Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Maintain decorative effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

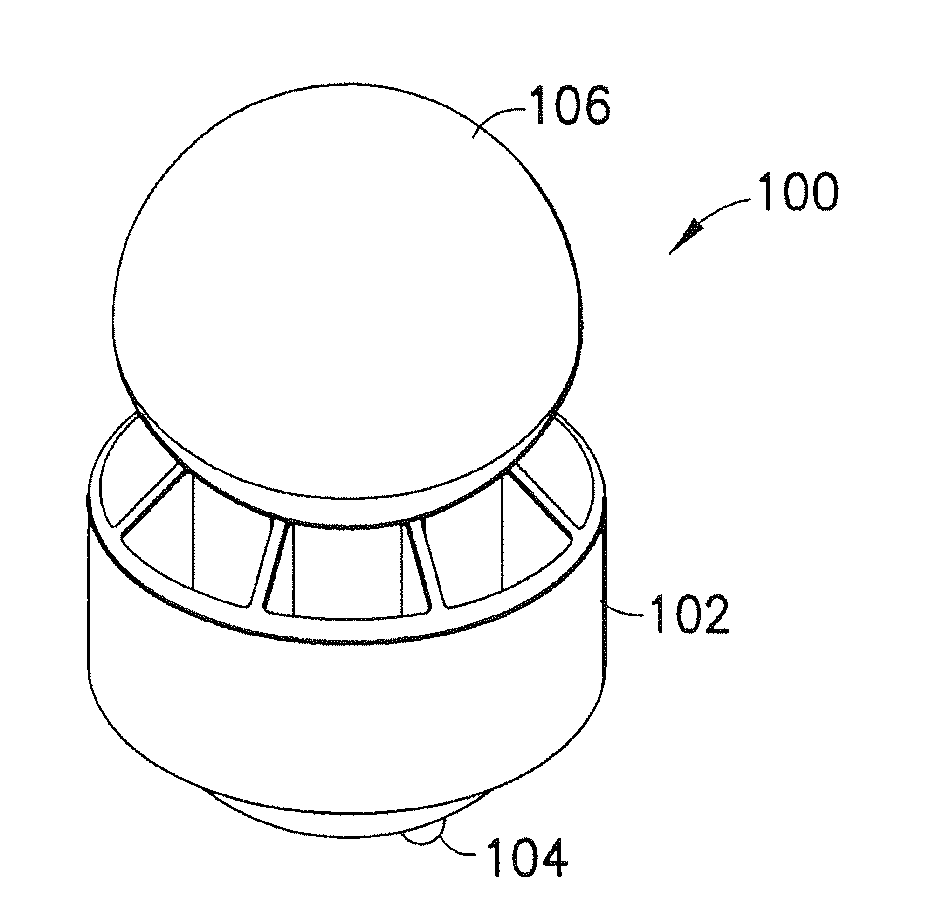

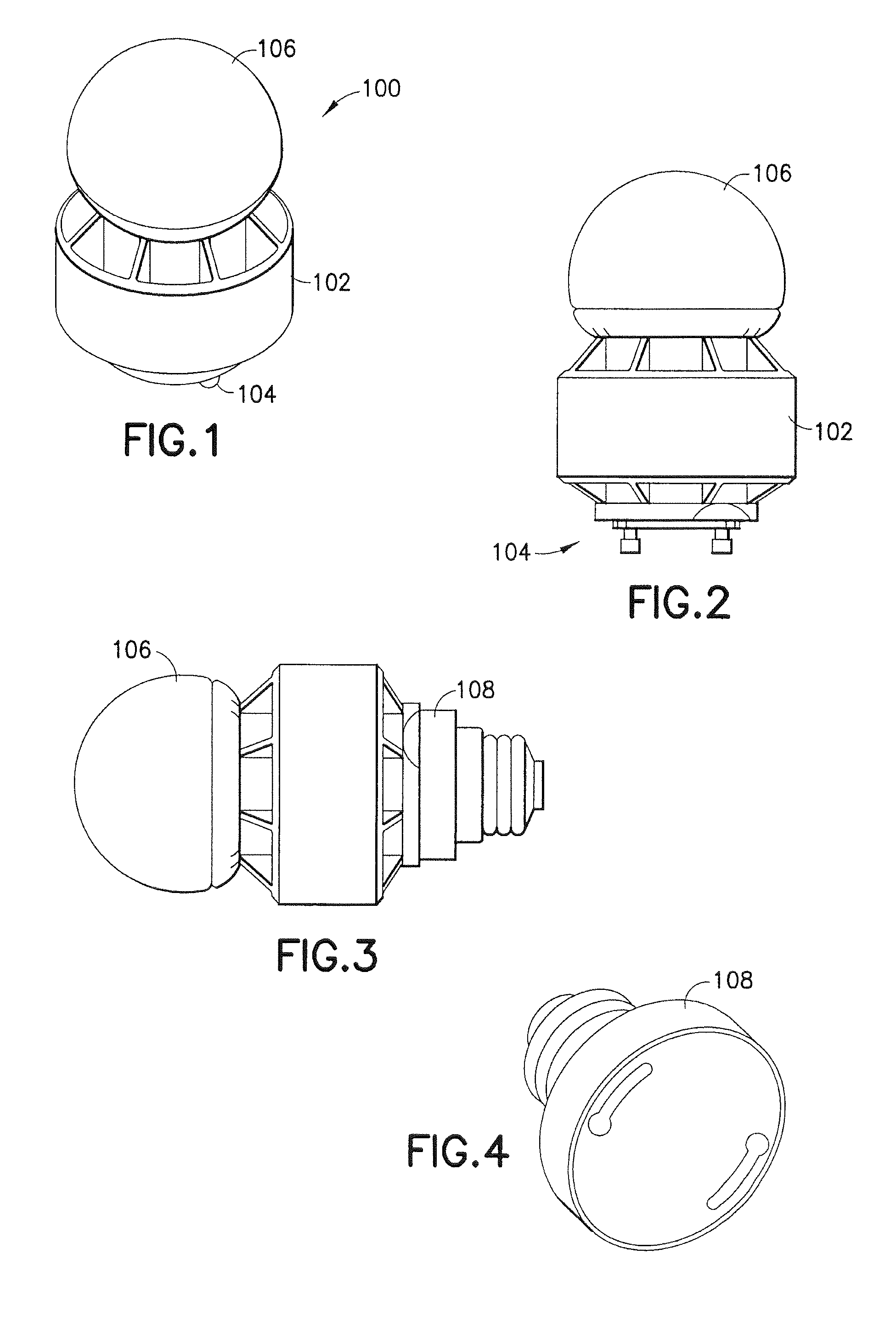

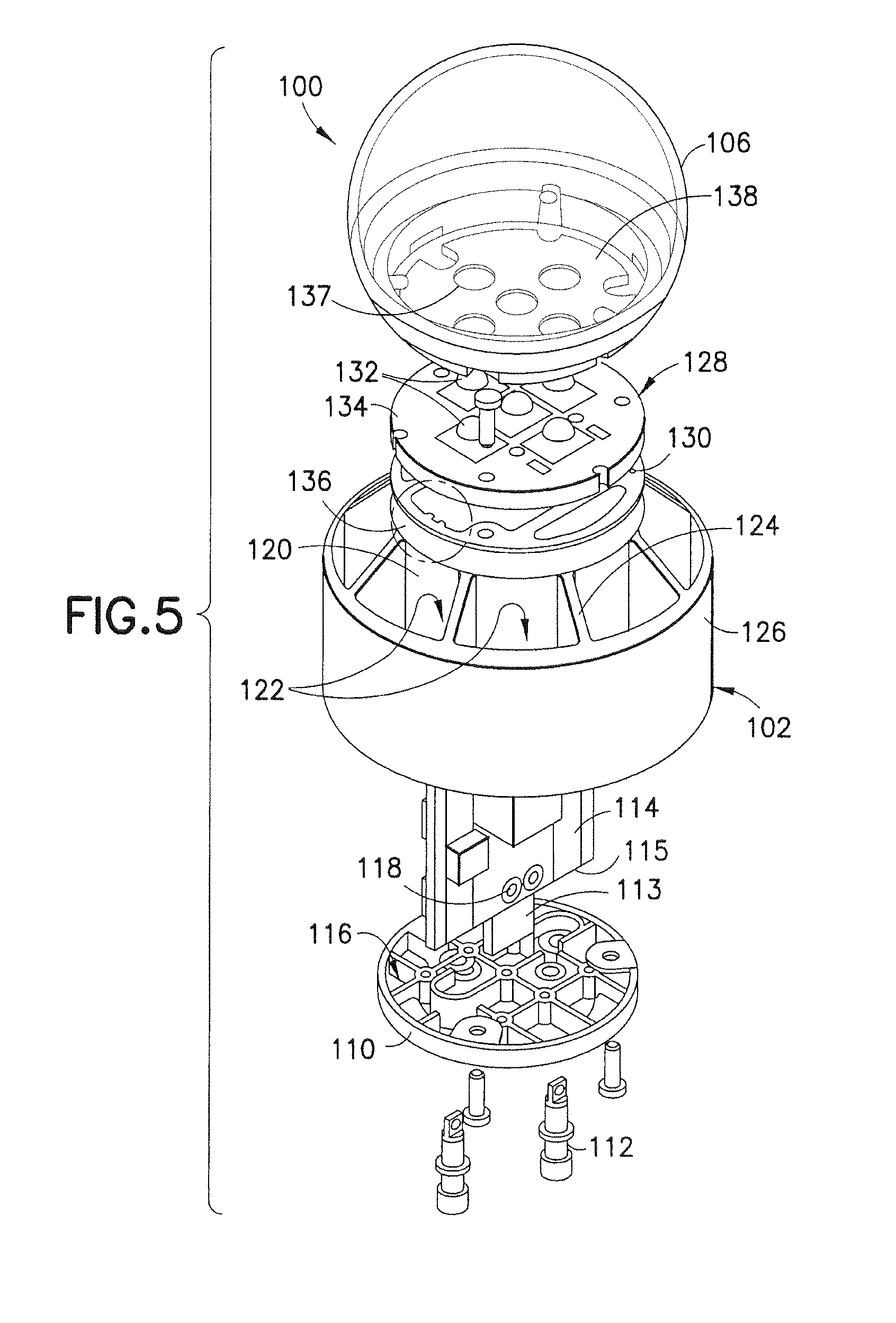

LED retrofit light engine

InactiveUS20090296387A1Easy to modifyImprove energy efficiencyNon-electric lightingLighting support devicesElectricityPower flow

A light engine is provided including a thermally conductive housing including a generally cylindrical wall defining a cavity, the cylindrical wall includes an inner surface and an outer surface, a plurality of ducted passageways being axially disposed on the outer surface, a light module including at least one light emitting diode (LED) for producing visible light, the light module coupled to a first end of the housing, wherein heat generated by the at least one LED is conducted to the housing, and a current driver circuit arranged on a substrate, the substrate configured to be disposed in the cavity of the housing and electrically coupled to the light module for providing current to the at least one LED. The ducted passageways aid in convective heat dissipation through a “chimney” type of affect.

Owner:SEA GULL LIGHTING PRODS

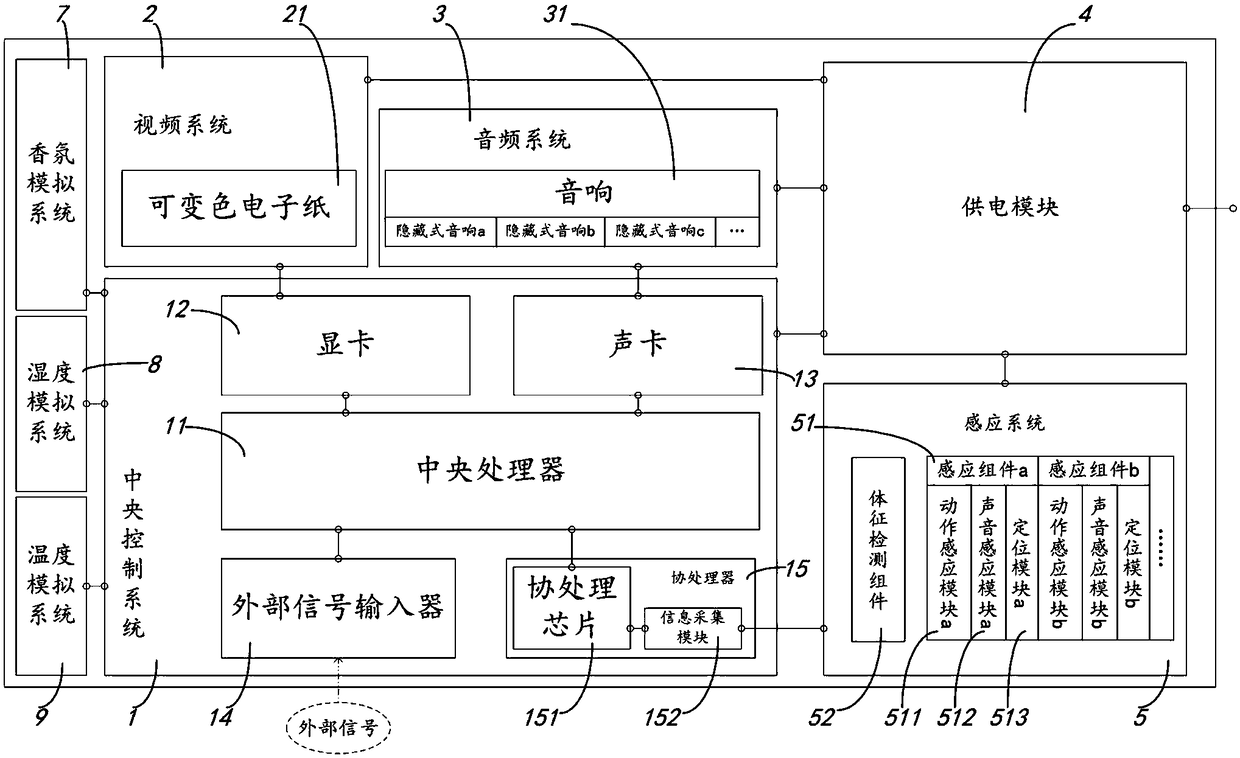

Immersive panoramic virtual reality system

PendingCN108388144AImprove beautyHuge development potential and application prospectsInput/output for user-computer interactionTransmission systemsInduction systemCo-processing

The invention relates to an immersive panoramic virtual reality system, including a video system, an audio system, an induction system, a central control system connected with the video system, the audio system and the induction system, and a power supply module. The video system includes a color-variable electronic paper pasted on an indoor floor and wall faces in a covering manner. The inductionsystem includes a plurality of induction components integrated in an indoor illuminating lamp, and includes an action induction module, a sound induction module and a positioning module. The centralcontrol system includes a central processing unit, an external signal input unit, a video card, a sound card and a co-processing module for driving the induction system. The co-processing module includes a co-processing chip and an information acquisition module. The immersive panoramic virtual reality system can provide virtual reality experience of 360-degree full coverage in a real display style, and provides a strong sense of reality, and a user can move freely without restraints and is not easy to feel fatigue and uncomfortable; and when not energized, the system still has a good hiding effect and does not damage an interior decoration effect.

Owner:河南天泰网安信息技术有限公司

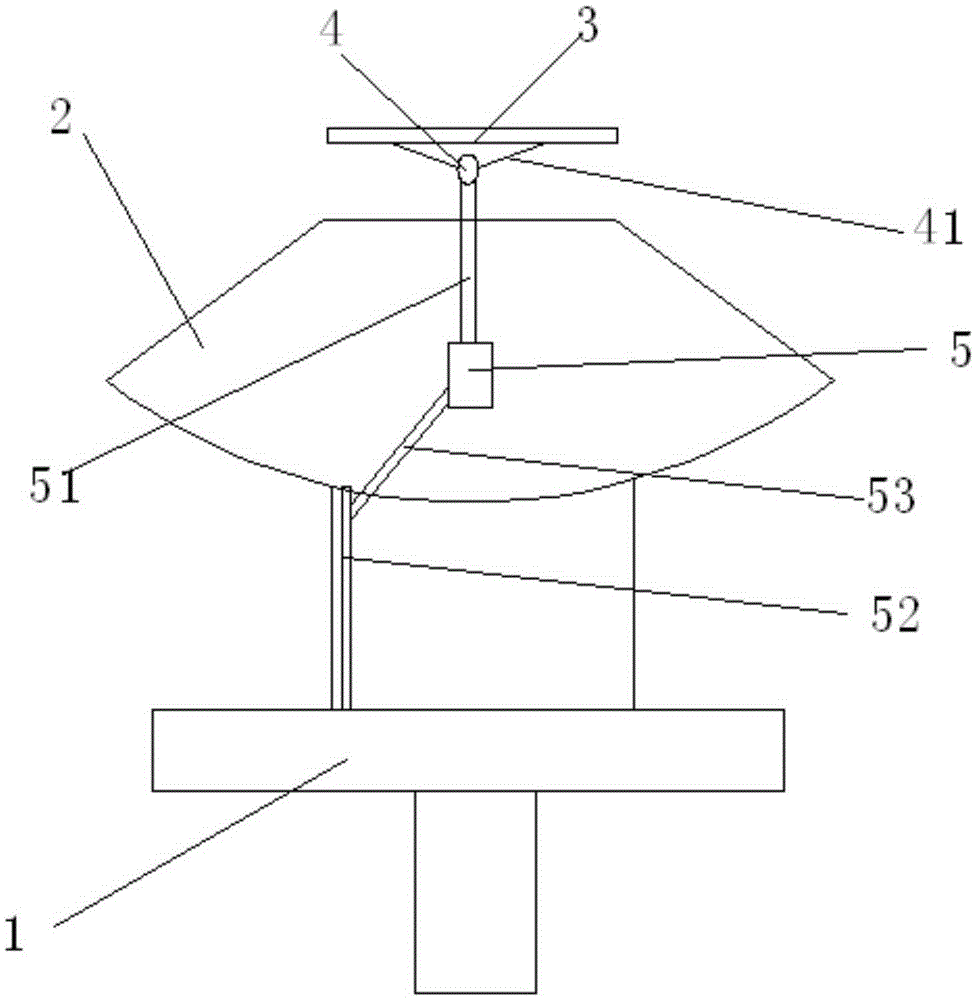

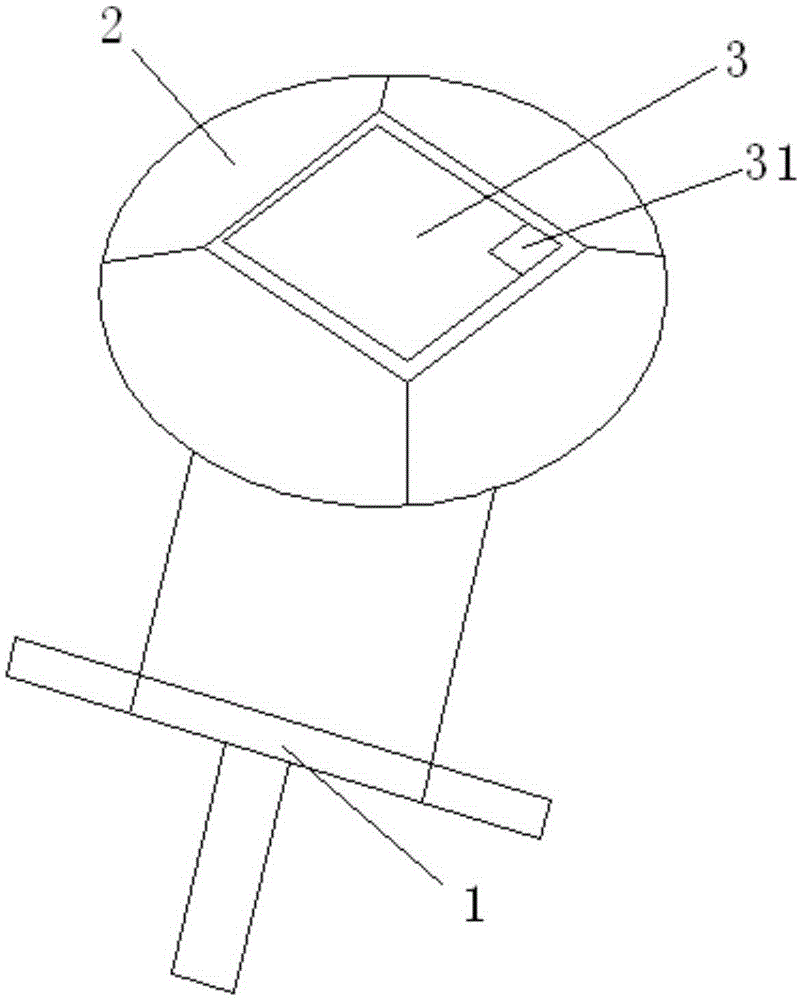

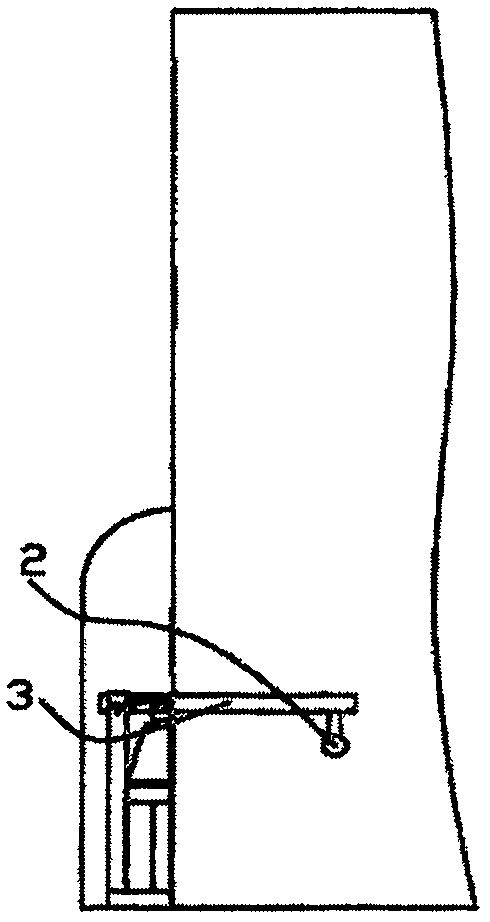

Solar lawn lamp

InactiveCN105258065AMaintain decorative effectIncrease power generationElectric circuit arrangementsCleaning using toolsLawnGenerating capacity

The invention discloses a solar lawn lamp. The solar lawn lamp comprises a lamp support (1), a lampshade (2), a solar cell panel (3), a rotating head (5), a cleaning mechanism, a control circuit and a light sensing piece (31). The light sensing piece (31) is arranged on the solar cell panel (3), and is connected with a control circuit; the control circuit controls the rotating head (5) to rotate according to the inclined angle between the solar cell panel (3) and the sun, and therefore the angle between the solar cell panel (3) and the sun is adjusted; and the cleaning mechanism comprises a rotating motor (5) and a brush (52). According to the solar lawn lamp, the angle between the solar cell panel (3) and the sun can be adjusted in real time, so that the generating capacity of the solar cell panel (3) can be maximum; and meanwhile, the inner wall of the lampshade can be cleaned, and the decoration effect is better.

Owner:JIANGSU YINJIA GROUP

Composite film-coated self-cleaning inorganic ecological decorative plate and preparation method thereof

ActiveCN105802367AMaintain decorative effectImpart superhydrophilicityCovering/liningsDextran coatingsComposite filmUltraviolet

The invention discloses a composite film-coated self-cleaning inorganic ecological decorative plate and a preparation method thereof.The preparation method comprises the following steps that 1, an inorganic ecological decorative plate is taken as a base body, and after the surface of the inorganic ecological decorative plate is subjected to dust blowing cleaning treatment, film coating loading is performed by adopting a photocatalytic hydrophilic coating through powder coating or spraying or a sol-gel method to obtain a TiO2-loaded inorganic ecological decorative plate; 2, the TiO2-loaded inorganic ecological decorative plate obtained in the step 1 is dried or subjected to ultraviolet curing, the drying temperature is 50 DEG C-85 DEG C, the drying time is 0.5-3 h, and after natural cooling is performed, the composite film-coated self-cleaning inorganic ecological decorative plate is obtained.Accordingly, the inorganic ecological decorative plate is taken as the base body, film coating loading is performed by adopting the photocatalytic hydrophilic coating through powder coating or spraying or the sol-gel method, moisture condensation is performed on kitchen and bath fumes, organic matter, sewage and dirt, outer curtain wall dust is self-removed, the self-cleaning capacity is high, and the durability is good.

Owner:HUBEI GREENS NEW BUILDING MATERIALS SCI & TECH YINGCHENG

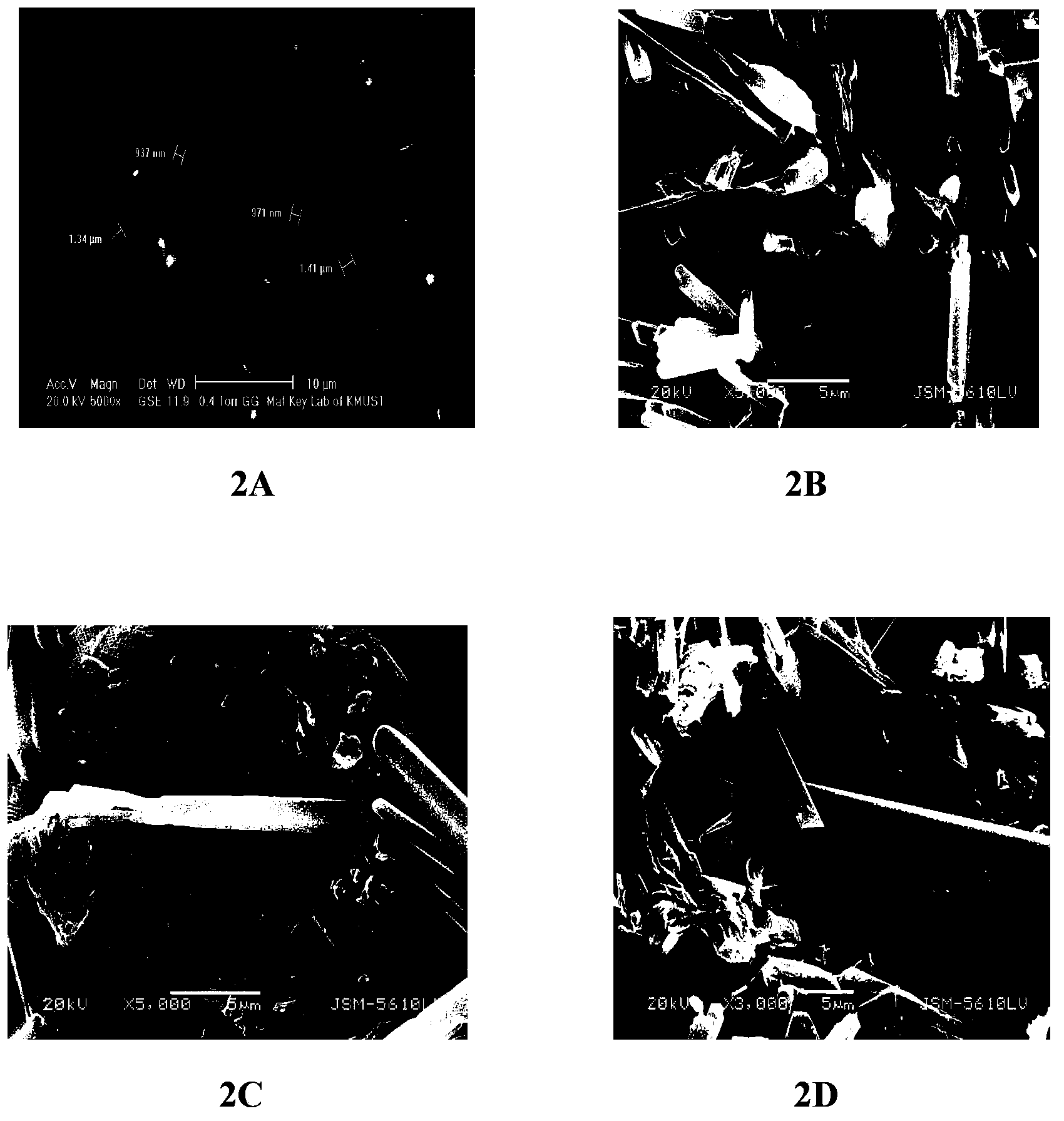

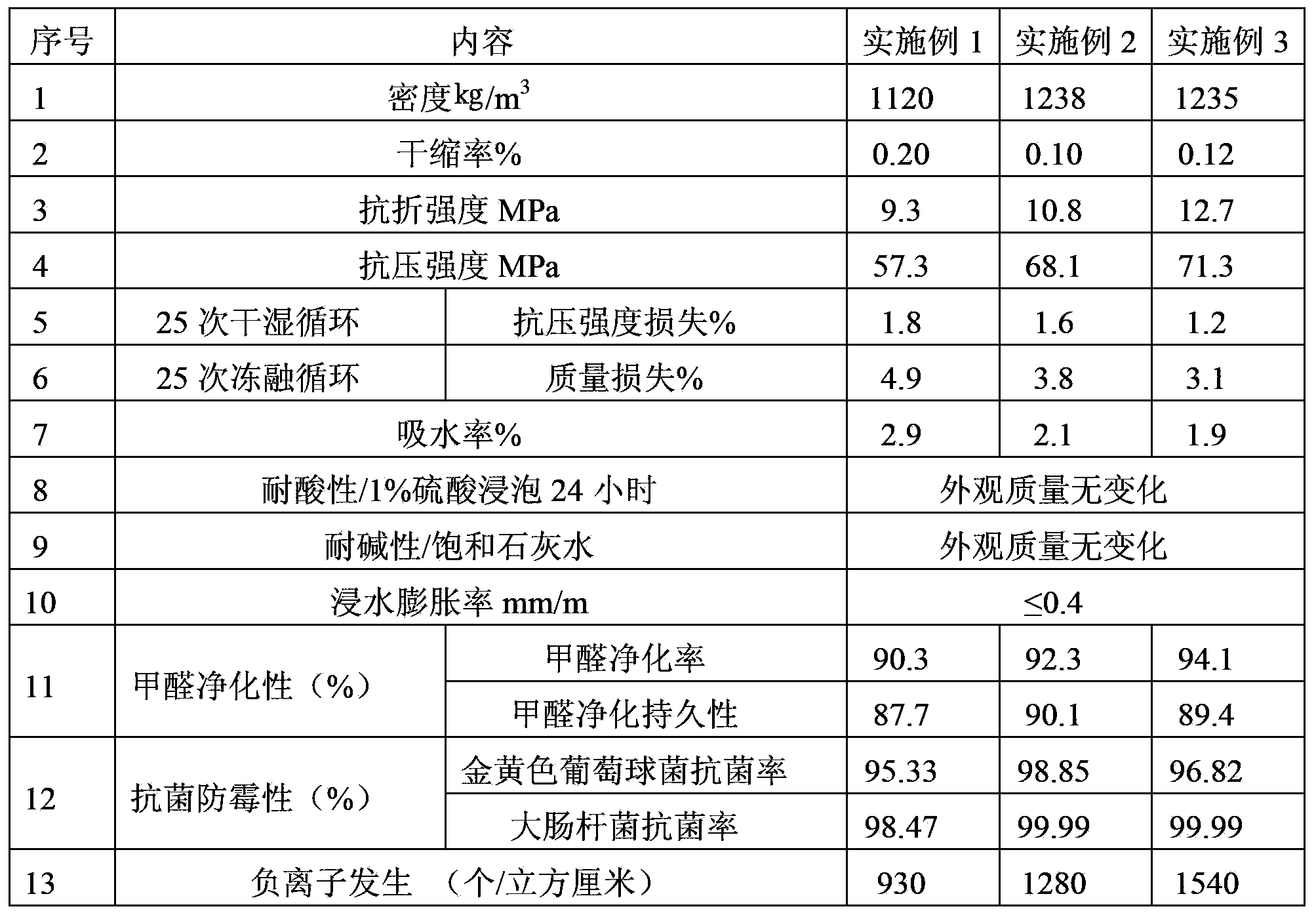

Inorganic ecologic wood, and preparation method and application thereof

The invention provides an inorganic ecologic wood. The inorganic ecologic wood is prepared through using, by weight, 100.0 parts of inorganic gelling powder, 6.0-42.0 parts of a dispersible vegetable fiber, 8.0-25.0 parts of amorphous SiO2 mineralization powder, 0.0-5.5 parts of a modification aid, and 23.5-26.2 parts of a complex formulation solution. The inorganic ecologic wood reserves the good plasticity and environmental protection characteristic of the inorganic material, and has the ecologic functions of formaldehyde cleaning, antibiosis, mildew resistance and negative ion generation. The invention also provides a preparation method of the inorganic ecologic wood, and applications of the inorganic ecologic wood as building materials comprising ecologic board, wood floors, interior and exterior decorative boards or decorative modeling boards and the like.

Owner:HUBEI GREENS NEW BUILDING MATERIALS SCI & TECH YINGCHENG

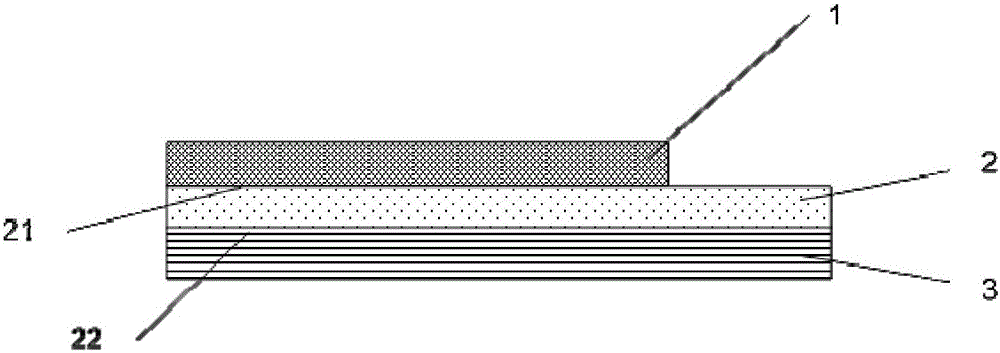

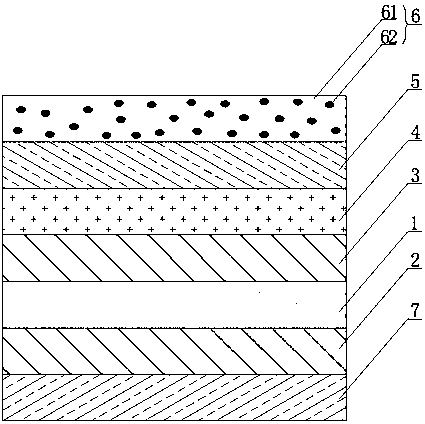

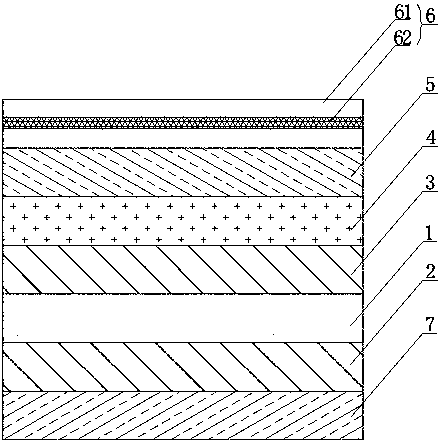

Decoration panel

PendingCN107176113AMaintain decorative effectIntegrated design is free and flexibleSuperstructure subunitsIdentification meansInterior spaceEngineering

The invention provides a decoration panel. The decoration panel comprises a decoration layer and an information displaying layer. The upper surface of at least part of the decoration layer is covered with the information displaying layer, when the information displaying layer does not display information, the upper surface of the decoration layer is seen by passengers, and when the information displaying layer displays the information, the upper surface of the decoration layer and the information displayed by the information displaying layer are simultaneously seen by the passengers. According to the decoration panel, the information displaying layer is arranged on the decoration layer, when the information displaying layer does not display the information, the decoration layer can be seen by the passengers through the information displaying layer to provide the decoration effect of a traditional decoration layer, but when the information displaying layer displays the information, the displayed information can be combined with the decoration layer and can be seen by the passengers, the information needed by the passengers is provided, and the decoration effect of the traditional decoration layer is retained; limiting on an interior space is broken away, and a better information displaying scheme is provided for car intelligence and internet.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

Preparation method of real stone lacquer not prone to fall sands

The invention discloses a preparation method of a real stone lacquer not prone to fall sands. The method comprises the following steps: (1) flushing natural color sands with water, immersing the flushed natural color sands in a modification solution, and performing filtration to obtain modified natural color sands; (2) adding nonenylsuccinic anhydride into a silicone acrylic emulsion, performing mixing and uniform stirring, and standing the obtained solution; and (3) adding a polyurethane leveling agent, an antifoaming agent and a film forming additive into deionized water, performing mixing and uniform stirring, adding the obtained solution into the silicone acrylic emulsion, uniformly stirring the obtained solution by a mixer, adding the modified natural sands, and performing mixing andstirring to prepare the finished product. The preparation method of the real stone lacquer not prone to fall sands has the advantages of simplicity in operation, and low cost, and the prepared real stone lacquer has the advantages of strong stability, no layering phenomenon in the storage process, excellent construction performances, excellent resistance to water, corrosion and aging, no sand falling especially after being dried, and maintenance of the decoration and protection effects for a long time.

Owner:安徽喜宝高分子材料有限公司

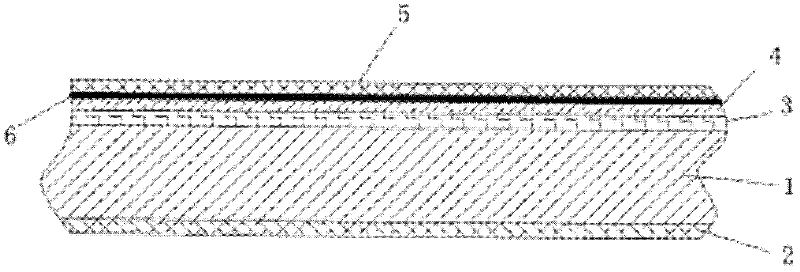

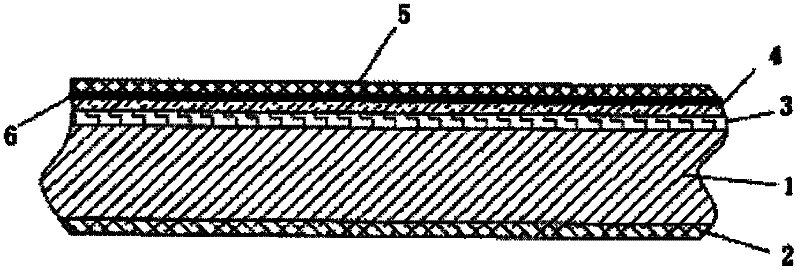

Double-sided metal composite panel

InactiveCN102259446ATo achieve the effect of decorationMaintain decorative effectMetal layered productsPolymer substrateThin layer

The double-sided metal composite board includes a substrate, a panel, an adhesive substrate, and a polymer PVC material adhesive layer for the panel. The panel adopts a thin layer, and the thickness of the substrate is greater than that of the panel. The substrate is made of conventional metal materials, such as steel plate or alloy aluminum, which can provide sufficient strength for the panel; the panel is made of non-ferrous metal foil or metal plate, such as brass, copper, etc., and the decoration can be achieved with less material. The effect of decoration; the adhesive layer is made of polymer PVC material, which plays the role of firmly bonding the substrate and the panel. The beneficial effect of the present invention is that it is easy to manufacture, uses less precious metal materials to compound with ordinary metal steel plates and aluminum plates, retains the decorative effect of metal materials, and combines the strength of ordinary metal steel plates and aluminum plates to make the overall decorative effect It is better, has a longer service life, reduces production costs, and meets the needs of popularization.

Owner:WUXI MEIYU METAL COMPOSITE NEW MATERIALS

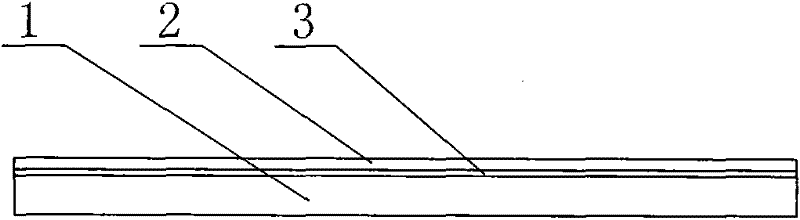

HIPS (High Impact Polystyrene) composite board

InactiveCN102529264AEnvironmentally friendly and non-toxicColorful appearanceSynthetic resin layered productsScreen printingComposite film

The invention provides an HIPS (High Impact Polystyrene) composite board, wherein a UV (Ultra Violet) coating is sprayed on the front surface of a PET (Polyethylene Terephthalate) transparent film layer; a screen printing layer is arranged on the bottom surface of the PET transparent film layer; a first adhesive layer is coated on the bottom surface of the screen printing layer in a rolling manner; the first adhesive layer is bonded to a PET / PVC (Polyvinyl Chloride) composite film layer; a second adhesive layer is coated on the bottom surface of the PET / PVC composite film layer in a rolling manner; and the second adhesive layer is bonded to an HIPS substrate layer. The HIPS composite board disclosed by the invention not only has the characteristics of strong layering feel, thick texture, environment friendliness and non-toxic performance but also is variable in patterns and colours according to requirements, thus, the HIPS composite board can be used for a panel of a refrigerator instead of colorized crystal glass.

Owner:SUZHOU HESHENG NEW MATERIALS

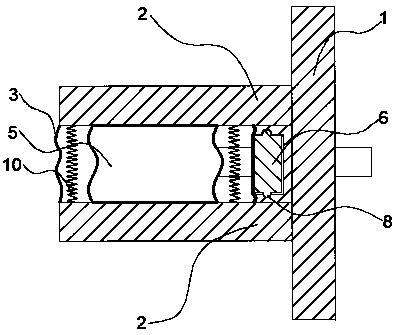

Clear water concrete clear seam strip capable of not being easily damaged during demoulding

ActiveCN108999397AMaintain decorative effectThe advantage of retaining the decorative effectForms/shuttering/falseworksForm treatmentInternal connectionBuilding construction

The invention relates to a tool used for construction and especially relates to a clear water concrete clear seam strip capable of not being easily damaged during demoulding. The seam strip comprisestwo clear seam forming plates, an end surface forming band, an internal connection band, an expansion capsule, a slide strip and a chute. The two ends of the end surface forming band are fixedly connected to the end portions of the two clear seam forming plates. The two ends of the internal connection band are fixedly connected to the inner side surfaces of the two clear seam forming plates. The slide strip is fixed in the outer side surface of the internal connection band. The internal connection band, the two clear seam forming plates and the end surface forming band form a cavity. The expansion capsule is in the cavity. The expansion capsule is provided with a capsule nozzle used for filling a gas or a liquid in the expansion capsule. The feed inlet of the capsule nozzle is located in the outer side of a template. In the invention, after being separated from the surface of a clear seam, the clear seam forming plates are moved out of the clear seam, the surface of the clear seam is not easy to damage, and the advantage of a clear seam decoration effect can be kept.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

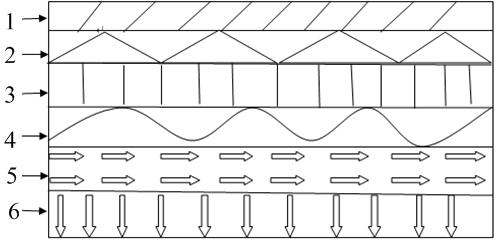

Waterborne multicolor architectural coating with super resistance to wipe and resistance to stains and preparation method of waterborne multicolor architectural coating

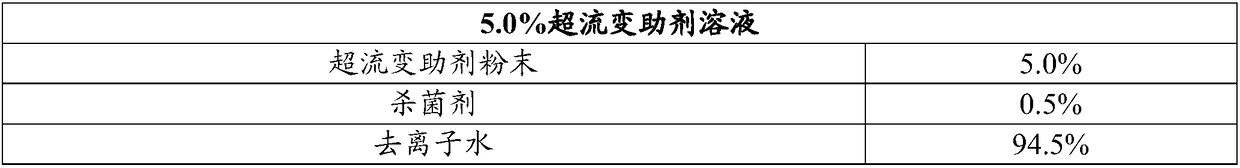

PendingCN109233641AMaintain decorative effectImprove protectionAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention relates to a waterborne multicolor architectural coating with super resistance to wipe and resistance to stains. The coating is prepared from a super rheological additive solution, a disperse phase and a continuous phase in a mass ratio being (320-330):(330-340):(350-395), wherein the mass concentration of the super rheological additive solution is 5.0%; the continuous phase containscontinuous phase emulsion, a coalescing agent, a bactericide, a multifunctional additive, a defoamer, an antifreezing agent, alkyl polyglucoside, an ultraviolet absorber and deionized water; the disperse phase contains disperse phase emulsion, hydroxyethyl cellulose, keratin, inorganic pigment, water-based color paste, cover packing, a dispersant, the defoamer, the multifunctional additive, the coalescing agent, the antifreezing agent, a thickener, a stabilizer, the super rheological additive solution with mass concentration being 5.0%, the bactericide and the deionized water; pH of the coating is 8.0-9.5. The invention further relates to a preparation method of the waterborne multicolor architectural coating.

Owner:上海三银涂料科技股份有限公司

Transparent PET (Polyester) composite board

InactiveCN102529265AChip-resistantScratch resistantSynthetic resin layered productsSpecial ornamental structuresPolyesterNon toxicity

The invention provides a transparent PET (Polyester) composite board. A facade of a transparent PET film layer is sprayed and coated with an UV (Ultraviolet) coating layer, the back surface of the transparent PET film layer is provided with a printed layer, the back surface of the printed layer is sprayed and coated with a priming paint layer, the back surface of the priming paint layer is rolled and coated with a rubber layer, and the rubber layer is adhered with an HIPS (High Impact Polystyrene) base board layer. The transparent PET composite board provided by the invention not only has the characteristics of scraping resistance, corrosion resistance, weather resistance, environmental protection, non-toxicity and the like, but also can be changed in patterns and colors according to requirements, and can be used on a refrigerator panel for replacing colorful crystal glass.

Owner:SUZHOU HESHENG NEW MATERIALS

Anti-fouling moldproof treatment process for sandstone

The invention discloses an anti-fouling moldproof treatment process for sandstone, belonging to the technical field of surface treatment of inorganic non-metal materials. The treatment process comprises the following steps: (1) mixing silver-carried nano double phosphate, nano zinc oxide, non-ionic surfactant and deionized water in a certain mass ratio, and evenly stirring; (2) brushing or spraying the mixed liquid obtained in the step (1) onto a sandstone surface, and airing the sandstone; (3) mixing trialkoxysilane, tetraalkoxysilane, fluorosilane and isopropanol in a certain mass ratio, and evenly stirring; and (4) brushing or spraying the mixed liquid obtained in the step (3) onto the sandstone surface, and drying at normal temperature for 24 hours. The sandstone treated by the treatment process can not be easily polluted and fouled, get moldy or the like due to the characteristic of porosity, thereby keeping the apparent decorative effect of the sandstone and maintaining the structure and physicochemical properties of the sandstone. The alternate freezing and thawing and alternate wetting and drying experiments indicate that the structure and physicochemical properties of the sandstone are normal. The outdoor all-weather simulation experiment proves that the sandstone can not be easily fouled or get moldy, and has a certain self-cleaning function.

Owner:上海奇葩环境科技有限公司

Seat stool in elevator car

The invention discloses a seat stool in an elevator car. The handrail function can be achieved, and the seat function can further be achieved under the situation that the use area of the car is not affected. The elevator car is internally provided a pair of side walls and an inner wall, handrails are arranged on any wall or the two walls or the three walls, the elevator car further comprises a plate serving as the seat stool, and the handrails are hinged to the walls through the plate. The mode that a fixed seat is arranged in a car in the past is changed, the seat stool serving as the handrails is provided, and the seat stool is arranged in an overturning type structure. The seat stool is simple in structure and applicable, the car space is used reasonably, the taking demand of a specialhuman body can be met, and the original design integrity and the decorative effect of the car can be maintained; and a seat backrest can serve as a backrest and can block a gap generated after the seat is overturned, and a protective cover at the rear end of the seat achieves a good safety protection effect.

Owner:当阳市安达机电有限责任公司

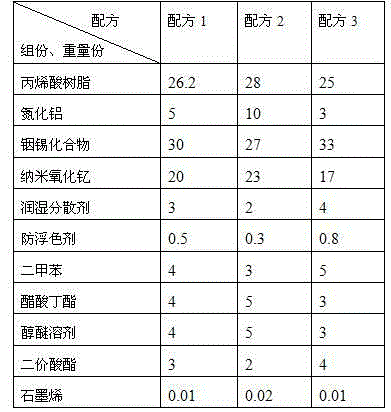

Heat reflection and dissipation type automotive clear top finish

InactiveCN104877509AAdd dimensionStrengthen the sense of metal effectReflecting/signal paintsXylyleneAcrylic resin

The invention relates to heat reflection and dissipation type automotive clear top finish. The heat reflection and dissipation type automotive clear top finish comprises, by weight, 10-30 parts of high-hydroxyl-value acrylic resin, 15-35 parts of low-hydroxyl-value acrylic resin, 1-5 parts of gloss enhancer, 18-25 parts of heat reflection solution, 1-5 parts of esters solvent, 1-5 parts of alcohol ether solvent, 1-3 parts of aliphatic dibasic esters, 0.1-1.0 part of levelling agent, 0.1-0.5 part of defoamer and 0.1-0.5 part of wetting agent. The heat reflection solution comprises acrylic resin, aluminium nitride, indium tin oxide, nanometer yttrium oxide, wetting dispersant, anti-flooding agent, xylene, butyl acetate, alcohol ether solvent, dibasic ester and graphene. The heat reflection and dissipation type automotive clear top finish plays roles in detecting, protecting finish paint in the under layer and convecting and dissipating heat reflected by the finish paint in the under layer, and stereoscopic impression, metal effect impression and mirror-surface impression of the sparkling finish are enhanced.

Owner:LIUZHOU LONGXI CHEM

Environment-friendly nano composite metal plate

InactiveCN102582161AColorful appearanceGuaranteed protective effectSynthetic resin layered productsMetal layered productsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses an environment-friendly nano composite metal plate, which comprises a steel plate, and is characterized in that a back paint layer is arranged on the back face of the steel plate; a bottom paint layer is arranged on the surface of the steel plate; a face paint layer is arranged on the bottom paint layer and is composited with a plastic layer; and the plastic layer is formed by bonding nanoscale PET (polyethylene terephthalate) plastic and a PBT (polybutylece terephthalate) plastic film via a bonding agent and is 22 to 40mum in thickness. The surface of the metal plate disclosed by the invention is composited with the nanoscale plastic layer, so the metal plate has environment-friendly and non-toxic performance, and patterns and colors of the metal plate can be changed according to requirements; and since nanoscale material is adopted, the surface of the metal plate is clean and is not easy to pollute; the metal plate also maintains the protective effect and the decorative effect of the plastic film, so the metal plate has a richer and more colorful appearance and is particularly suitable for being used in the household appliance manufacturing industry.

Owner:SUZHOU XINYING NEW MATERIAL TECH

Attapulgite finishing coating mortar and preparation method thereof

The invention discloses attapulgite finishing coating mortar and a preparation method thereof and relates to the technical field of building materials. The finishing coating mortar is prepared from acomponent A and a component B; during use, the component A and the component B are mixed according to the ratio; the component A is prepared from the following raw materials: modified epoxy resin, 42.5 white Portland cement, a quartz sand mixture, heavy calcium carbonate powder and nanometer aluminum oxide; and the component B is prepared from the following raw materials: modified attapulgite, alkali resistant acrylic emulsion, texanol, color paste and natural vegetable oil. According to the preparation method disclosed by the invention, by carrying out modifying treatment on the epoxy resin and the attapulgite, weather fastness and compressive strength of the finishing coating mortar are enhanced; and the preparation method has the advantages of low cost, simple process, no pollution andsuitability for industrial production.

Owner:安徽万博材料科技有限公司

Water-based air purification paint and preparation method thereof

InactiveCN113122084AGood for healthTo achieve the purpose of purifying the airGas treatmentElectrostatic separationRare-earth elementPtru catalyst

A water-based air purification paint is prepared from the following components in percentage by mass: 25 to 35 percent of modified acrylic resin, 20 to 30 percent of a pigment, 10 to 20 percent of a filler, 3 to 7 percent of light rare earth elements, 1 percent of an activating agent, 0.5 percent of a catalyst and 2.5 percent of an auxiliary agent. The invention also provides a preparation method of the water-based air purification paint. The water-based air purification paint provided by the invention can maintain the existing decorative effect, eliminate harmful substances in air and increase the concentration of negative oxygen ions in air.

Owner:深圳市通晟供应链发展有限公司

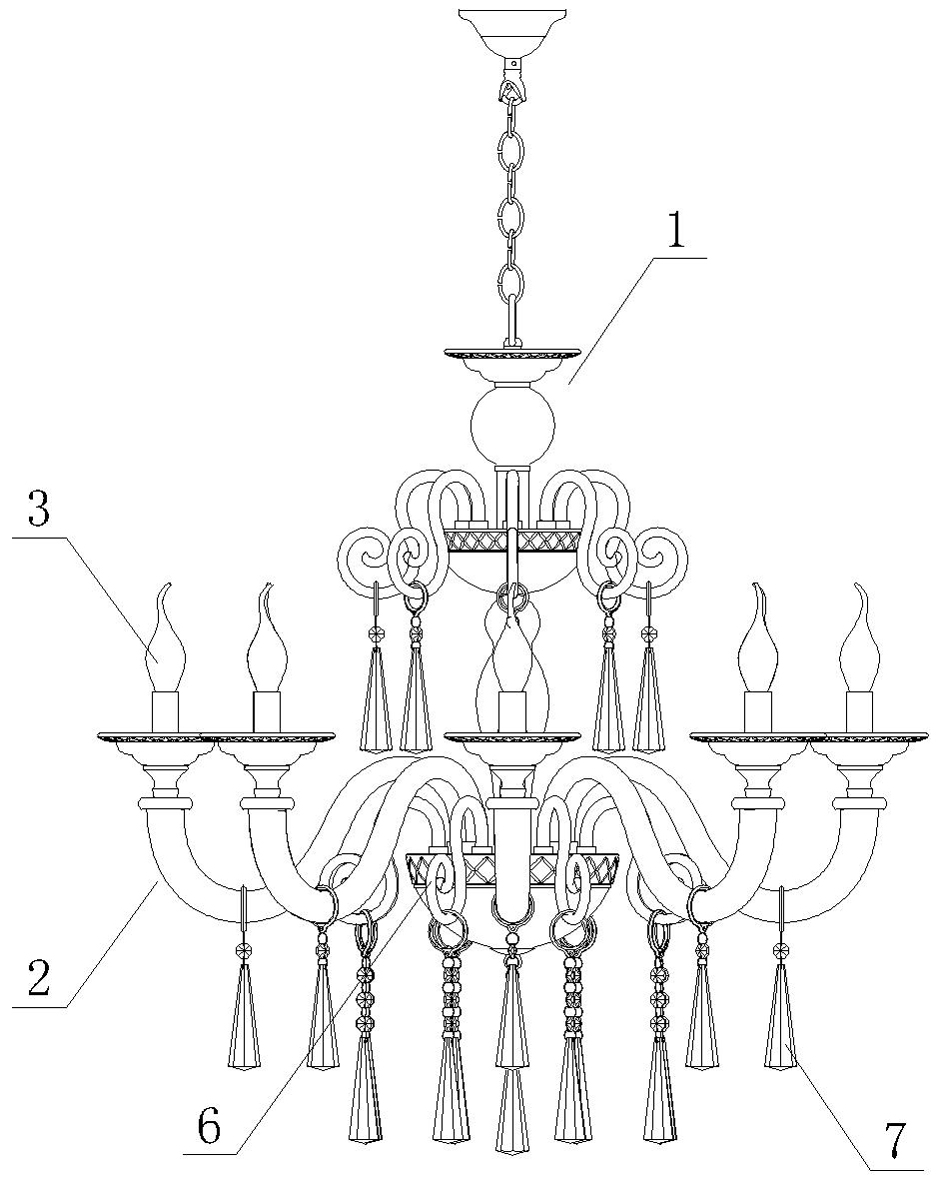

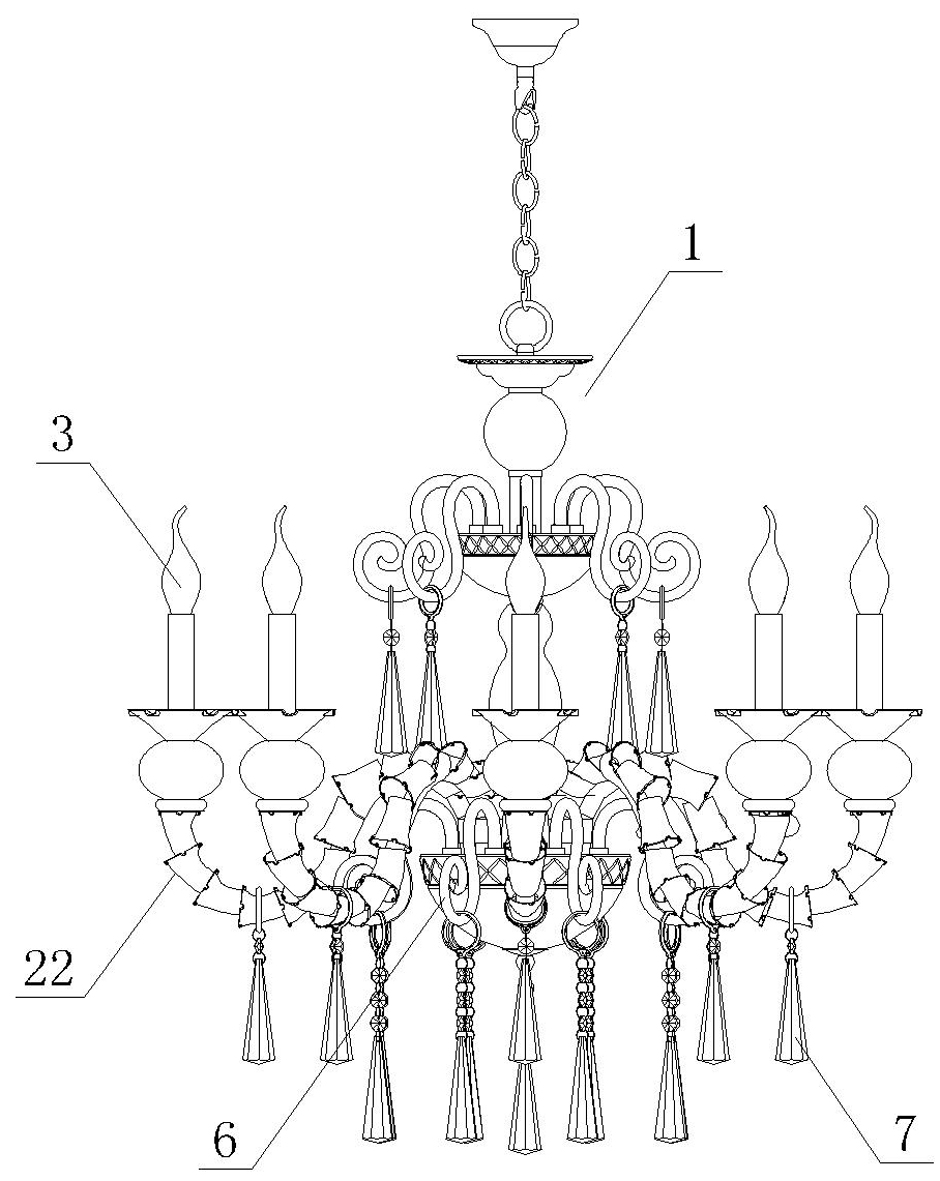

Lamp with auxiliary lighting and decorating functions

InactiveCN102062336AKeep it practicalMaintain decorative effectElectric circuit arrangementsLighting elementsEngineeringLuminescence

The invention relates to a lamp with auxiliary lighting and decorating functions, which comprises a lamp holder, a lamp arm connected to the lamp holder, and a luminous assembly and is characterized in that the lamp arm is made into a light transmission arm; and the luminous assembly comprises a main lamp arranged at the exterior of the lamp arm as a main light source, an auxiliary lamp arranged in the lamp arm as an auxiliary light source, and a circuit controller for controlling the on and off of the main lamp and the auxiliary lamp. In the invention, a structure that the lamp arm is made into a light transmission pipe and the outer end and interior of the lamp arm are respectively provided with the main lamp and the auxiliary lamp is adopted, thus, the original lighting practicability and decoration of the lamp are maintained through a filament lamp serving as the main lamp when the lamp in the invention is used, and the luminescence of the lamp arm is utilized to supply the auxiliary lighting at night to further enhance the ornamentation and decoration effects of the lamp, thereby effectively solving the problems that the existing lamp is only provided with a main light source, has weak decoration effect and the like.

Owner:王小勇

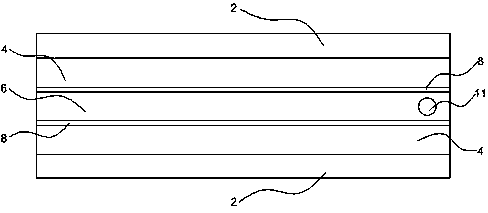

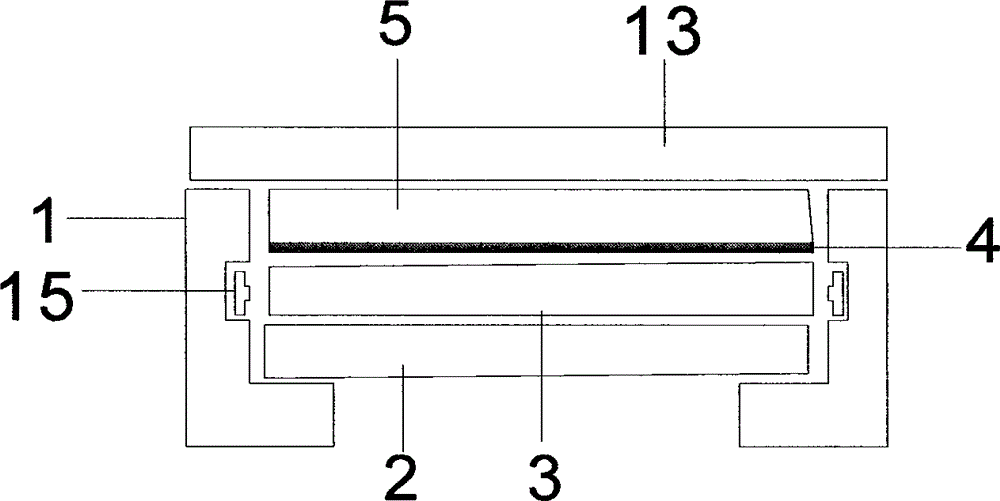

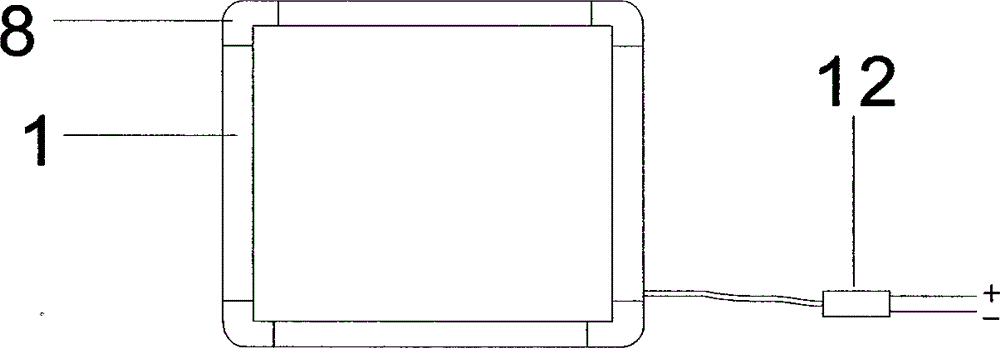

Light-emitting diode (LED) panel lamp with cross-stitched embroidery as background picture

InactiveCN105299503AMeet the requirements of personalized decorationMaintain decorative effectPoint-like light sourceProtective devices for lightingLight guideEngineering

The invention relates to the field of light-emitting diode (LED) illumination, in particular to an LED panel lamp. The LED panel lamp comprises aluminum frame strips, a light-pervious plate, a light guide plate, a cross-stitched embroidery, a backboard, LED lamp beads, corner braces, a power adapter, an L-shaped fixing piece, edge covering clamp strips, an aluminum bottom shell and a wall hook. The aluminum frame strips are in L shapes. A lamp groove is formed in the inner side of one edge of each aluminum frame strip. The aluminum frame strips are spliced and assembled into a square frame through the corner braces. The LED lamp beads are welded onto an aluminum-based printed circuit board (PCB) strip, so that an LED lamp bar is manufactured, and the LED lamp bar and the power adapter are connected into an illumination circuit through a power line. The cross-stitched embroidery is flatly spread on the surface of the backboard and fixed to the backboard through the edge covering clamp strips. According to the LED panel lamp, the cross-stitched embroidery is used as a background picture of the LED panel lamp, so that the decorative effect of the LED panel lamp is improved, and other application functions, besides the handcraft decoration function, in life of the cross-stitched embroidery are enriched.

Owner:易日权

Steel-plate sandwich panel and processing method therefor

InactiveCN106881920AMaintain corrosion resistanceMaintain decorative effectLaminationLamination apparatusSheet steelComposite plate

The invention relates to a steel-plate sandwich panel and a processing method therefor. The steel-plate sandwich panel comprises wrapping steel composite plates at the two sides and a solid material filled between the wrapping steel composite plates. Each steel composite plate comprises wrapping stainless steel plates at the two sides and a middle carbon steel plate; and the solid material is a high-density polyethylene material or foamed ceramic material. A heat insulating material is stuck to the back face of the steel-plate sandwich panel, so that a heat preservation and decoration integrated panel can be formed. The steel-plate sandwich panel disclosed by the invention has the characteristics of high decoration performance, good durability, high strength, convenience in mounting, economical efficiency and reasonableness and can be applied to the fields of architectural decoration, building enclosure and partition, container manufacturing, and the like.

Owner:宝钢建筑系统集成有限公司

Double-side metal composite plate

InactiveCN103331962AEasy to makeGood decorative effectMetal layered productsSteel platesPrecious metal

The invention discloses a double-side metal composite plate. The double-side metal composite plate comprises a face plate, a basal plate and a bonding layer, wherein the face plate and the basal plate are arranged at the outer layer; the bonding layer is configured to be a middle layer; the thickness of the basal plate is greater than the thickness of the face plate. The double-side metal composite plate disclosed by the invention is convenient to manufacture; through compositing less noble metal material with an ordinary steel plate, a decorative effect of the original noble metal material is maintained and the strength of the ordinary steel plate is integrated, so that the total decorative effect can be excellent, the service life is long, the production cost is reduced, and the need of the popularity is met.

Owner:WUXI MEIYU METAL COMPOSITE NEW MATERIALS

Decorative insulation board system

ActiveCN103114694BAvoid failureEasy to installCovering/liningsBiochemical engineeringBuilding material

The invention relates to the field of building material decoration, in particular to a decoration insulation board system which can maintain decoration effect and safety of a decoration insulation board for a long time. The decoration insulation board system comprises a decoration insulation integrated board and a fixed piece. The decoration insulation integrated board comprises a decoration layer, a middle layer and a fastening piece, and one side face of the middle layer, paralleled with the thickness direction of the middle layer, is provided with a clamping groove. One side of the fastening piece buckles edges of one side of the decoration layer, far from the middle layer, and the other side of the fastening piece extends into the clamping groove and clamps the inner wall of one side of the clamping groove, close to the decoration layer, and then the decoration layer and the middle layer are connected in a fastening mode. The fixed piece comprises a first connection base body and a second connection base body which is used for being connected with a wall. The first connection base body and the second connection base body are connected in a perpendicular mode so as to form an L shape. The first connection base body is provided with a clamping protrusion and a baffle, both the clamping protrusion and the baffle are perpendicular to the first connection base body and paralleled with the second connection base body; and the baffle is arranged between the clamping protrusion and the second connection base body.

Owner:刘兴兵

Dustproof artistic decoration bonsai

InactiveCN109228777AAvoid easy stainingAvoid getting stainedSpecial ornamental structuresEngineeringProcessing cost

The invention provides a dustproof artistic decoration bonsai. The dustproof artistic decoration bonsai comprises a tray, an ornament and a tray cover, wherein the tray cover is transparent, and the ornament is located in an interlayer between the tray and the tray cover. The dustproof artistic decoration bonsai exposed to outside can be prevented from being stained with dust, so that use time ofthe dustproof artistic decoration bonsai is prolonged greatly, and the attractive and decorative functions of the dustproof artistic decoration bonsai are kept for a long time; the dustproof artisticdecoration bonsai is simple in structure and convenient to produce, has low processing cost and maintenance cost and keeps the decorative effect for a long time.

Owner:杨玲利

Technology for manufacturing nano elastic rough exterior wall paint

The invention discloses a manufacture technology of a nano elastic galling external wall paint, which comprises the steps of: the initial stirring, sanding, mixing, filtering and screening of the paint; nano paste is added in the mixing process of the paint, and the nano paste includes 80 percent to 82 percent of nano silicon dioxide, 13 percent to 15 percent of nano zinc oxide, 1 percent to 2 percent of nano double thinning agent, 1 percent to 2 percent of nano reinforcing agent, 1 percent to 2 percent of nano anti-aging agent and 1 percent to 2 percent of nano thickening agent. The utilization rate of the paste is high, the cost is low and the technology is simple and environment-friendly.

Owner:浙江无奇涂料股份有限公司

A kind of foam glass ceramic composite brick and preparation method thereof

The invention relates to the field of building decorating materials, in particular to a foam glass ceramic composite brick and a manufacturing method thereof. The method comprises the following manufacturing steps that 1, foam glass raw materials are cleaned; 2, the raw materials in the step 1 and a foaming agent silicon carbide are mixed according to the ratio to obtain a mixture, ball milling is carried out on the mixture, and a spray drying tower is used for carrying out powder spraying and pelleting; 3, the mixture prepared in the step 2 is weighed according to the formula, tiled or pressed to be formed, and then placed into a mullite or crystallization silicon carbide die, the bottom and the periphery of the die are padded with a layer of high-temperature-resistant paper or coated with a layer of high-temperature-resistant slurry; 4, a ceramic thin plate or a tile is placed on the powder in the step 3 horizontally, and enters a roller kiln or a tunnel kiln to be sintered; 5, products are taken out, and polishing, edging, chamfering and edge cutting are carried out on the products. In the foam glass sintering process, the common tile or the ceramic thin plate is sintered at the same time, the excellent characteristics of the common tile or the ceramic thin plate are retained, and the products are economical and practical.

Owner:成都的卢高科技有限公司

Plastic UHF (ultra-high frequency)-RFID (radio frequency identification) bottle cap

InactiveCN103612824AKeep shapeMaintain decorative effectLocking devicesBottle capBiomedical engineering

The invention discloses a plastic UHF (ultra-high frequency)-RFID (radio frequency identification) bottle cap. A part of a radio frequency identification body is manufactured on the plastic bottle cap or a component of the plastic bottle cap in advance; and the complete plastic UHF-RFID bottle cap is manufactured by an assembling, adhering or welding process.

Owner:高洪强

High-elasticity anti-aging vehicle door sealing strip

The invention mainly relates to the technical field of vehicle product processing, and discloses a high-elasticity anti-aging vehicle door sealing strip, which is prepared from the following raw materials: polyether polyol, polyurethane, a foamed silica gel, polyimide, isooctyltriethoxysilane, phthalate, azodicarbonamide, tricalcium phosphate, nanometer titanium dioxide, and nanometer zinc oxide.According to the present invention, the high-elasticity anti-aging vehicle door sealing strip has characteristics of strong elasticity, strong compression deformation resistance, water resistance, dust resistance, sound resistance, thermal insulation and excellent aging resistance, and can effectively delay the corrosion of ultraviolet rays and air pollutants, and the service life can be prolongedto 6 years, such that the replacement frequency of the vehicle door sealing strip can be significantly reduced, the resources can be saved, the environment can be protected, and the use cost of the vehicle can be reduced; and the polyether polyol and the polyurethane are slowly mixed and heated, such that the raw materials are fully grafted so as to improve the elasticity and the strength of thesealing strip.

Owner:李晓波

A composite coating type self-cleaning inorganic ecological decorative board and preparation method thereof

ActiveCN105802367BMaintain decorative effectImpart superhydrophilicityCovering/liningsDextran coatingsComposite filmUltraviolet

The invention discloses a composite film-coated self-cleaning inorganic ecological decorative plate and a preparation method thereof.The preparation method comprises the following steps that 1, an inorganic ecological decorative plate is taken as a base body, and after the surface of the inorganic ecological decorative plate is subjected to dust blowing cleaning treatment, film coating loading is performed by adopting a photocatalytic hydrophilic coating through powder coating or spraying or a sol-gel method to obtain a TiO2-loaded inorganic ecological decorative plate; 2, the TiO2-loaded inorganic ecological decorative plate obtained in the step 1 is dried or subjected to ultraviolet curing, the drying temperature is 50 DEG C-85 DEG C, the drying time is 0.5-3 h, and after natural cooling is performed, the composite film-coated self-cleaning inorganic ecological decorative plate is obtained.Accordingly, the inorganic ecological decorative plate is taken as the base body, film coating loading is performed by adopting the photocatalytic hydrophilic coating through powder coating or spraying or the sol-gel method, moisture condensation is performed on kitchen and bath fumes, organic matter, sewage and dirt, outer curtain wall dust is self-removed, the self-cleaning capacity is high, and the durability is good.

Owner:HUBEI GREENS NEW BUILDING MATERIALS SCI & TECH YINGCHENG

A self-cleaning curtain wall decorative board and its processing technology

ActiveCN106088422BGood spreadabilityImprove superhydrophilicityAntifouling/underwater paintsCovering/liningsWeather resistanceFluoropolymer

The invention relates to a self-cleaning curtain wall decorative sheet and a manufacturing technique thereof and belongs to the technical field of building materials. The self-cleaning curtain wall decorative sheet is composed of a substrate layer, a first passivation layer, a second passivation layer, a backing paint layer, a primer layer, a finish paint layer and a self-cleaning layer. The first passivation layer and the second passivation layer are located on the lower surface and the upper surface of the substrate layer correspondingly. The backing paint layer is located under the first passivation layer. The primer layer is located on the second passivation layer. The primer layer, the finish paint layer and the self-cleaning layer are sequentially arranged from bottom to top. The self-cleaning layer is a titanium dioxide / silicon dioxide composite layer, and fluoropolymer formed by water-soluble fluorine-containing polymer is arranged in the self-cleaning layer. The self-cleaning curtain wall decorative sheet is applied to the building decoration field such as high-rise building outer walls and large exhibition halls and has the advantages of weather resistance, corrosion resistance, self-cleaning and the like.

Owner:浙江墙煌新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com