Environment-friendly nano composite metal plate

A nano-composite, metal plate technology, applied in the direction of metal layered products, synthetic resin layered products, layered products, etc., can solve the problems of covering metal luster, losing the texture of metal materials, affecting the appearance of products, etc. Pollution, colorful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

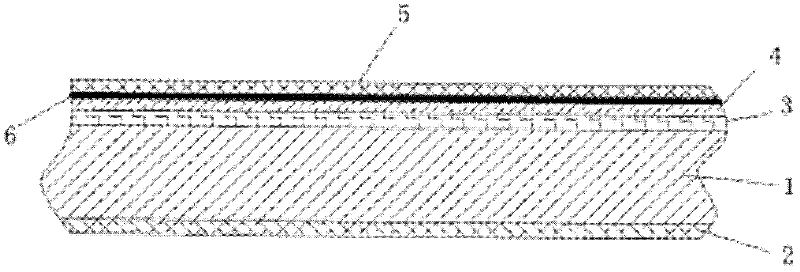

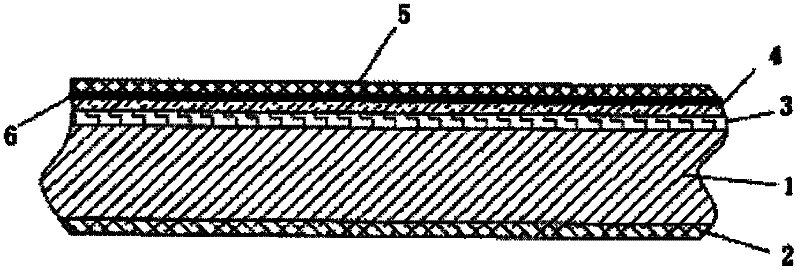

[0018] Such as figure 1 as shown,

[0019] An environment-friendly nano-composite metal plate, comprising a steel plate 1, the back of the steel plate 1 is provided with a back paint layer 1, the surface of the steel plate 1 is provided with a primer layer 3, and the primer layer 3 is provided with a top coat layer 4 , the topcoat layer 4 is compounded with a plastic layer 5, the plastic layer 5 is composed of nanoscale PET plastic and PBT plastic film bonded by an adhesive, and the thickness of the plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com