Conductive welding wire for solar cell and preparation method thereof

A solar cell and welding wire technology, applied in welding equipment, circuits, welding media, etc., can solve the problems of high production cost of solar cell panel welding, environmental pollution of conductive welding wire, low photoelectric conversion efficiency of solar cell panels, etc., and achieves increased photoelectric conversion. Efficiency, good wetting and spreading, and the effect of reducing high temperature impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

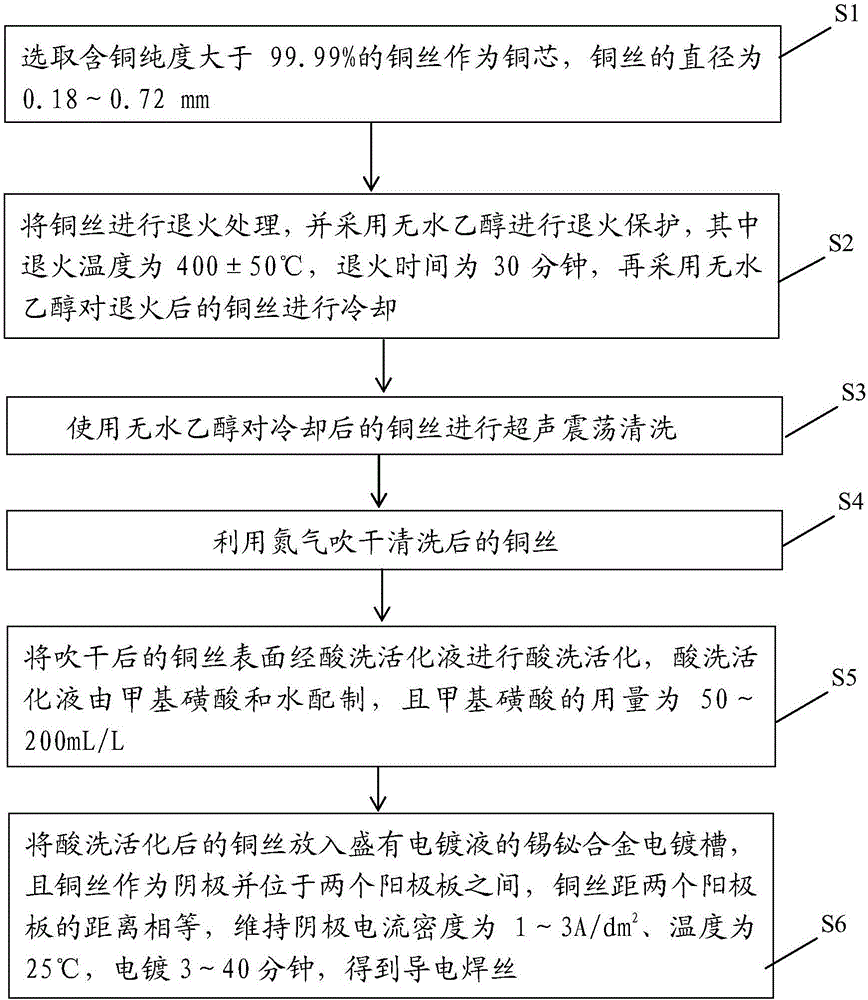

[0023] Also, see figure 2 , figure 2 Shown is a flowchart of a method for preparing a conductive welding wire for solar cells according to the present invention. The present invention also provides a method for preparing the above-mentioned conductive welding wire for solar cells, and the above-mentioned preparation method includes the following steps:

[0024] Step S1: Select copper wire with a copper content greater than 99.99% as the copper core, and the diameter of the copper wire is, for example, 0.18-0.72 mm;

[0025] Step S2: annealing the copper wire, and using absolute ethanol for annealing protection, wherein the annealing temperature is 400±50° C., and the annealing time is 30 minutes, and then using absolute ethanol to cool the annealed copper wire;

[0026] Step S3: using absolute ethanol to perform ultrasonic vibration cleaning on the cooled copper wire;

[0027] Step S4: drying the cleaned copper wire with nitrogen;

[0028] Step S5: Pickling and activatin...

Embodiment 1

[0032] In this embodiment, the preparation method of the conductive welding wire used for solar cells comprises the following steps:

[0033] (1) Select copper wire with a copper purity greater than 99.99% as the copper core, and the diameter of the copper wire is 0.40mm;

[0034] (2) annealing the copper wire, and using absolute ethanol for annealing protection, wherein the annealing temperature is 400±50°C, and the annealing time is 30 minutes, and then using absolute ethanol to cool the annealed copper wire;

[0035] (3) Use dehydrated alcohol to carry out ultrasonic vibration cleaning to the copper wire after cooling;

[0036] (4) Utilize nitrogen to blow dry the copper wire after cleaning;

[0037] (5) Pickling and activating the surface of the dried copper wire by pickling activating solution, the pickling activating solution is for example prepared by methanesulfonic acid and water, and the consumption of methanesulfonic acid is 50mL / L;

[0038](6) The copper wire aft...

Embodiment 2

[0041] In this embodiment, the preparation method of the conductive welding wire used for solar cells comprises the following steps:

[0042] (1) Select copper wire with a copper purity greater than 99.99% as the copper core, and the diameter of the copper wire is 0.21mm;

[0043] (2) annealing the copper wire, and using absolute ethanol for annealing protection, wherein the annealing temperature is 400±50°C, and the annealing time is 30 minutes, and then using absolute ethanol to cool the annealed copper wire;

[0044] (3) Use dehydrated alcohol to carry out ultrasonic vibration cleaning to the copper wire after cooling;

[0045] (4) Utilize nitrogen to blow dry the copper wire after cleaning;

[0046] (5) Pickling and activating the surface of the dried copper wire with a pickling activating solution, the pickling activating solution is for example prepared by methanesulfonic acid and water, and the consumption of the methanesulfonic acid is 100mL / L;

[0047] (6) The coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com