuit from the numerical control system command and then sends the Z-axis pulse through the signal output conversion circuit to realize the multi-axis distribution of the numerical control command. , control multiple engraving heads 3 to feed the tool uniformly according to the command program, and perform automatic feed and tool setting of each axis and return to complete the tool setting signal according to the requirements of the CNC system command. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com