Solar cell structure

A technology for solar cells and solar cells, applied in the field of solar cells, can solve the problems of rising fragmentation rate, cell fragmentation, power loss, etc., and achieve the effect of reducing usage and improving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

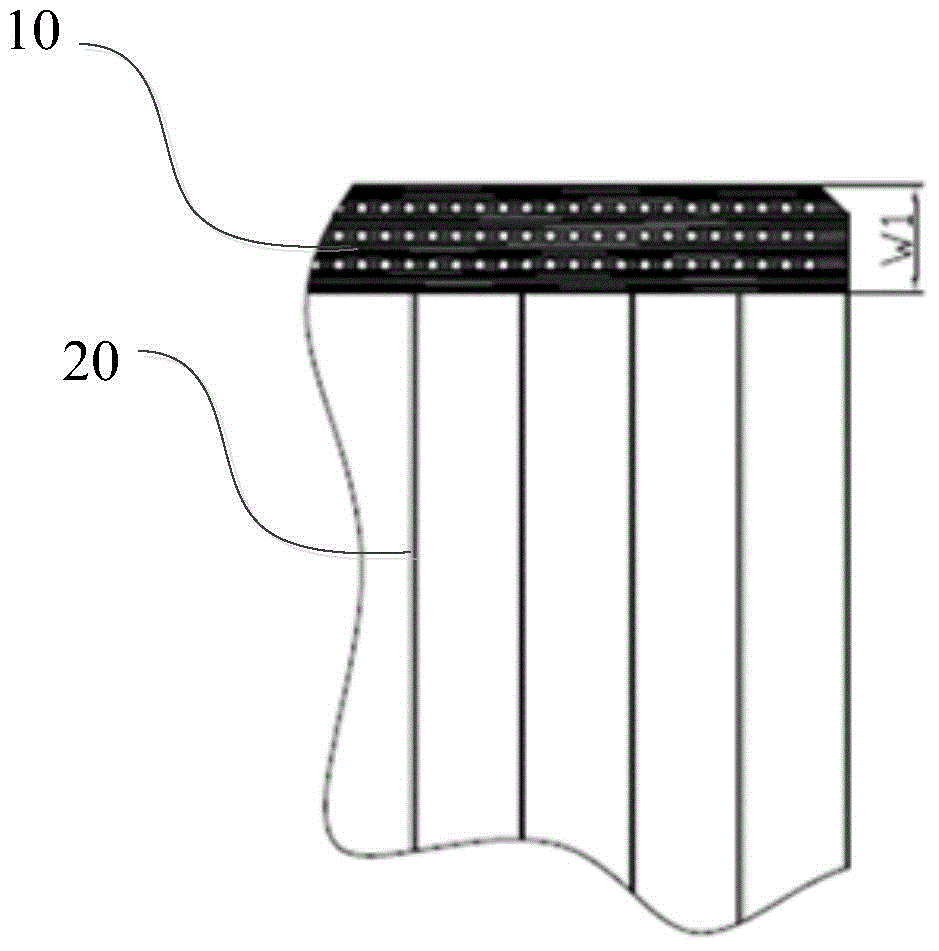

[0026] As mentioned in the background art section, in the production of components in the prior art, it is necessary to use solder ribbons to connect the front side of a cell to the back side of an adjacent cell to form a series circuit. This design has the following characteristics: the components made of cells must be welded with ribbons, and the stress of welding will cause fragments of the cells; the temperature of welding will destroy the PN junction of the cells; The power loss caused by this is 3% to 4%. When the solar cell with this structure is formed into a module, a certain gap must be maintained between the cell and the cell directly for the bending of the solder ribbon. If the distance is too small, the fragmentation rate will increase.

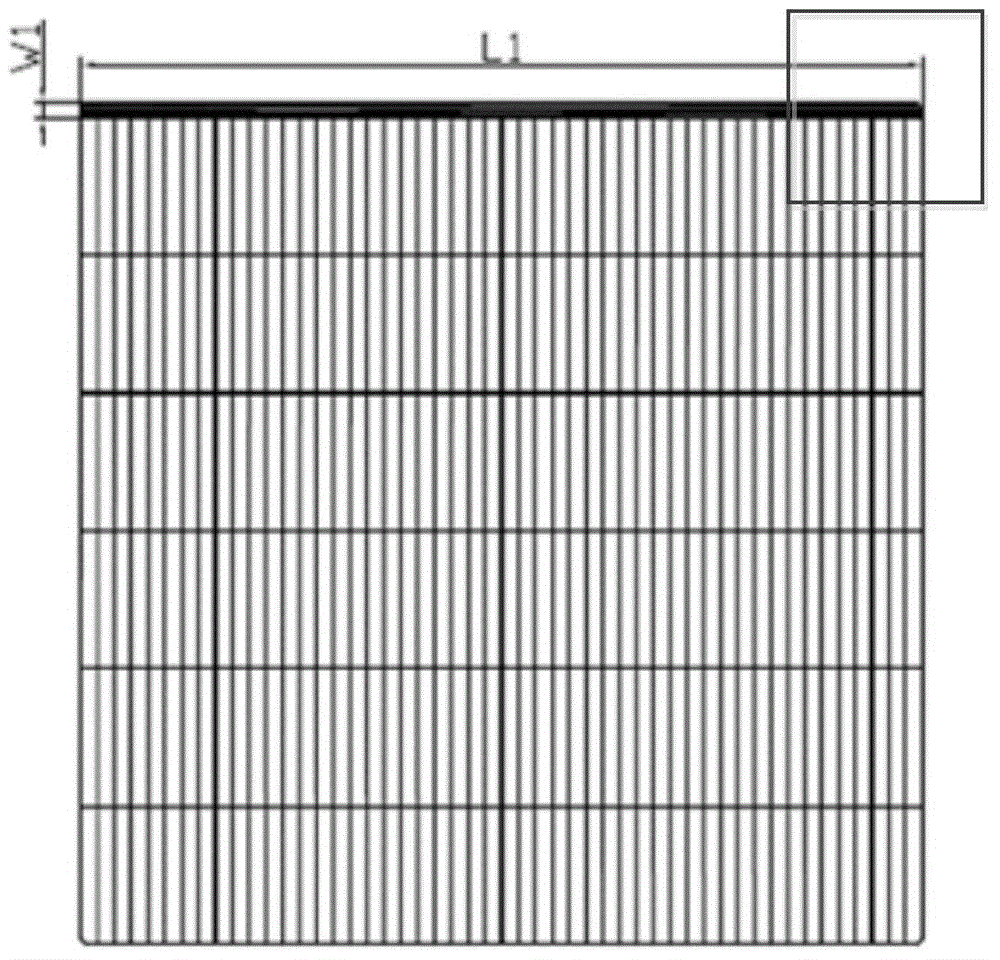

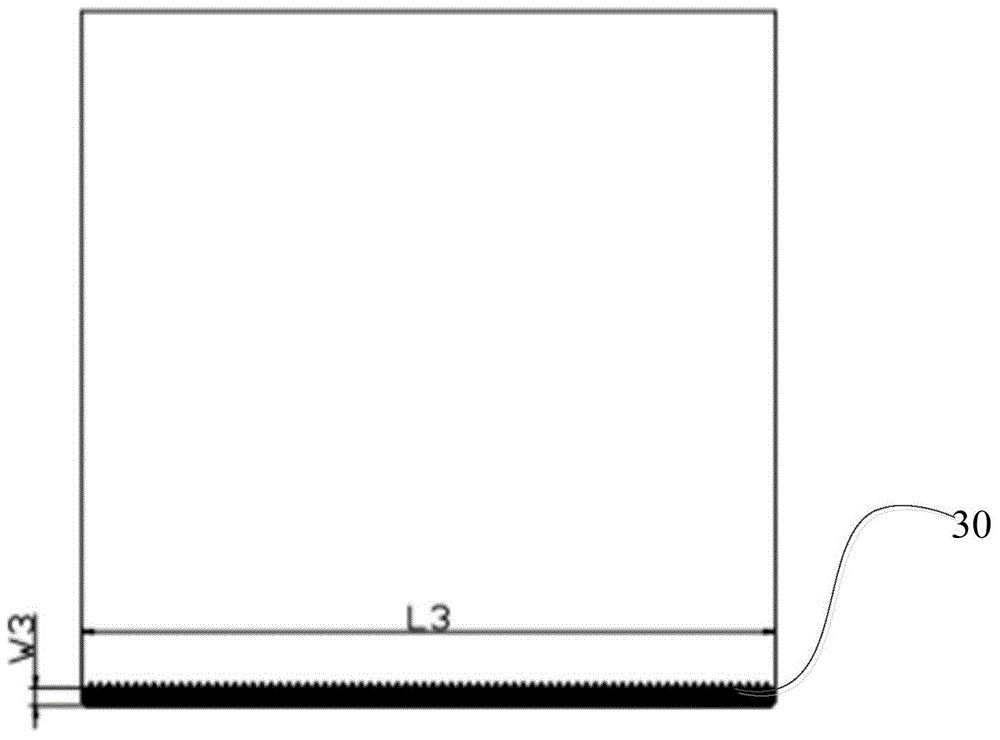

[0027] Based on this, an embodiment of the present invention provides a solar cell structure, including a solar cell sheet, a front electrode is provided on the front side of the solar cell sheet, a back electrode and a back elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com