Method for printing pattern on solar battery sheet

A technology for printing solar cells and patterns, applied in printing, circuits, printing devices, etc., can solve problems such as the negative impact on the electrical performance of solar cells, and achieve the effect of not affecting current transmission and not increasing the shading area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

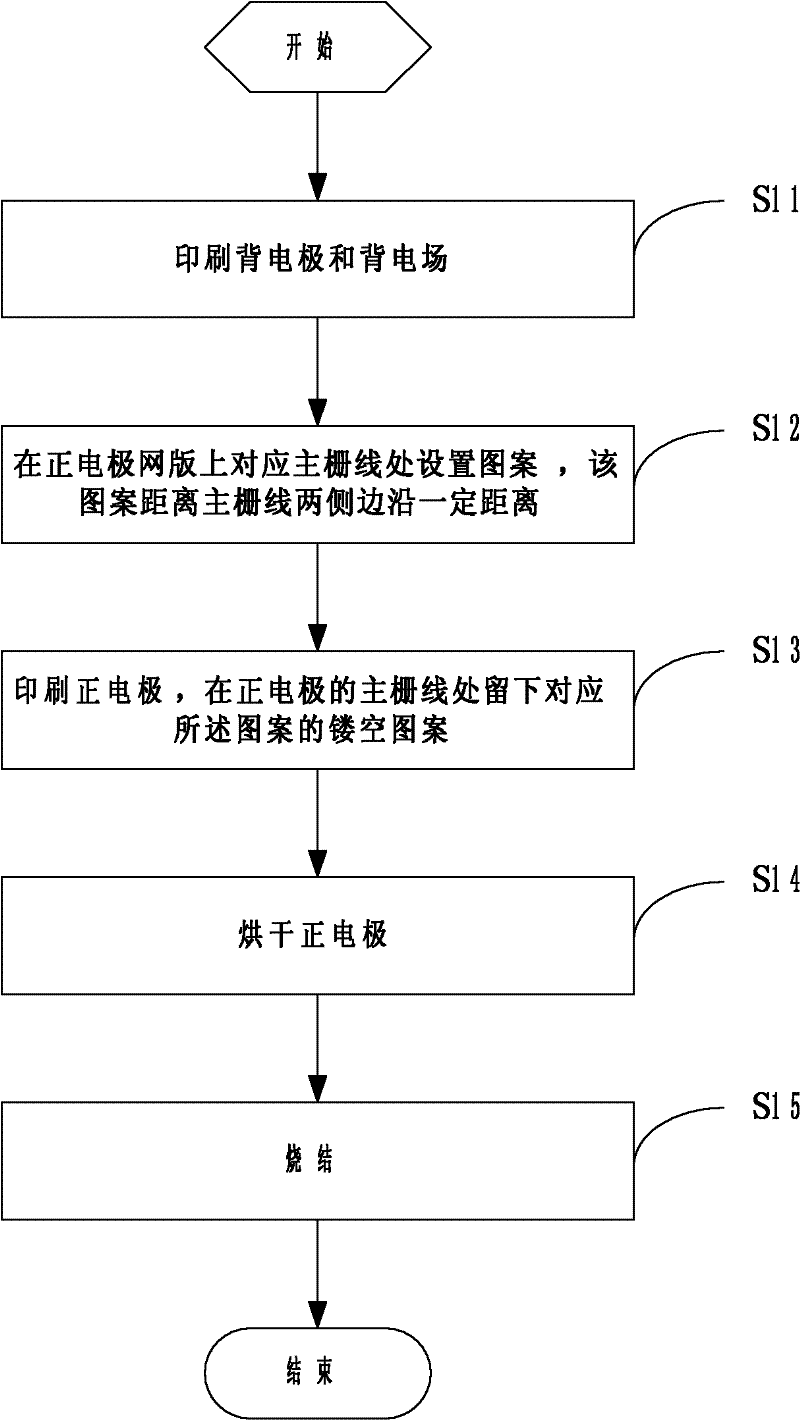

[0038] This embodiment provides a method for printing patterns on solar cell sheets, the basic process is as follows figure 1 shown, including the following steps:

[0039] Step S11 , printing the back electrode and the back electric field.

[0040] Step S12 , setting a pattern on the positive electrode screen corresponding to the busbar, and the pattern is a certain distance away from the edges on both sides of the busbar.

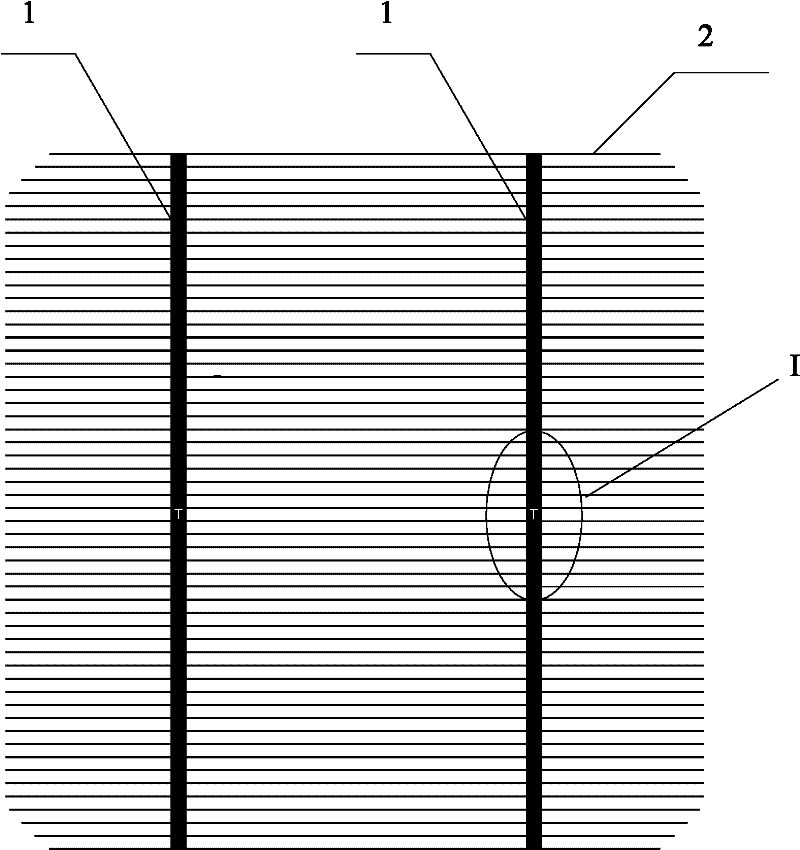

[0041] Step S13 , printing the positive electrode, leaving a hollow pattern corresponding to the pattern at the busbar of the positive electrode.

[0042] Step S14, drying the positive electrode.

[0043] Step S15, sintering.

[0044] The embodiment of the present invention chooses to set the pattern on the busbar, as long as the pattern does not cut off the busbar, it will not affect the electrical performance of the solar cell, and realizes the effect of setting the logo on the solar cell.

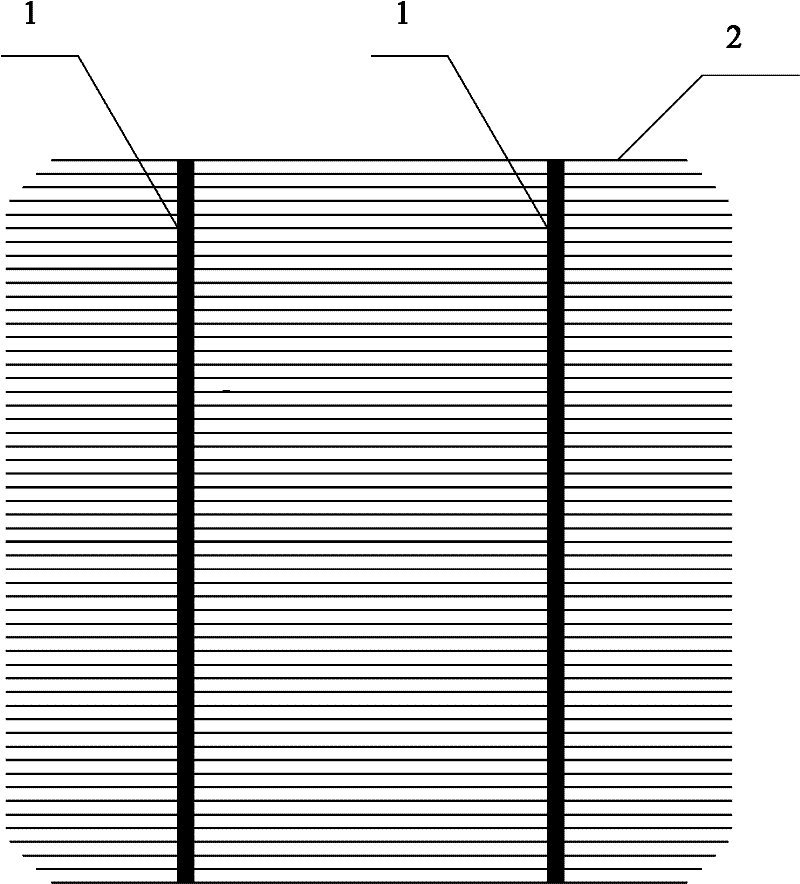

[0045] A specific example is used to supplement the descri...

Embodiment 2

[0061] This embodiment provides yet another method for printing patterns on solar cell sheets, the basic process of which is as follows Figure 5 shown, including the following steps:

[0062] Step S501, printing the back electrode and the back electric field;

[0063] Step S502, printing the positive electrode and drying;

[0064] Step S503, sintering;

[0065] Step S504, setting a pattern on the main grid line of the positive electrode.

[0066] The present embodiment is the same as the first embodiment in that the patterns are arranged on the busbars, and the difference is that the patterns are arranged after the printing and sintering is completed. In comparison, the examples save more slurry.

[0067] The specific method of setting the pattern on the busbar of the positive electrode may be: printing the pattern with a preset paste on the busbar of the positive electrode, or directly using a tool to print the pattern on the busbar of the positive electrode Draw patterns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com