Sandwich panel, method of forming core material for sandwich panel, and method of forming sandwich panel

一种夹芯板、芯材的技术,应用在化学仪器和方法、应用、家用元件等方向,能够解决夹芯板强度下降、体积大、难以提高隔热性或者吸音性等问题,达到保证压缩刚性、保证弯曲刚性或者剪切刚性、实现轻量化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

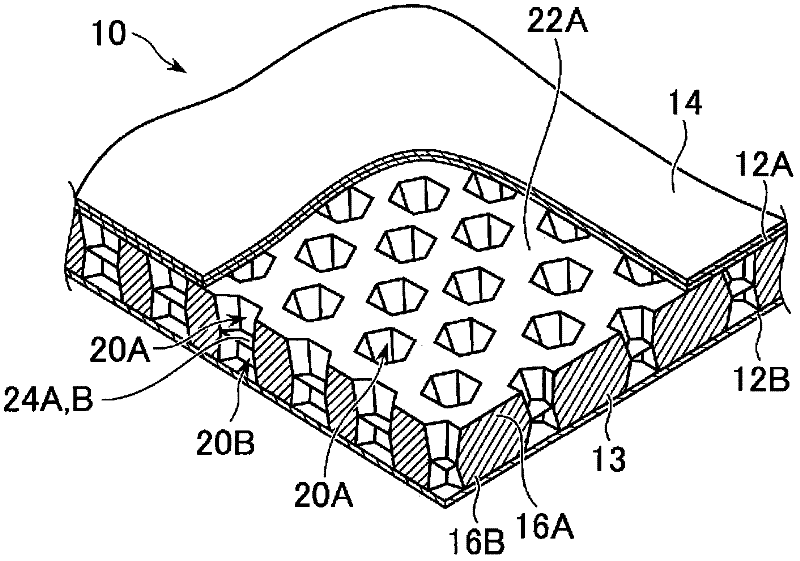

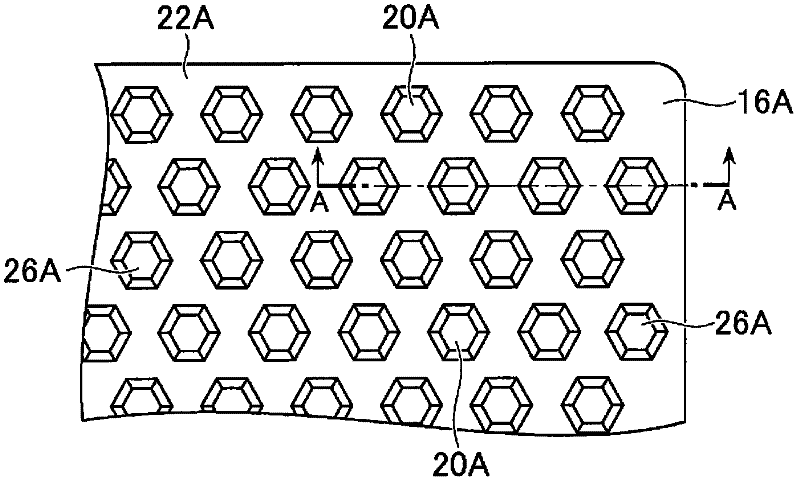

Embodiment 1

[0229] As a thermoplastic resin, a propylene homopolymer (manufactured by Sun Aroma Co., Ltd., PF814) with a long-chain network structure of 3.0 g / min MFR at 230° C. is used as a foaming agent and a nucleating agent. Add the amount of talc MB3 weight ratio to the propylene homopolymer, mix it with an extruder, and store it in the cylindrical space between the mandrel and the outer cylinder of the mold, that is, the stocker, and use a cylindrical plunger to fill the cylinder Shaped parison is extruded into the half-mold, and air is blown to the parison with a pressure of 0.1 MPa after closing the mold, thereby obtaining a plurality of concave parts 20 and hollow parts 19 formed by a regular hexagon with a side length of about 4mm. It is the core material 13 (sample 1) of 15 mm. However, MFR is measured based on JIS K-7210 under the condition of a test load of 2.16 kg. The extrusion rate of the stocker used in the present invention is 200cm 3 / sec or more, preferably 500cm 3 ...

Embodiment 2

[0232] Air is not blown with pressure in the parison after mold closing, but the parison is closely contacted on the mold cavity by sucking the air between the parison and the mold. Other processes are the same as in Example 1, thereby producing a A core material 13 having a solid portion and a thickness of 15 mm having a plurality of concave portions 20 formed of a regular hexagon with a side length of about 4 mm (sample 2). The average density of the core material 13 obtained by embodiment 2 is 0.1g / cm 3 (Conversion of foaming rate: 9 times), the equivalent density is 0.08g / cm 3 (Conversion of foaming rate: equivalent to 11 times).

Embodiment 3

[0234] Except for reducing the amount of foaming agent added, the same method as in Example 2 was used to manufacture a solid portion with a thickness of 15 mm core material 13 (sample 3). The average density of the core material 13 obtained by embodiment 2 is 0.13g / cm 3 (Conversion of foam rate: 7 times), the equivalent density is 0.11g / cm 3 (Conversion of foaming rate: equivalent to 8 times).

[0235] After that, a crystalline ethylene-propylene block copolymer (manufactured by Japan Polychem Co., Ltd., Novatec PP EC9) with an MFR of 0.5 g / min at 230° C. was used as a thermoplastic resin, and 30 wt % of talc was mixed as a filler. - Extrude two boards from the mould, close the half-mold to clamp the core material 13 between the two boards, and take it out from the mold after cooling to obtain a sandwich board 10 .

[0236] Thus, it was confirmed that the molding of the composite sandwich panel is practical.

[0237]The inventors of the present invention confirmed the eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com