Continuous large-power turbine fracturing equipment

A high-power, turbine technology, used in mechanical equipment, lubrication of turbine/propulsion units, air inlets of turbine/propulsion units, etc., can solve low output power, immature technology, and can not meet stable and high-power operations. requirements and other issues, to achieve the effect of reducing the failure rate, stable and efficient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

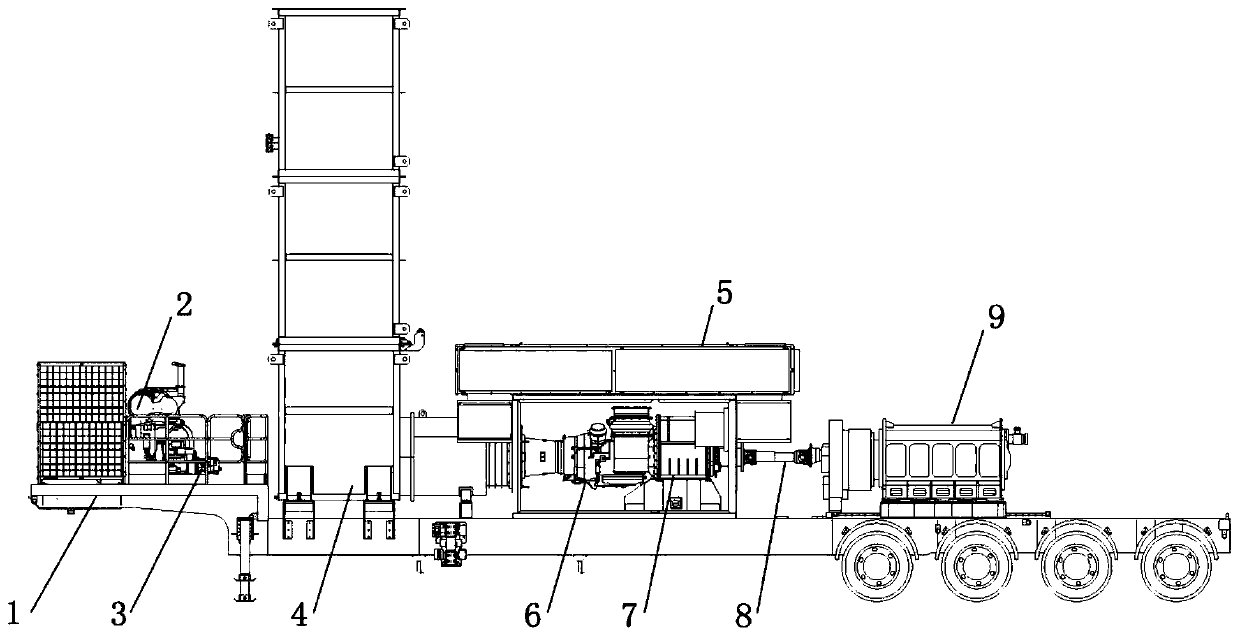

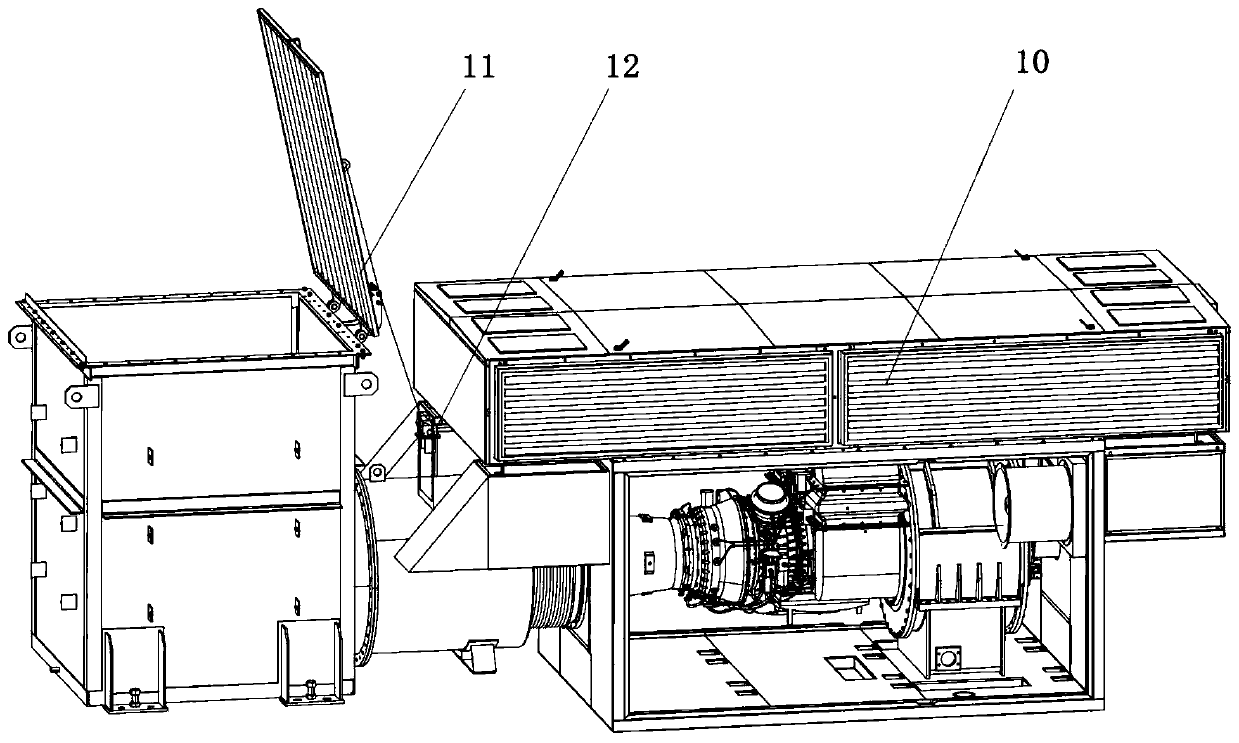

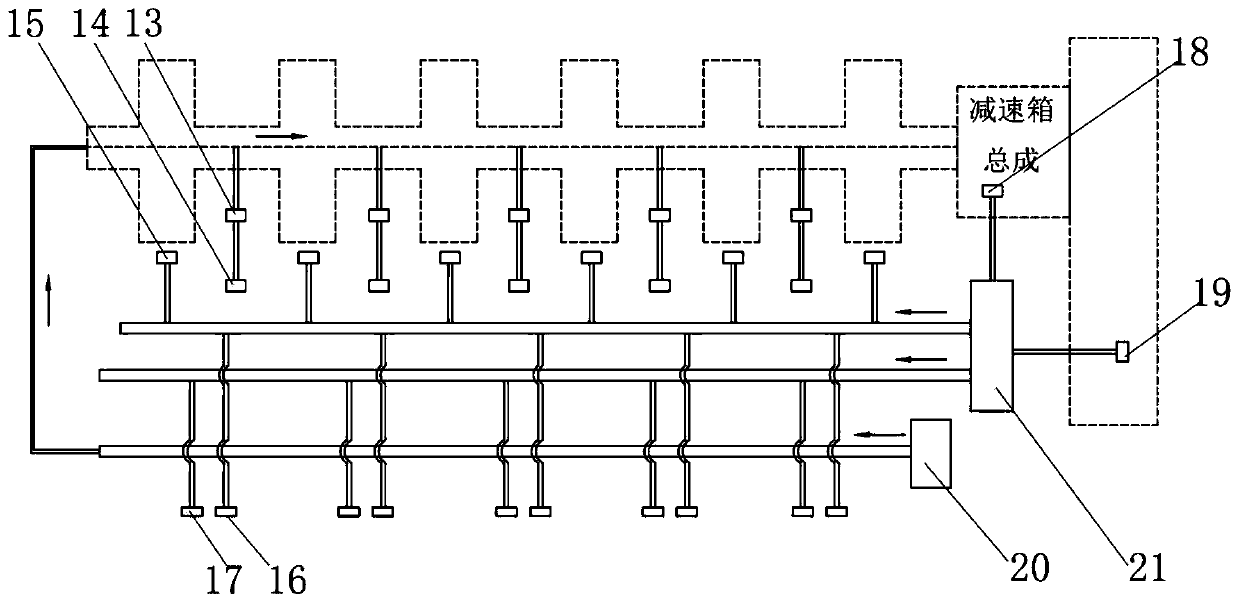

[0032] Such as Figures 1 to 3 As shown, a continuous high-power turbine fracturing equipment includes a turbine engine 6, a reduction box 7, a transmission shaft 8 and a plunger pump 9, the turbine engine 6 and the reduction box 7 are arranged on the same straight line, and the reduction box 7 passes through The transmission shaft 8 is connected with the plunger pump 9, and the angle of the transmission shaft 8 is between 2-4°. The transmission of the turbine engine 6 is guaranteed to be stable and efficient, and the failure rate is reduced.

[0033] The power of the plunger pump 9 is above 5000HP. The plunger pump 9 is a five-cylinder plunger pump. The output of the high-power plunger pump 9 provides basic conditions for continuous high-power turbo fracturing equipment.

[0034] The continuous high-power turbine fracturing equipment includes a chassis 1, on which the turbine engine 6, reduction box 7, transmission shaft 8 and plunger pump 9 are arranged, and the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com