Tin bismuth cuprum series leadless solder and preparation method thereof

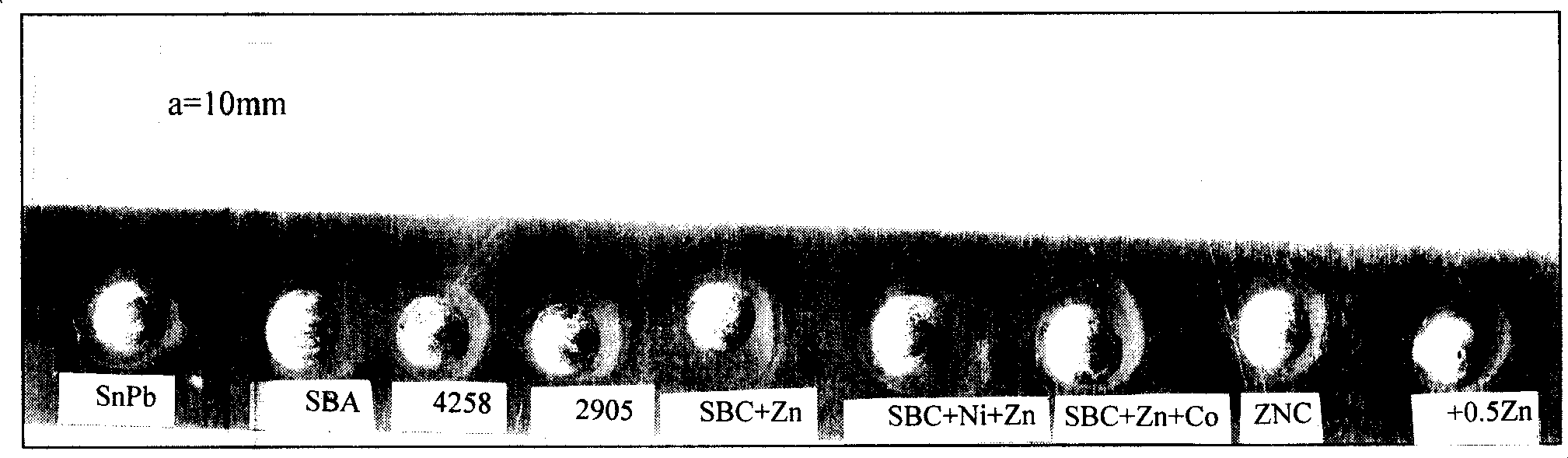

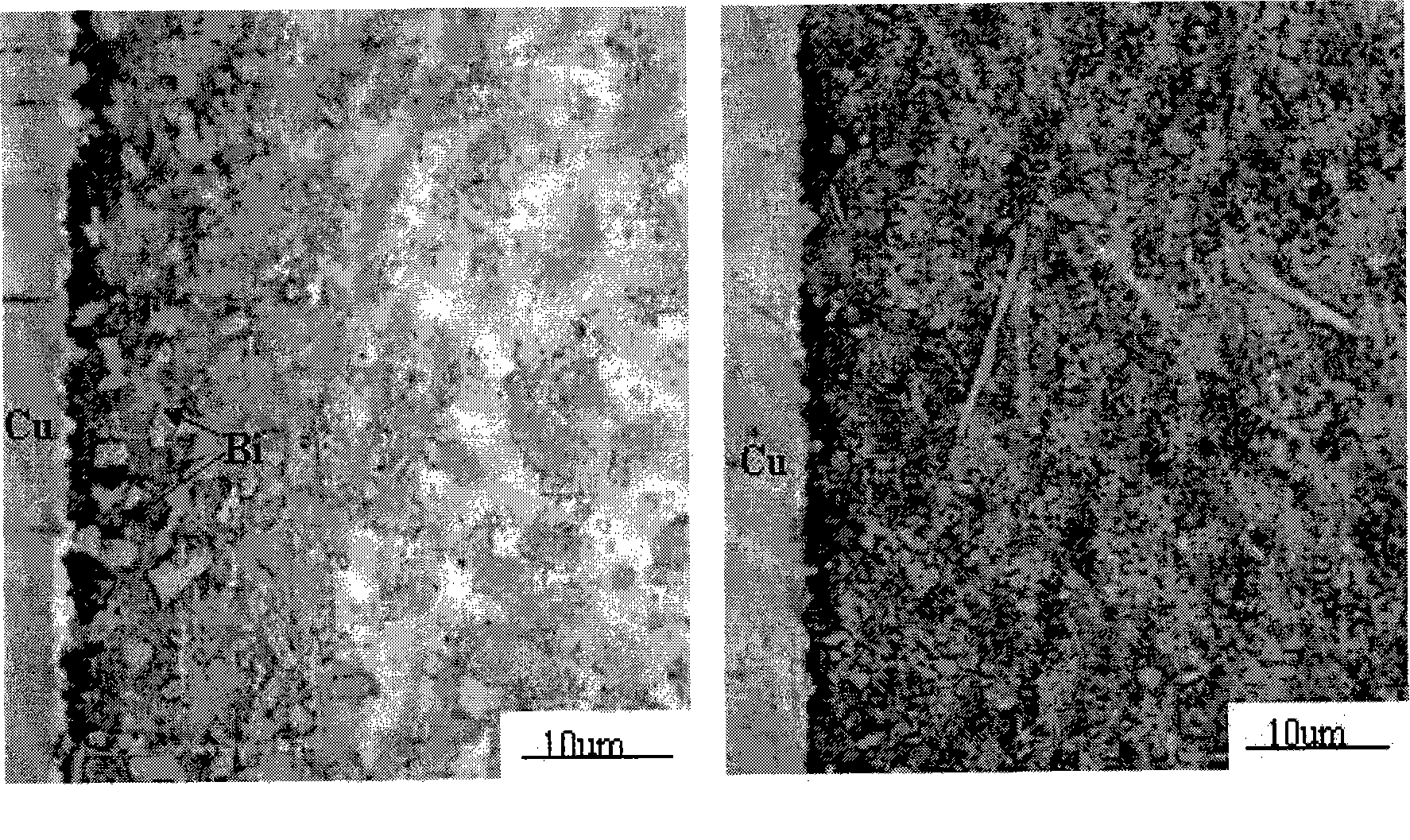

A lead-free solder and copper-based technology, applied in the direction of welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as the effect of lowering the melting point of solder, doubts about reliability, and instability of the interface layer, and achieve reduction Effects of high temperature impact damage, saving Ag consumption, and good solder wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

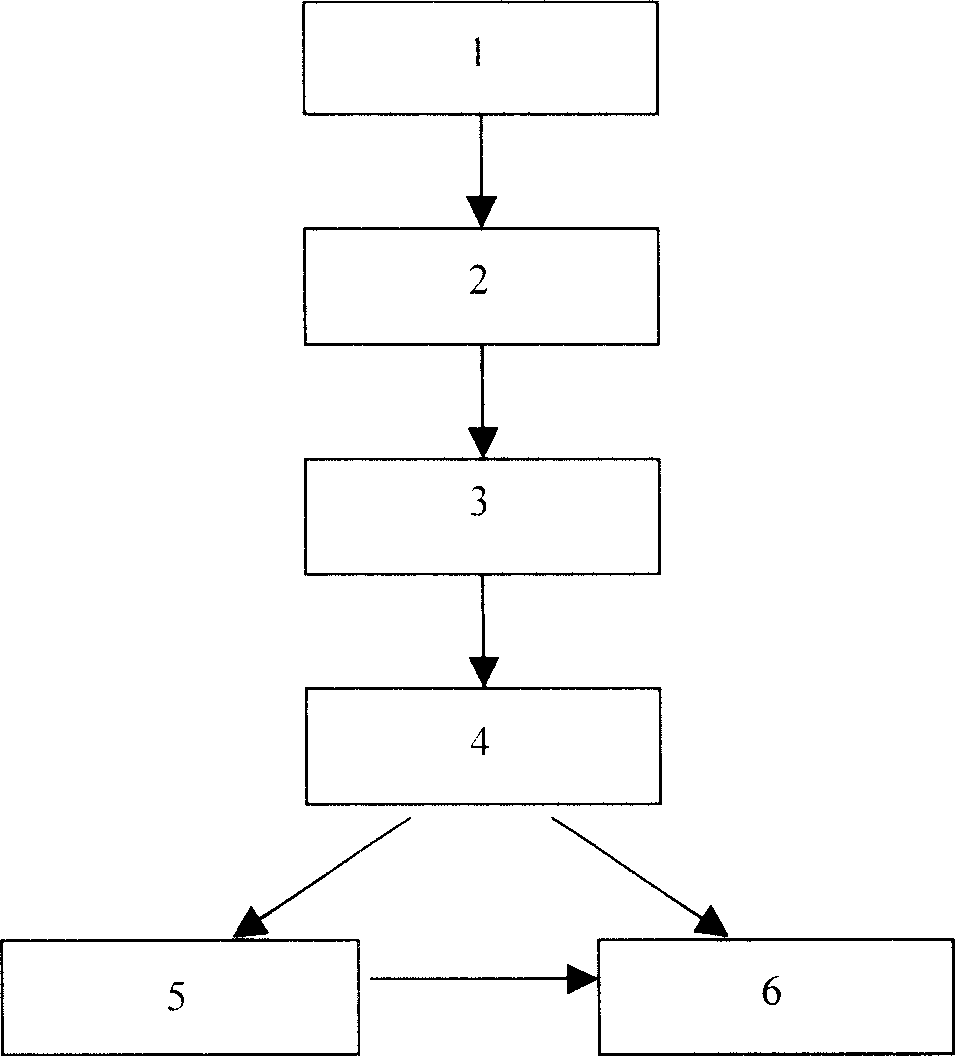

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Sn-29Bi-0.5Cu-0.1Zn alloy: Prepare 5.0 kg of Sn-Cu10 and Sn-Zn9 master alloys in a vacuum intermediate frequency induction melting furnace. Melt in a melting furnace to 650°C, add weighed pure Cu flakes or pure Zn blocks, strengthen stirring and melt to a furnace temperature of 500-600°C, stir and keep warm for 10 minutes, pour into square ingots to prepare Sn-Cu10 and Sn-Zn9 Master alloy; ② Analyze the uniformity of master alloy composition. Weigh 5g of Sn-Cu10 master alloy, 1.1g of Sn-Zn9 master alloy, 29g of pure Bi, and 64.9g of pure Sn. Then melt and heat pure Sn to 290°C in a resistance furnace, add weighed pure Bi and Sn-Cu10 master alloy in turn, and finally put Sn-Zn9 master alloy, heat to 290°C and keep it for 10 minutes, and pour it into a cylindrical mold In the process, after the ingot is completely solidified, remelt the ingot to 250 ° C for 10 minutes, pull out the surface oxide slag, and pour it into the ingot mold to make an ingot for la...

Embodiment 2

[0029] Preparation of Sn-29Bi-0.5Cu-0.05Zn-0.1Ni alloy: The preparation of the master alloy is the same as in Example 1, except that the melting temperature is 900°C when preparing the Sn-Ni10 master alloy. Weigh 5g of Sn-Cu10 master alloy, 29g of pure Bi, 0.56g of Sn-Zn9 master alloy, 1g of Sn-Ni10 master alloy, and 4.44g of pure Sn. Then melt and heat pure Sn to 290°C in a resistance furnace, add weighed pure Bi and three intermediate alloys in turn, heat to 290°C for 10 minutes, pour it into a cylindrical mold, and wait until the ingot is completely solidified before adding The ingot was remelted to 250°C for 10 minutes, the surface oxide slag was pulled out, and poured into an ingot mold to make an ingot for later use.

Embodiment 3

[0031] Preparation of Sn-29Bi-0.5Cu-0.5Zn alloy: the preparation method is the same as Example 1. Weigh 5g of Sn-Cu10 master alloy, 29g of pure Bi, 5.56g of Sn-Zn9 master alloy, and 60.44g of pure Sn. Melt pure Sn in a resistance furnace and heat it to 290°C, add weighed pure Bi and Sn-Cu10, Sn-Zn9 master alloys in turn, heat to 290°C and keep it for 10 minutes, pour it into a cylindrical mold, and wait until the ingot is completely cast After solidification, remelt the ingot to 250°C for 10 minutes, and pour it into an ingot mold to make an ingot for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com