High-strength cast aluminium alloy material

A technology for casting aluminum alloy with high strength, applied in the field of aluminum alloy materials, can solve the problems of high-cost formula, poor castability, poor stress corrosion resistance, etc., and achieve the effect of reducing formula cost and breaking technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

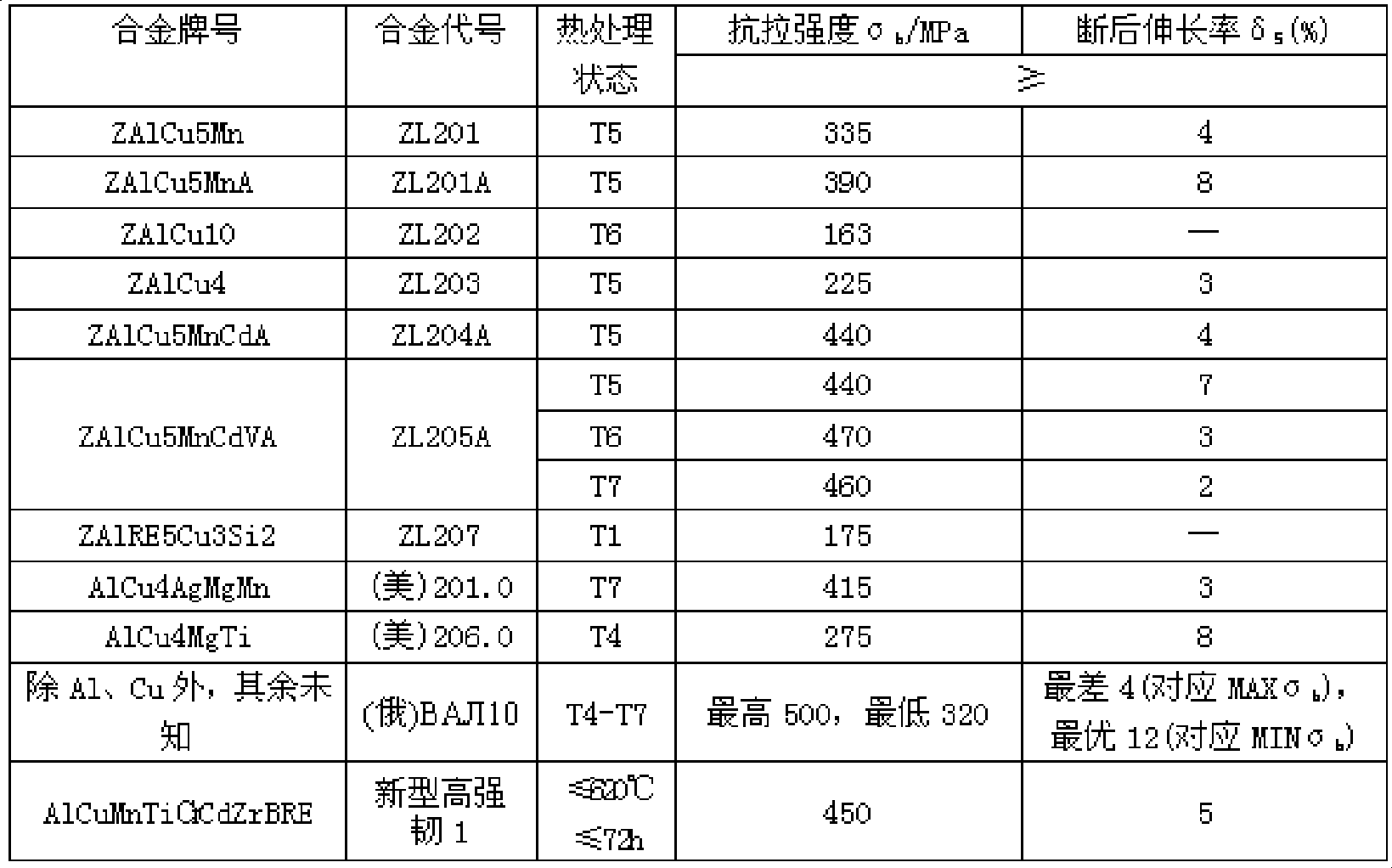

[0025] Embodiment: By weight percentage, the alloy composition is Cu 2.0-6.0%, Mn 0.05-1.0%, Ti 0.01-0.5%, Cr 0.01-0.2%, Cd 0.01-0.4%, Zr 0.01-0.25%, B 0.005 ~0.04%, RE 0.05~0.3%, and the rest are Al and trace impurity elements.

[0026] The mixed rare earth RE contains not less than 98% of the total amount of various rare earths, and the mixed rare earth RE contains 45% of cerium by weight percentage. (Since the ionic radii, oxidation states, and all other elements are similar, REEs often co-occur with other elements in minerals.)

[0027] (1) Add an appropriate amount of aluminum ingot or molten aluminum into the melting furnace, heat it to melt it completely and keep it warm at 660-850°C;

[0028] (2) According to the proportion of the formula, first add Cu, Mn alloy elements and stir evenly, then add Ti, Cr, Cd, Zr, B, RE trace elements, and stir evenly;

[0029] (3) Then carry out in-furnace refining to above-mentioned alloy melt; Add refining agent (can adopt chlorine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com