Formula and preparation method of low-carbon lubricating oil

A lubricating oil and formula technology, applied in the field of lubricating oil, can solve the problems of reducing the service life of three-way catalytic converters in automobiles, high fuel consumption, and affecting air quality, and achieves improved shear stability and anti-oxidation stability, Strengthen the utilization rate of energy and solve the effect of high temperature and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

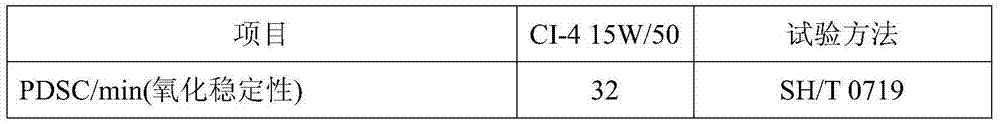

Examples

Embodiment 1

[0038] Example 1: 30 parts of synthetic base oil (a mixture of synthetic base oil PAO-10 and synthetic base oil PAO-6, the contents of which are 20 parts and 10 parts respectively), three types of hydrogenation are added in the blending equipment by weight percentage 38 parts of base oil (a mixture of three types of hydrogenated base oil 250N and 150N+, the content is 25 parts and 13 parts respectively), the second type of hydrogenated base oil 500N is 15 parts, and the fifth type of synthetic phenolic ester base oil 0810 is 12 parts 5 parts, hydrogenated base oil 150BS is 5 parts, heat up to 60 ℃, keep constant temperature, stir and reconcile evenly within 40 minutes;

[0039] Then add 9.0 parts of viscosity index improver, high molecular weight phenolic ester ashless antioxidant: 3.0 parts, liquid mixed dialkyl diphenylamine: 2.8 parts; 803 pour point depressant: 0.3 parts, molybdenum salt friction reducer: 0.5 parts, Amino sulfide ester: 1.6 parts, boronated ashless dispers...

Embodiment 2

[0044] Example 2: 10 parts of synthetic base oil (a mixture of synthetic base oil PAO-10 and synthetic base oil PAO-6, each containing 5 parts), three types of hydrogenated base oil 50 parts were added in the blending equipment by weight percentage Parts (a mixture of three types of hydrogenated base oils 250N and 150N+, the contents are 20 parts and 30 parts respectively), two types of hydrogenated base oils 500N are 22 parts, five types of synthetic phenolic ester base oils 0810 are 10 parts, plus The hydrogen base oil 150BS is 8 parts, and the temperature is raised to 60°C to maintain a constant temperature and evenly adjust;

[0045] Then add 9.0 parts of viscosity index improver, high molecular weight phenolic ester ashless antioxidant: 1.5 parts, liquid mixed dialkyl diphenylamine: 2.5 parts; 803 pour point depressant: 0.3 parts, molybdenum salt friction reducer: 0.2 parts, Amino sulfide ester: 1.6 parts, boronated ashless dispersant: 1.0 parts, sulfurized calcium alkylp...

Embodiment 3

[0050] Example 3: 5 parts of synthetic base oil (a mixture of synthetic base oil PAO-10 and synthetic base oil PAO-6, each containing 2.5 parts), three types of hydrogenated base oil 55 parts were added to the blending equipment by weight percentage Parts (a mixture of three types of hydrogenated base oils 250N and 150N+, the contents are 25 parts and 20 parts respectively), two types of hydrogenated base oils 500N are 20 parts, five types of synthetic phenolic ester base oils 0810 are 10 parts, plus After the hydrogen base oil 150BS is 10 parts, the temperature is raised to 60°C, and the temperature is maintained at a constant temperature, and the mixture is uniform within 40 minutes;

[0051] Then add 9.0 parts of viscosity index improver, high molecular weight phenolic ester ashless antioxidant: 1.5 parts, liquid mixed dialkyl diphenylamine: 2.5 parts; 803 pour point depressant: 0.3 parts, molybdenum salt friction reducer: 0.2 parts, Amino sulfide ester: 1.6 parts, boronate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com