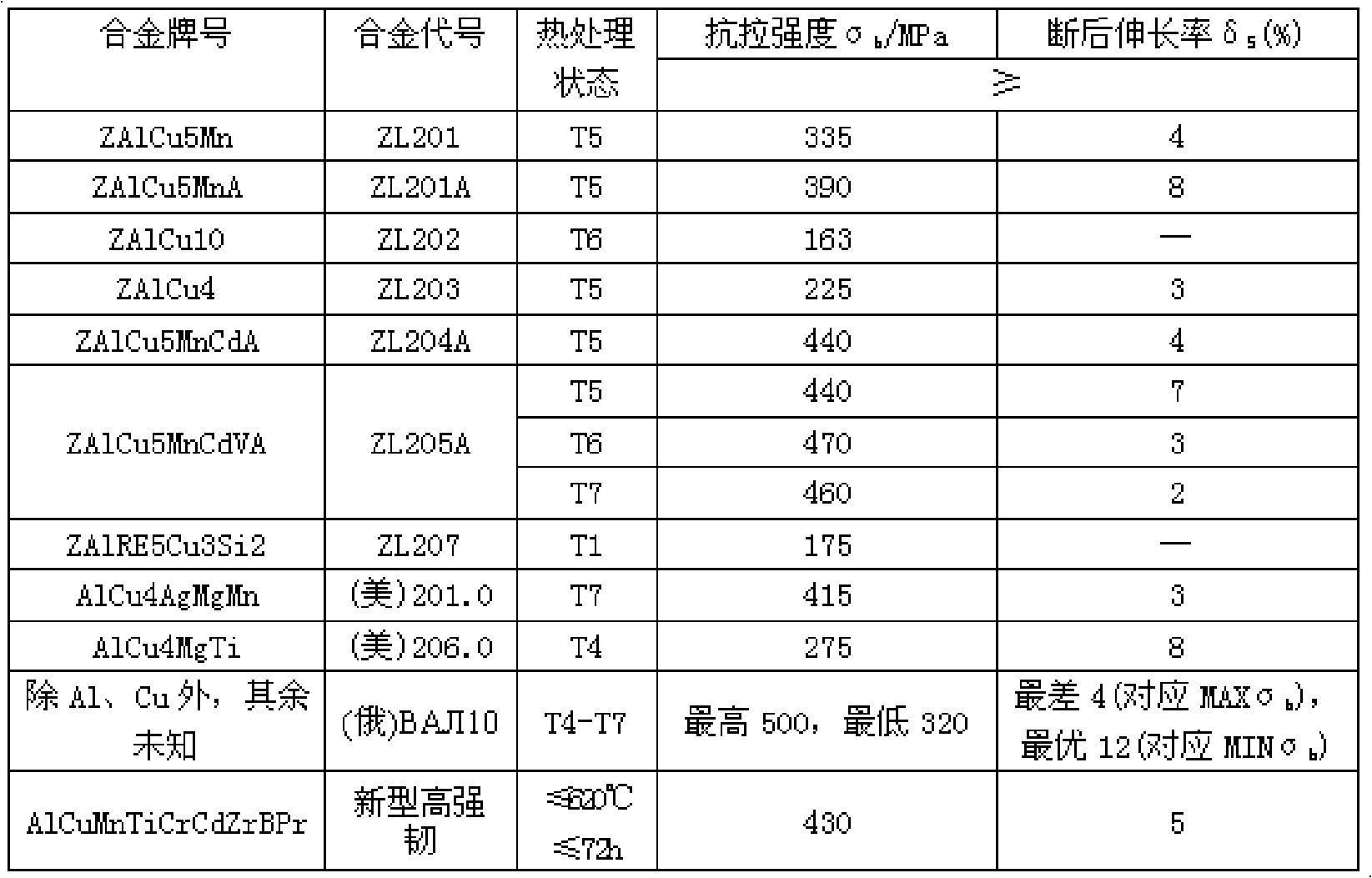

High-strength cast aluminium alloy material

A casting aluminum alloy, high-strength technology, applied in the field of aluminum alloy materials, can solve problems such as poor castability, high-cost formula, poor stress corrosion resistance, etc., to achieve the effect of breaking the technical bottleneck and reducing the cost of formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: by weight percentage, the alloy composition is Cu2.0~6.0%, Mn0.05~1.0%, Ti0.01~0.5%, Cr0.01~0.2%, Cd0.01~0.4%, Zr0.01 ~0.25%, B0.005~0.04%, Pr0.05~0.3%, and the rest are Al and trace impurity elements.

[0025] (1) Add an appropriate amount of aluminum ingot or molten aluminum into the melting furnace, heat it to melt it completely and keep it warm at 660-850°C;

[0026] (2) Add Cu and Mn alloy elements according to the formula ratio and stir evenly, then add Ti, Cr, Cd, Zr, B, Pr trace elements, and stir evenly;

[0027] (3) Then carry out in-furnace refining to above-mentioned alloy melt; Add refining agent (can adopt chlorine, hexachloroethane, manganese chloride etc. as refining agent according to different working conditions) in alloy melt, and stir evenly, simultaneously In order to prevent the melt from absorbing moisture and burning, melt refining should be operated in a closed environment as much as possible;

[0028] (4) The alloy liquid is poure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com