Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

215results about "Noise reduction installations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

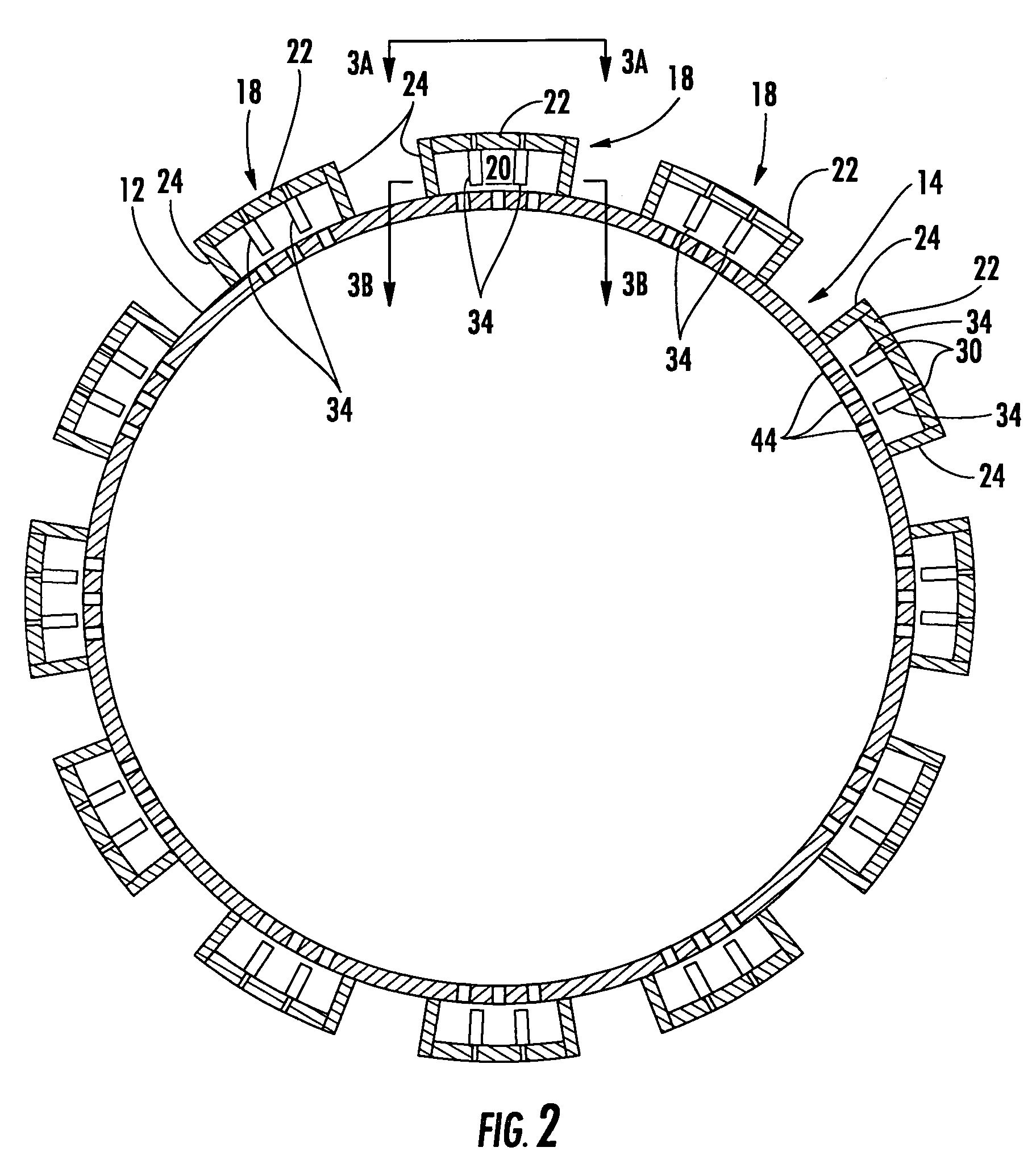

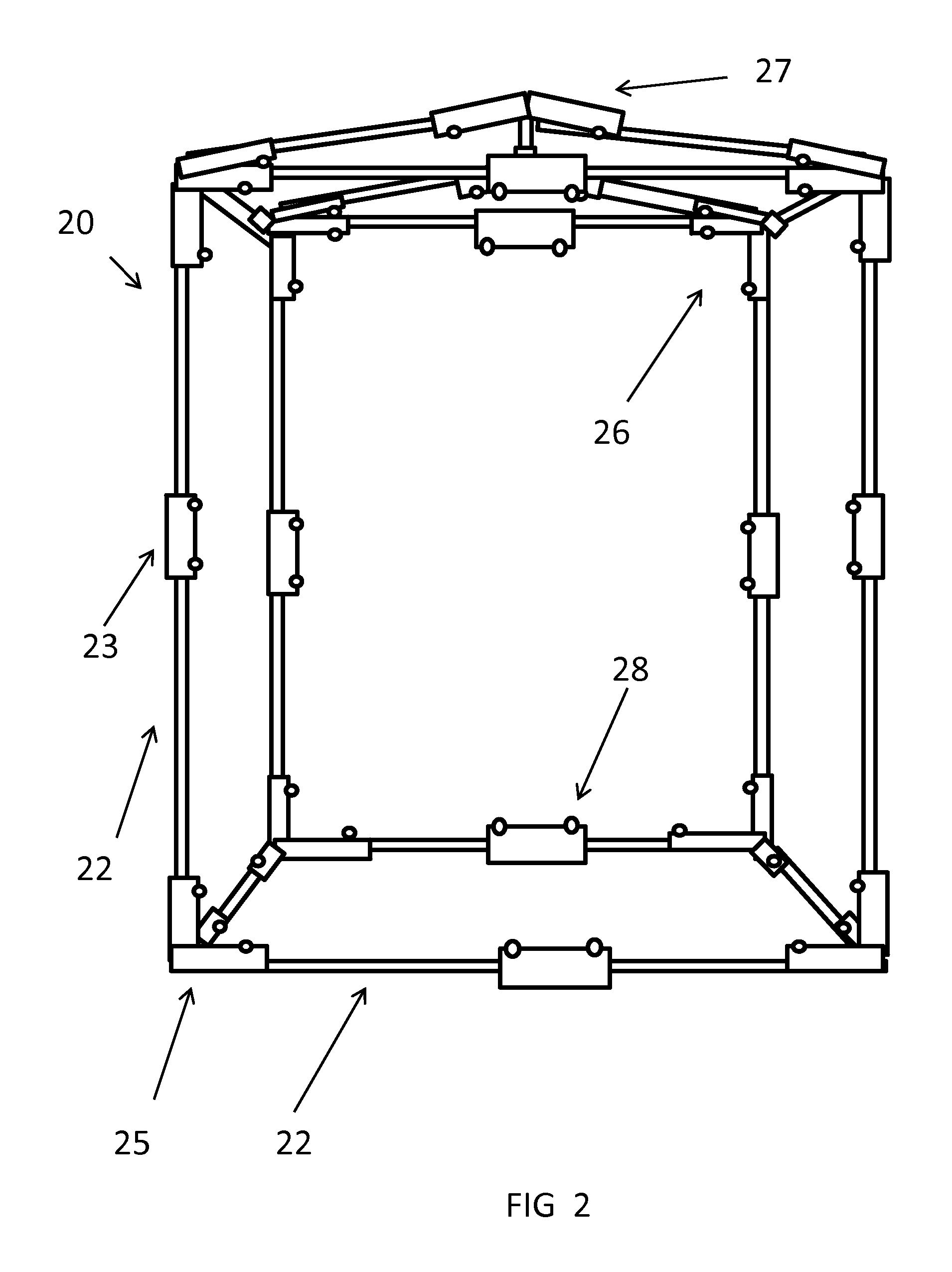

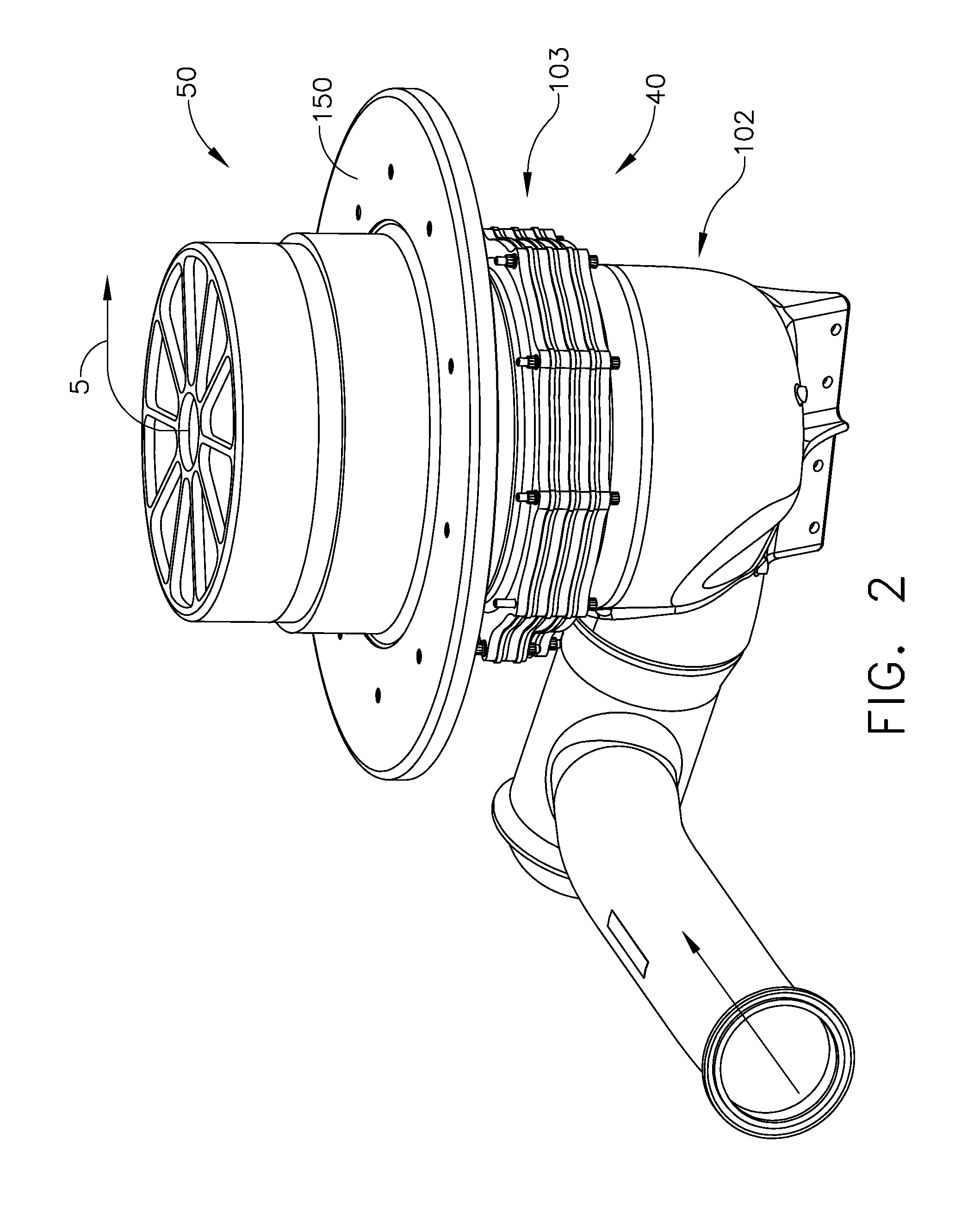

Acoustic resonator with impingement cooling tubes

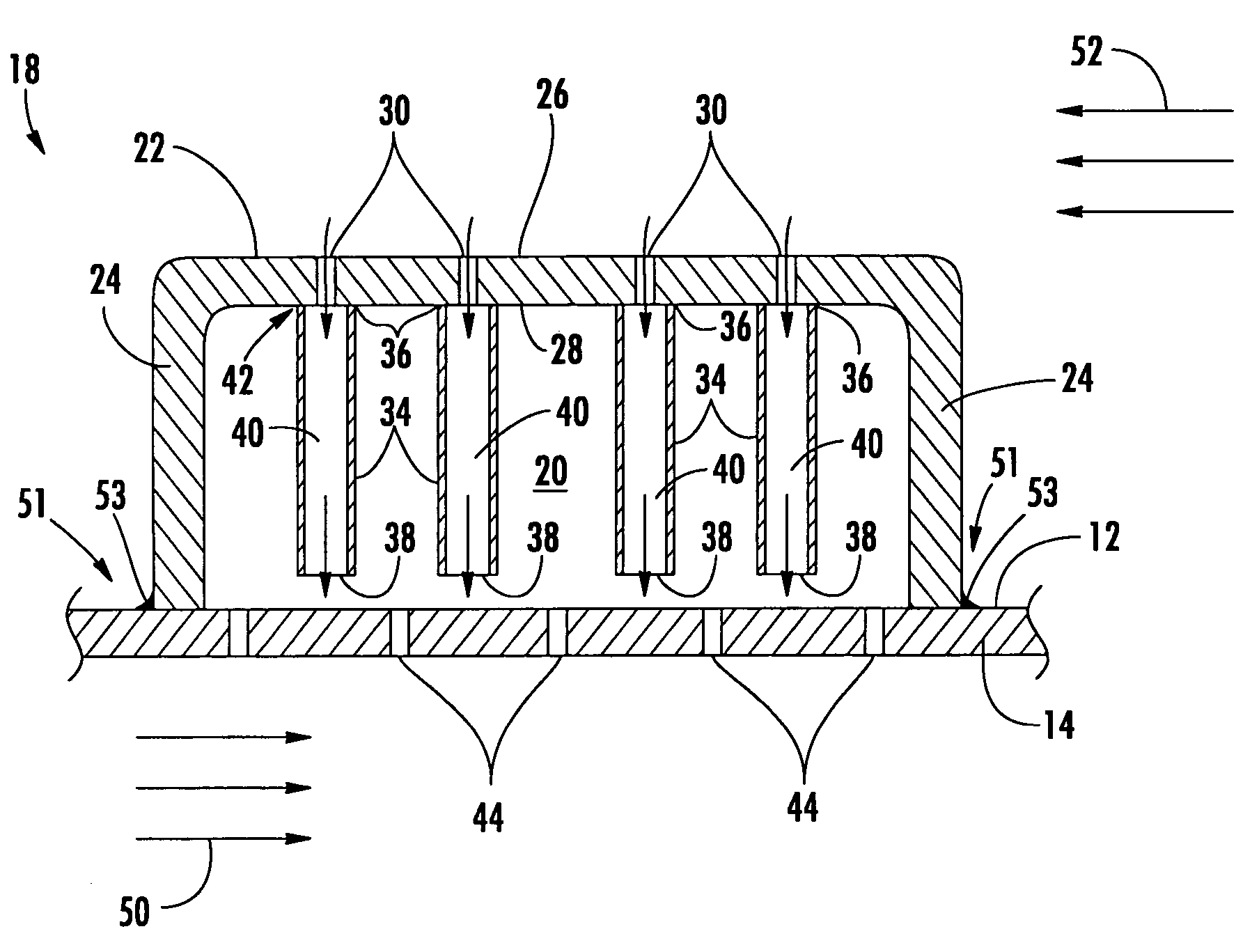

Aspects of the invention are directed to an acoustic resonator with improved impingement cooling effectiveness. The resonator includes a plate with an inside face and an outside face. A plurality of passages extend through the plate. The resonator includes a side wall that extends from and about the plate. A plurality of cooling tubes are attached to the resonator plate such that an inner passage of each cooling tube is in fluid communication with a respective passage in the resonator plate. The resonator can be secured to a surface of a turbine engine combustor component to define a closed cavity. The ends of the cooling tubes are spaced from the surface. Thus, a coolant can enter the passages in the plate and can be directed to the surface so as to impingement cool the surface. The cooling tubes can minimize coolant loss by dispersion in the cavity.

Owner:SIEMENS ENERGY INC

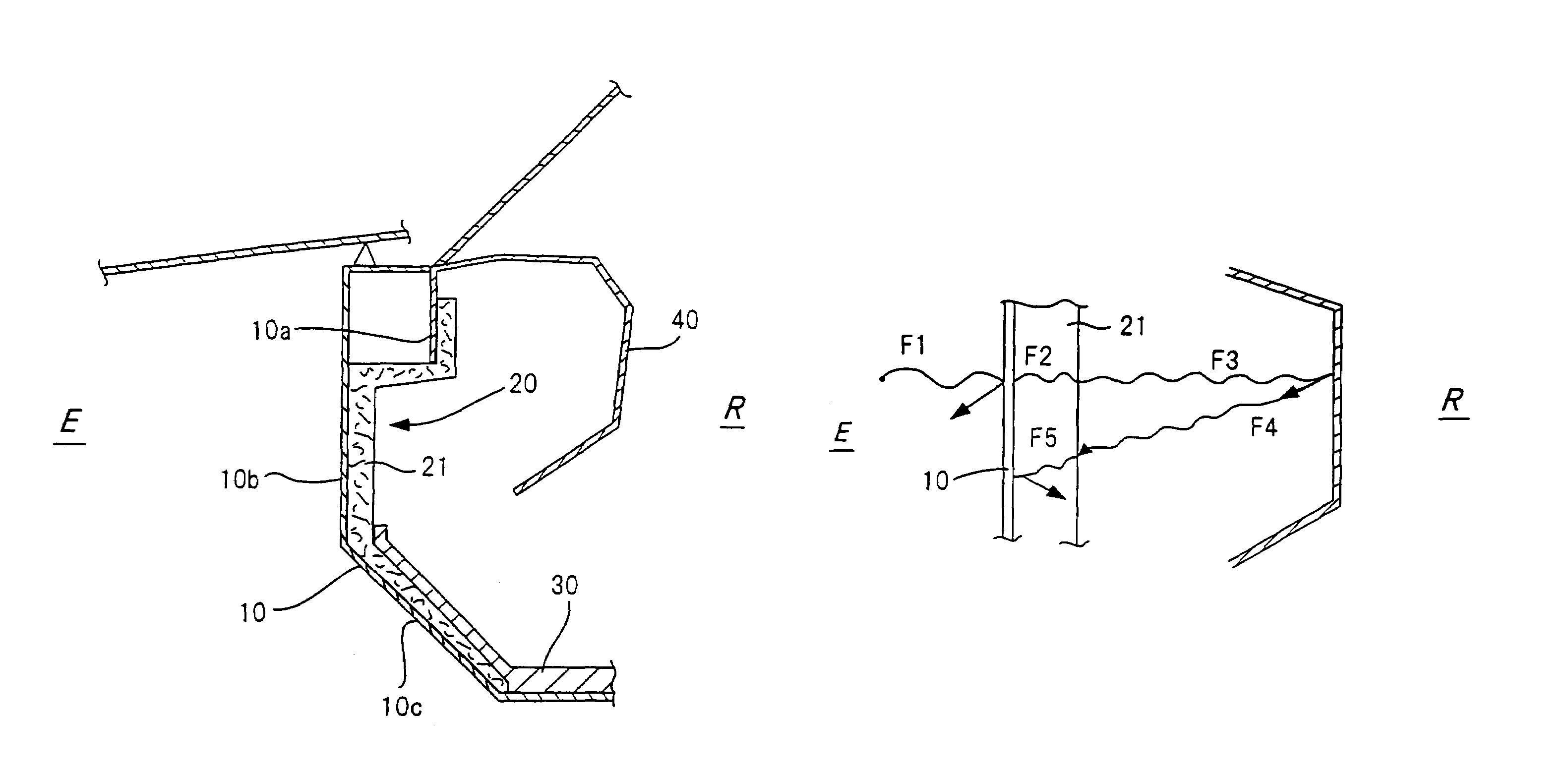

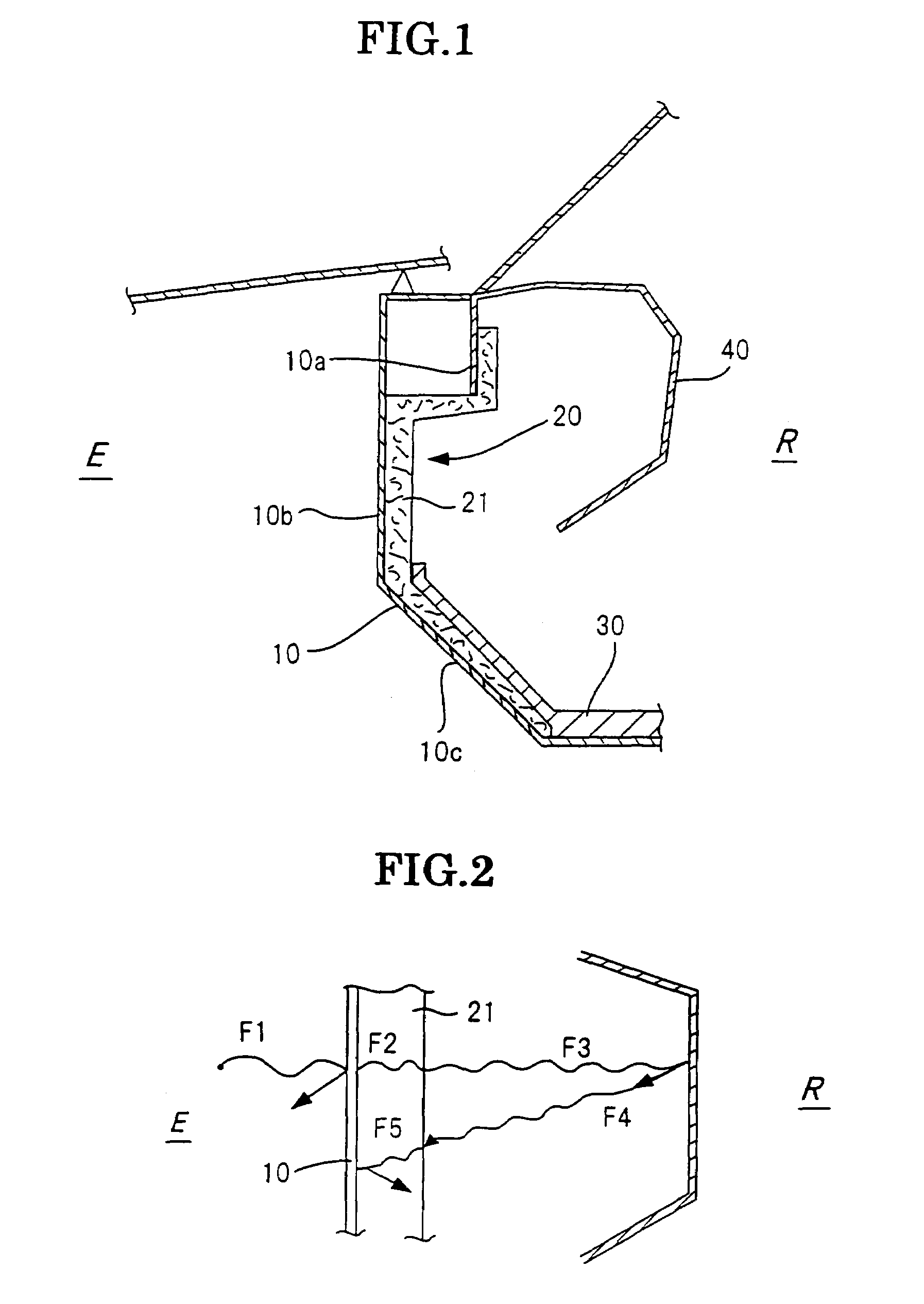

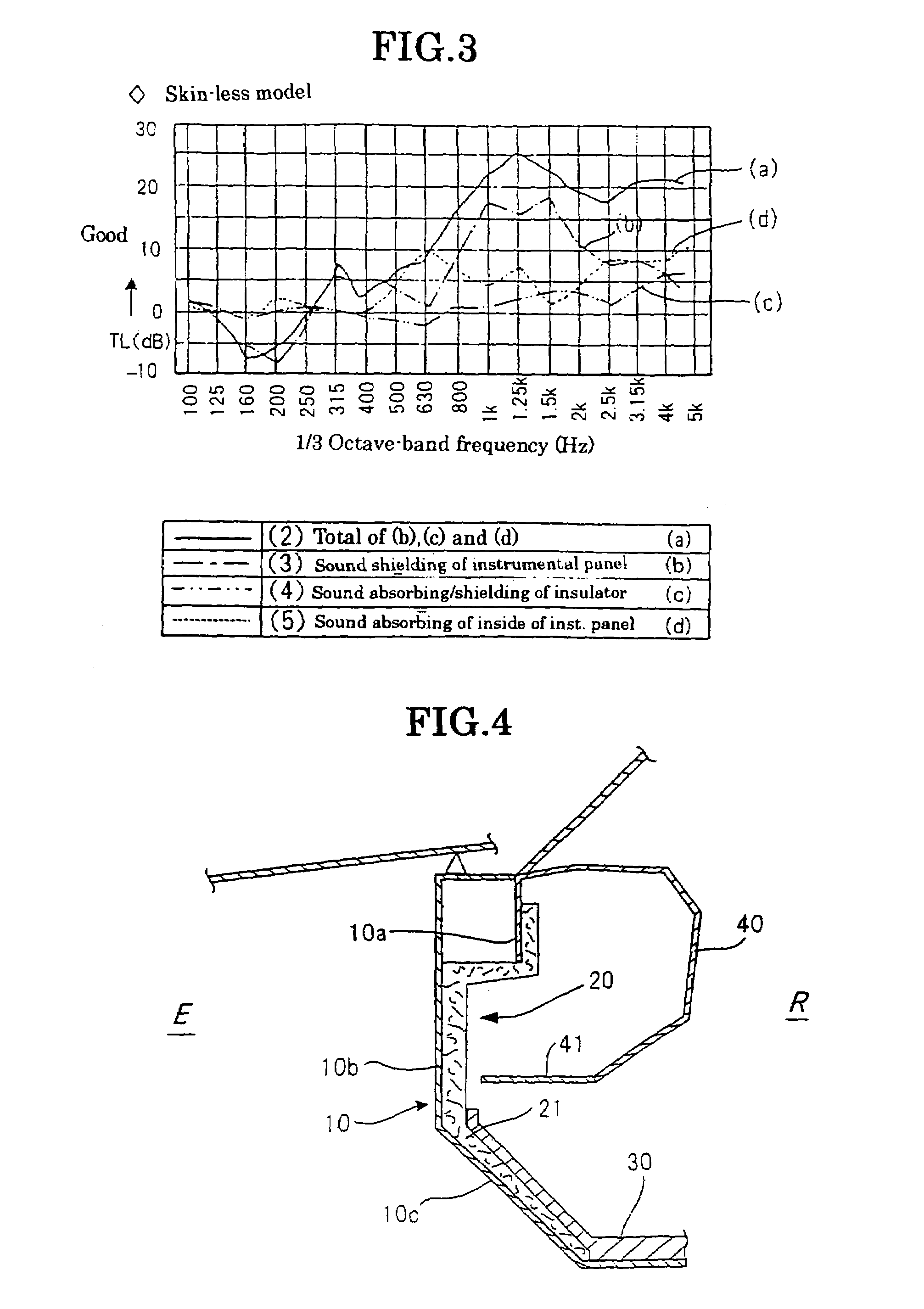

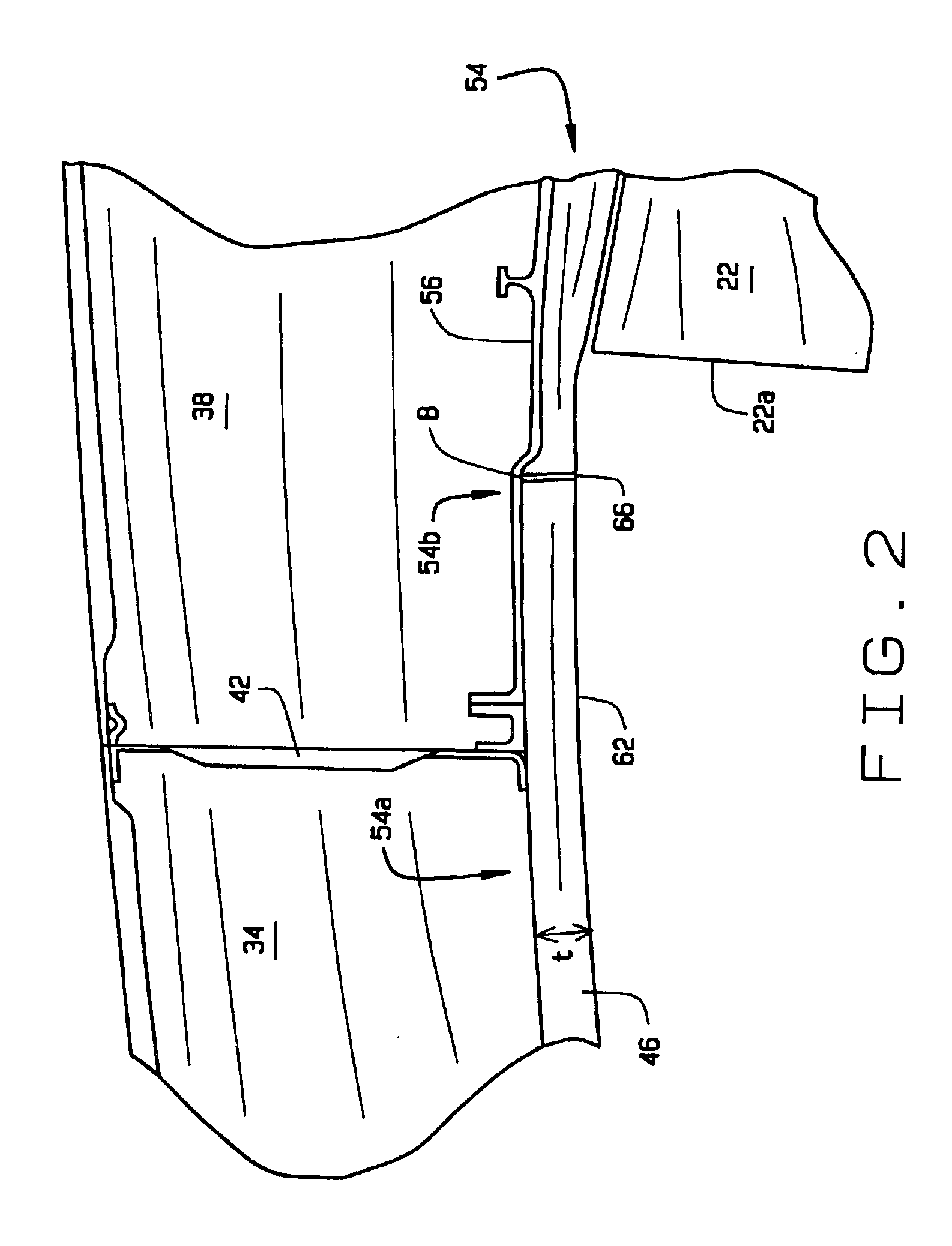

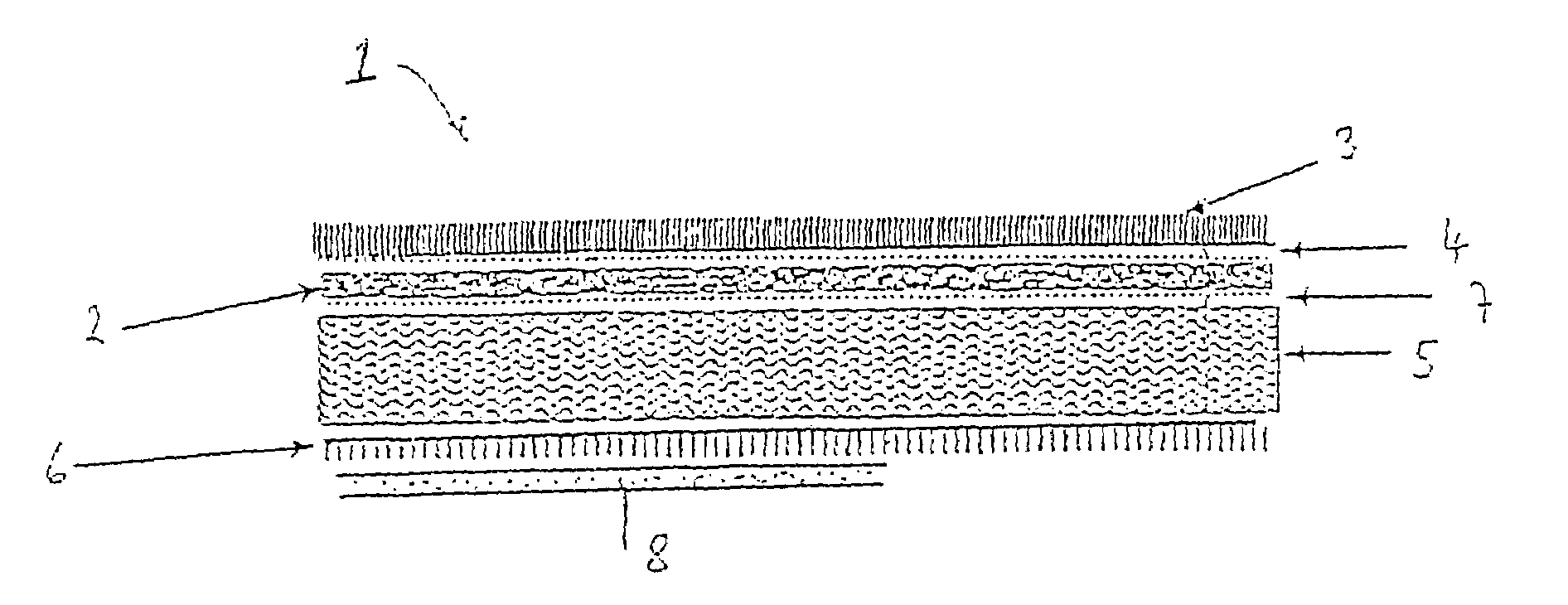

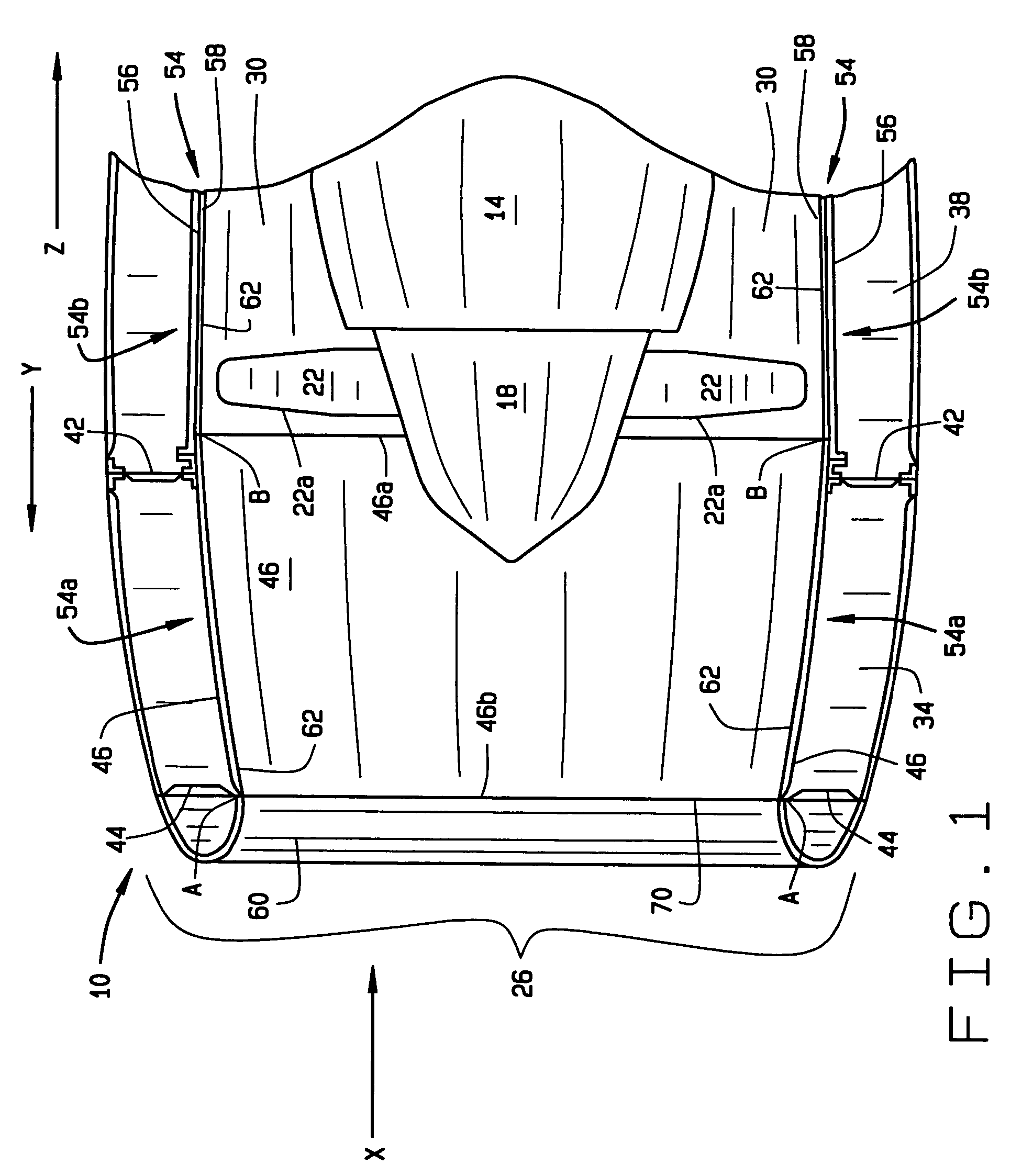

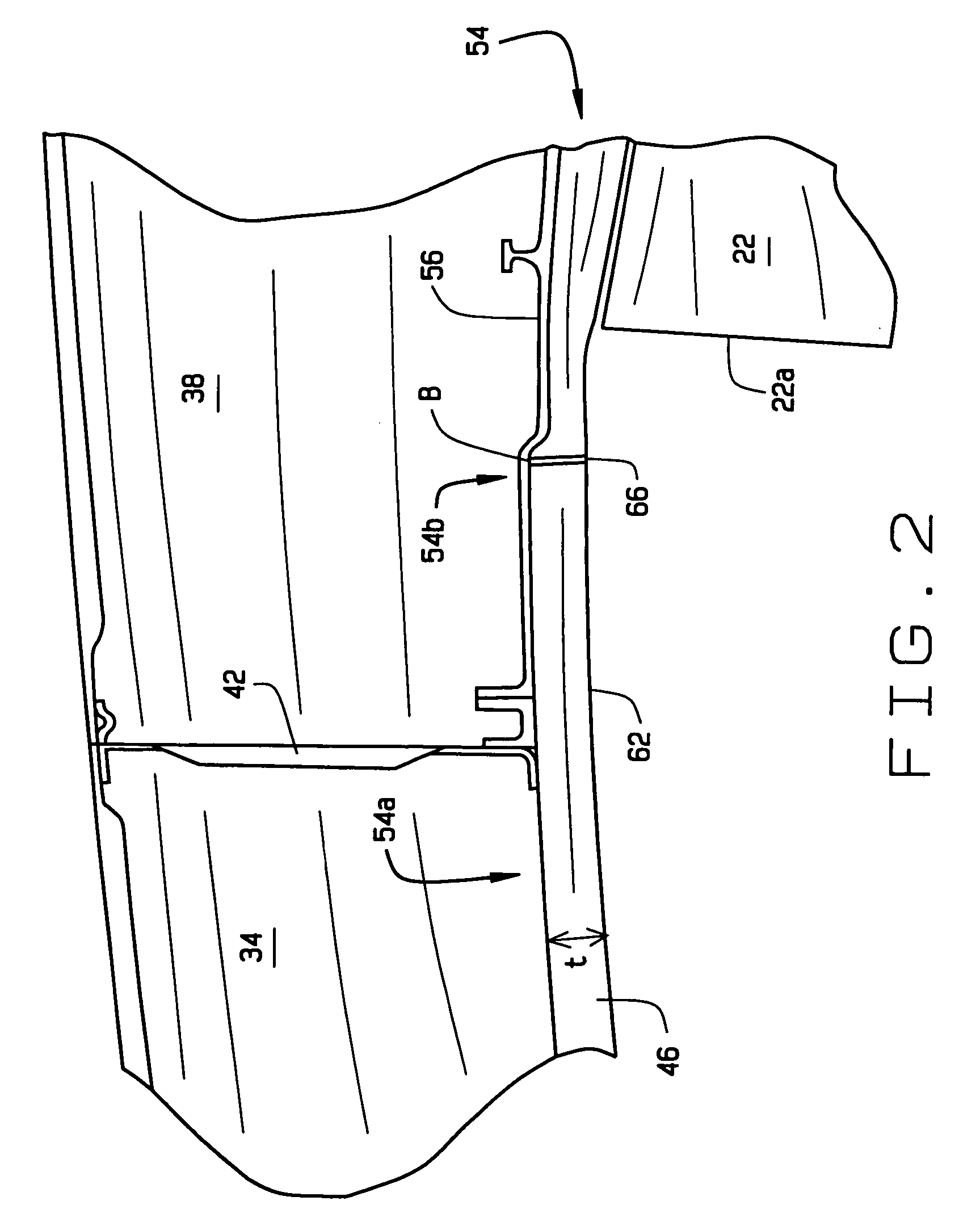

Soundproof material for vehicle and method of manufacturing the material

An insulator dash (20) installed on the interior side surface side of a dash panel (10), comprising a single sound absorbing layer (21) formed of a fiber assembly or a laminated assembly having light and soft skin layers (22,23,26,27,28) laminated on the surface of sound absorbing layer (21), wherein, since the reflected noise reflected from the inner surface of an instrument panel (40) is taken again from the front surface side into the sound absorbing layer (21) for sound absorption in addition to the sound absorbing and shielding performance of the insulator dash (20), the sound absorbing performance in the instrument panel (40) can be increased, whereby the weight can be reduced and a rise of sound pressure in the instrument panel (40) can be abolishing a conventional sound shielding layer so as to increase a silentness in a cabin.

Owner:KASAI KOGYO CO LTD

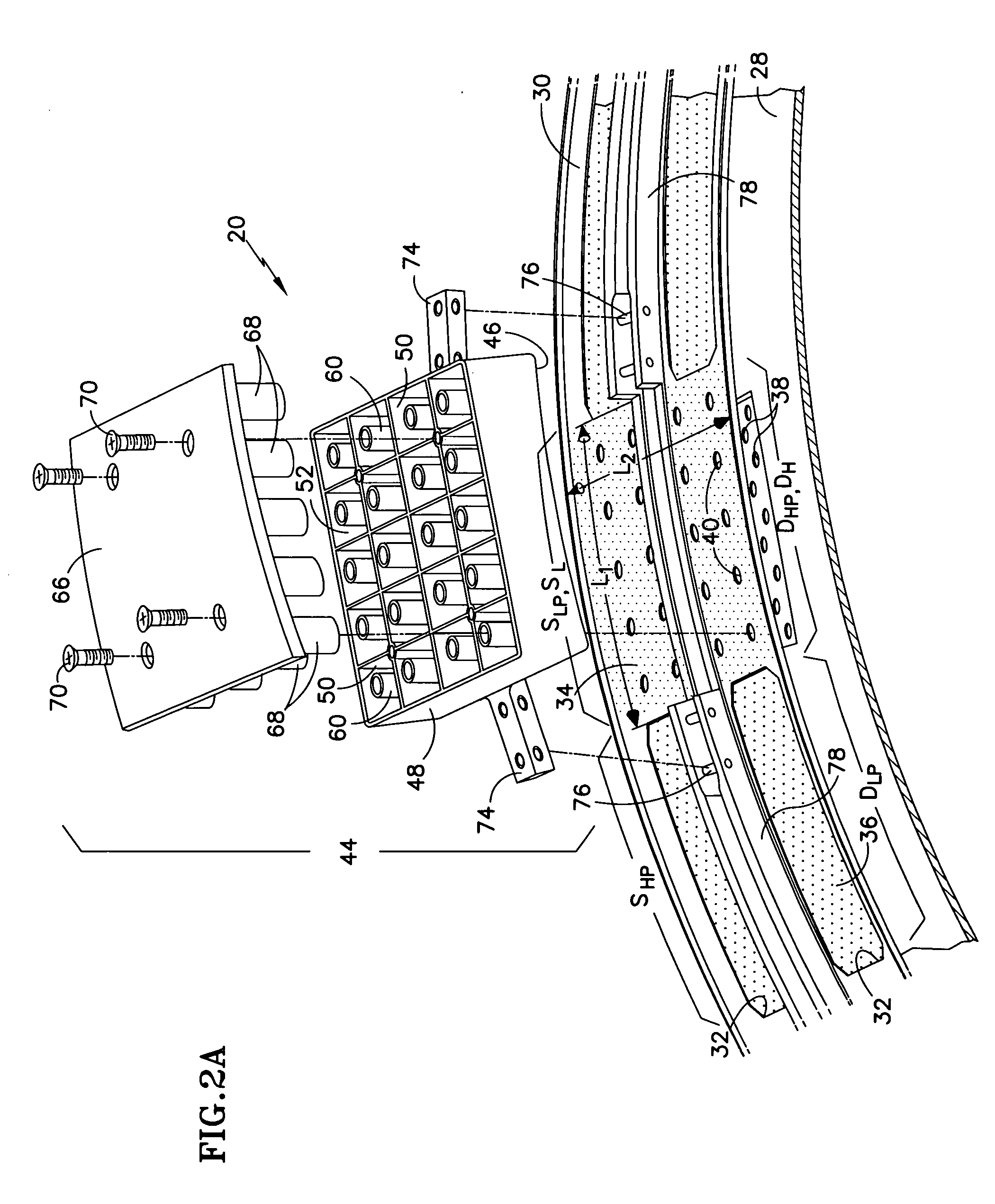

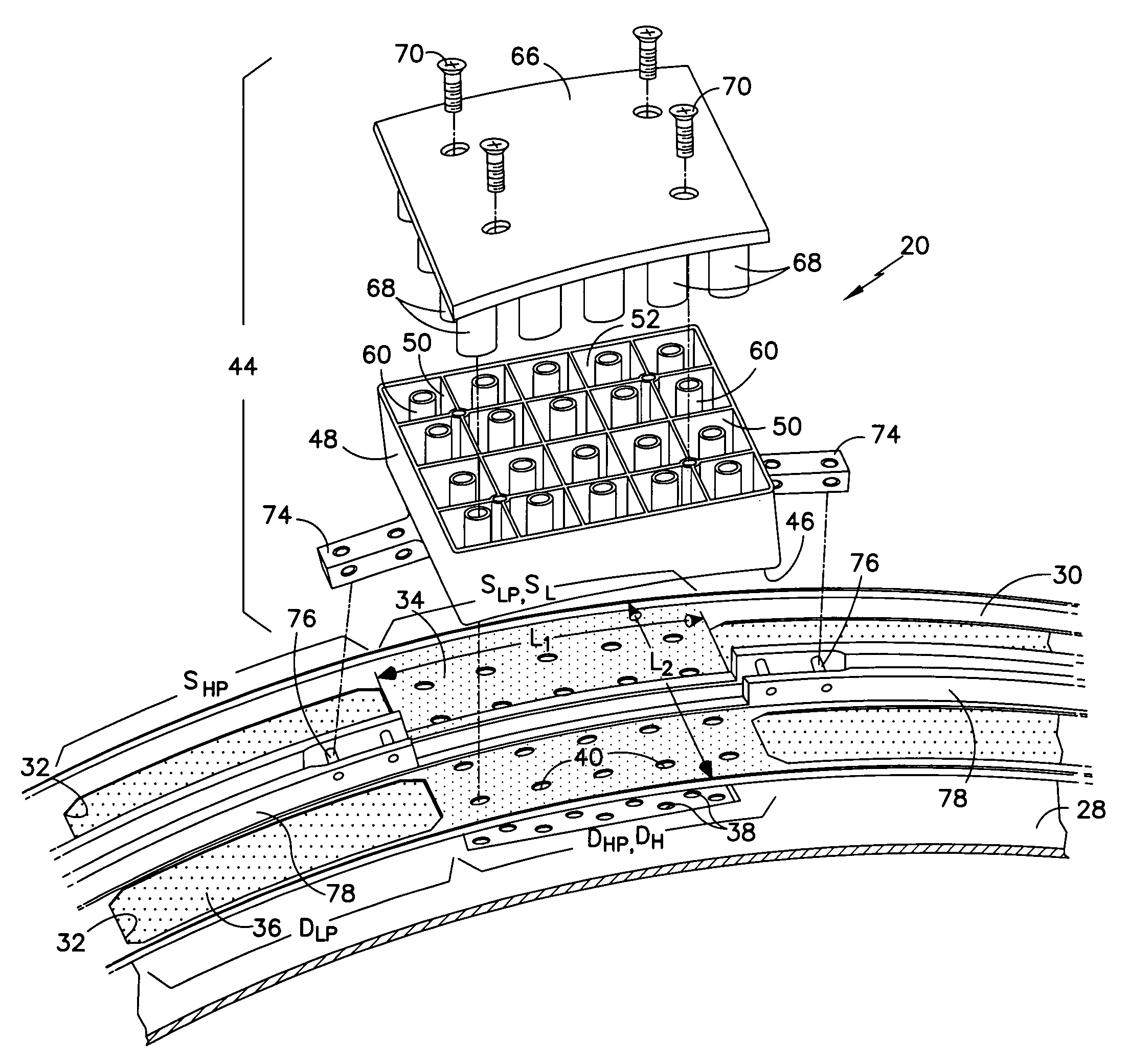

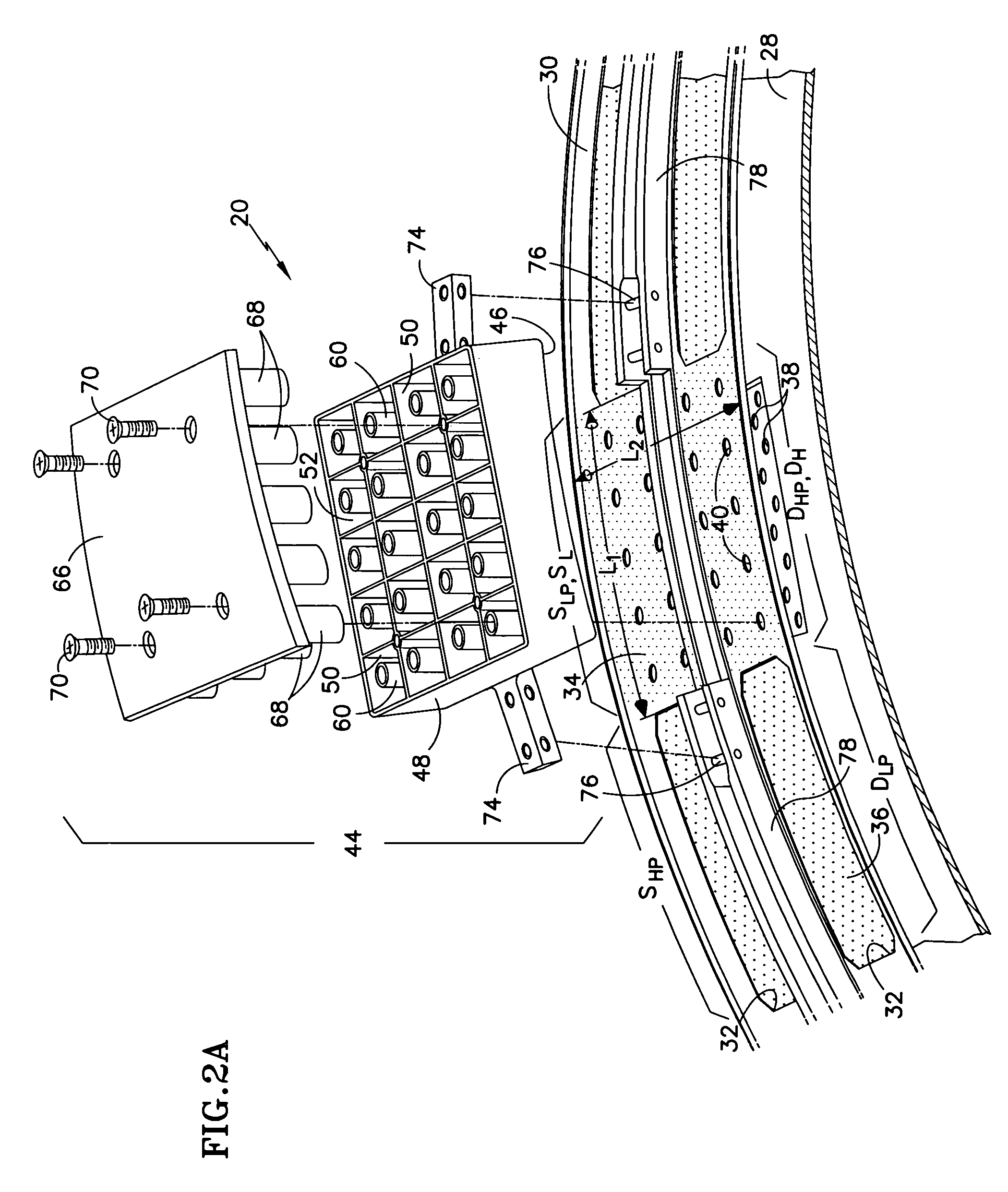

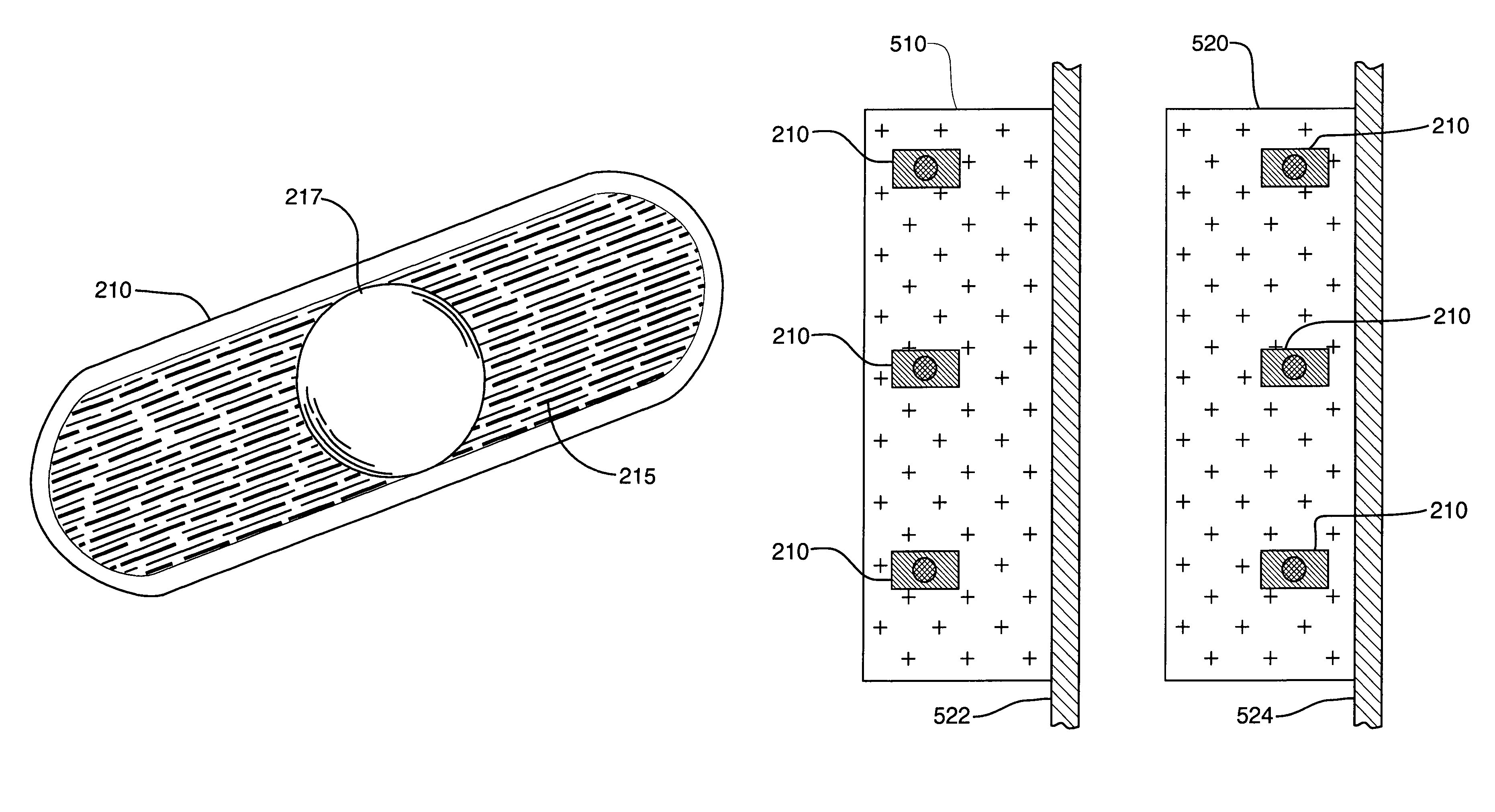

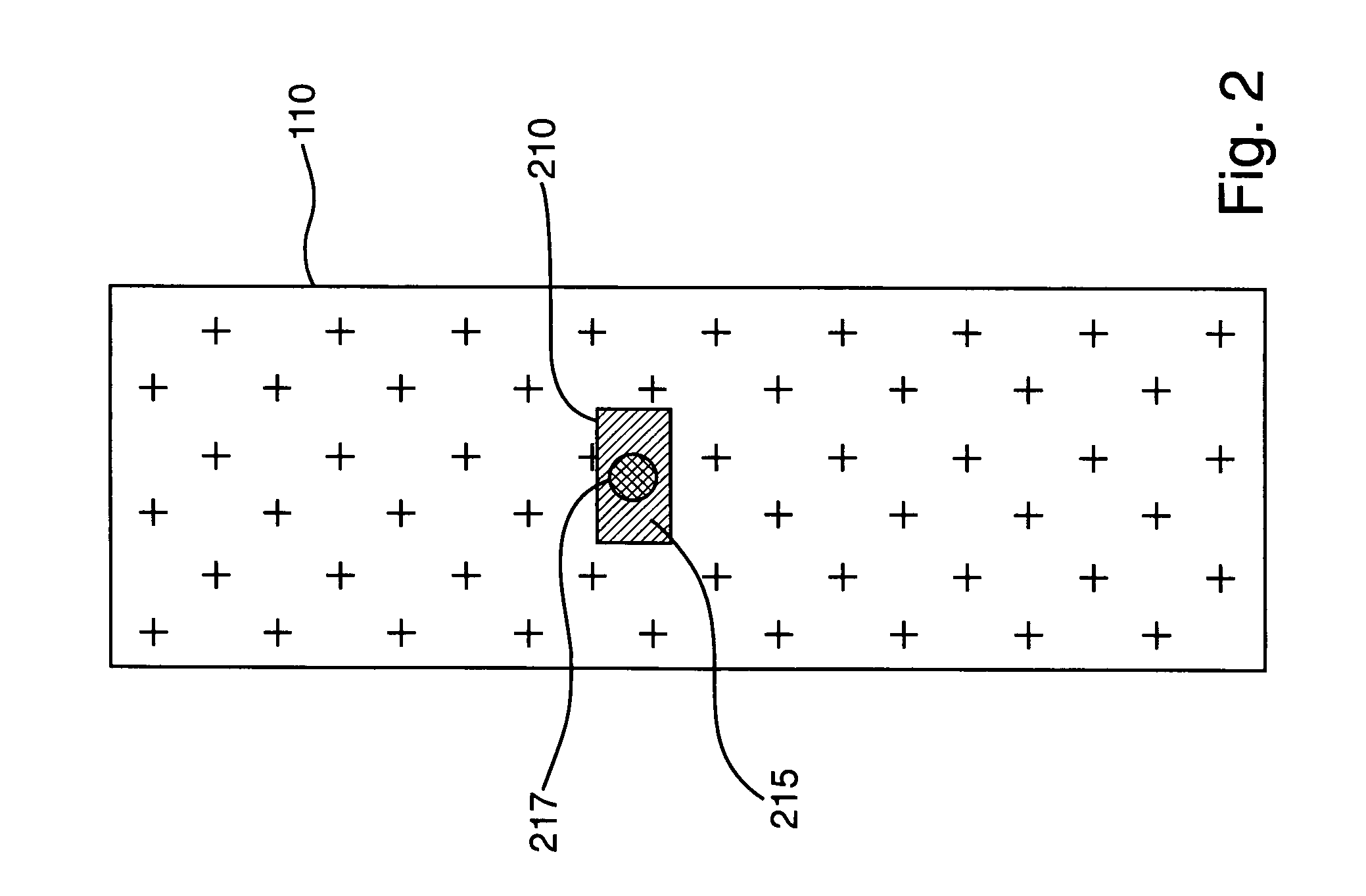

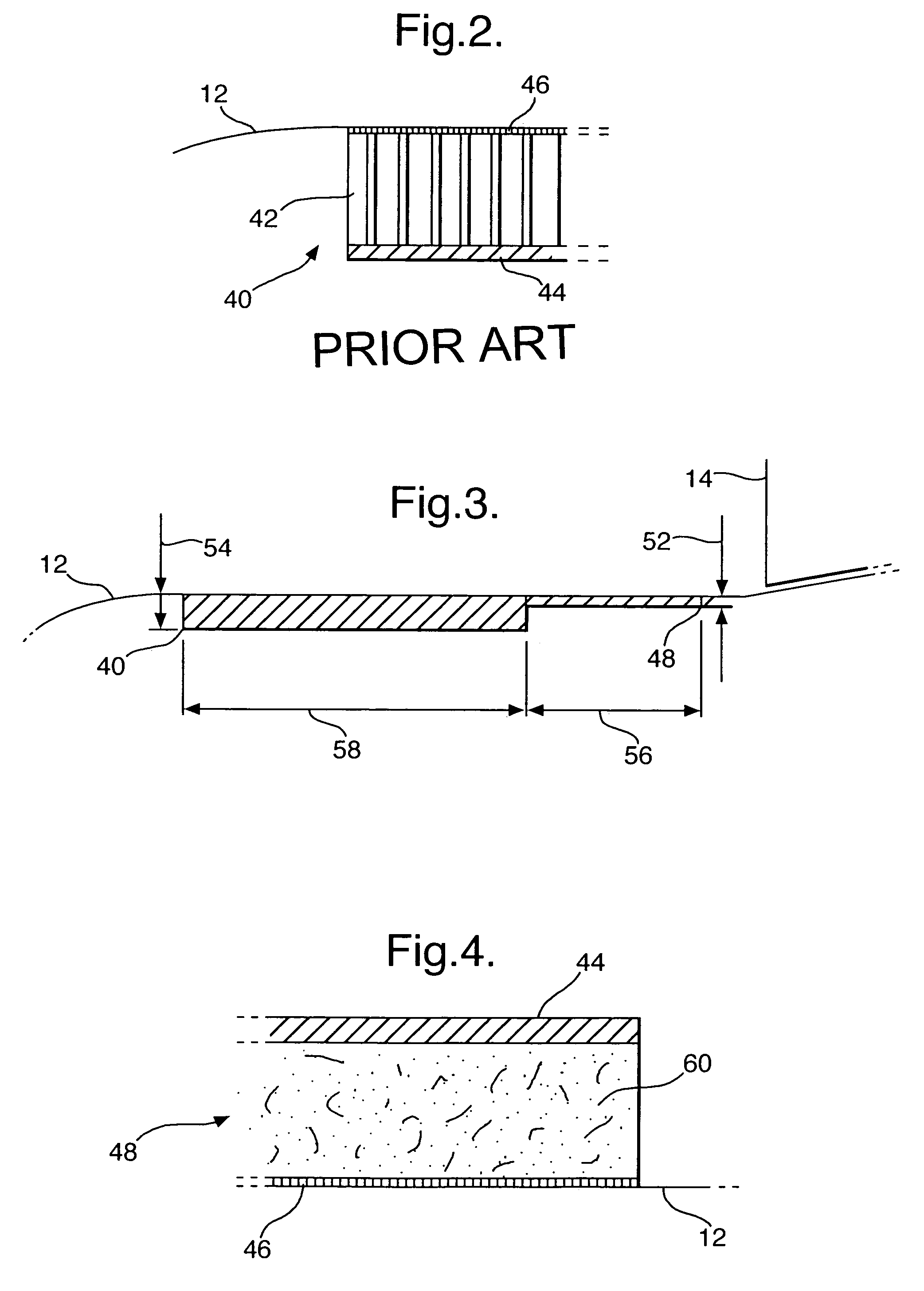

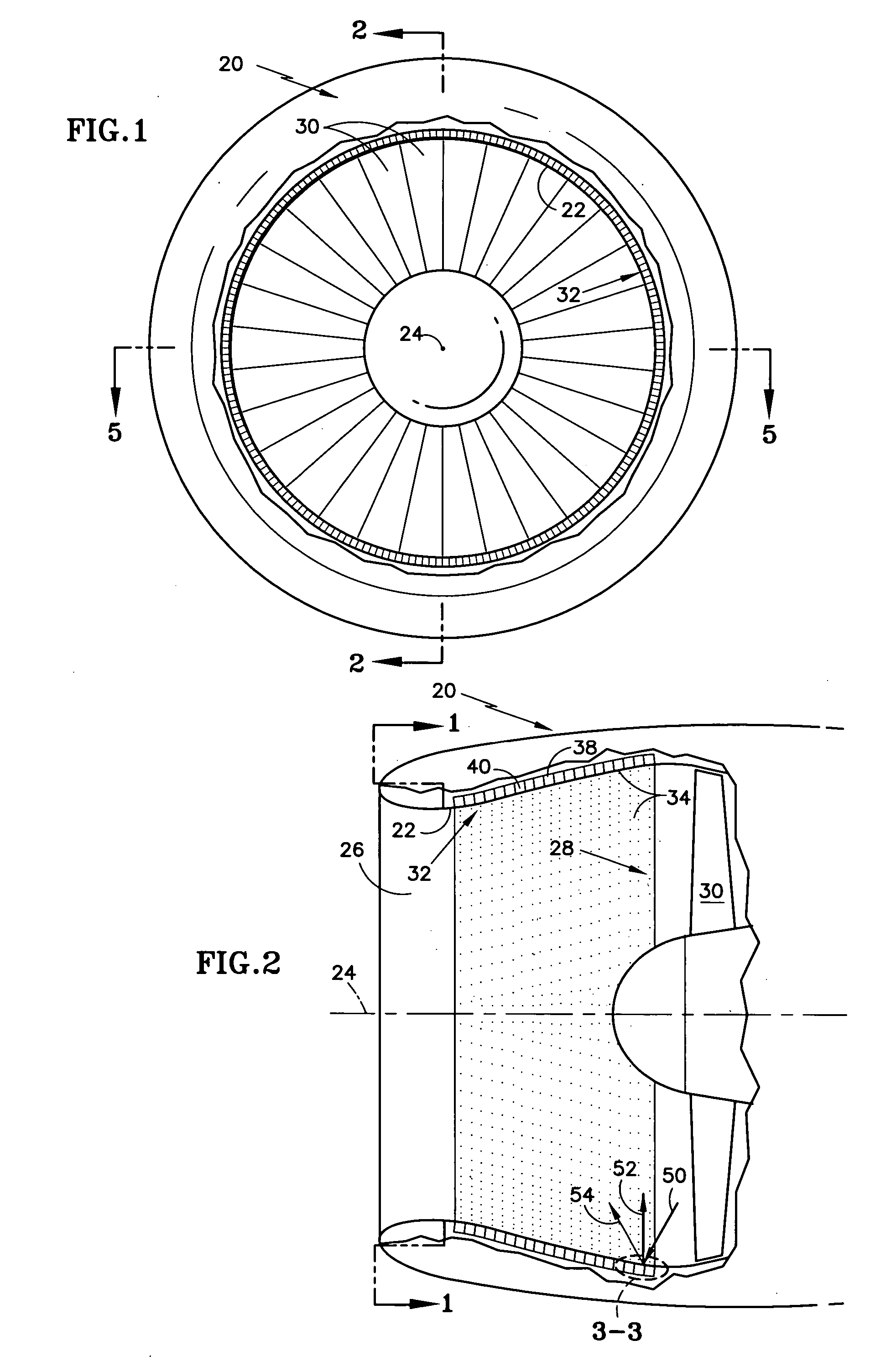

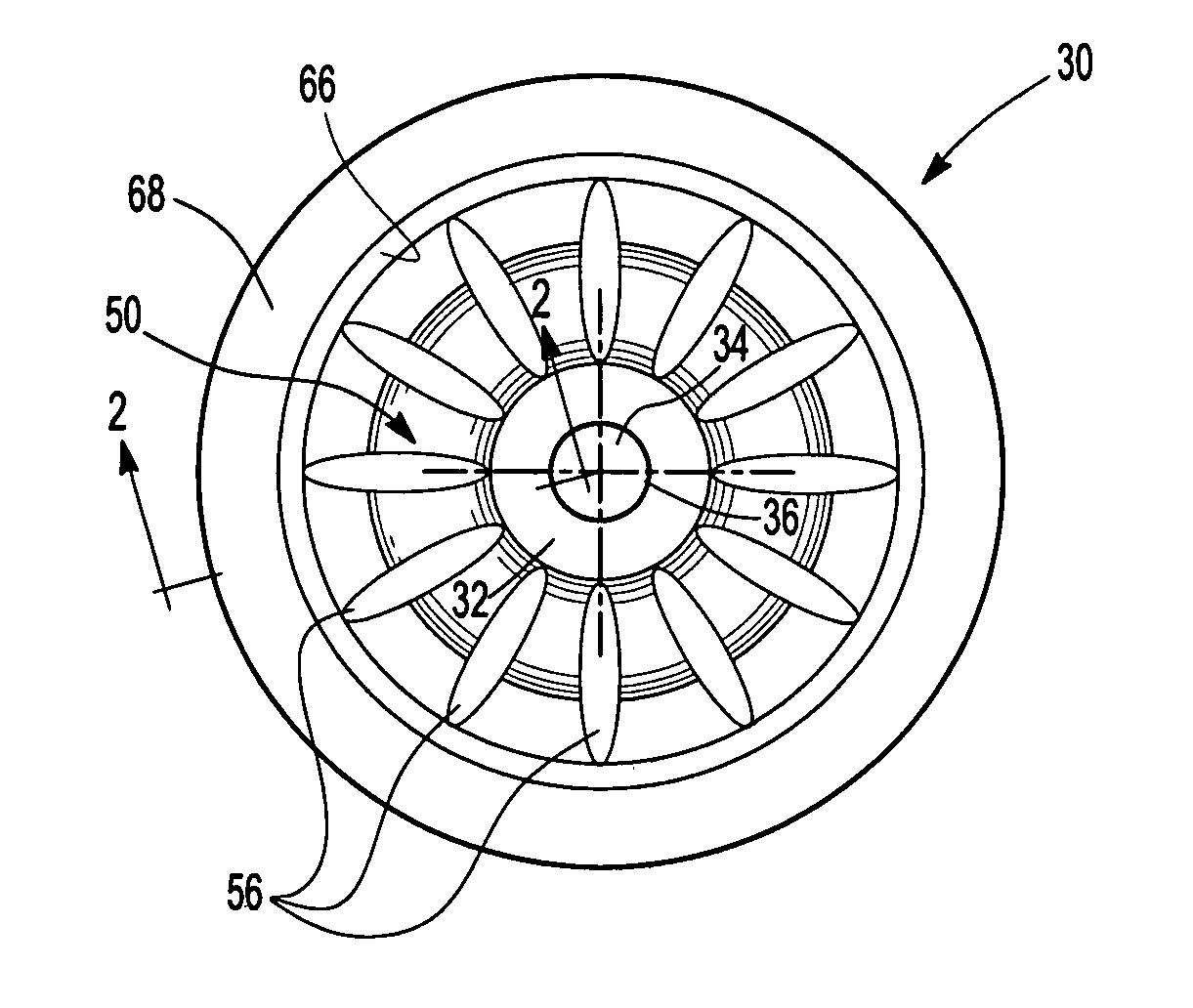

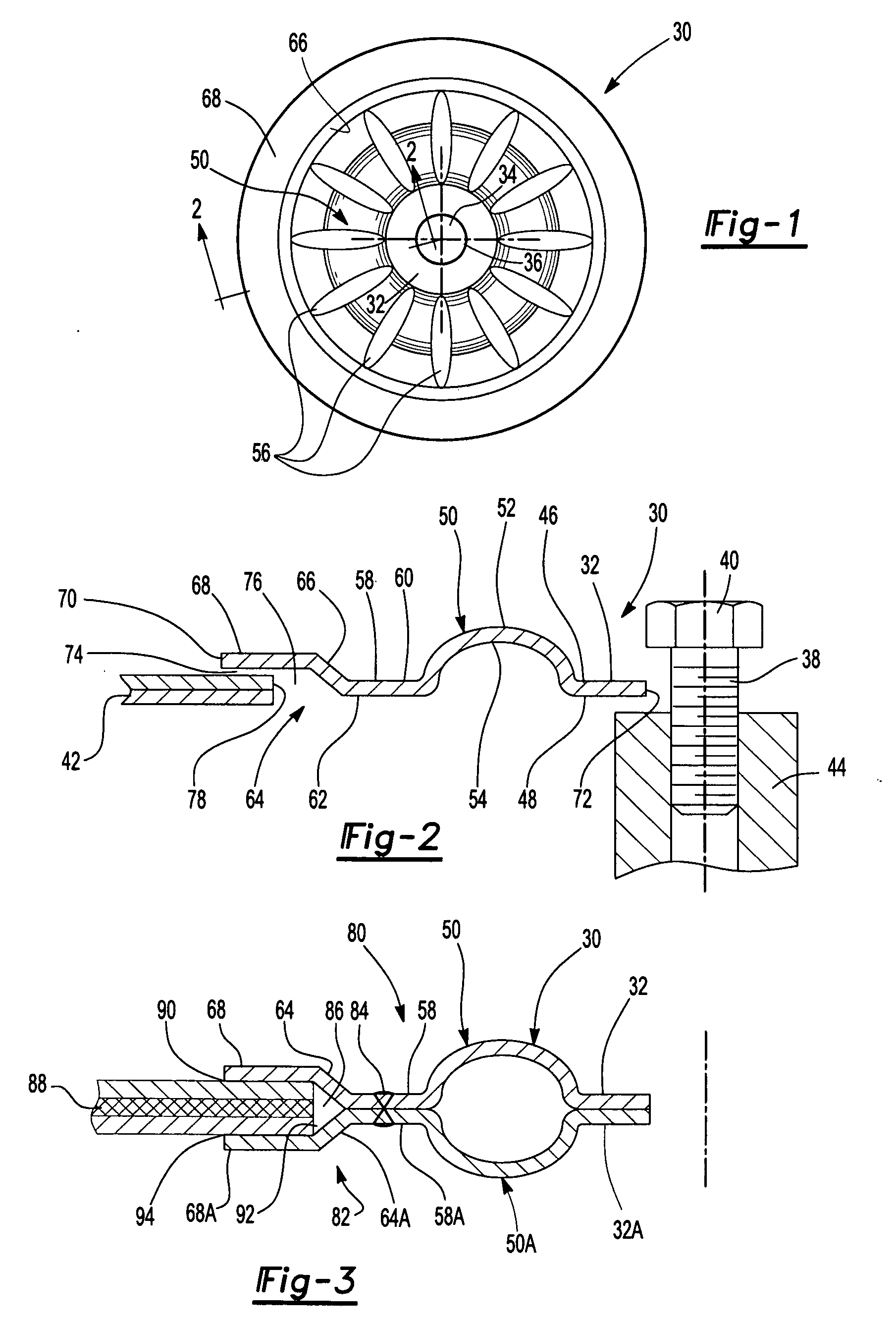

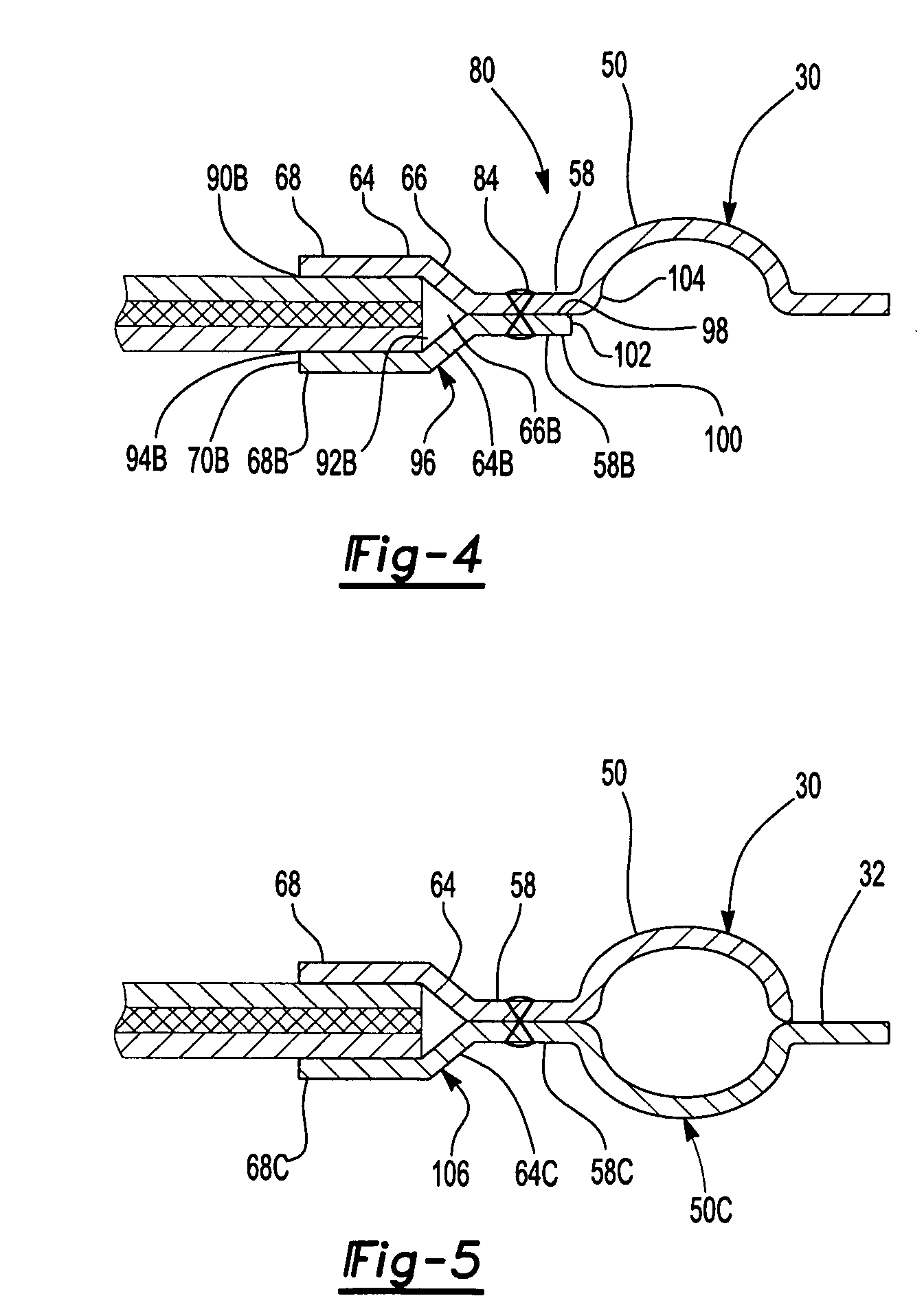

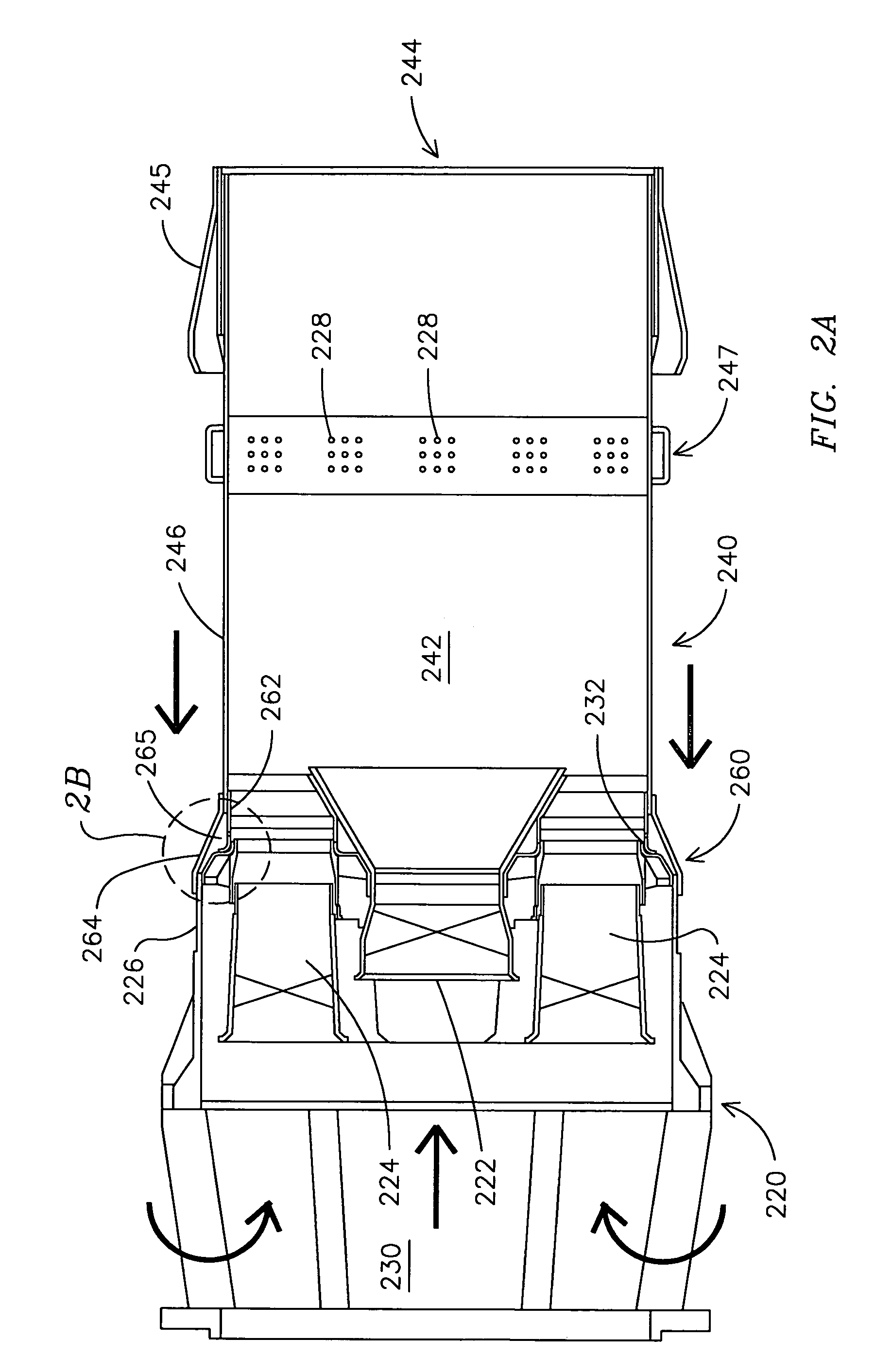

High admittance acoustic liner

ActiveUS20050284690A1High admittanceImproved acoustic admittanceNoise reduction installationsWallsPorosityCoolant flow

A cooled acoustic liner useful in a fluid handling duct includes a resonator chamber 52 with a neck 56, a face sheet 86, and a coolant plenum 80 residing between the face sheet and the chamber. Coolant bypasses the resonator chamber, rather than flowing through it, resulting in better acoustic admittance than in liners in which coolant flows through the resonator chamber and neck. In one embodiment, the liner also includes a graze shield 88. Openings 40, 38 penetrate both the face sheet and the shield to establish a relatively low face sheet porosity and a relatively high shield porosity. The shielded embodiment of the invention helps prevent a loss of acoustic admittance due to fluid grazing past the liner. Another embodiment that is not necessarily cooled, includes the resonator chamber, low porosity face sheet and high porosity shield, but no coolant plenum for bypassing coolant around the resonator chamber. An associated method of retrofitting an acoustic treatment into a fluid handling module includes installing openings in the module and mounting a resonator box 44 on the module so that the inlets to the resonator necks register with the installed openings.

Owner:RAYTHEON TECH CORP

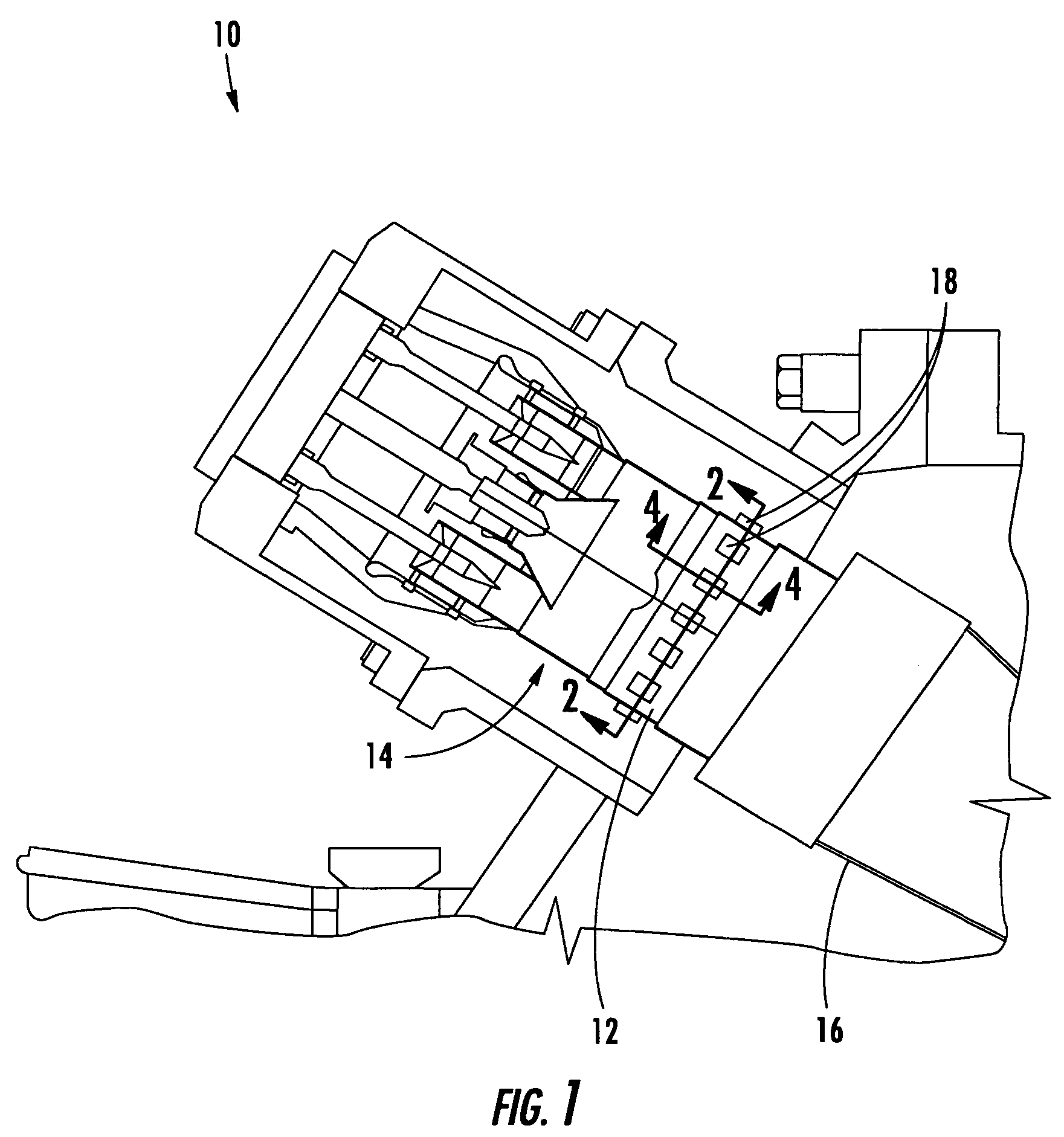

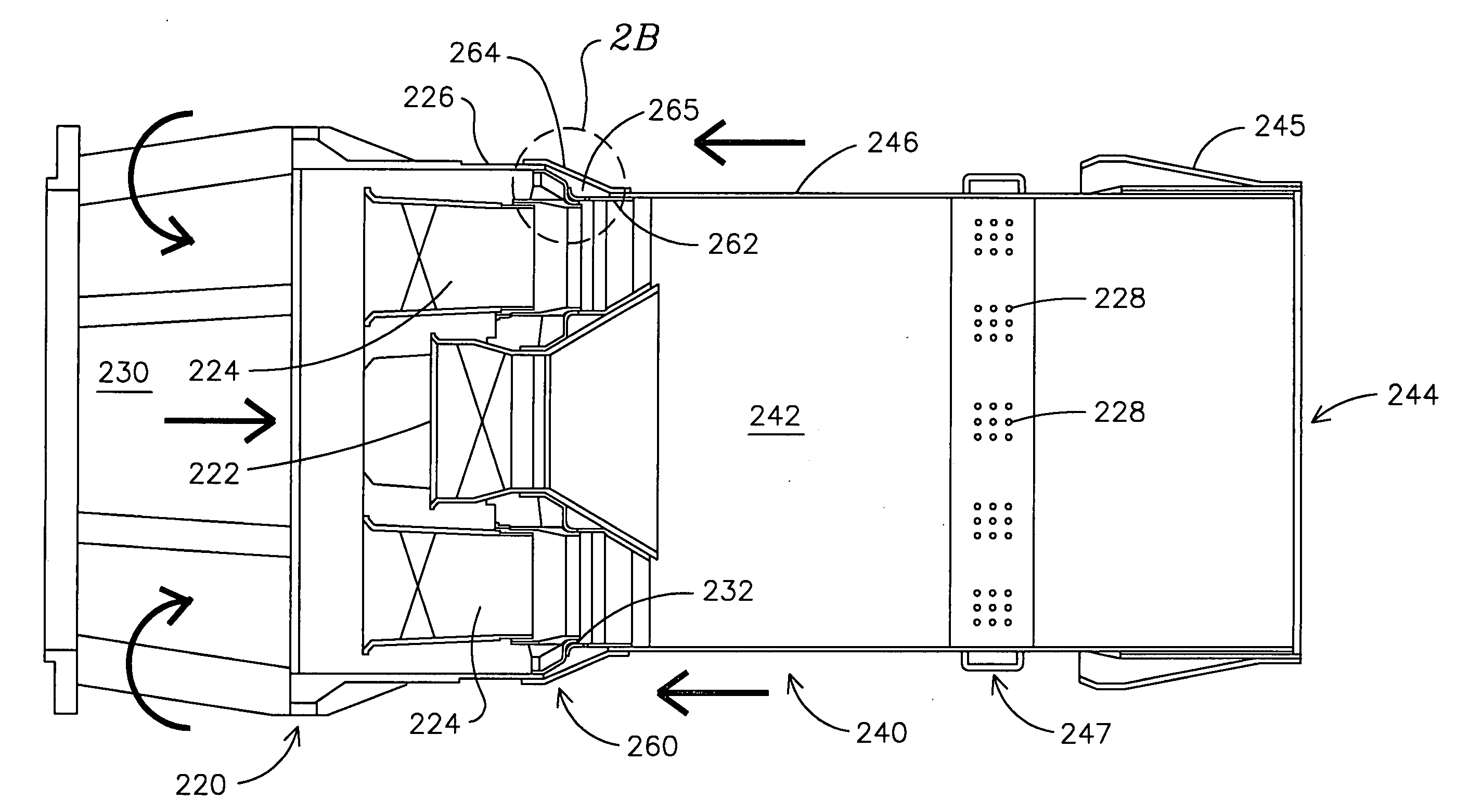

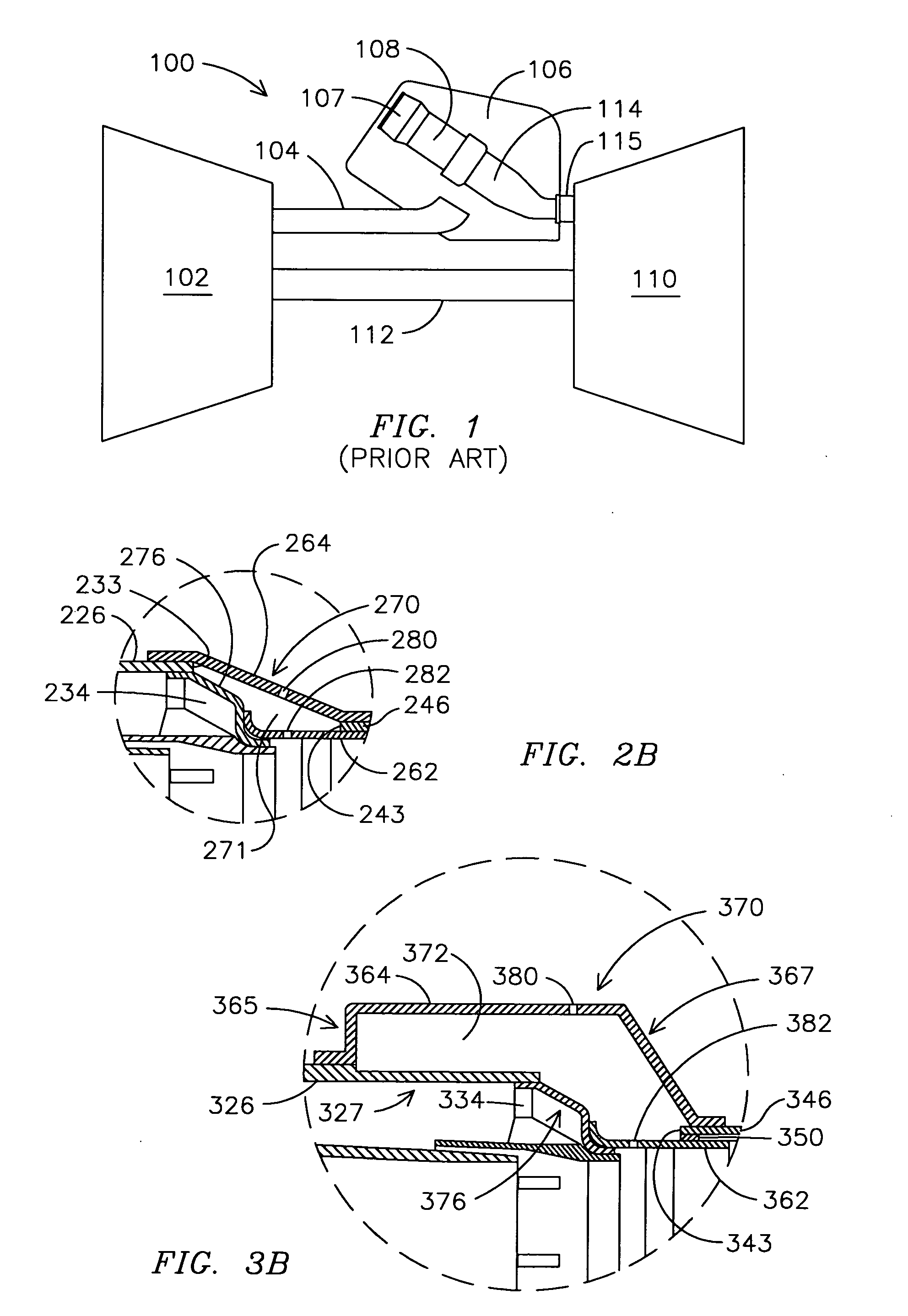

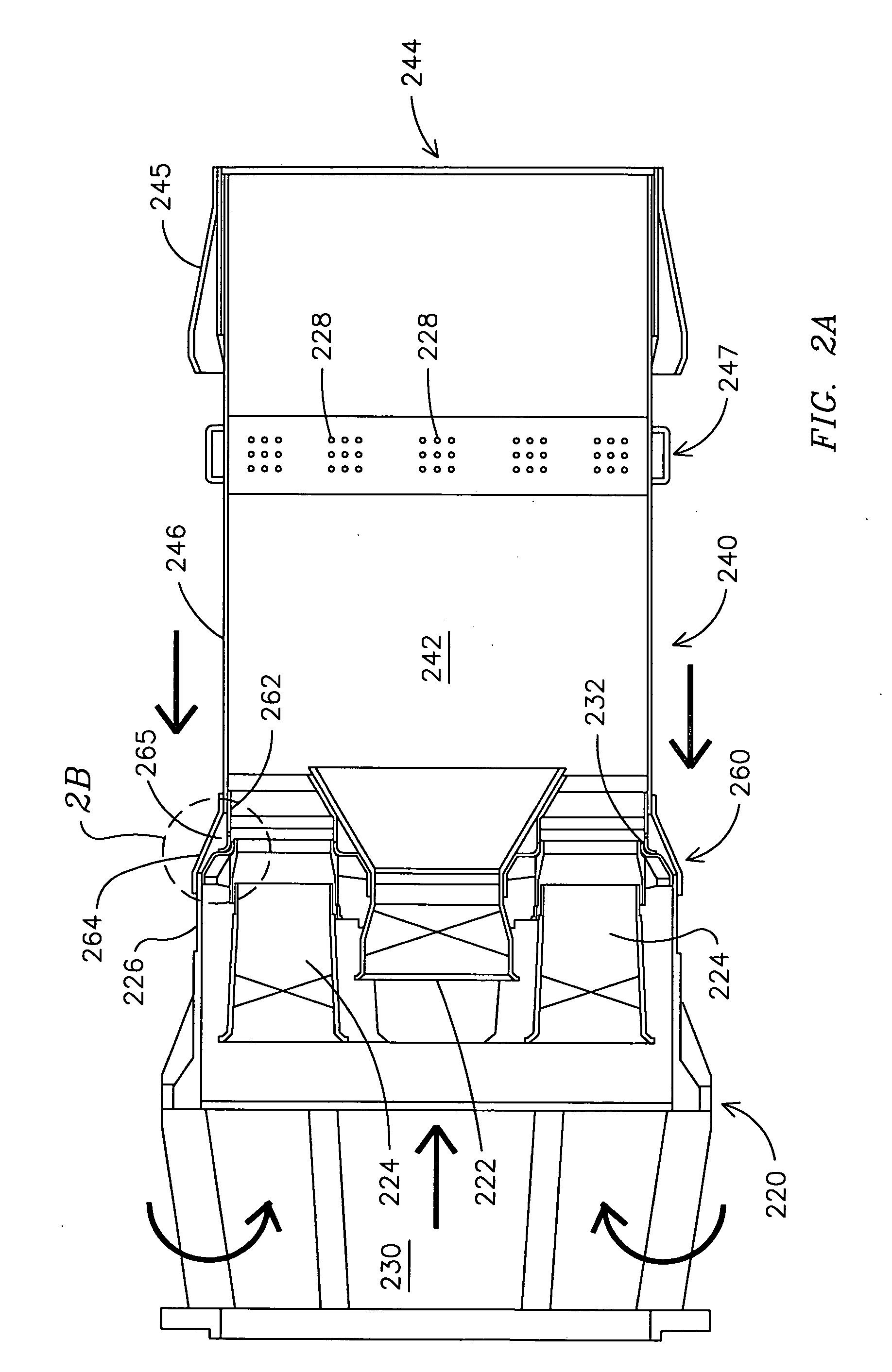

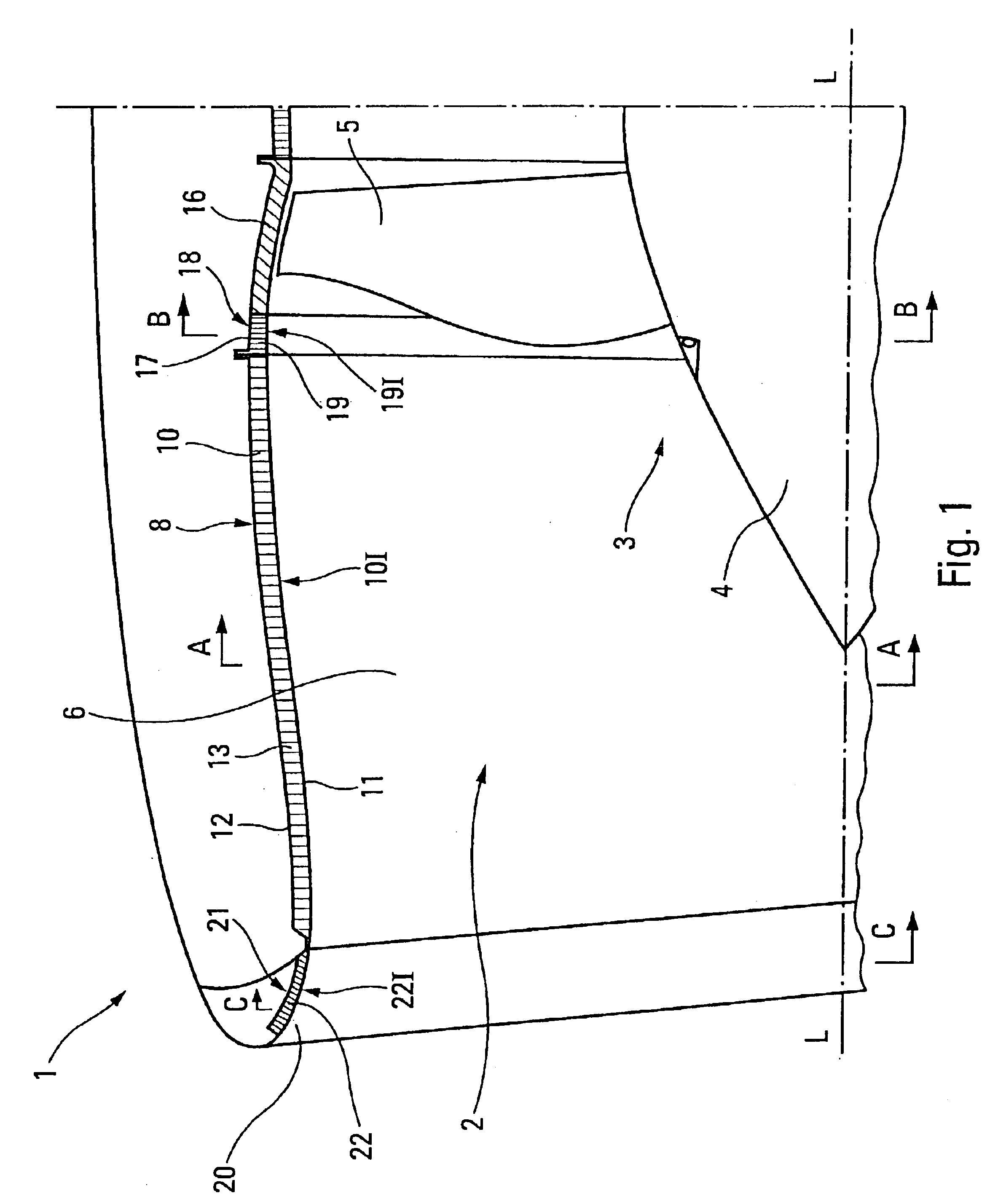

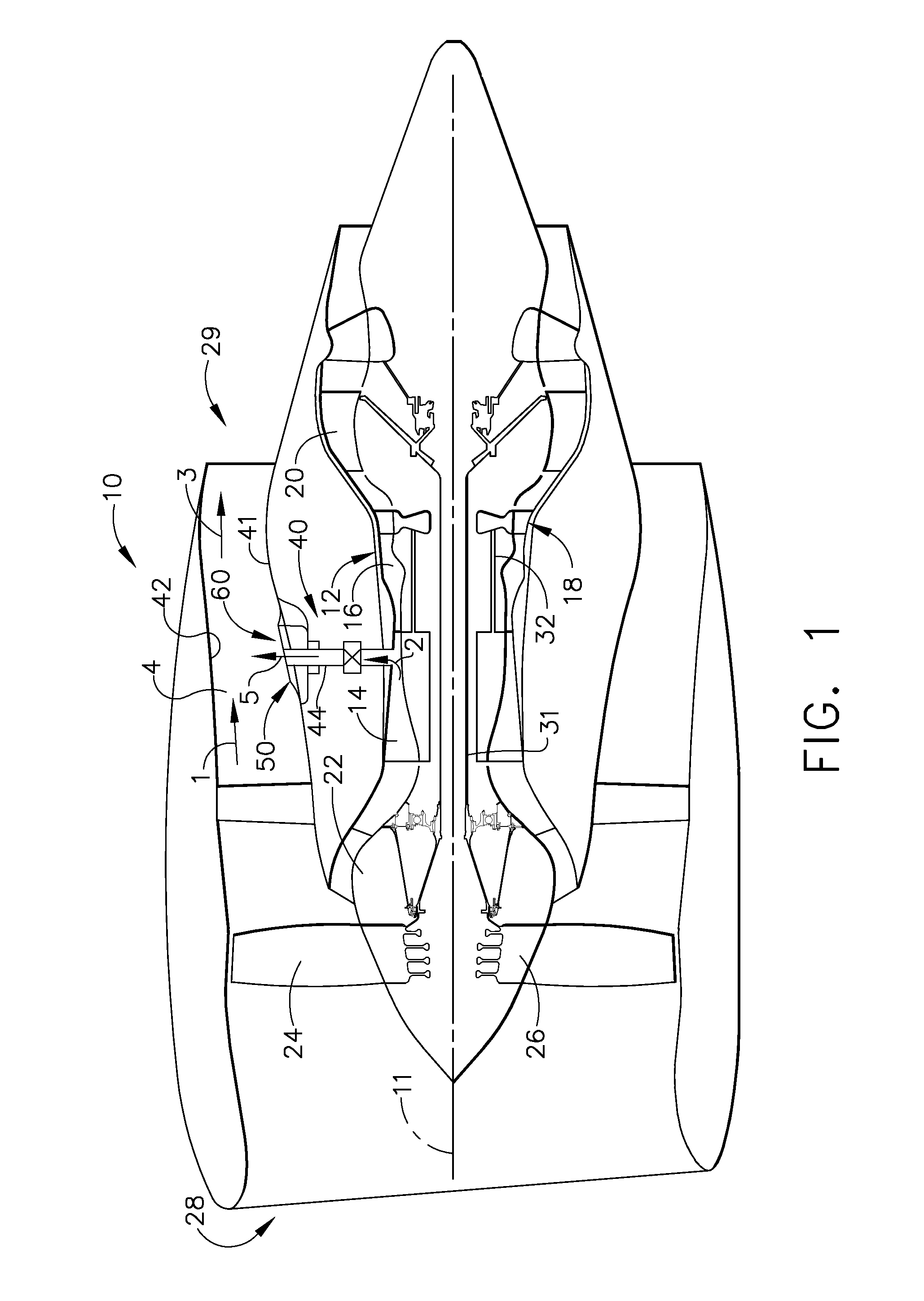

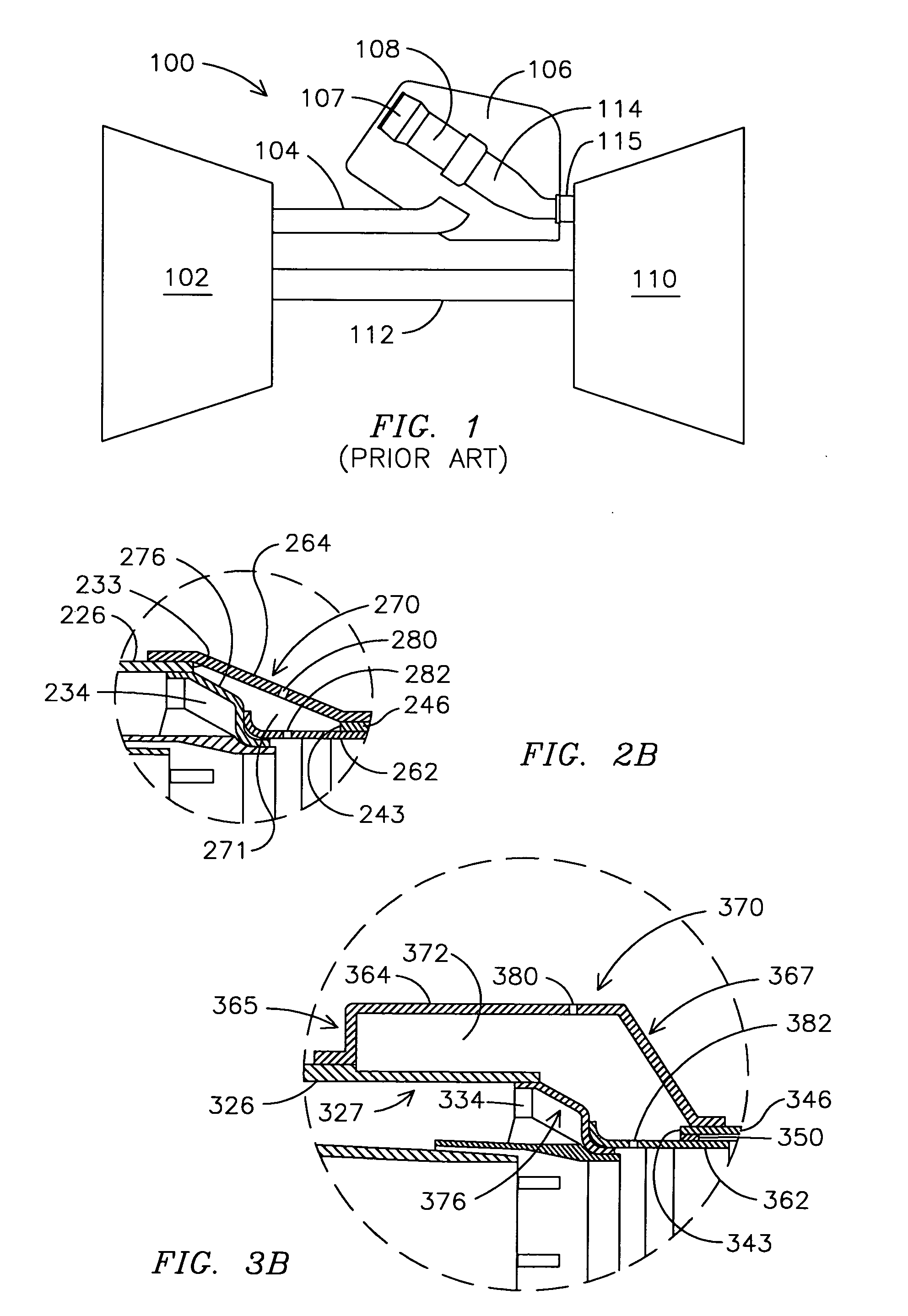

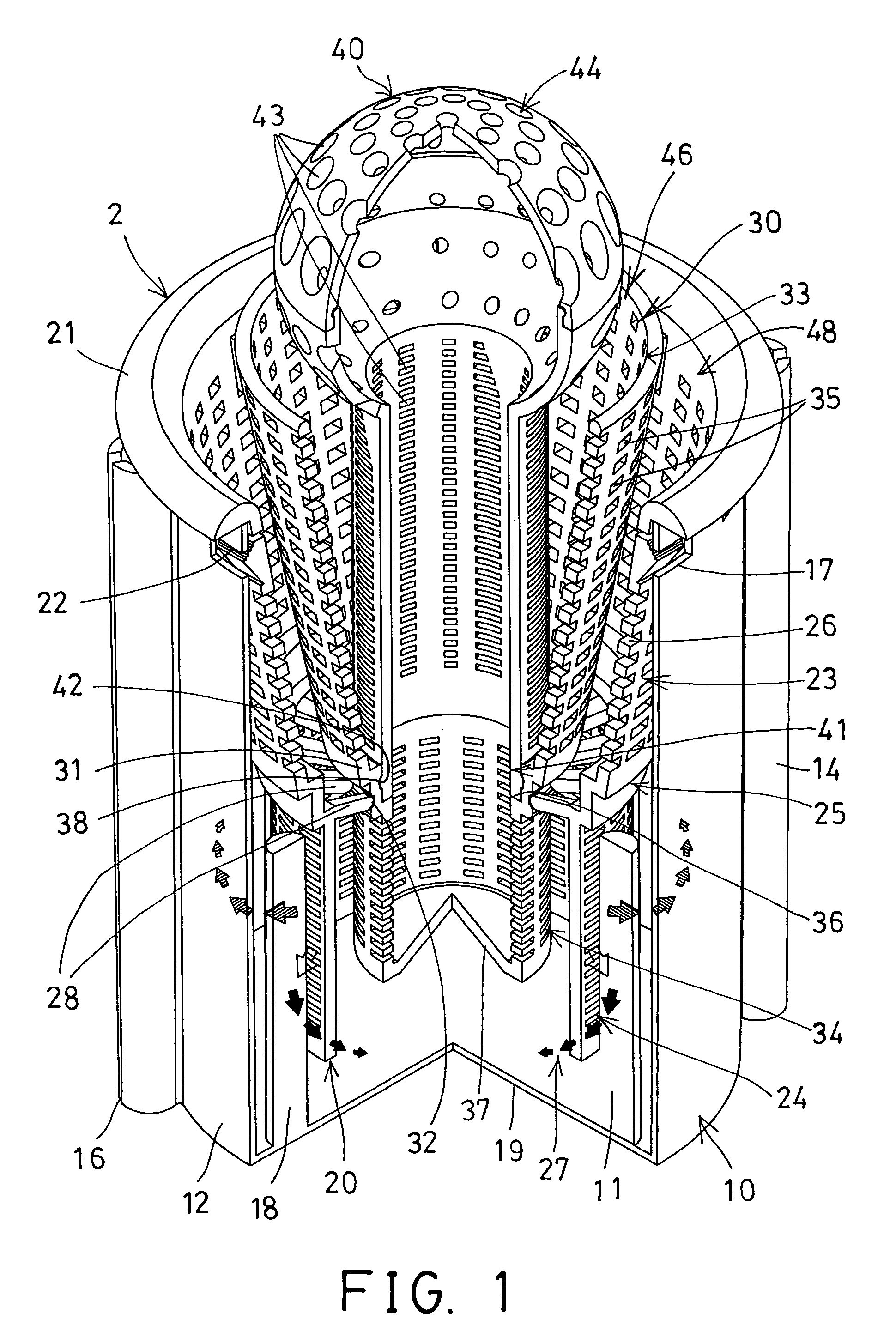

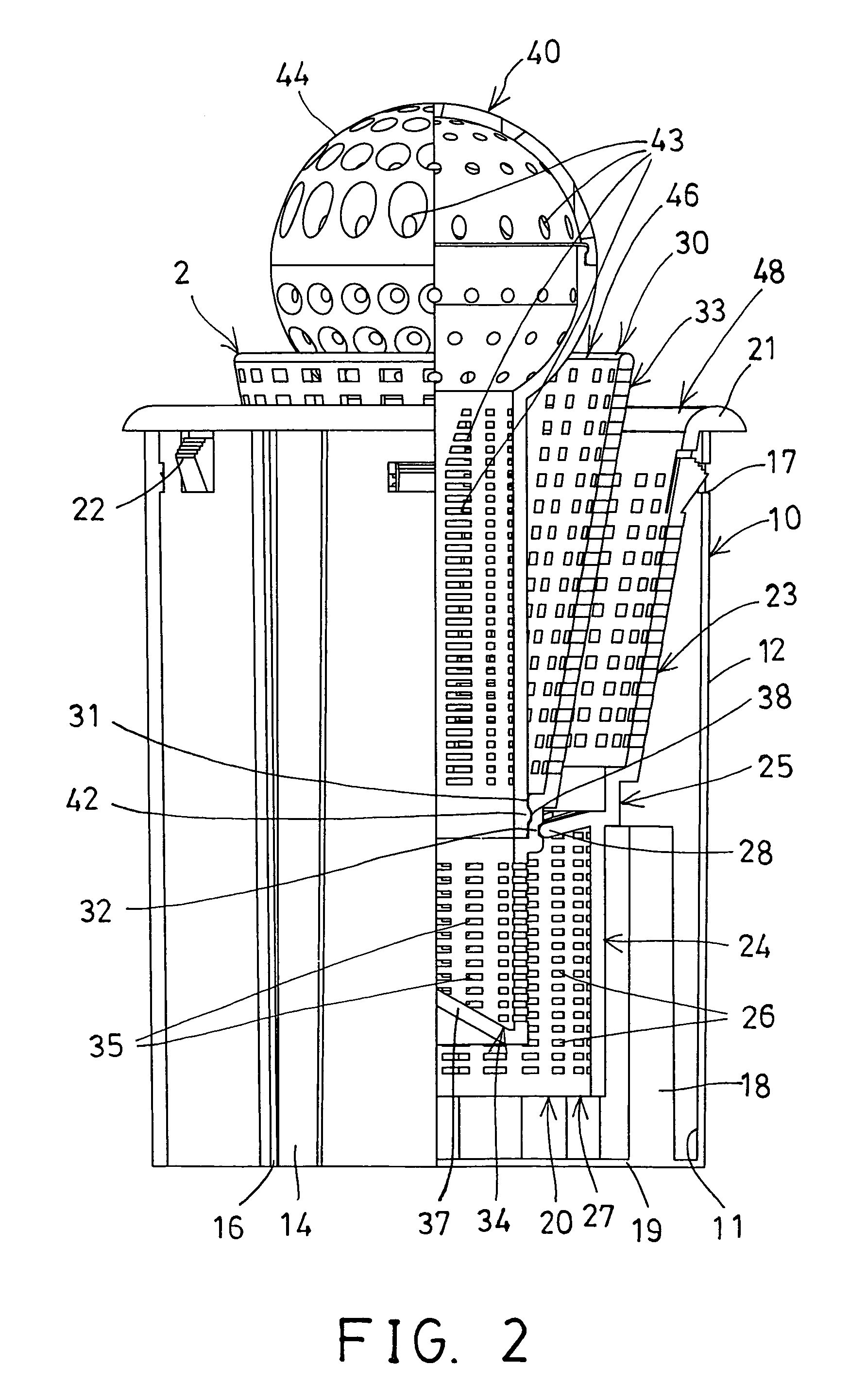

Resonator device at junction of combustor and combustion chamber

InactiveUS20080041058A1Continuous combustion chamberNoise reduction installationsCombustion chamberCombustor

One or more Helmholtz-type resonators (270) is / are provided at the junction (260) of a combustor (220) and a combustion chamber (240) of a gas turbine engine (100). In one embodiment, adjacent Helmholtz-type resonators (290, 291, 292), which may be separated by respective baffles (285), have different volumes that help provide for damping different undesired combustion-generated acoustic pressure waves. In some embodiments, a structural member (435) may be provided between adjacent Helmholtz-type resonators (425, 426, 427, 428) at the junction. At least one of the plurality of Helmholtz-type resonators comprises one or more inlet openings (480), and one or more exit openings (482). Embodiments (370, 425-429) are described in which Helmholtz-type resonators provided at the junction are enlarged in size using various approaches. The positioning at the junction, upstream of the space (242) in which combustion occurs, and providing a plurality of differently sized resonators, provides for improved flexibility and resonator damping efficiencies.

Owner:SIEMENS ENERGY INC

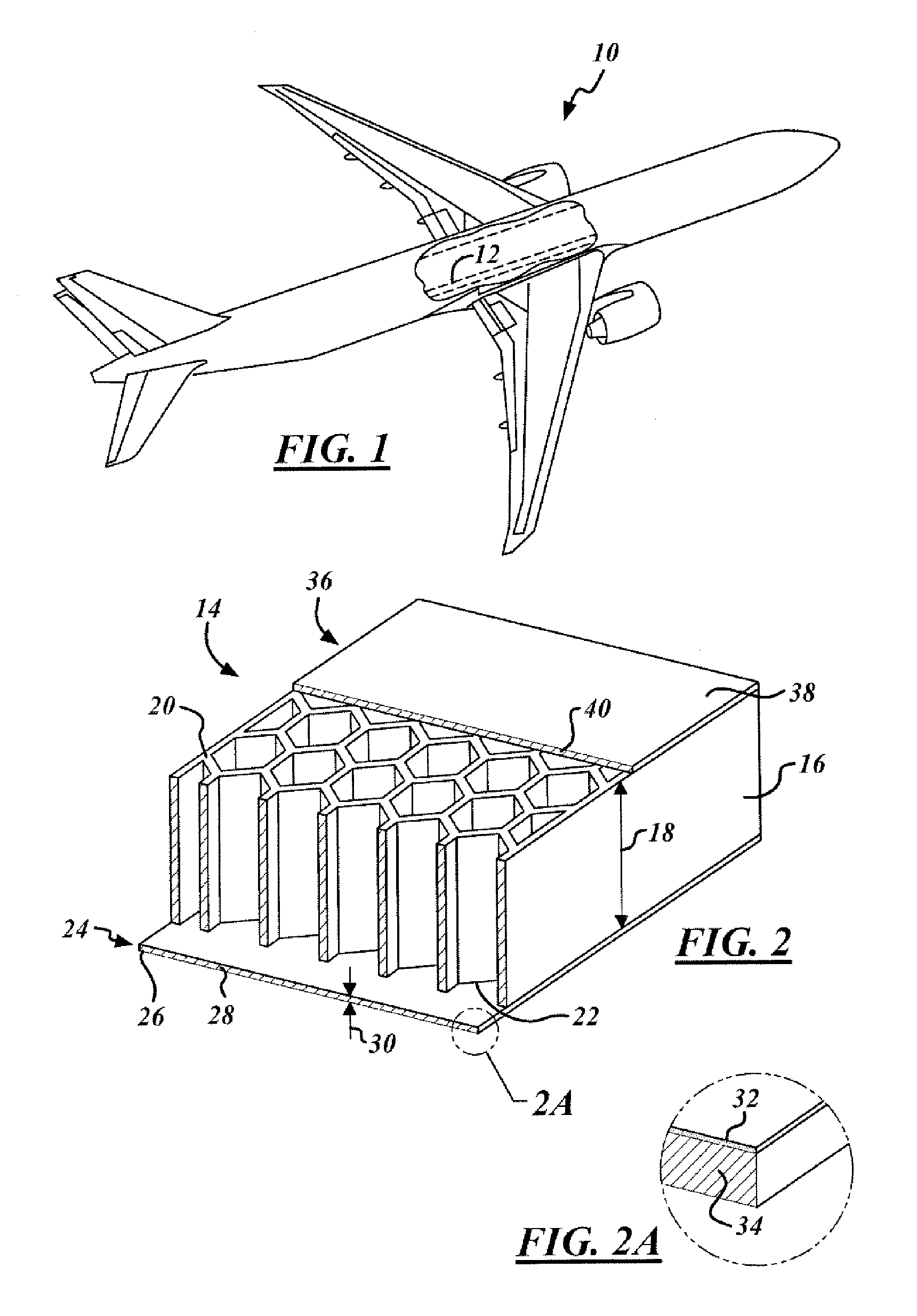

Integrally damped composite aircraft floor panels

Owner:THE BOEING CO

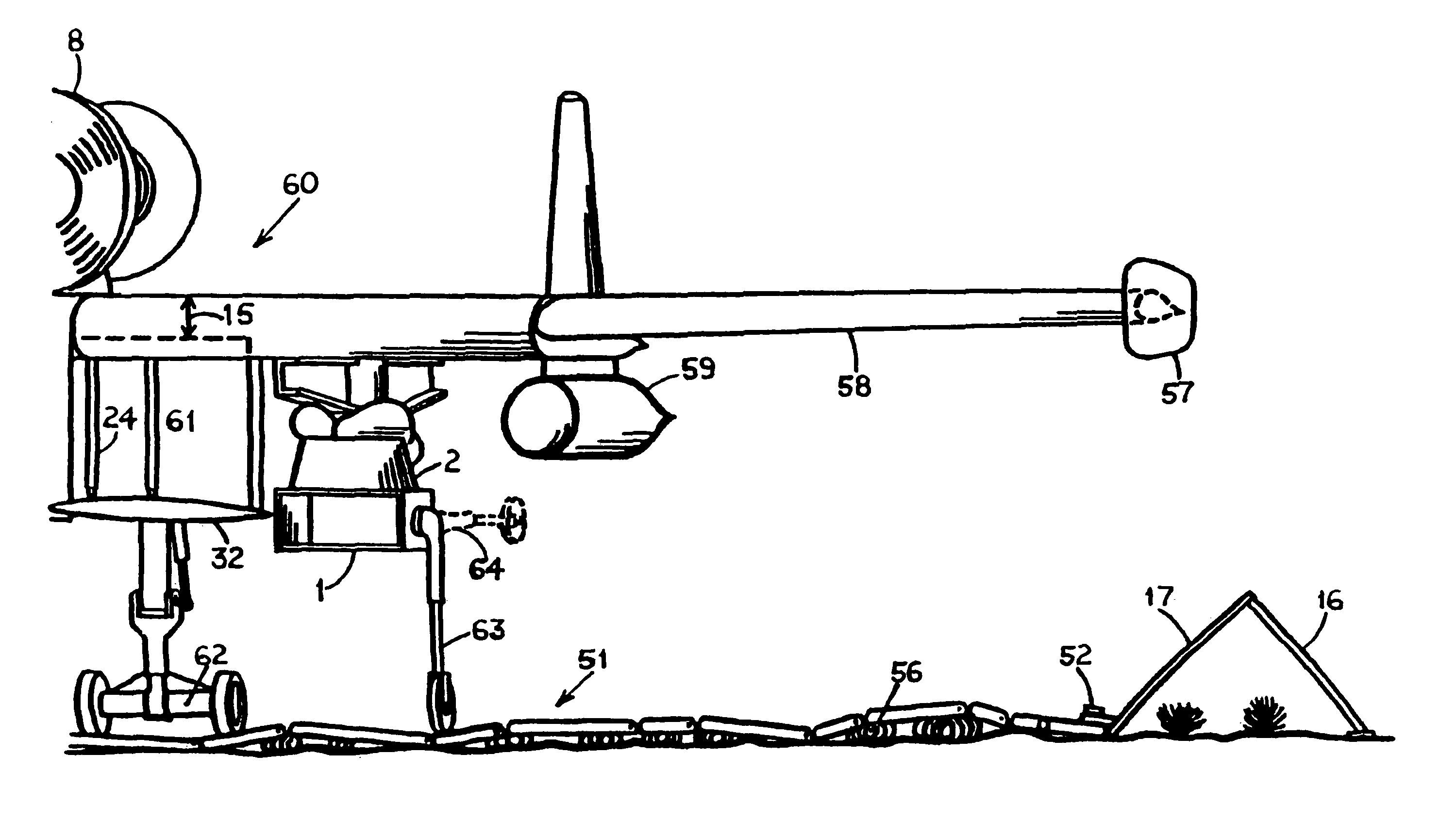

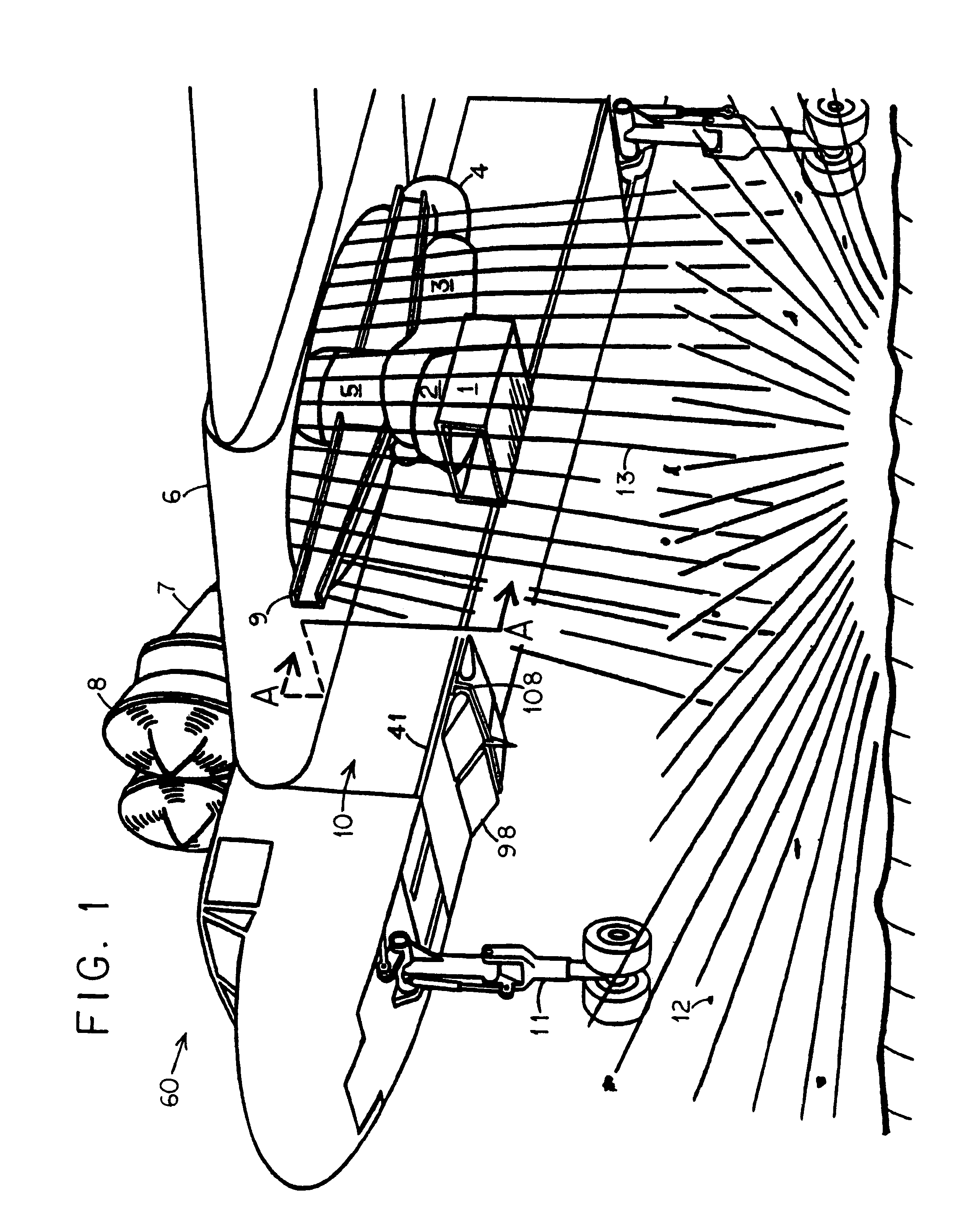

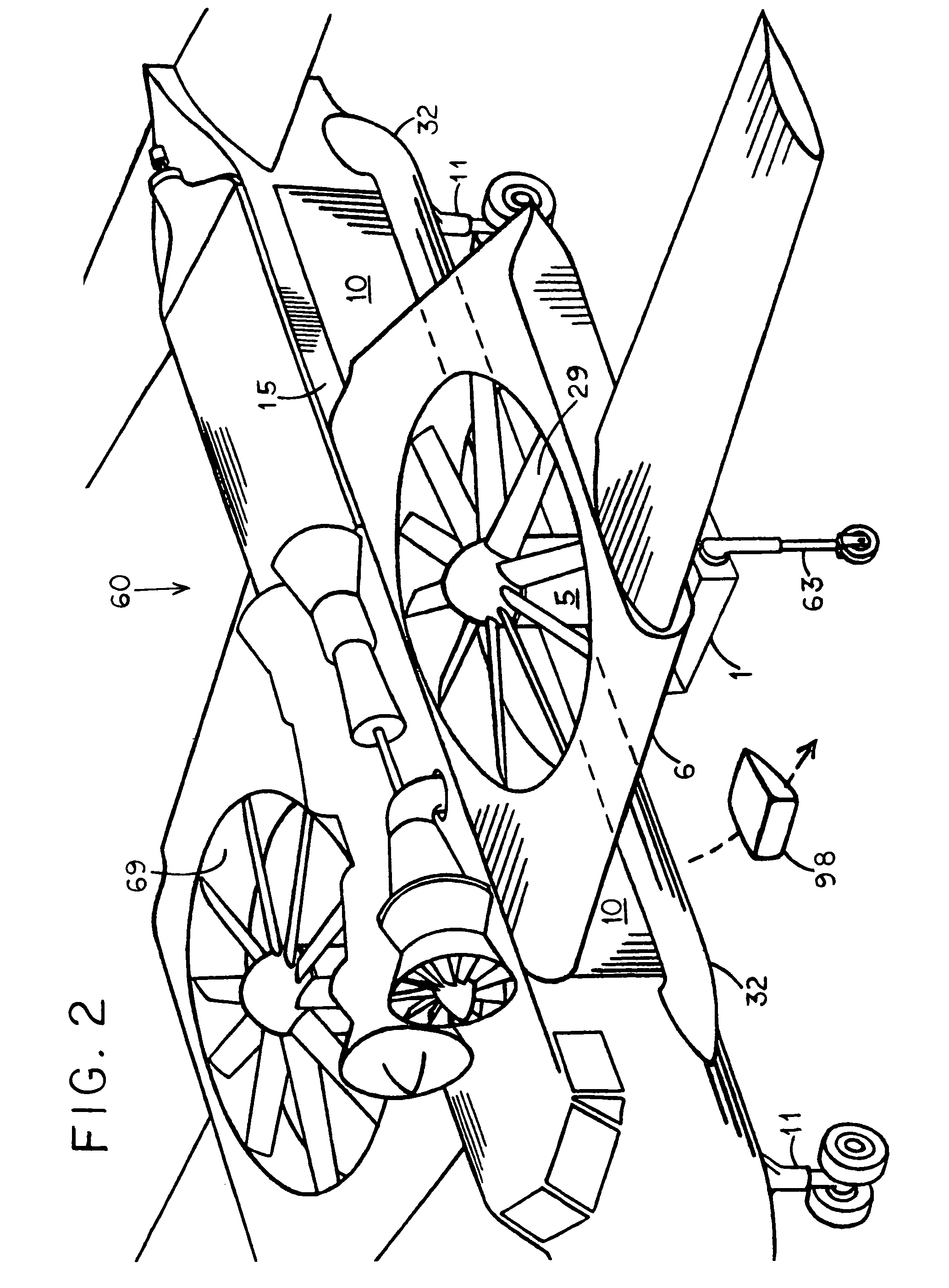

Fly-in landing pad for lift-fan aircraft

InactiveUS9022312B2Easy to unrollIncrease widthAircraft navigation controlNoise reduction installationsJet aeroplaneFlying debris

Owner:KOSHELEFF PATRICK A

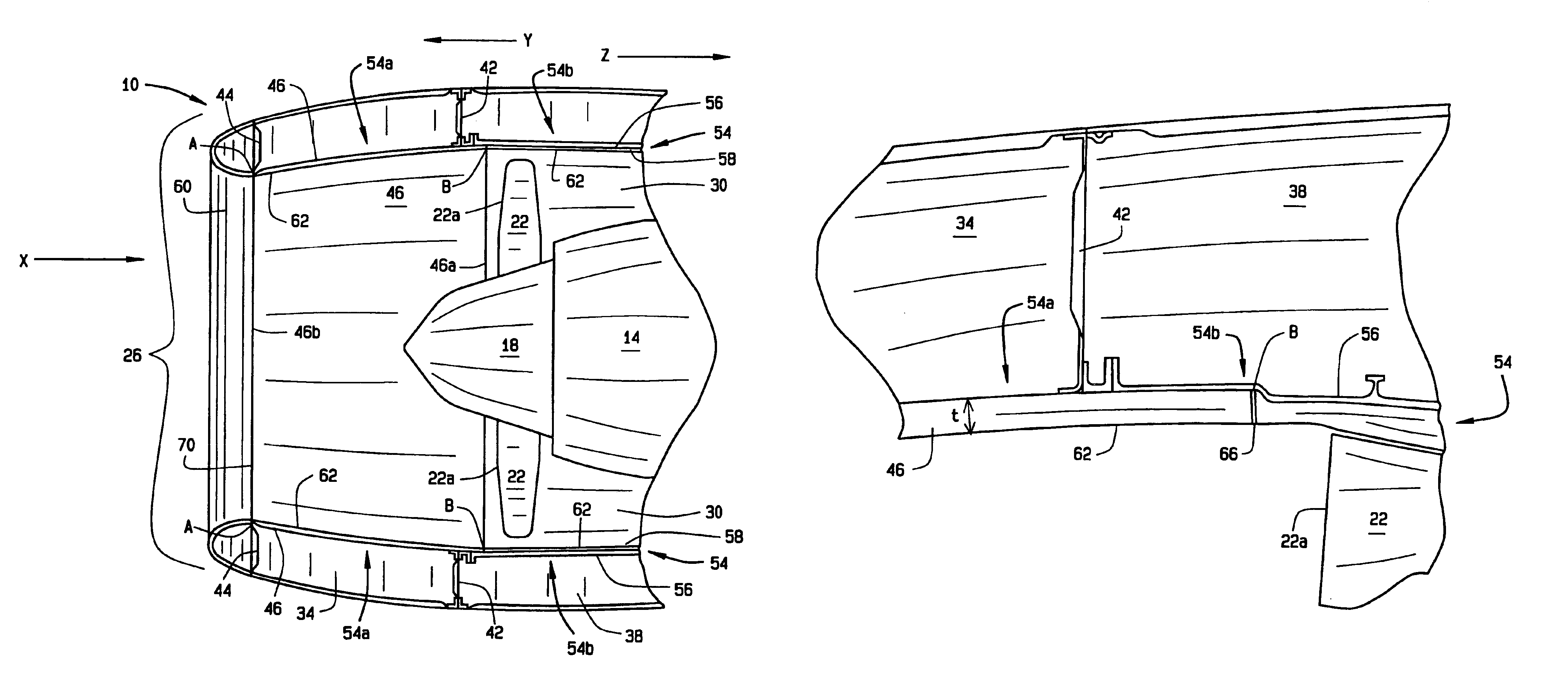

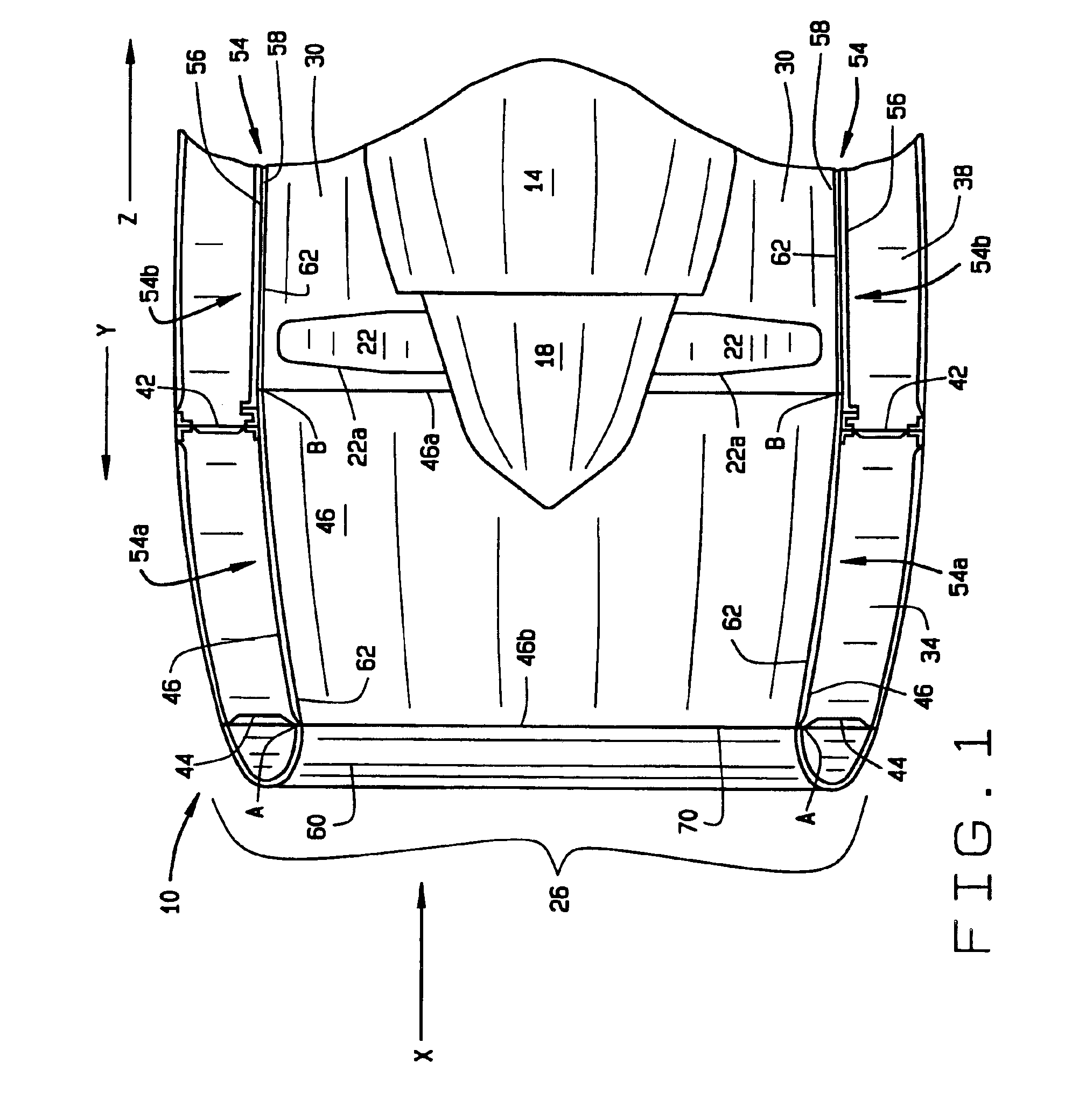

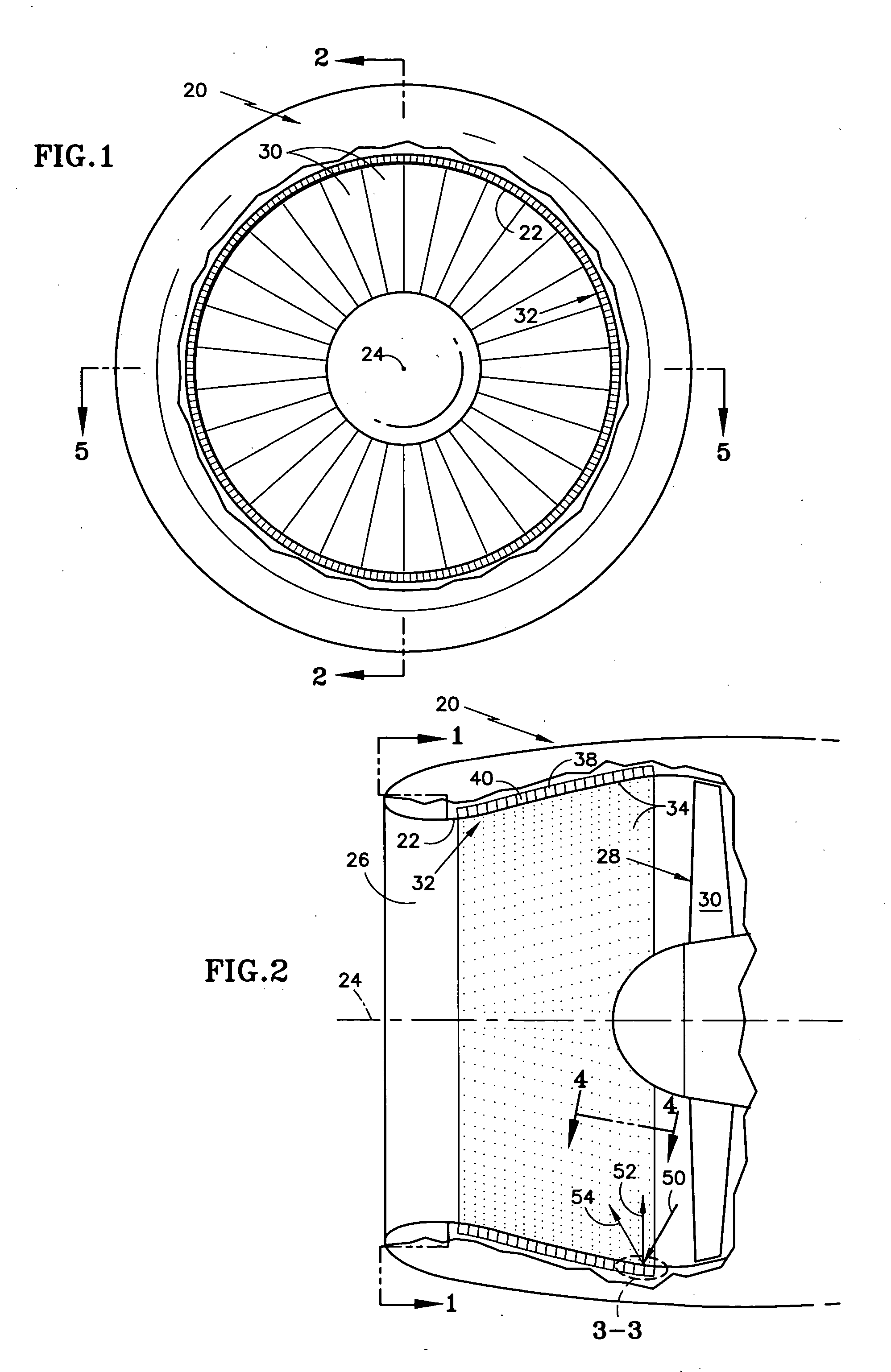

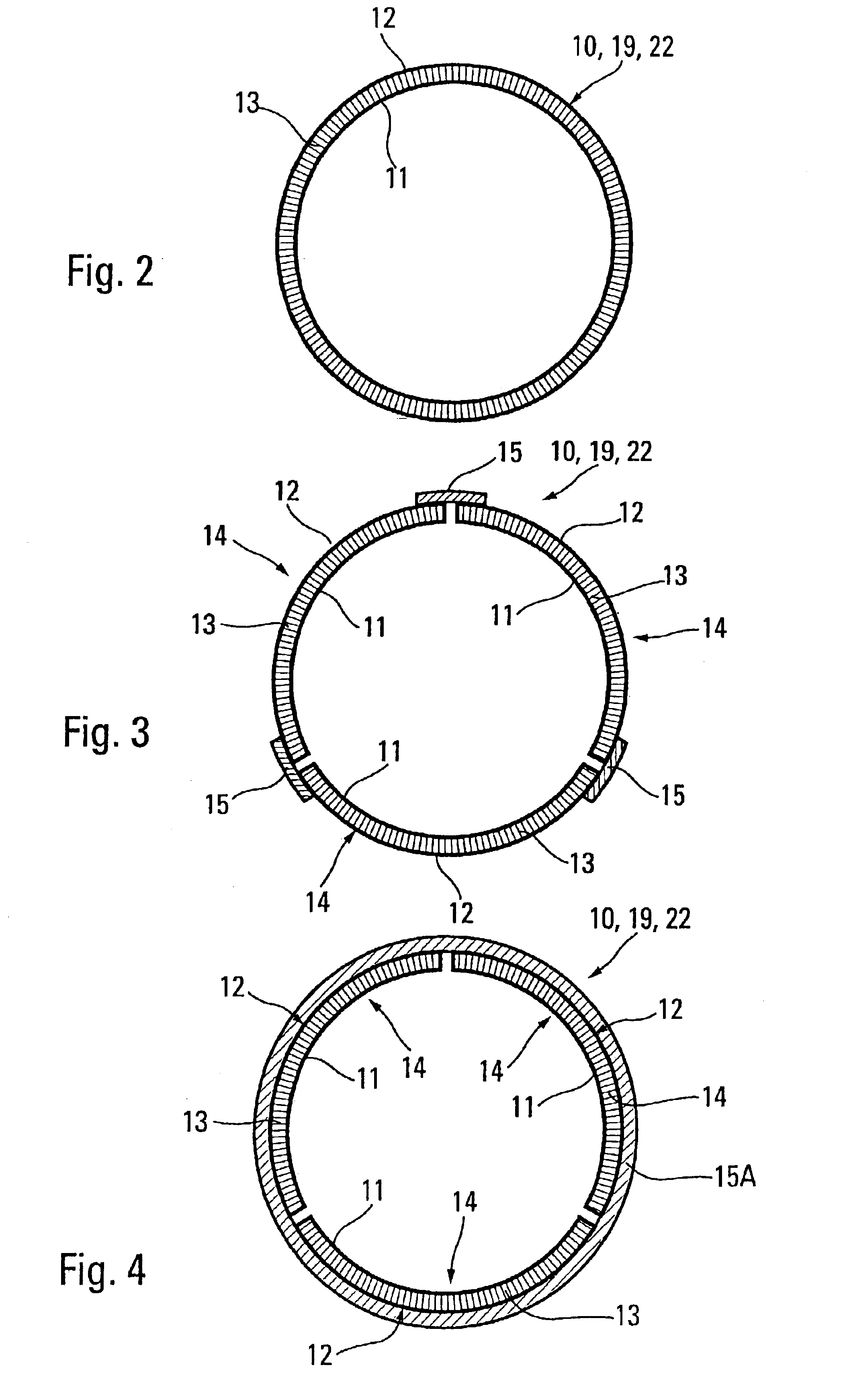

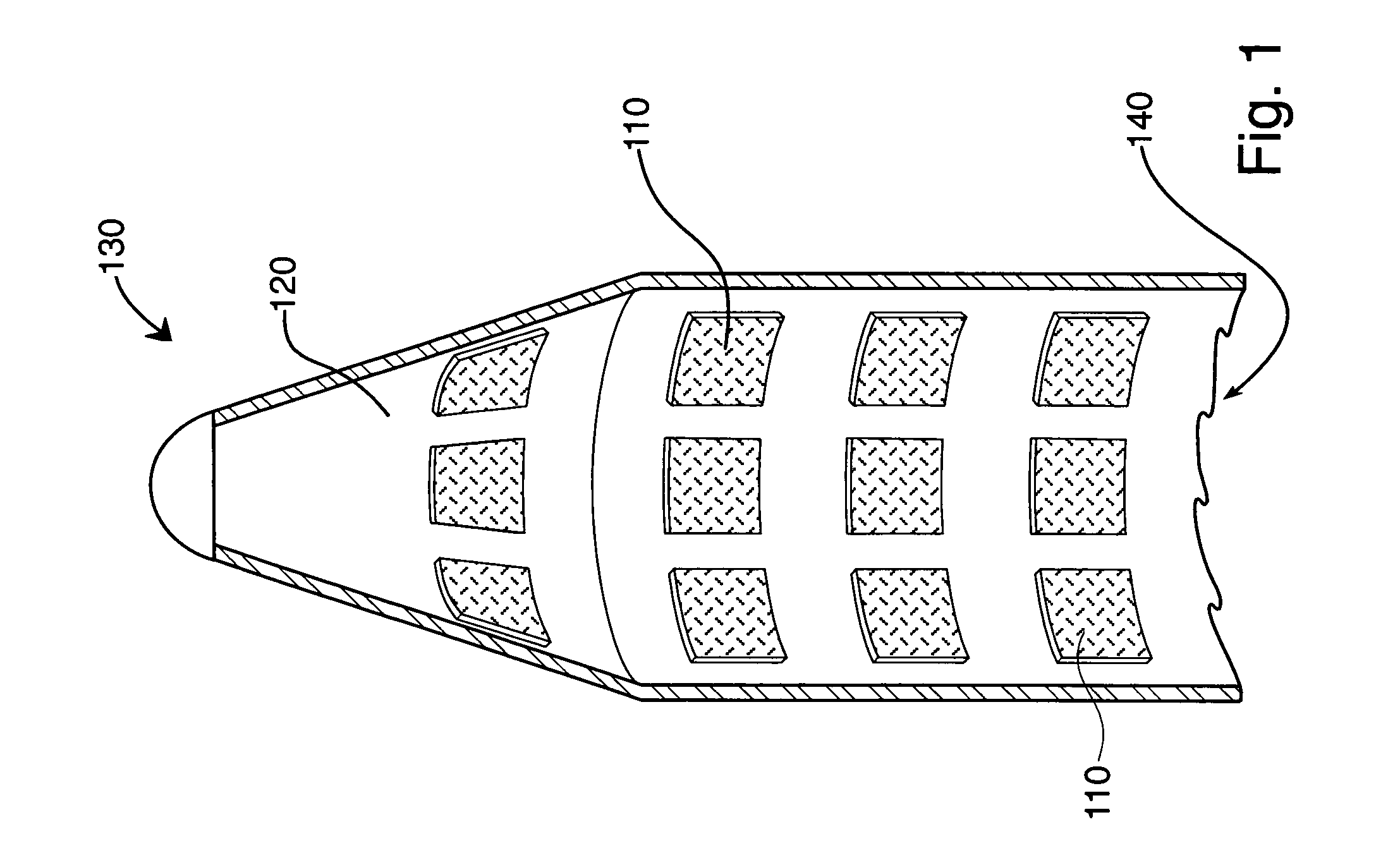

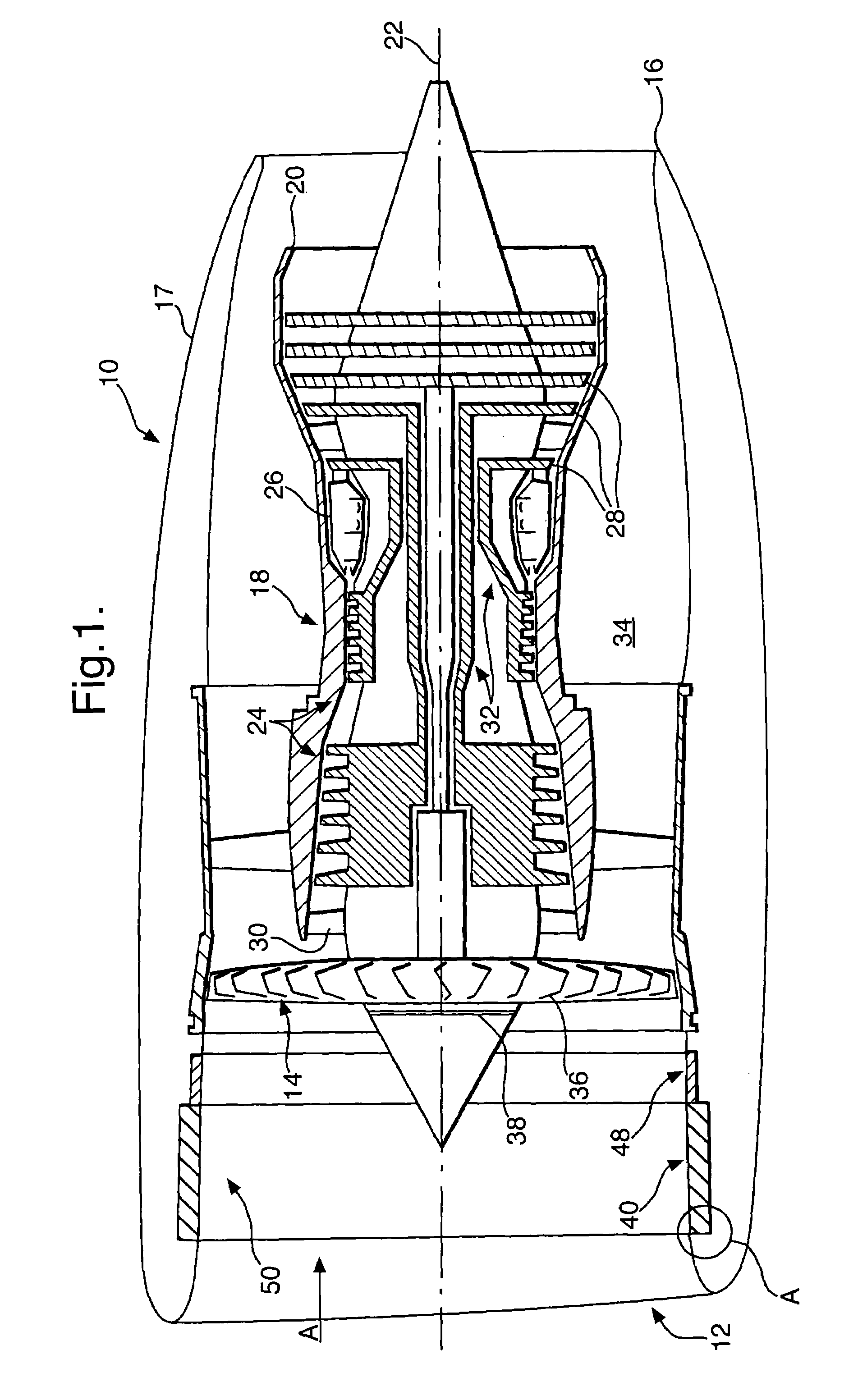

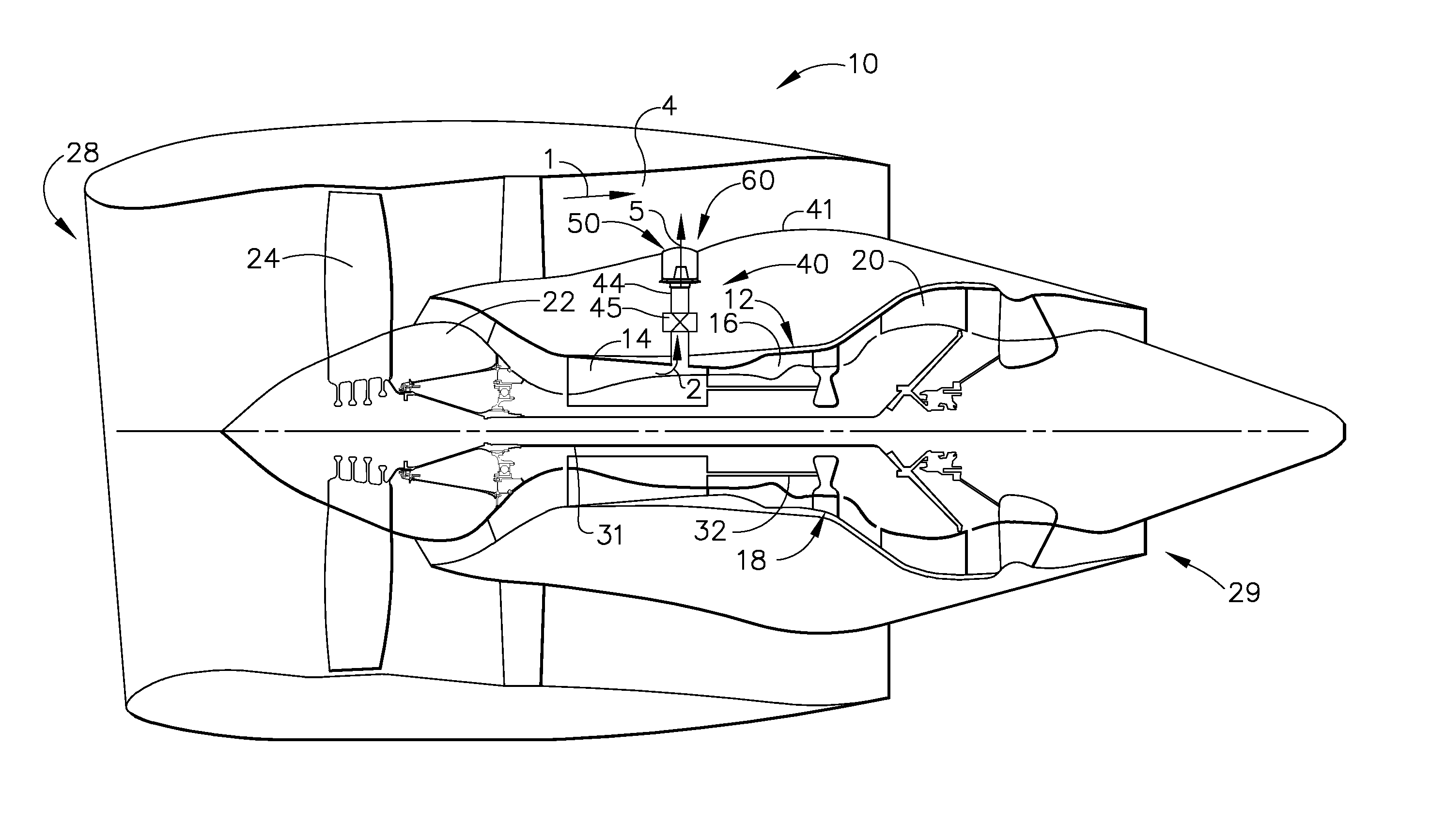

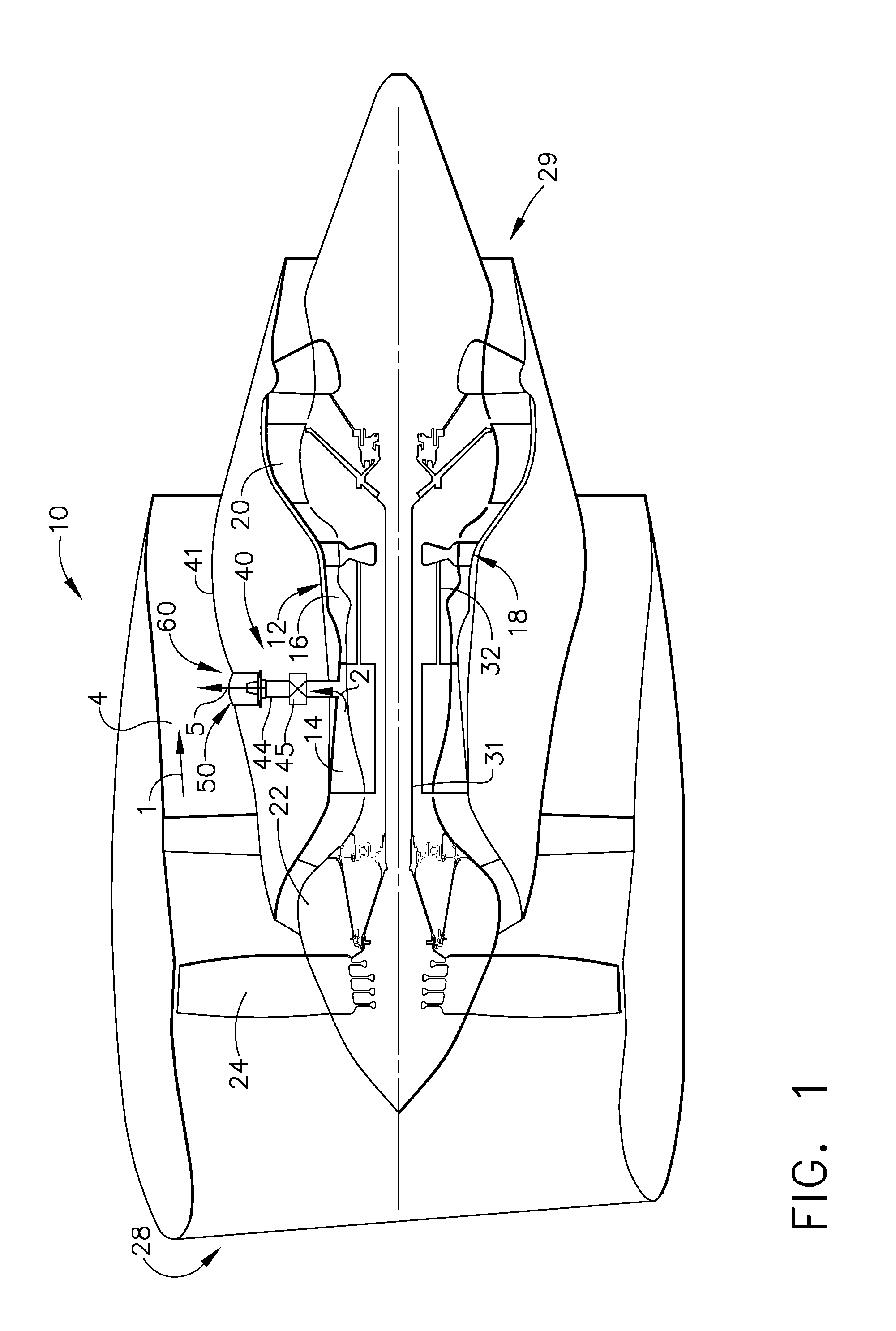

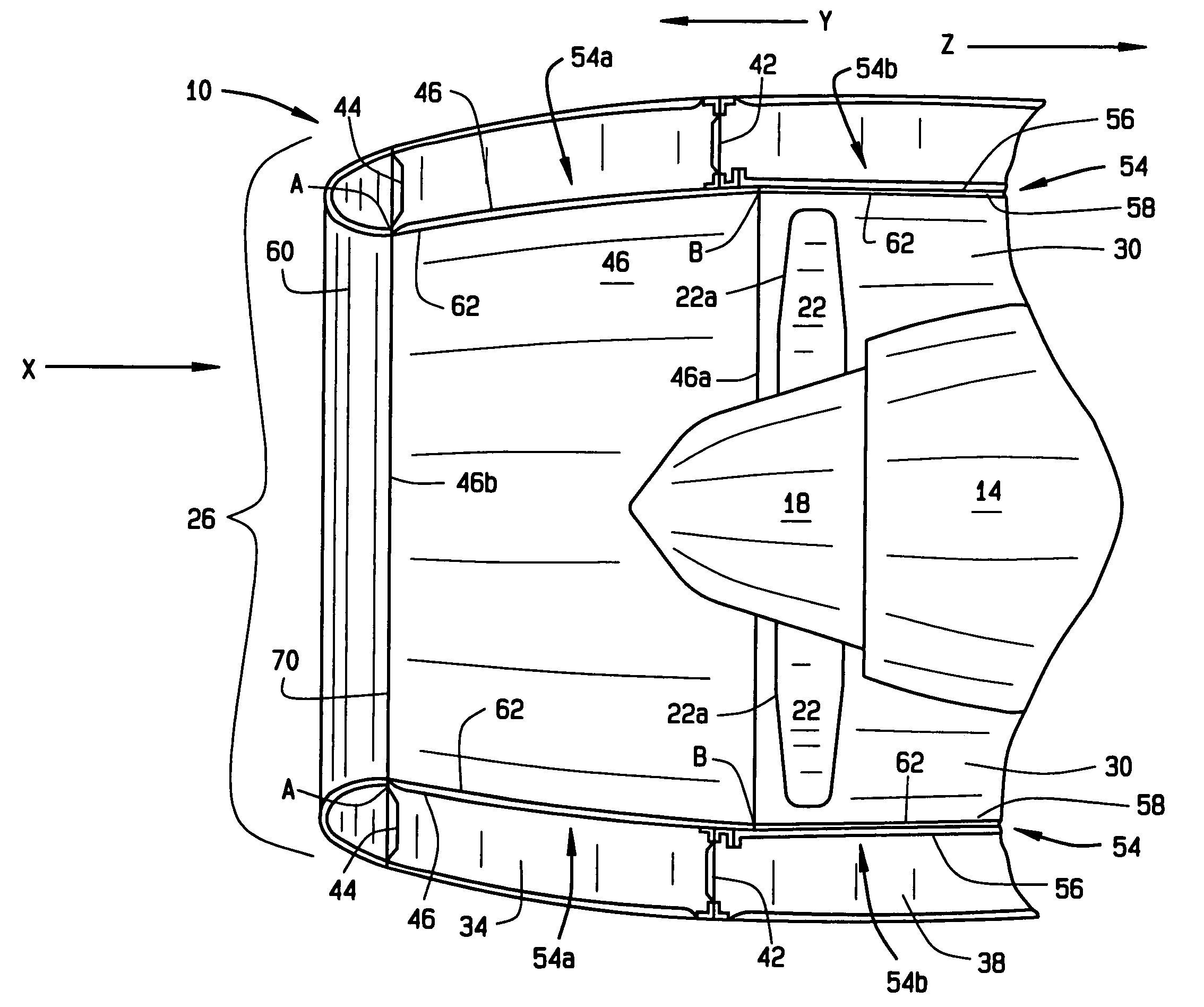

Annular acoustic panel

InactiveUS6920958B2Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

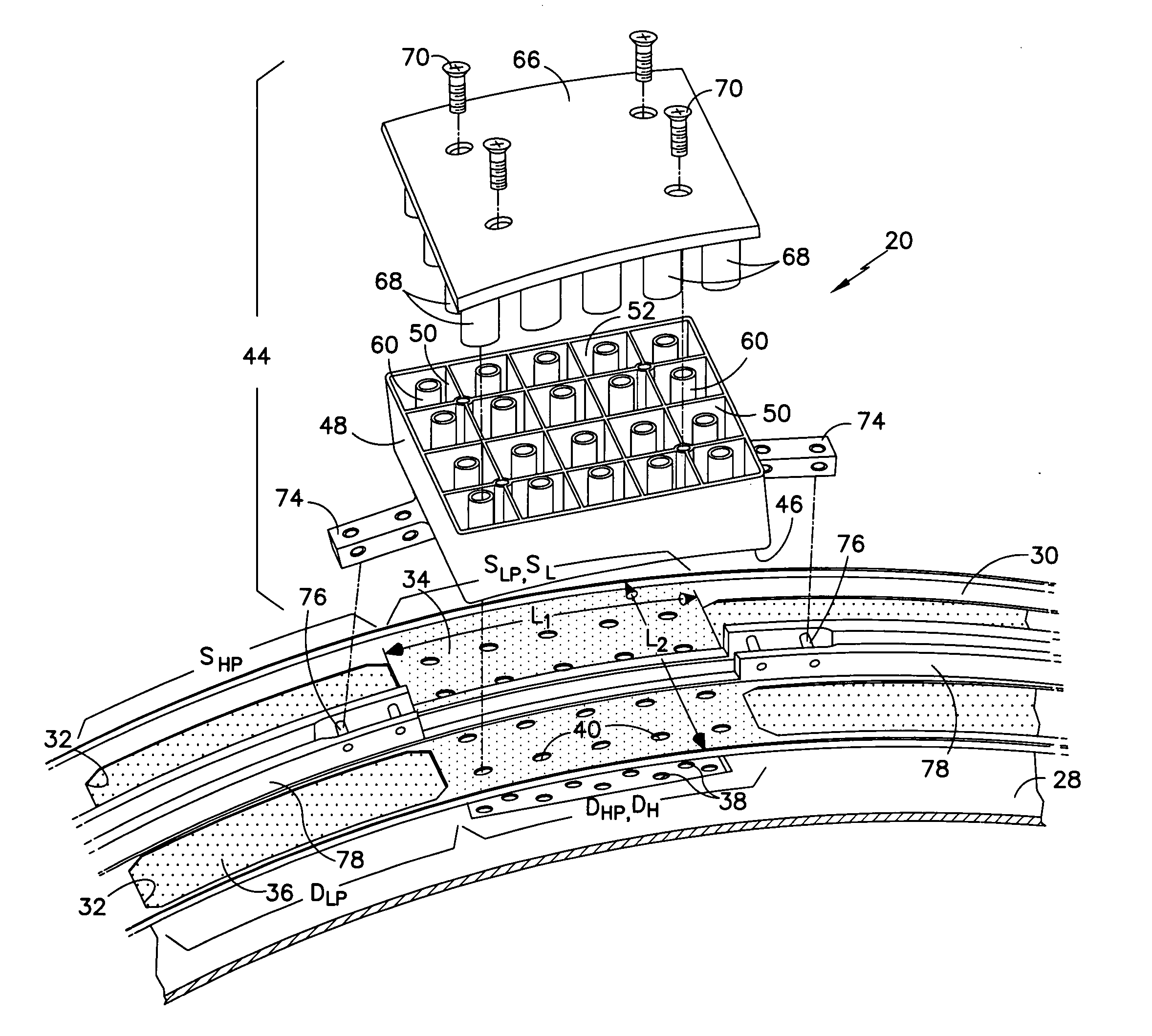

High admittance acoustic liner

ActiveUS7337875B2High admittanceImproved acoustic admittanceNoise reduction installationsWallsPorosityCoolant flow

A cooled acoustic liner useful in a fluid handling duct includes a resonator chamber 52 with a neck 56, a face sheet 86, and a coolant plenum 80 residing between the face sheet and the chamber. Coolant bypasses the resonator chamber, rather than flowing through it, resulting in better acoustic admittance than in liners in which coolant flows through the resonator chamber and neck. In one embodiment, the liner also includes a graze shield 88. Openings 40, 38 penetrate both the face sheet and the shield to establish a relatively low face sheet porosity and a relatively high shield porosity. The shielded embodiment of the invention helps prevent a loss of acoustic admittance due to fluid grazing past the liner. Another embodiment that is not necessarily cooled, includes the resonator chamber, low porosity face sheet and high porosity shield, but no coolant plenum for bypassing coolant around the resonator chamber. An associated method of retrofitting an acoustic treatment into a fluid handling module includes installing openings in the module and mounting a resonator box 44 on the module so that the inlets to the resonator necks register with the installed openings.

Owner:RTX CORP

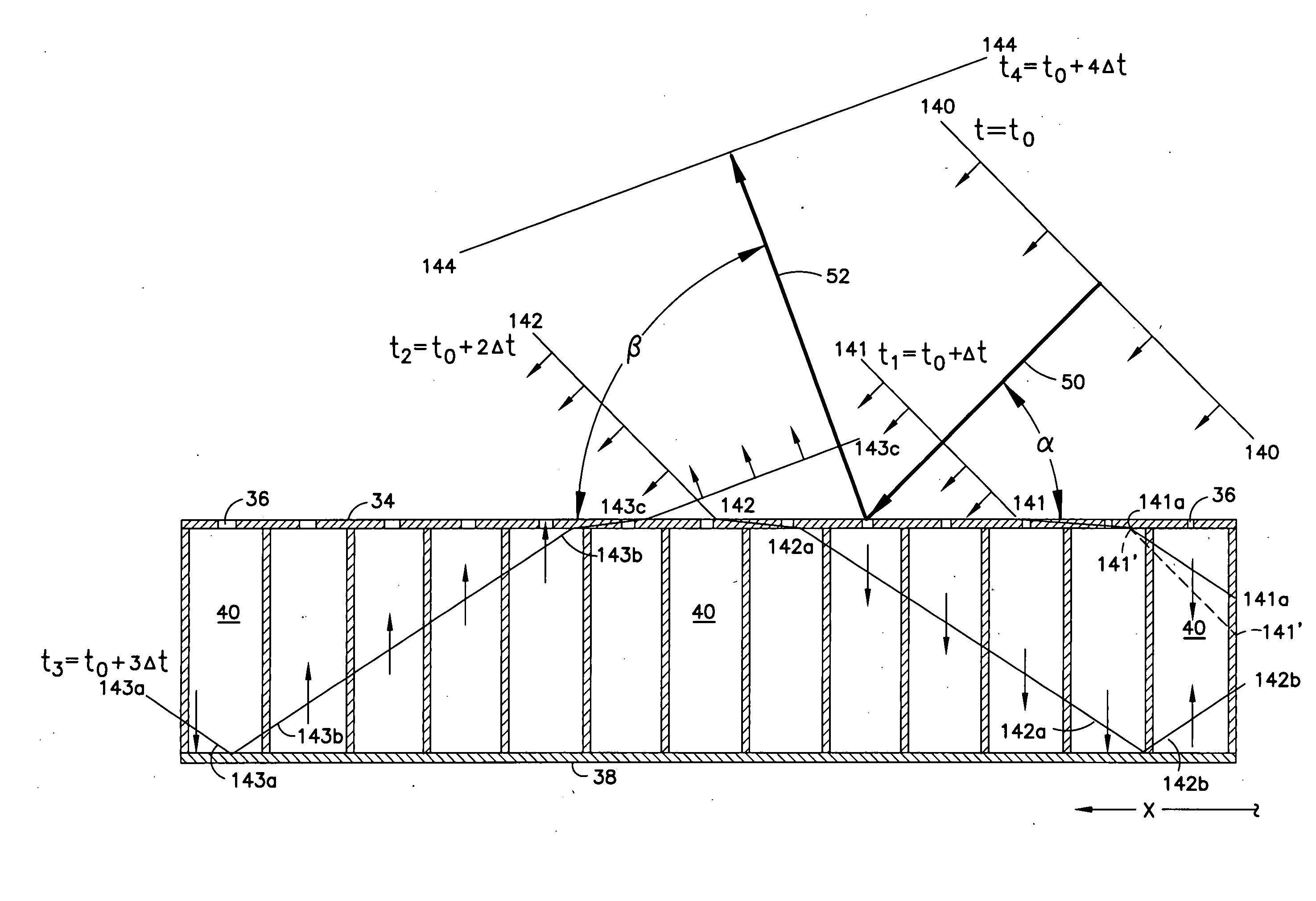

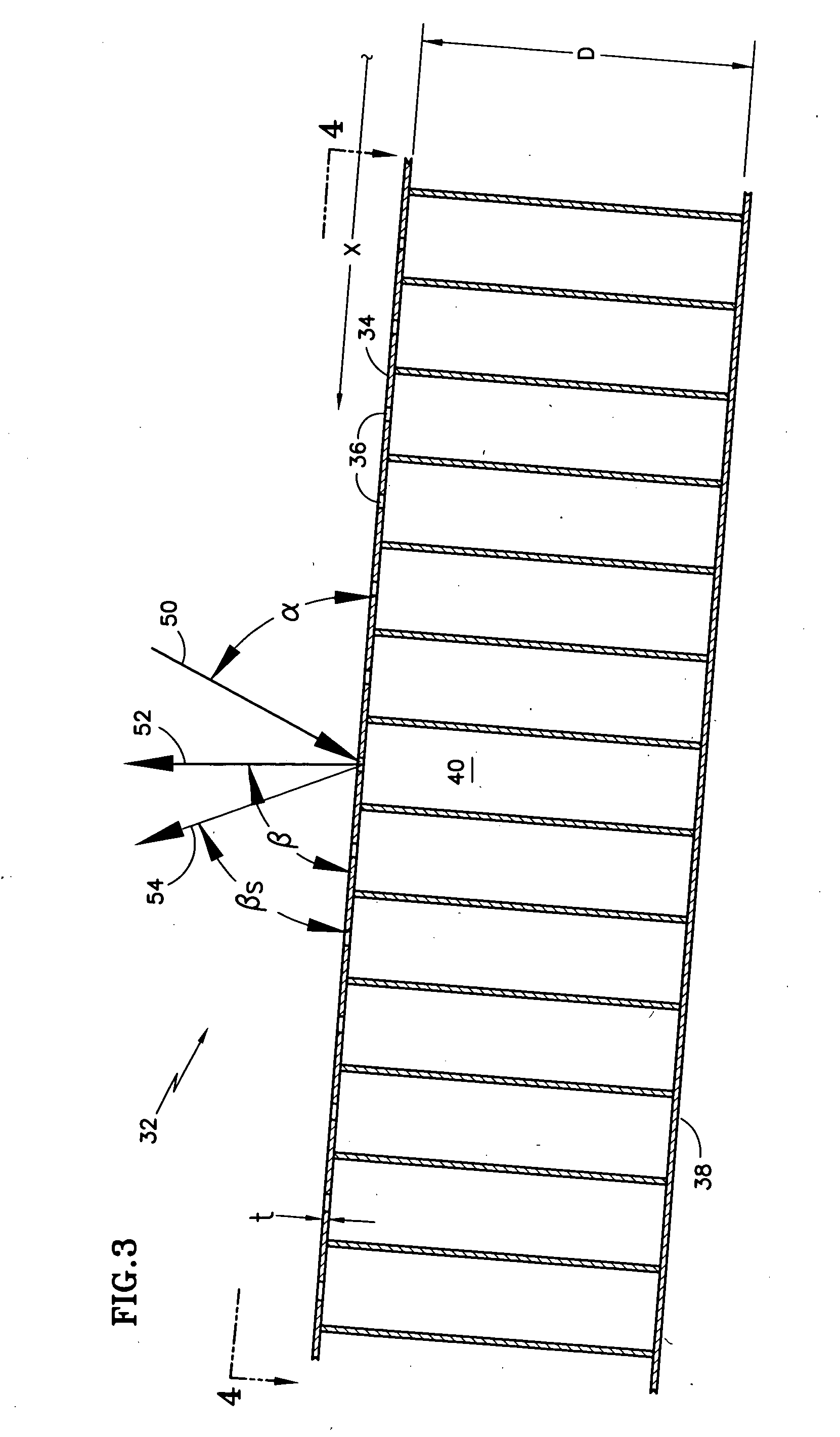

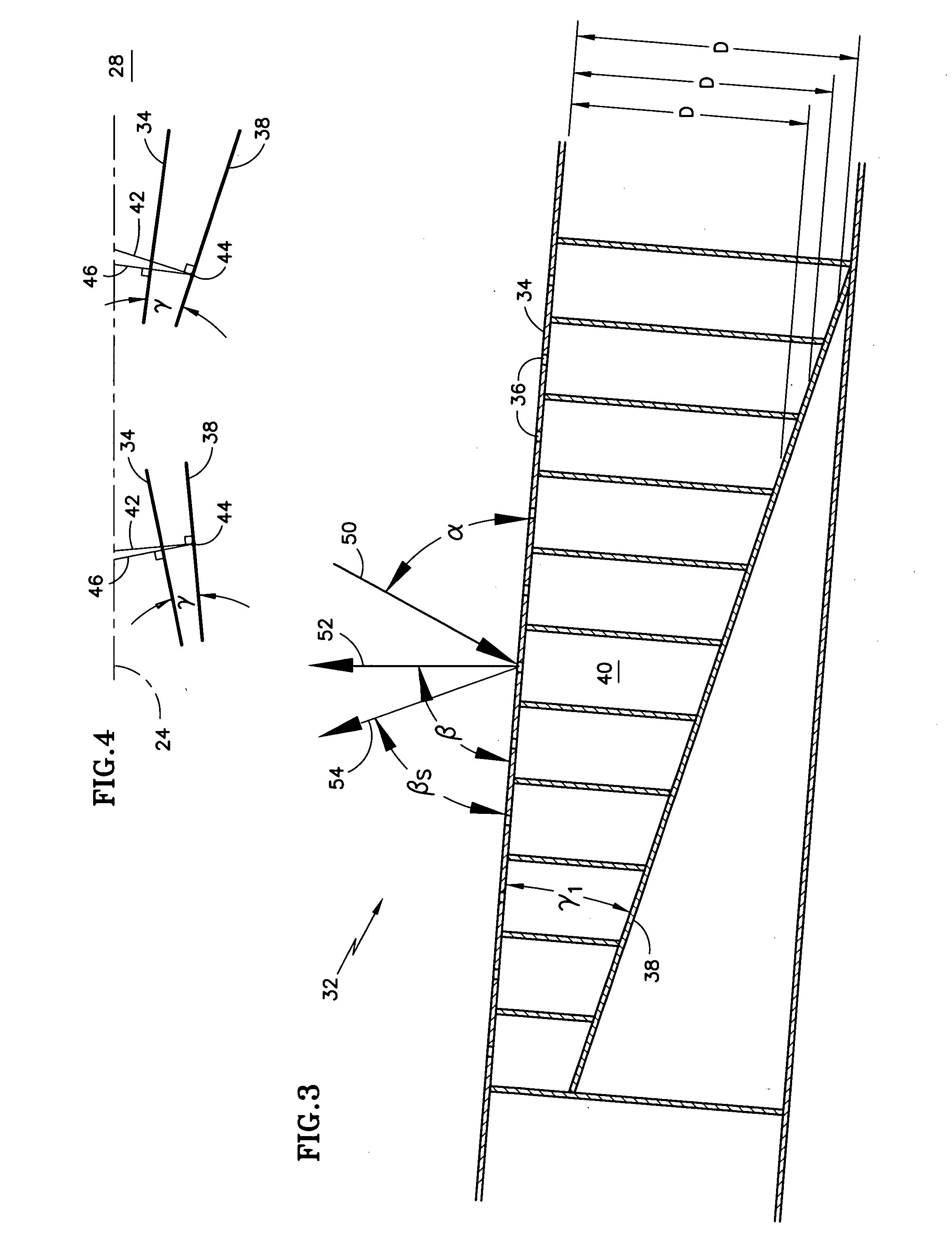

Acoustic liner with nonuniform impedance

InactiveUS20060169532A1Without jeopardizing aerodynamic performanceNoise reduction installationsPump componentsEngineeringAcoustic wave

A fluid handling duct such as a turbine engine inlet duct 20 includes an acoustic liner 32 comprising a face sheet 34 and a backwall 38 laterally spaced from the face sheet. The liner has a nonuniformly distributed acoustic impedance to direct sound waves incident on the backwall in a prescribed direction relative to the face sheet. The nonuniform impedance is spatially distributed to regulate the direction in which noise signals reflect from the backwall, thereby reducing noise propagation from the duct to the surrounding environment.

Owner:RAYTHEON TECH CORP

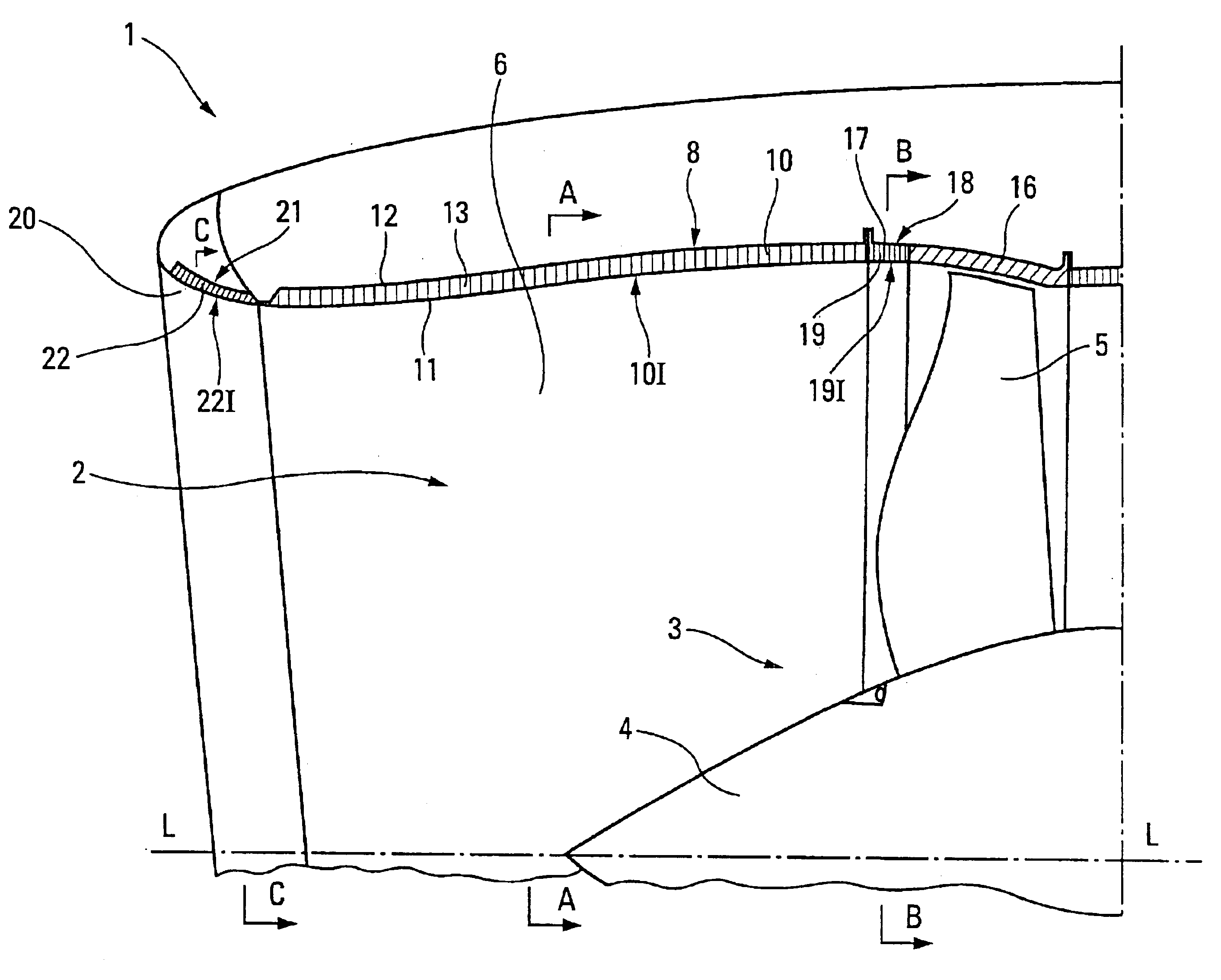

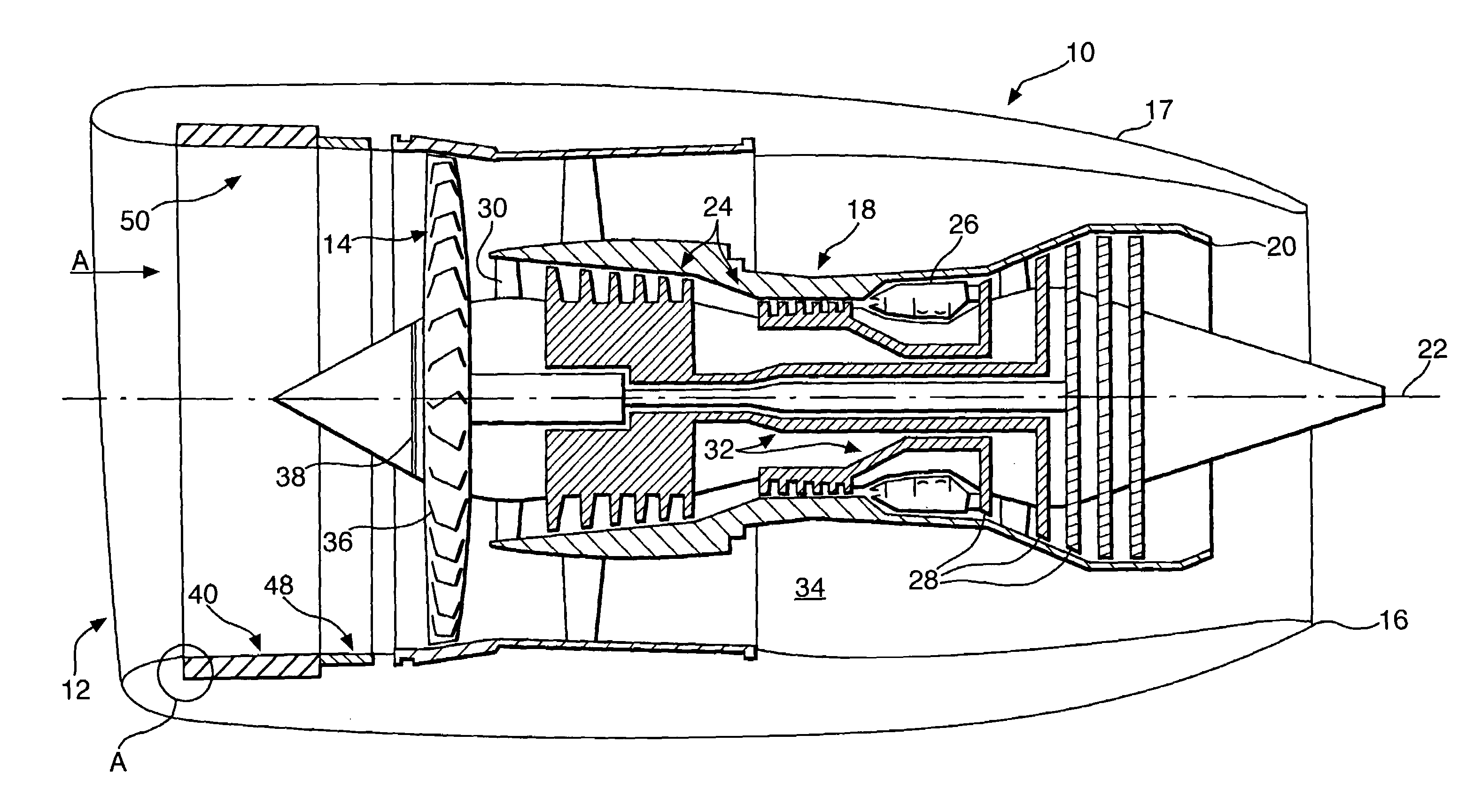

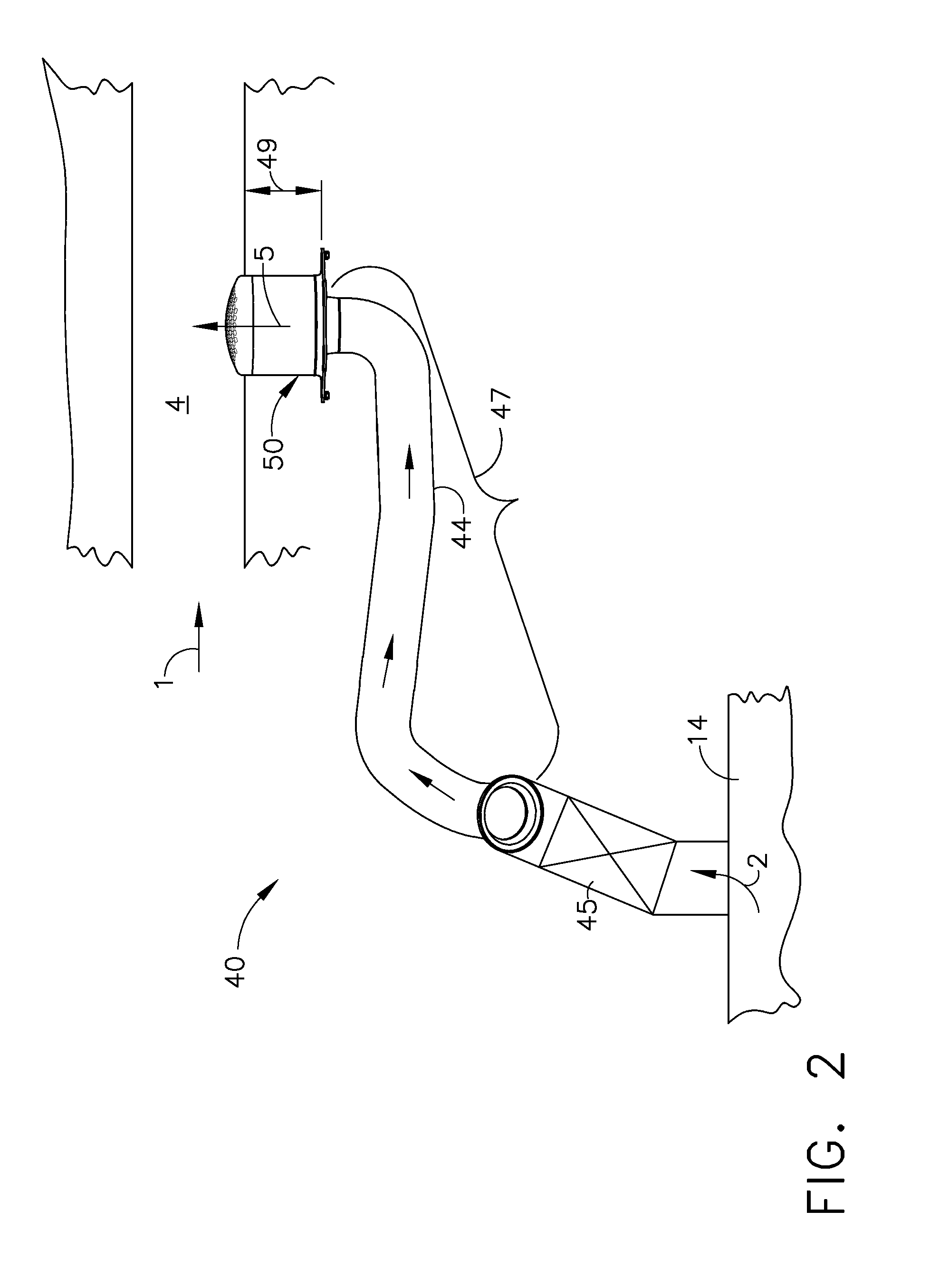

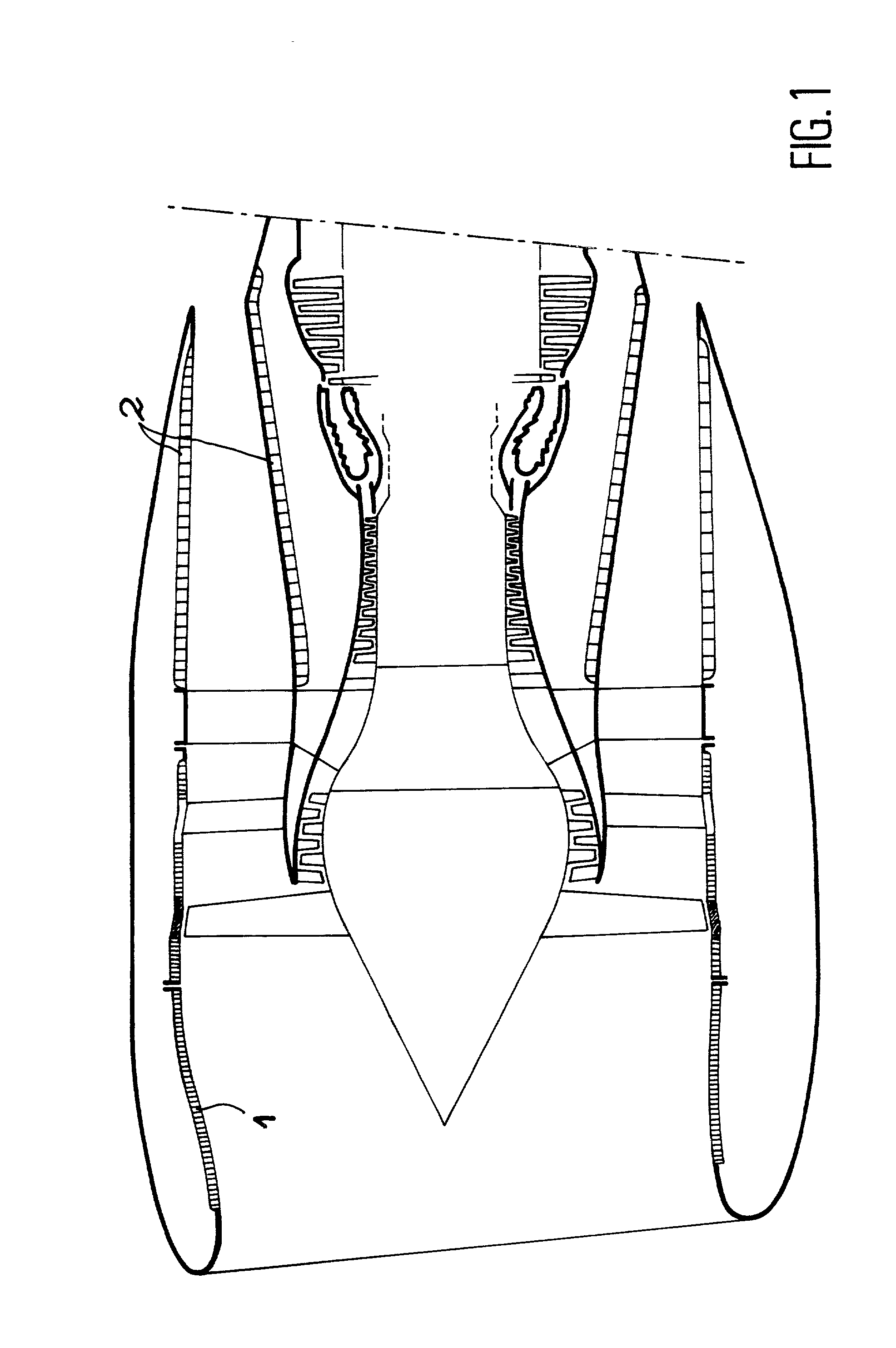

Aircraft engine pod with acoustic attenuation

InactiveUS6896099B2Improve the attenuation effectRemove noiseNoise reduction installationsPump componentsNacelleEngineering

An internal duct of an aircraft engine pod may include a fan and a tubular air intake having a first acoustic attenuation internal tubular piece. The first acoustic attenuation internal tubular piece is acoustically homogeneous, is of the resonator type, and has no internal assembly fish-plate. Additionally, the internal duct may include a tubular fan casing and a tubular transition part for connecting the air intake to the fan casing. An internal face of the tubular transition part is acoustically homogeneous also. Moreover, the internal face of the first acoustic attenuation internal tubular piece and the internal face of the tubular transition part are disposed in aerodynamic continuity.

Owner:AIRBUS OPERATIONS (SAS)

Sound absorptive protective mat

InactiveUS6983822B2Improve acoustic propertiesNoise reduction installationsVehicle arrangementsEngineeringSound Absorber

Owner:AUTONEUM MANAGEMENT AG

Passive acoustic barrier

A capsule contains fluid and a solid inertial mass that is free to move within the capsule. The capsule is embedded in a foam panel. A plurality of such foam panels are attached to the internal wall of a launch vehicle fairing. This device augments acoustic energy dissipation with damping the resonant frequency of the fairing to reduce the amount of energy that is transmitted into the acoustic volume contained within the wall. Incorporating a plurality of capsules respectively tuned to many frequencies provides broadband structural attenuation. This abstract is provided to comply with the rules requiring an abstract, and is intended to allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

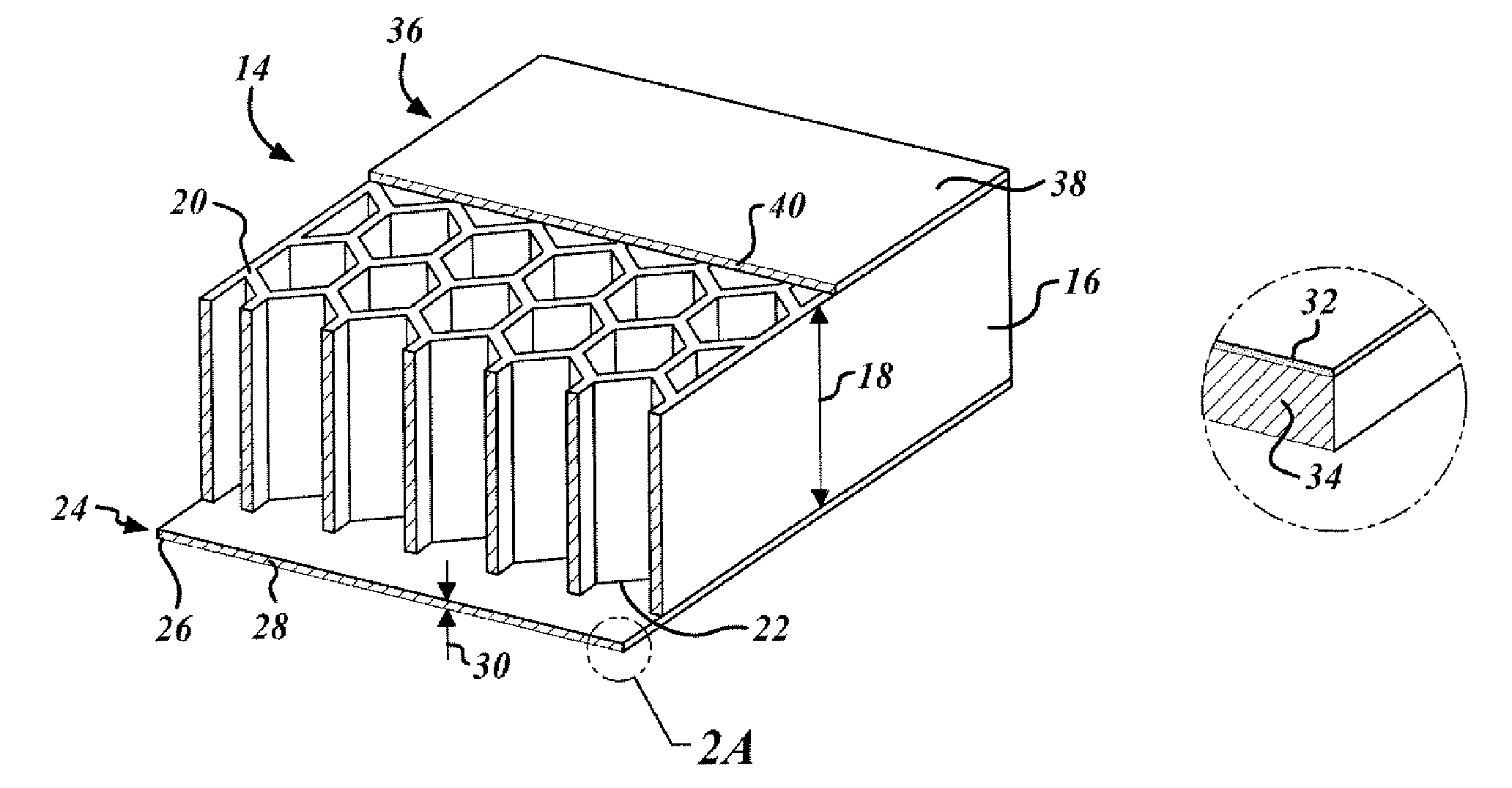

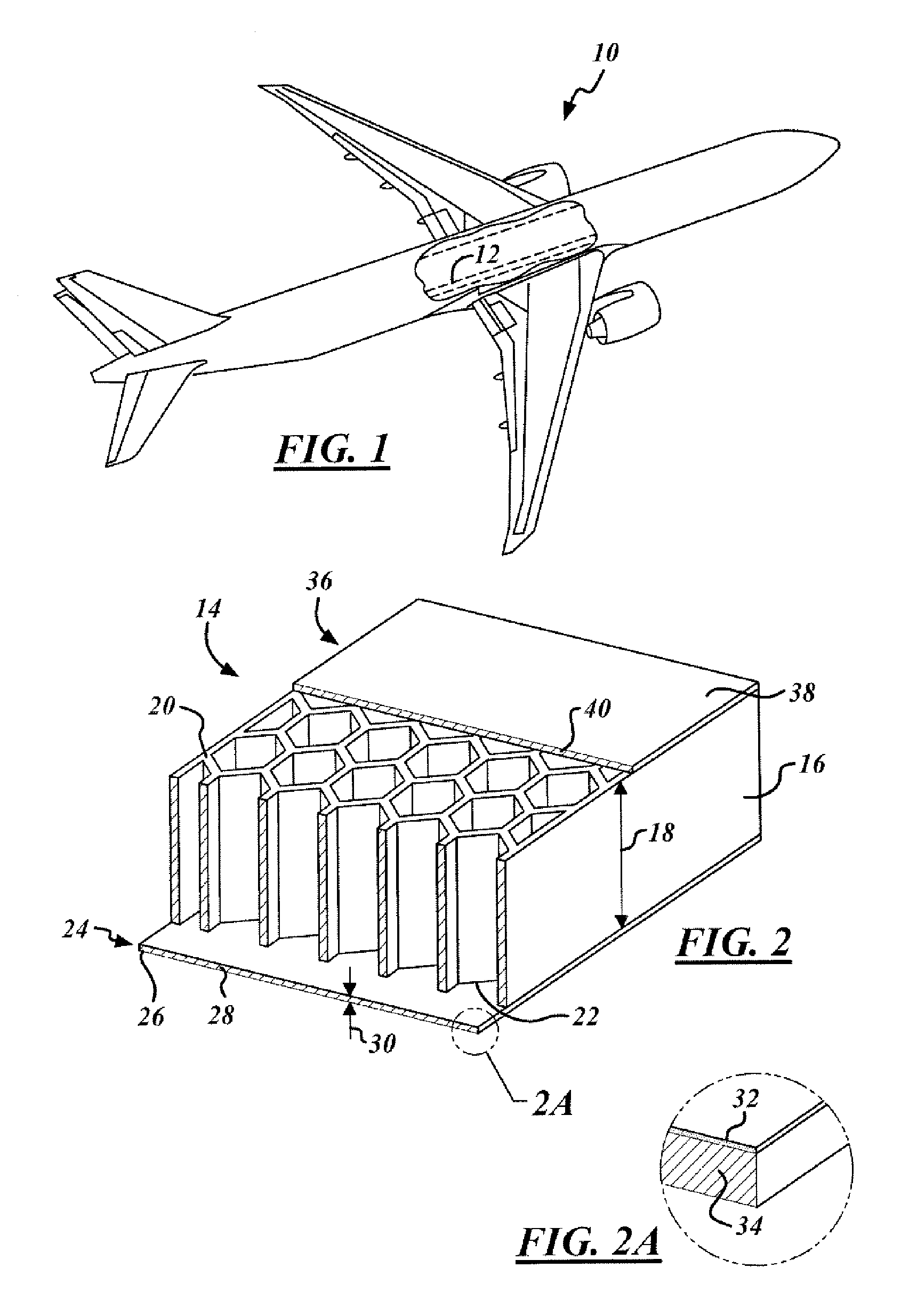

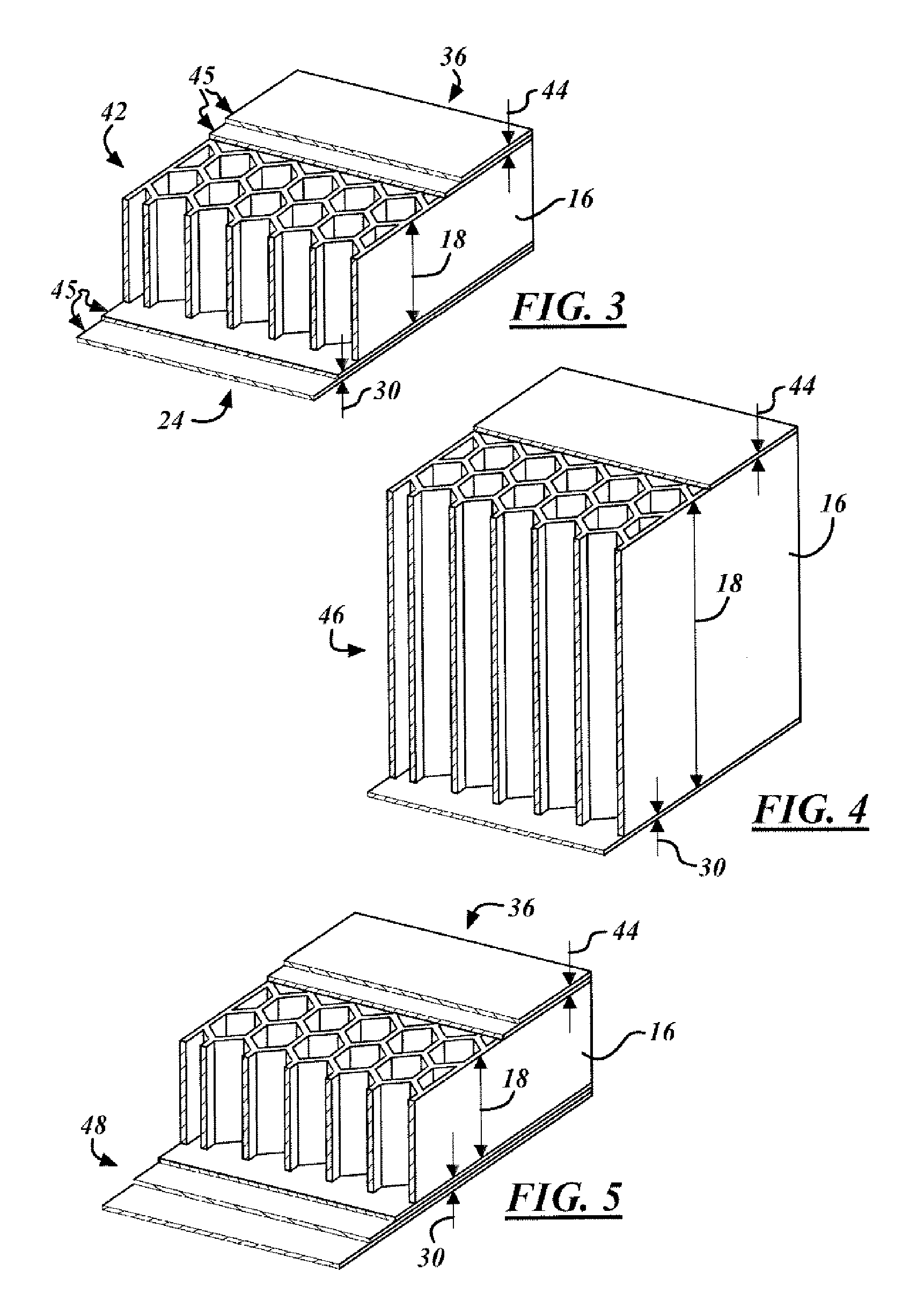

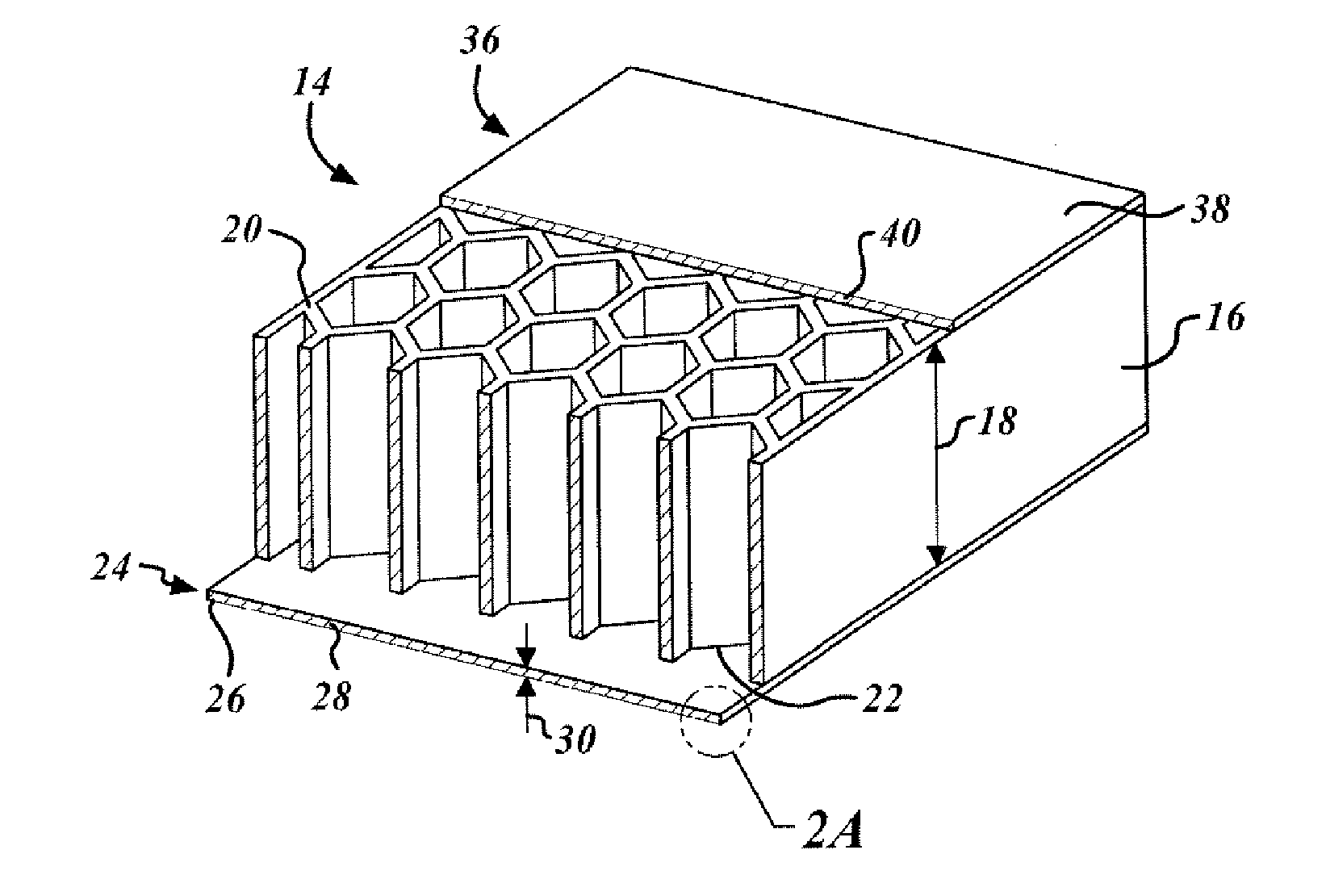

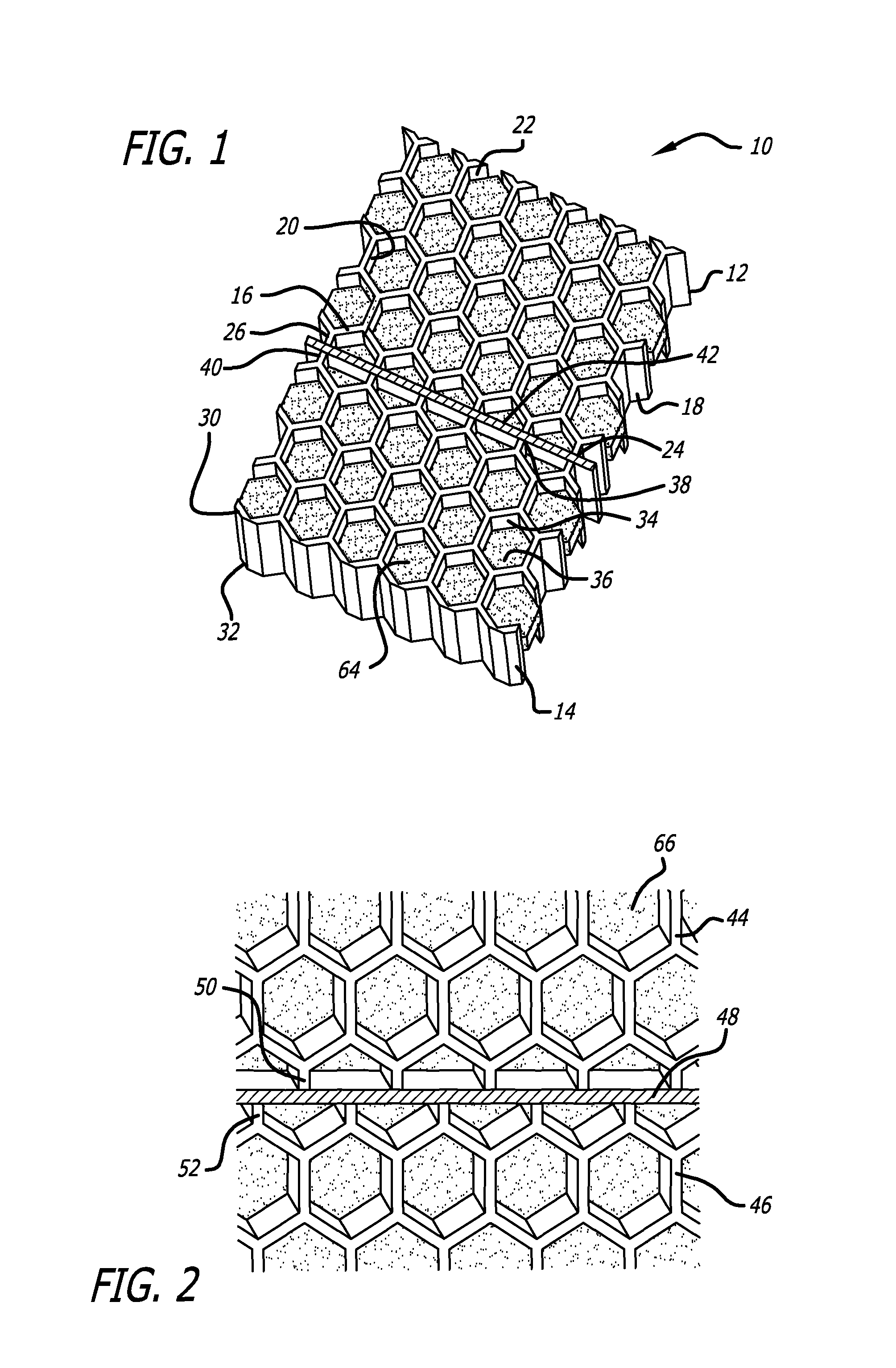

Integrally damped composite aircraft floor panels

ActiveUS20070102239A1Suppress vibration noiseNoise reduction installationsSynthetic resin layered productsEpoxyHoneycomb

In accordance with the present invention an aircraft floor panel is provided comprising a honeycomb core element having an upper core surface, a lower core surface, and a core thickness. An upper face sheet assembly is mounted to and seals the upper core surface and includes at least one upper material sheet impregnated with an upper epoxy resin. A lower damping face sheet assembly is mounted to and seals the lower core surface and includes at least one lower material sheet infused with a highly damped lower epoxy resin. The lower damping face sheet assembly dampens vibrational noise.

Owner:THE BOEING CO

Acoustic liner for gas turbine engine

InactiveUS7124856B2Low costEasy maintenanceCeilingsNoise reduction installationsEngineeringGas turbines

A passive acoustic liner system (50) for attenuating a sound field comprising, in acoustic series, a mode-scattering segment (48) and a sound-absorbing segment (40), wherein the mode scattering segment (48) provides a reactance between −12 and −2 ρc and the sound absorbing segment (40) provides a reactance between −1 and 0 ρc thereby providing a reactance discontinuity such that mode-scattering of the sound field enables the sound-absorbing segment (48) to further absorb the scattered sound.

Owner:ROLLS ROYCE PLC

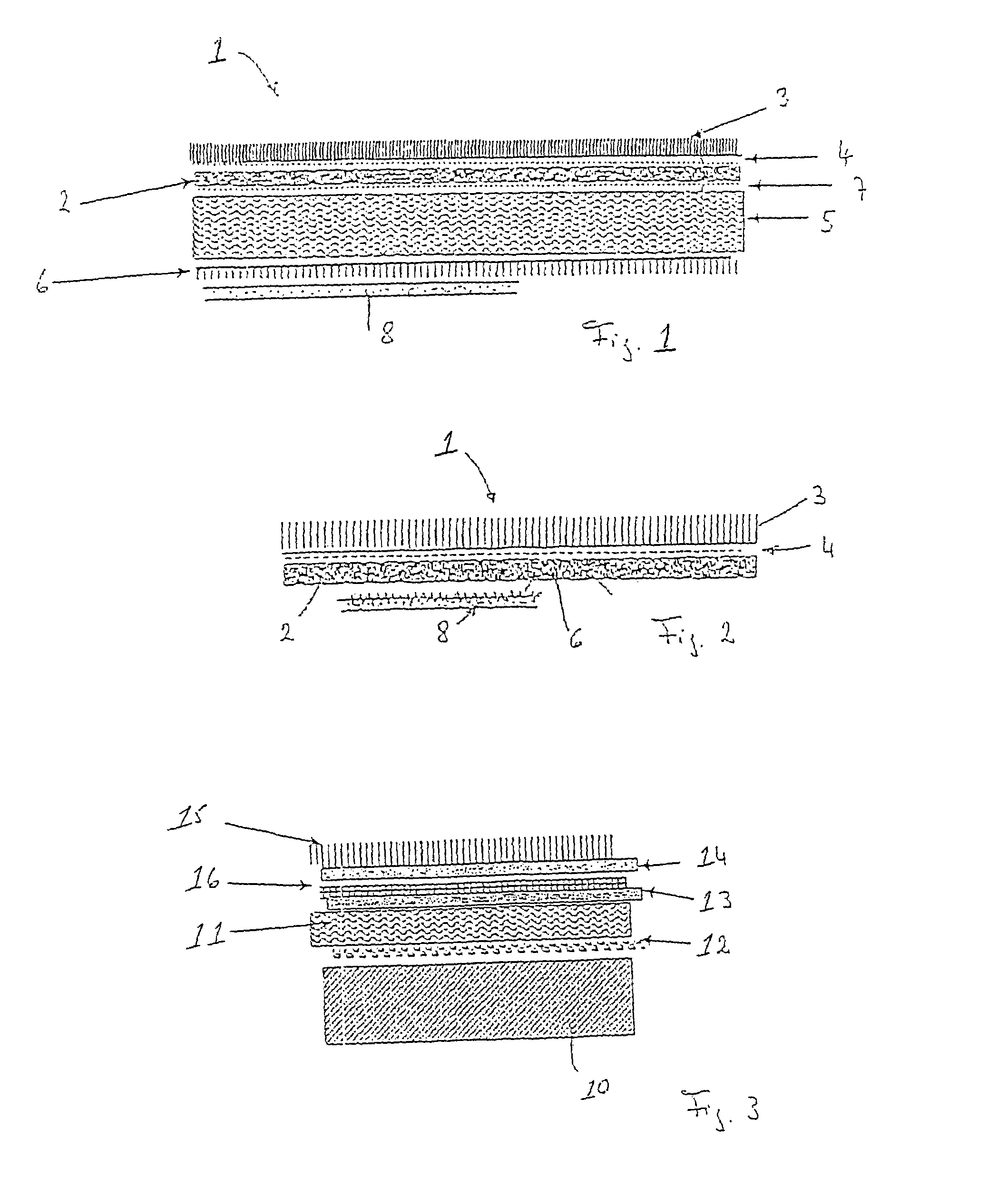

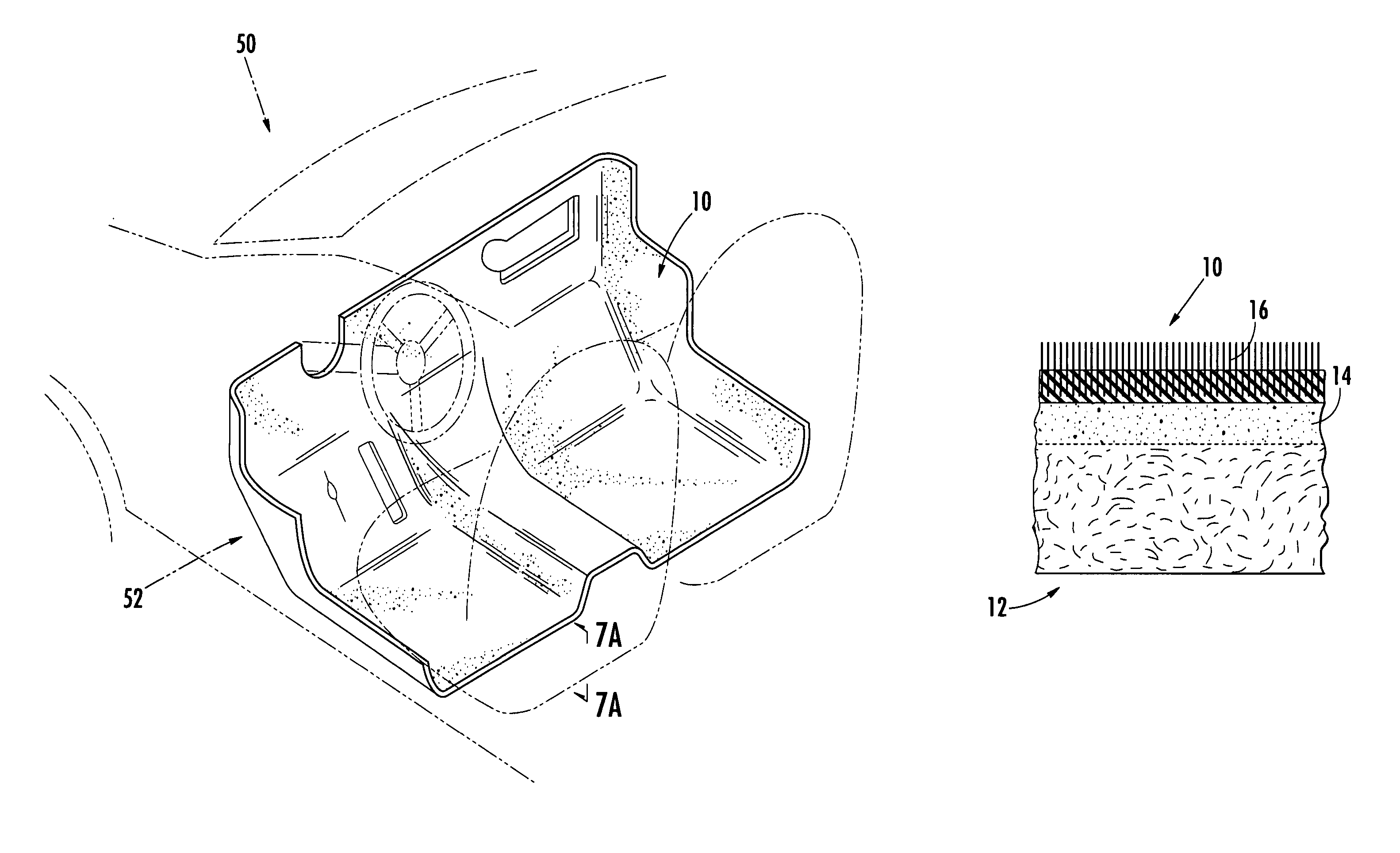

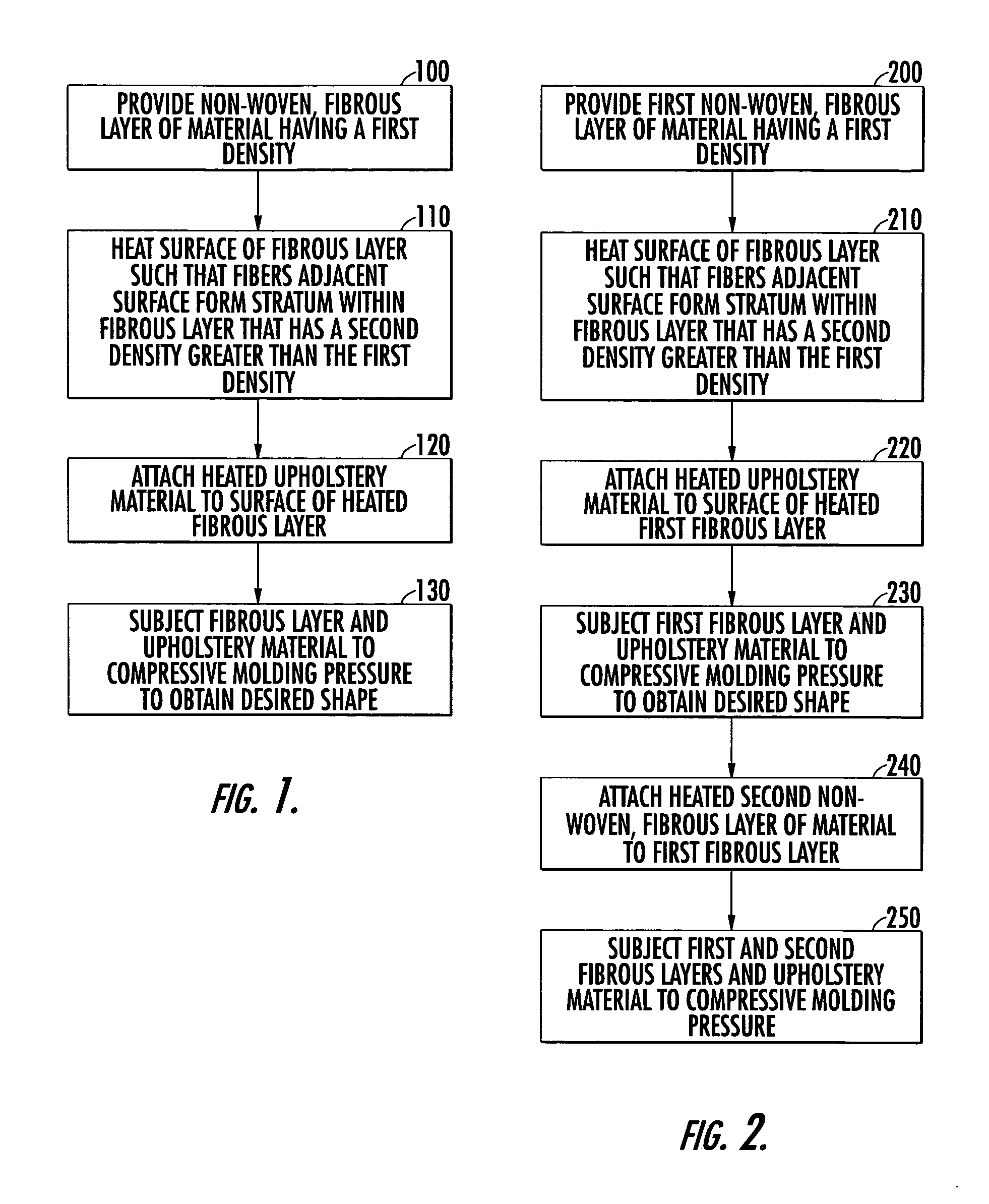

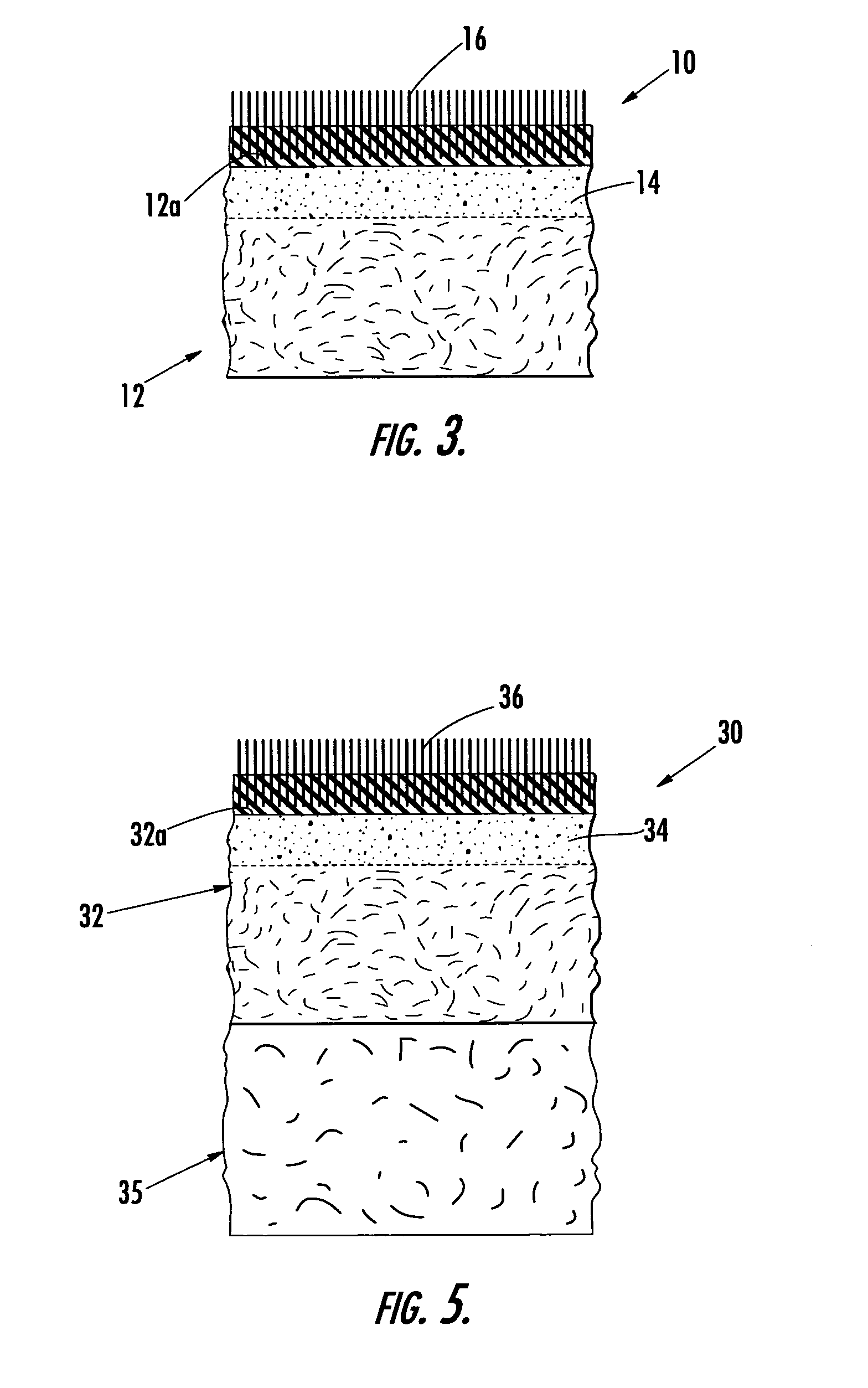

Multi-density sound attenuating laminates and methods of making same

InactiveUS7055649B2Reduce noiseEffective attenuationNoise reduction installationsVehicle arrangementsShell moldingMetallurgy

Sound attenuating laminates, and methods of making the same, are provided. Heat is applied to a surface of a non-woven, fibrous layer of material to form a stratum of melted fibers having a density greater than that of the remainder of the fibrous layer. The density of the melted fibers is effective in attenuating noise traversing the fibrous layer of material. Upholstery material, such as carpeting, is attached to the surface of the heated fibrous layer. The fibrous layer and upholstery material are then subjected to compressive molding pressure to obtain a desired shape. The compressive molding pressure may further tune the sound attenuating properties of the fibrous layer by selectively changing the densities of portions of the fibrous layer.

Owner:AURIA SOLUTIONS UK I LTD

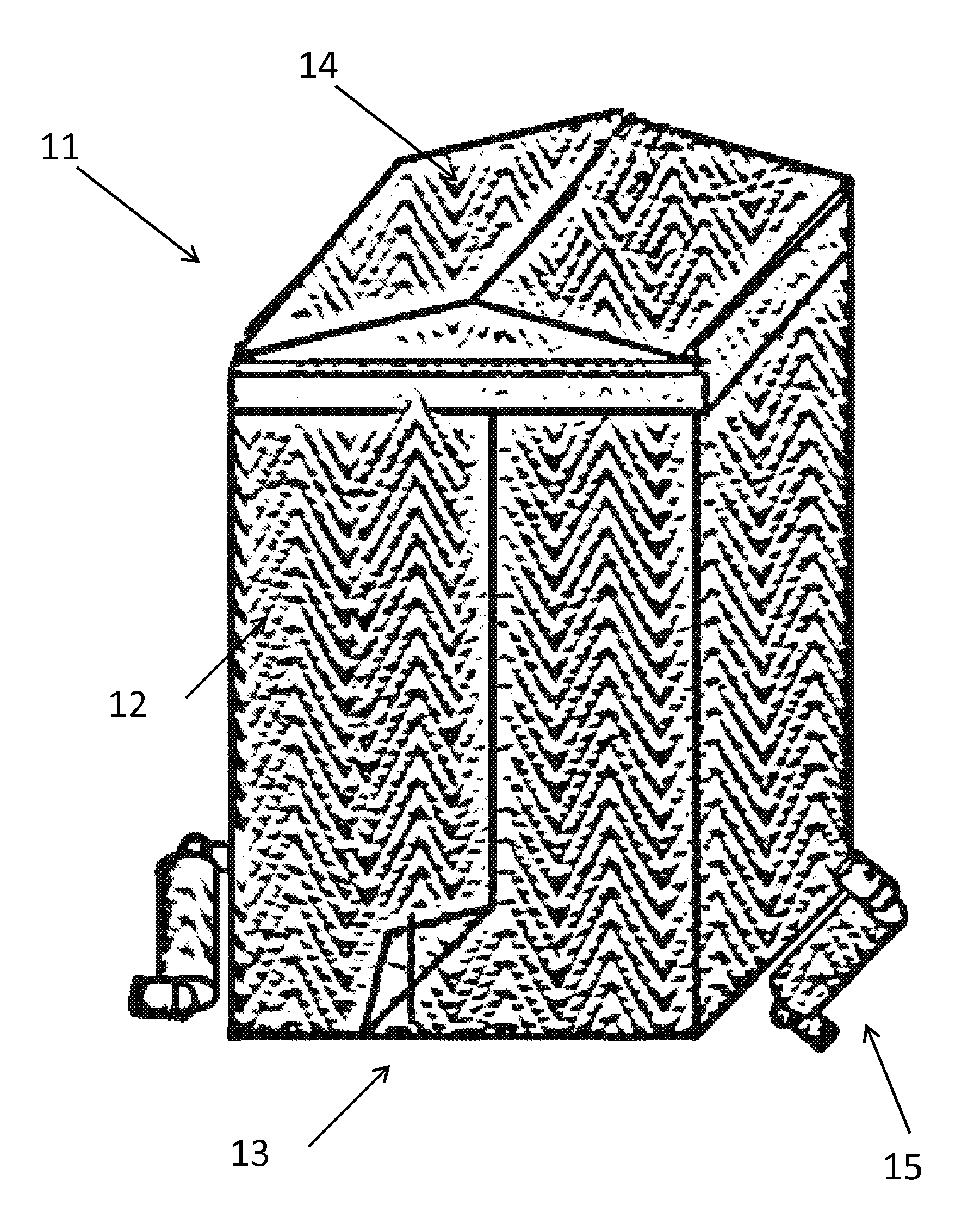

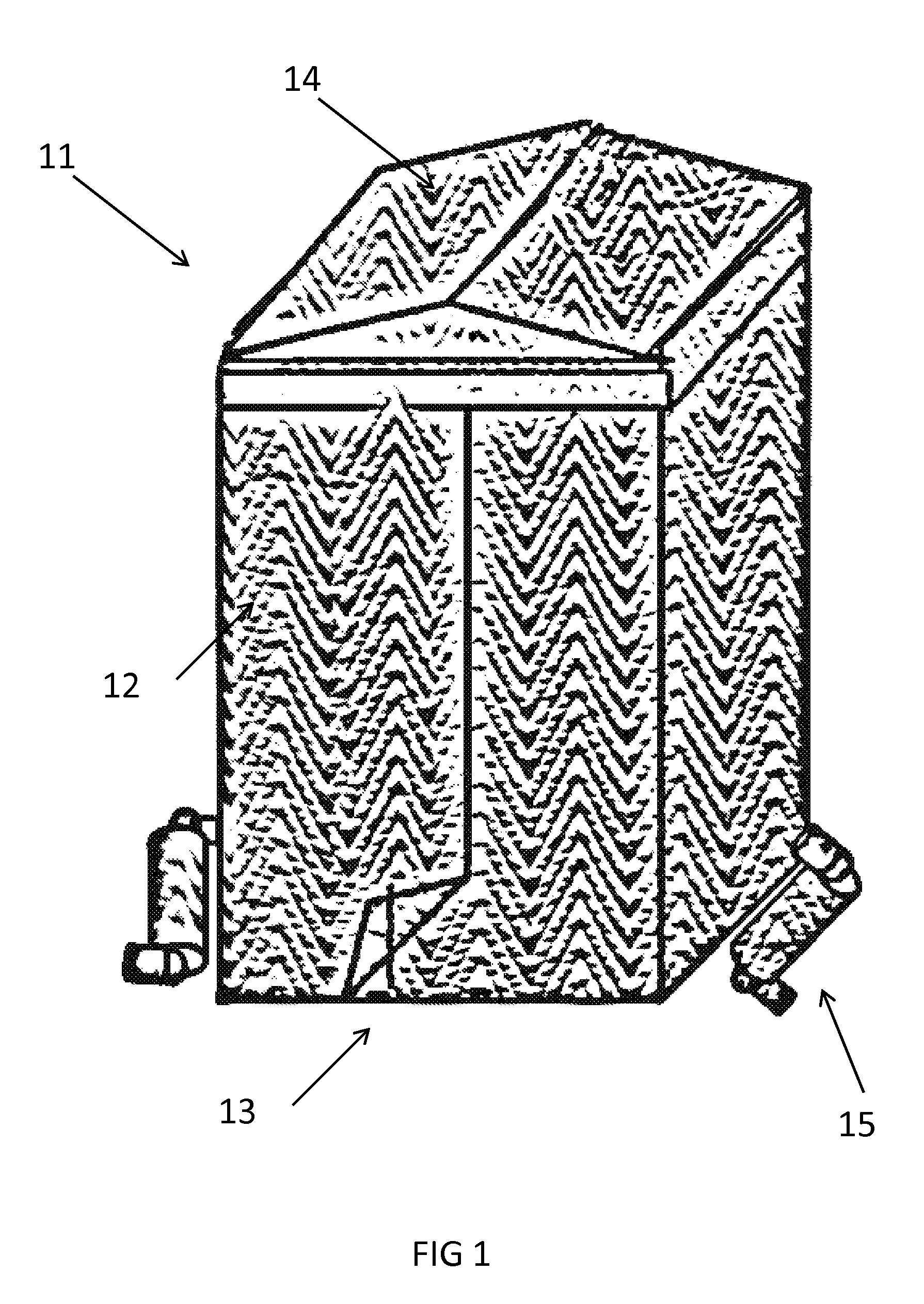

Mobile soundproof enclosure with changeable room geometry and optional ventilation noise cancelling device

InactiveUS8136626B1Easy to disassembleImprove sound insulationNoise reduction installationsLighting and heating apparatusDouble wallEngineering

Mobile soundproof enclosure with changeable internal room shape and optional ventillation noise cancelling device consisting of a frame that can be assembled and disassembled by a single person without using tools and that in disassembled state is small enough to fit in a trunk of a car; a cover made with flexible sound absorbent sheet material creating completely enclosed room with double walls with air space in between, corner sound traps made with flexible sound absorptive sheet material that can be individually positioned to change internal shape of the room and an air vent noise cancelling device made with flexible sound absorbing sheet material having inlet portion, which enters a center portion at an angle, the center portion larger than the inlet portion and outlet portion which exits the center portion at an angle; the whole enclosure can be disassembled to compactly fold for easy storage or transportation.

Owner:ALIEV ADIL ALIYEVICH

High pressure drop muffling system

ActiveUS20120006615A1Noise reduction installationsEngine fuctionsVena contracta diameterHigh pressure

A system for venting a high-pressure flow stream is disclosed, the system comprising a device having a plurality of orifice plates, each orifice plate having a plurality of orifices, wherein the plurality of orifice plates are oriented relative to each other such that the pressure of the flow stream substantially drops.

Owner:GENERAL ELECTRIC CO

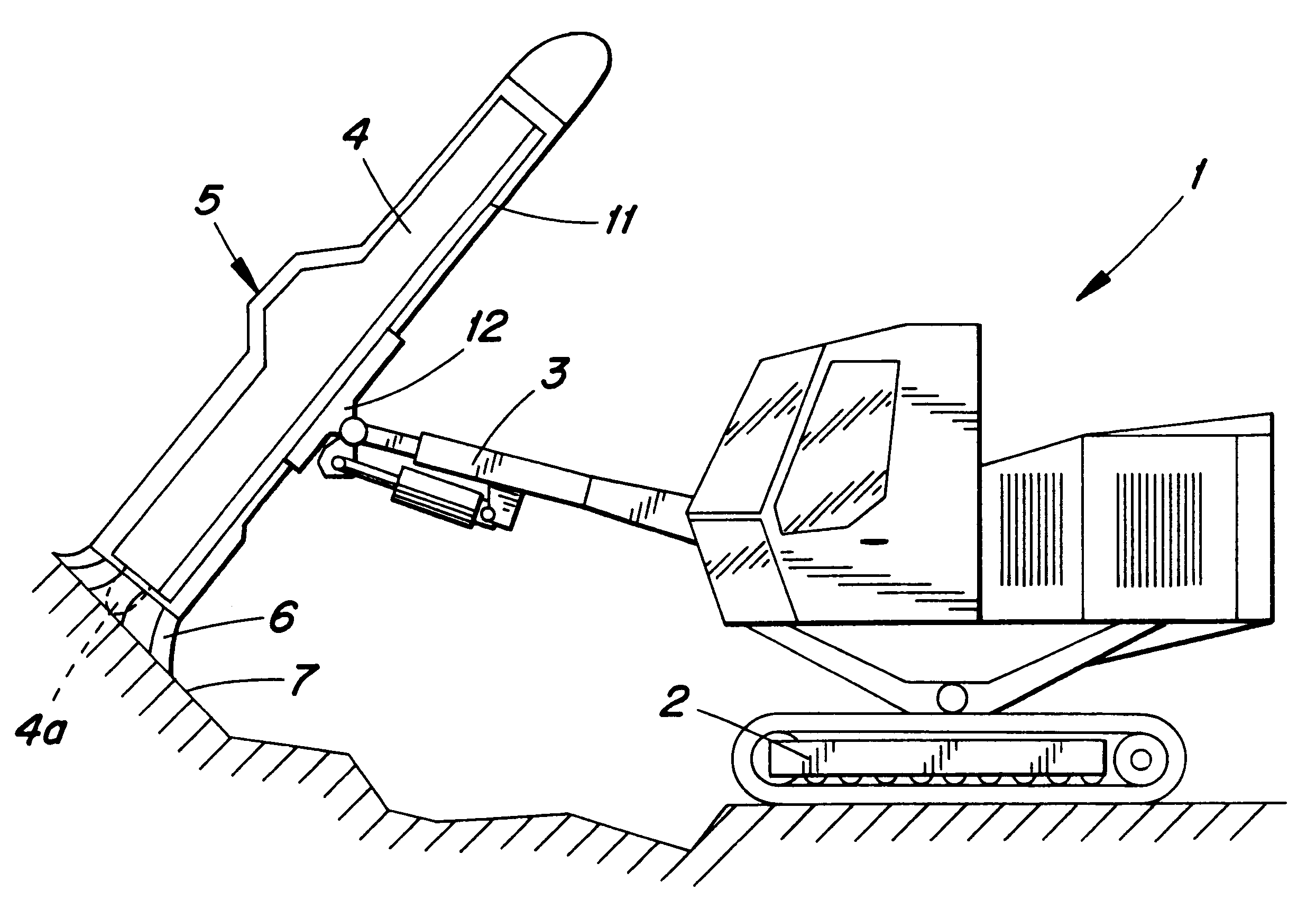

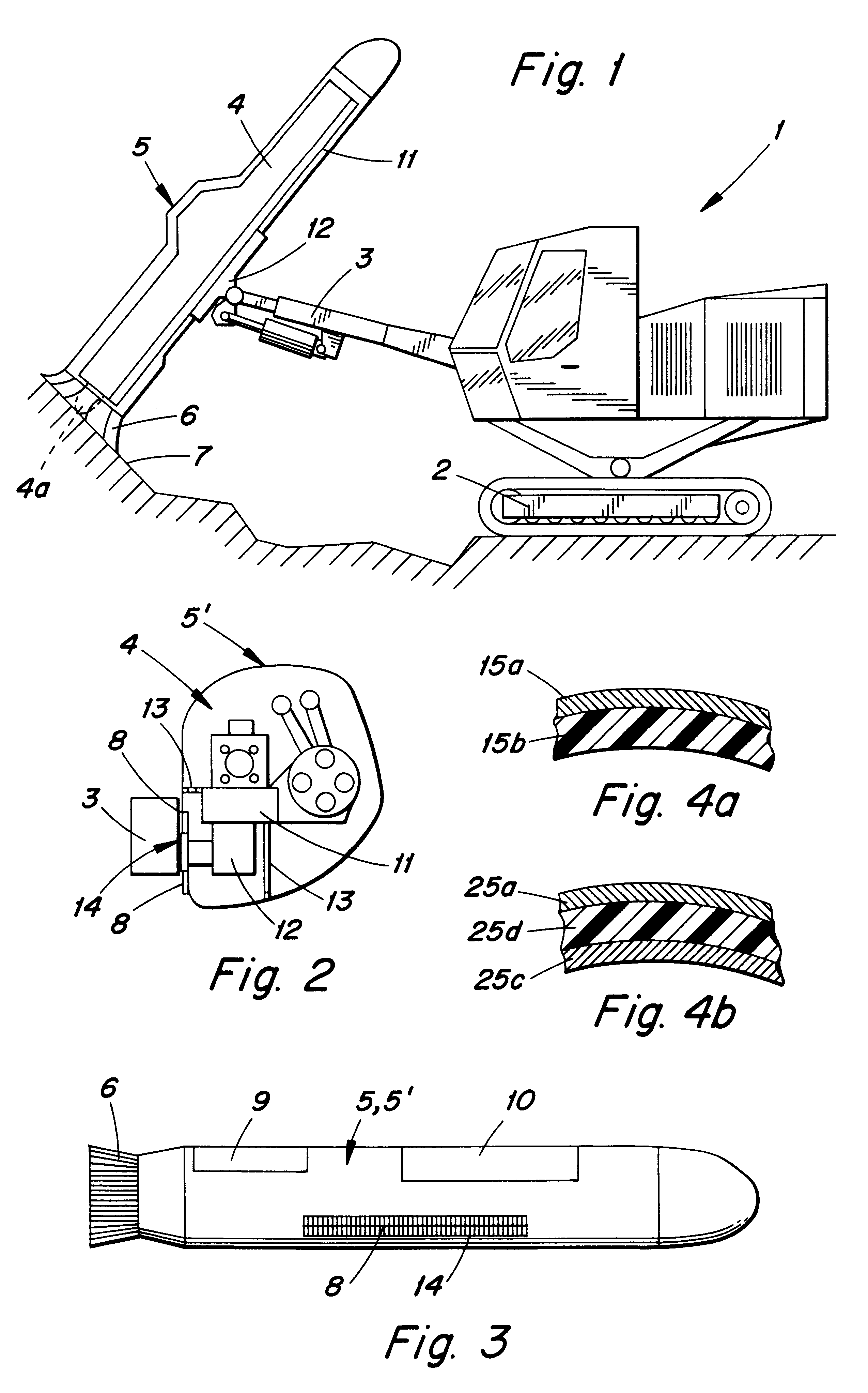

Casing for noise attenuation in a rock drilling rig

InactiveUS6199656B1Avoid noiseDegree of utilization can be raisedEarth drilling toolsNoise reduction installationsWell drillingEngineering

A rock drilling rig includes a movable carrier with a boom attached to it and movable in various ways. The free end of the boom is provided with drilling equipment. The drilling equipment is enclosed in a casing that prevents noise generated during drilling from spreading to the surroundings. The casing is arranged to move together with a feed beam and relative to the cradle mounted on the end of the boom. A flexible noise attenuating skirt projects forwardly from a front end of the casing for forming a sealed chamber around a drilling head.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

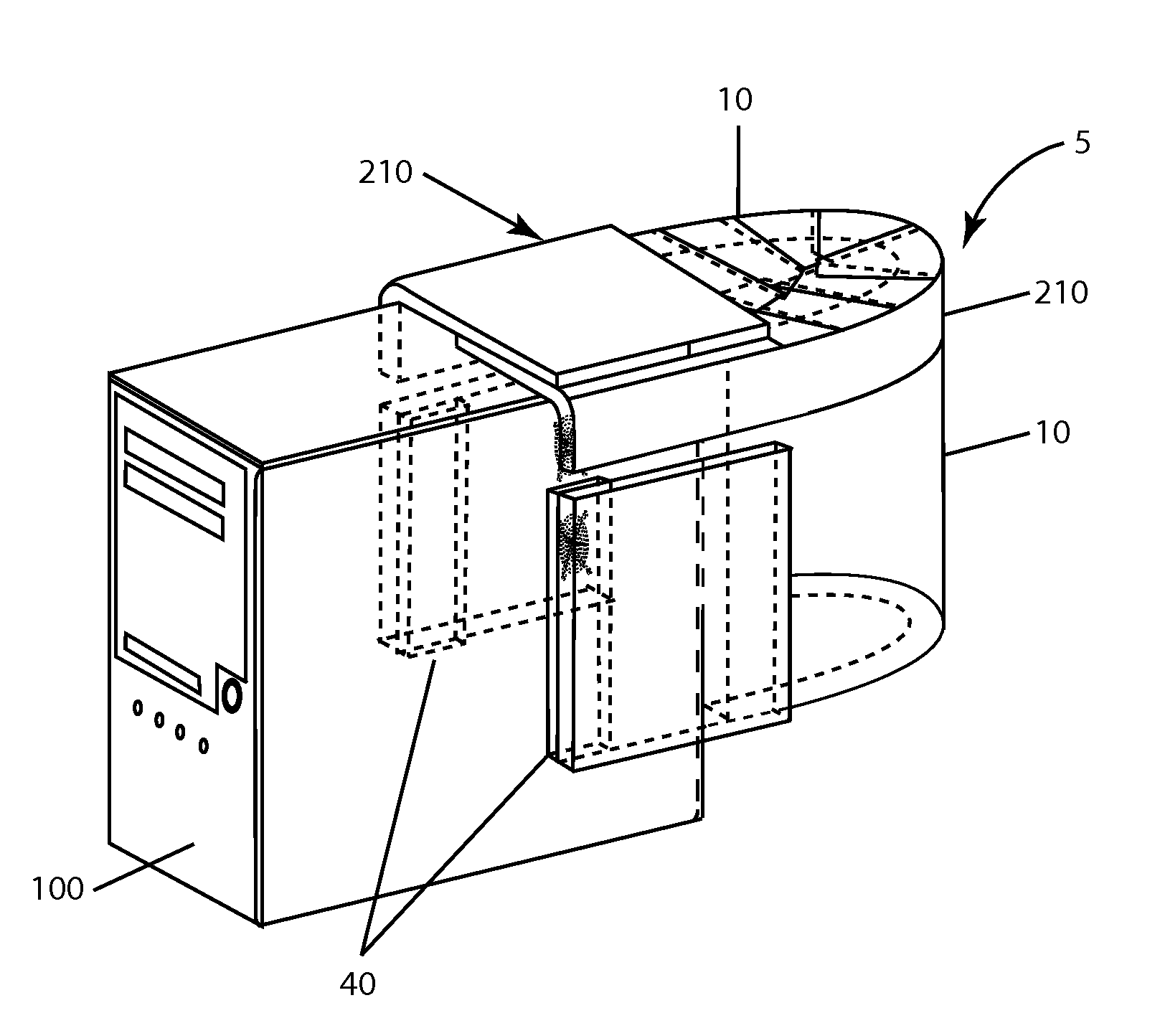

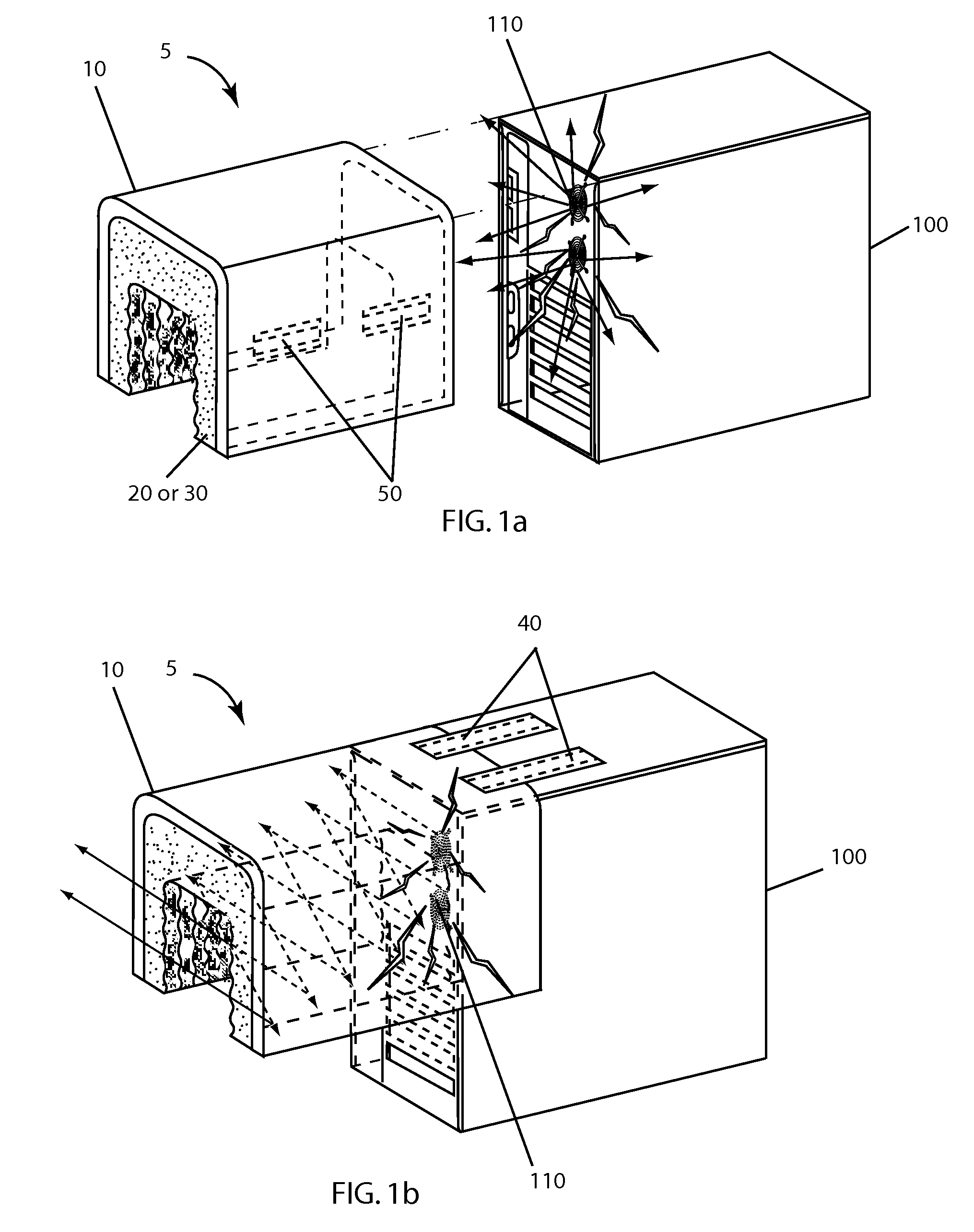

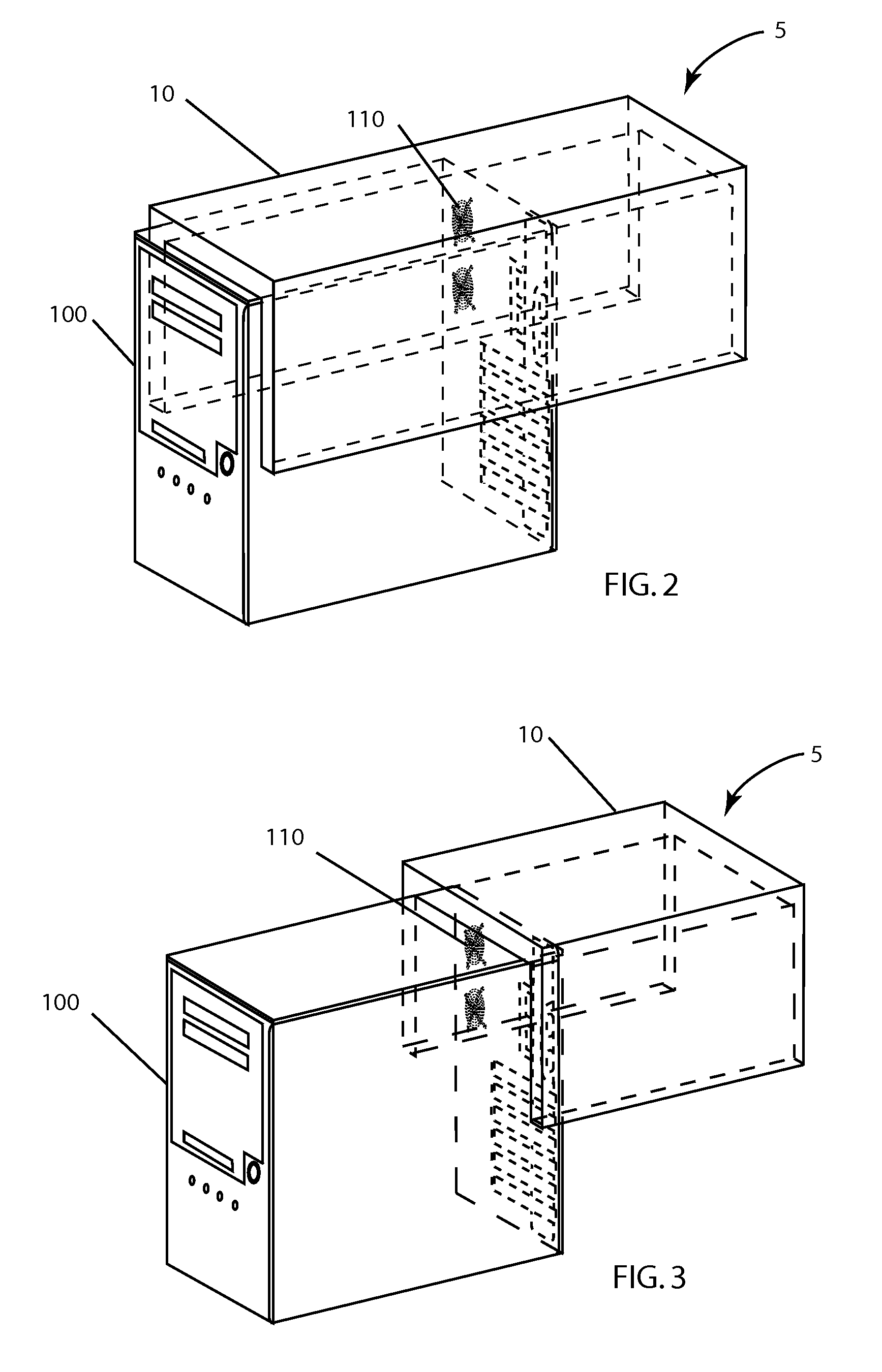

Acoustic noise reduction device for electronic equipment, including personal computers

An acoustic noise reduction accessory device is attachable to or integral with a personal computer or other electronic equipment. The device reduces acoustic noise emitted from the rear of the equipment, in particular the acoustic noise from fans. The device comprises an acoustic barrier or shielding member. The barrier is shaped in various forms external to the computer or integrally extending from its back around one or more fans of the computer so as to reduce airflow minimally. Acoustic absorbing material is layered upon the acoustic barrier and may be combined with vibration-absorbing material. The barrier may be shaped from a solid or flexible member(s) to accommodate different-sized electronics and formed to include baffles and structures to direct airflow while absorbing noise. Also it may be made adjustable by one or more slidable members. The device is easily assembled and collapsible for storage.

Owner:KAWAR MAHER S

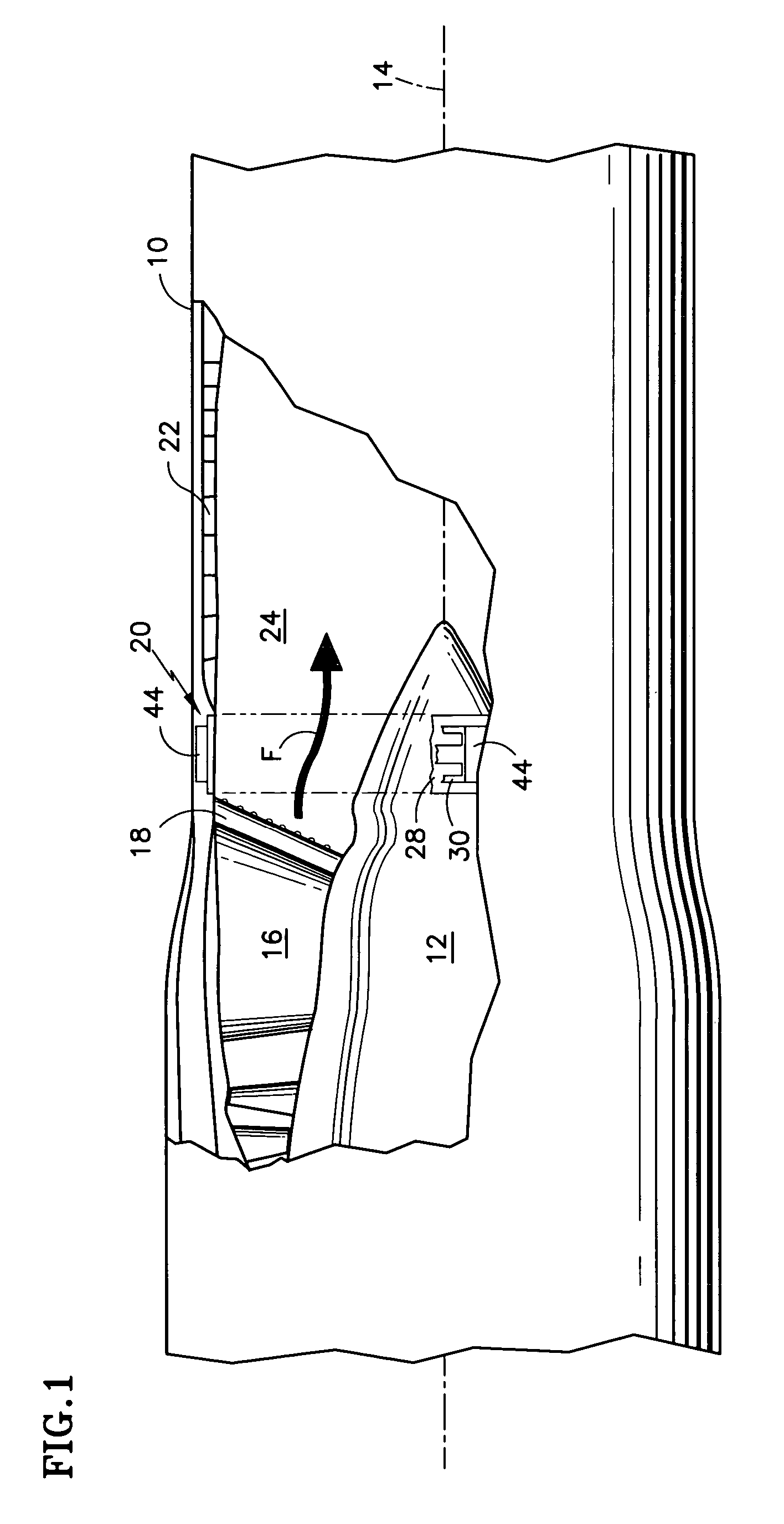

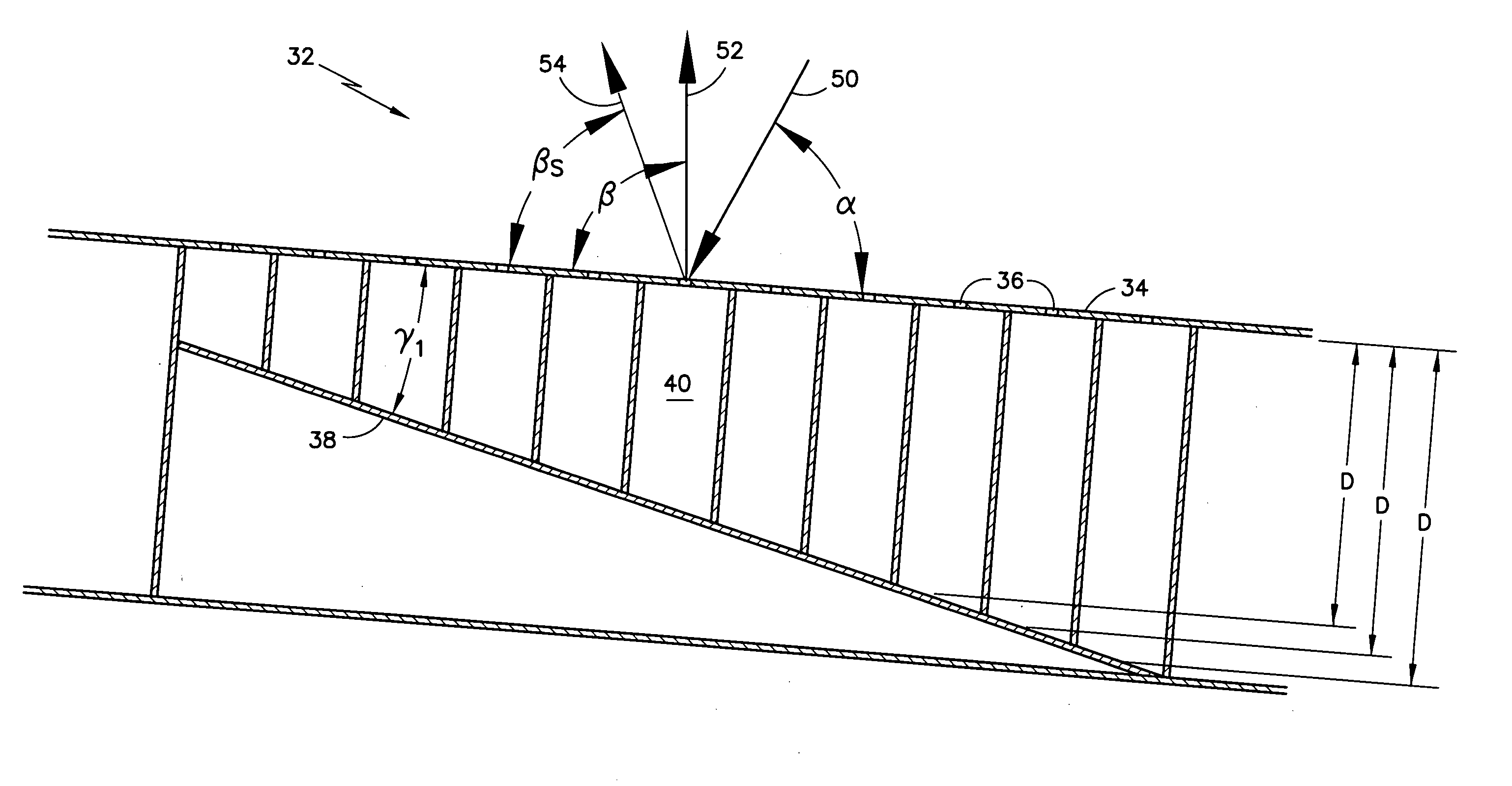

Acoustic liner with a nonuniform depth backwall

InactiveUS20060169533A1Without jeopardizing aerodynamic performanceNoise reduction installationsEngine manufactureEngineeringAcoustic wave

A fluid handling duct such as a turbine engine inlet duct 20 includes an acoustic liner 32 comprising a face sheet 34 and a backwall 38 laterally spaced from the face sheet. The backwall is offset from the face sheet by a nonuniform depth D to direct sound waves incident on the backwall in a prescribed direction relative to the face sheet. In one embodiment of the invention, the backwall comprises a ramp. In another embodiment, the backwall comprises a series of steps offset from the face sheet by different depths. The nonuniform depth of the backwall may be tailored to regulate the direction in which noise signals reflect from the backwall, thereby reducing noise propagation from the duct to the surrounding environment.

Owner:UNITED TECH CORP

Compact high-pressure exhaust muffling devices

Compact, high-pressure exhaust muffling devices are disclosed. Some example muffling devices may include an inner flow conditioner including an inlet configured to convey a pressurized fluid flow into an inner flow conditioner interior. The inner flow conditioner may include a plurality of inner flow conditioner holes. The muffling device may include an exhaust can disposed substantially around the inner flow conditioner and arranged to receive the pressurized fluid flow via the inner flow conditioner holes into an exhaust can interior. The exhaust can may include a plurality of exhaust screen holes arranged to discharge the pressurized fluid flow from the exhaust can interior. The exhaust can interior may be substantially devoid of flow obstructions between the plurality of inner flow conditioner holes and the exhaust screen holes.

Owner:GENERAL ELECTRIC CO

Heat shield and an insulating isolator for the heat shield

An insulating isolator for a heat shield has a unitary first land, a bead portion, a second land and a half bead. The first land defines a fastener aperture. In one case, a plurality of circumferentially spaced apart petals is formed in the isolator. The petals may be separated by gaps. In another case, a set of circumferentially spaced apart apertures are formed in the isolator.The heat shield may have at least two disk apertures. Two metallic disks are located in the area of at least one of the two disk apertures. The metallic disks are connected to each other, have aligned fastener openings that are smaller than the disk apertures and they are smaller than the metallic sheet. One of the metallic disks may have a bead.

Owner:DANA AUTOMOTIVE SYST GRP LLC

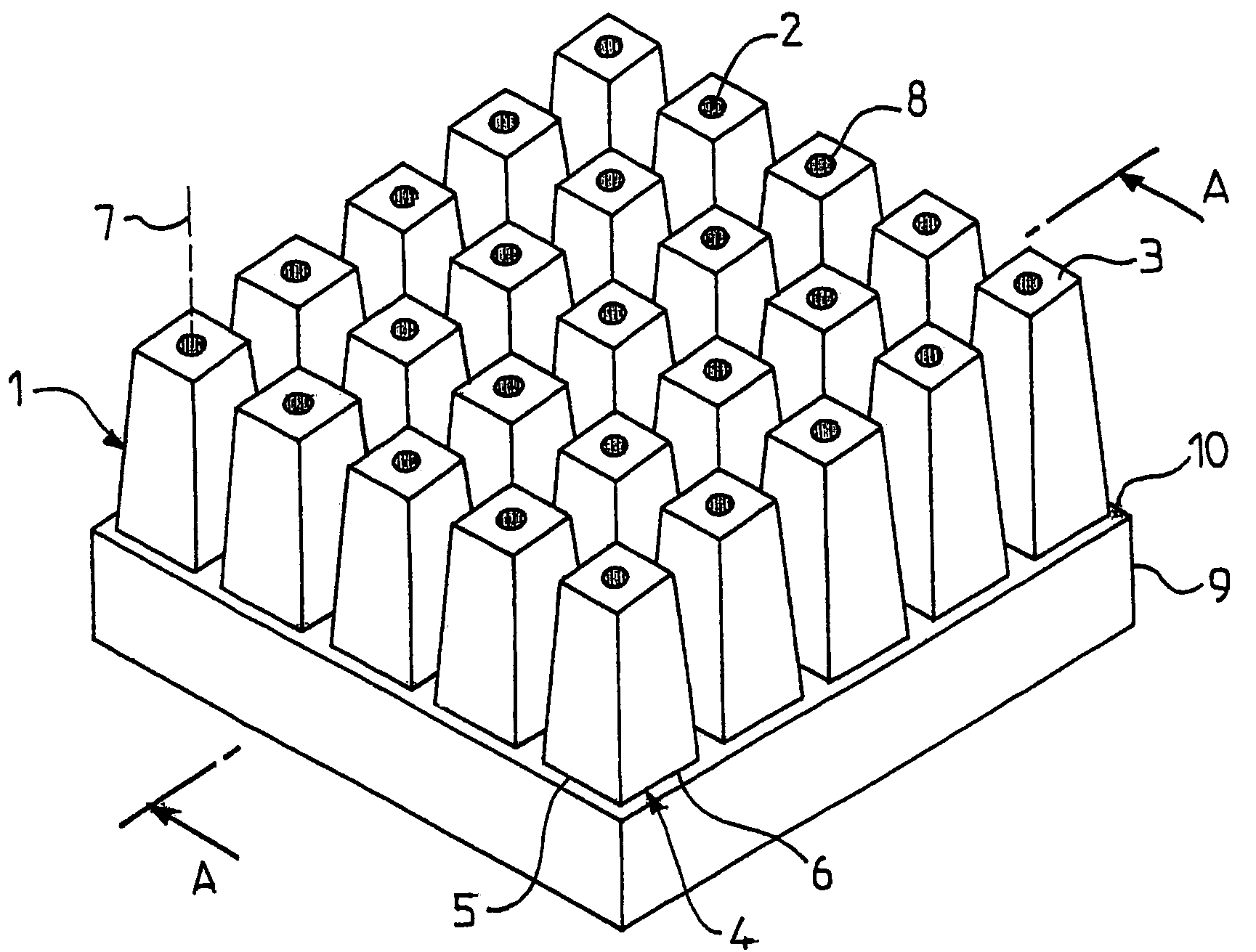

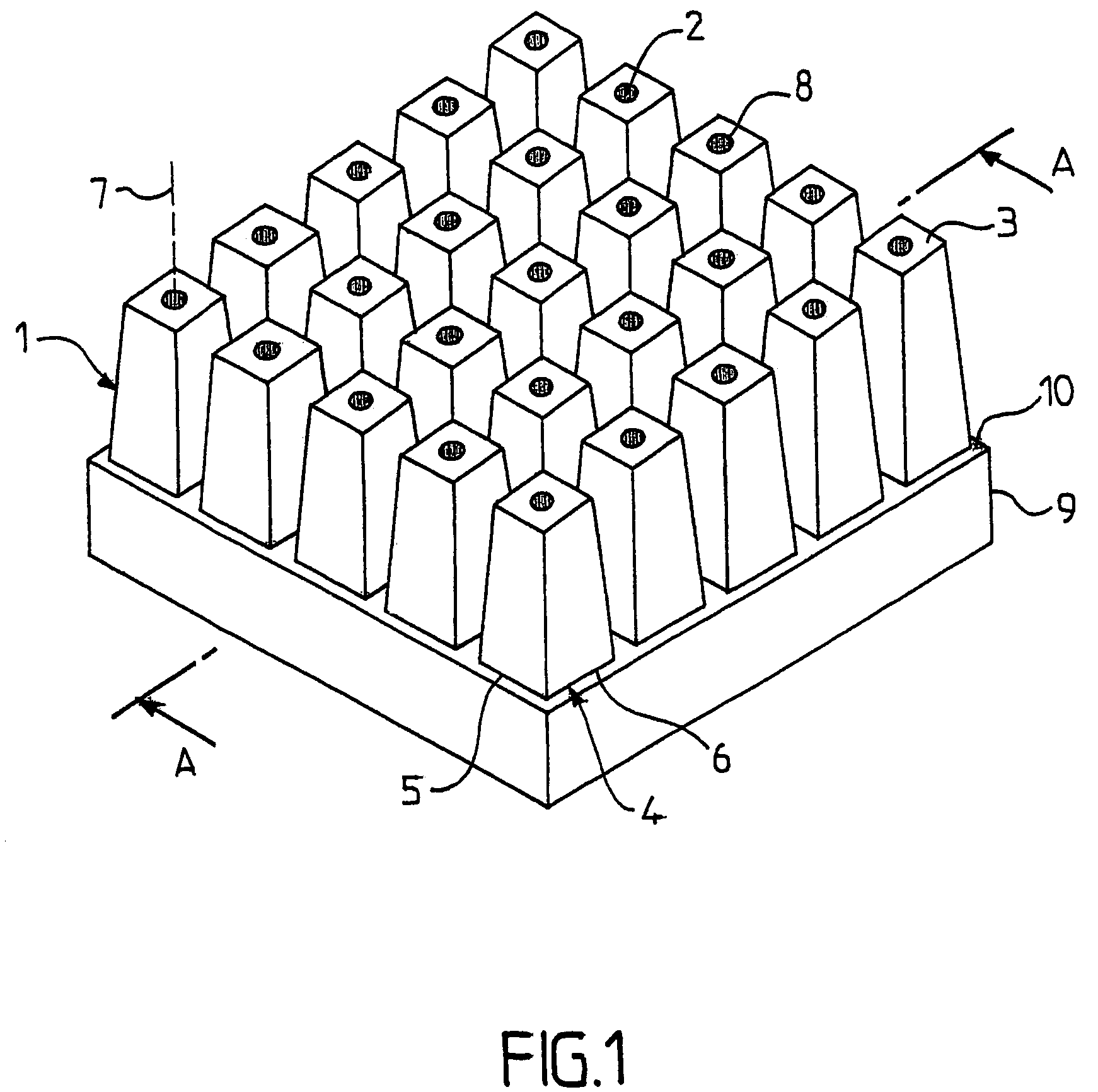

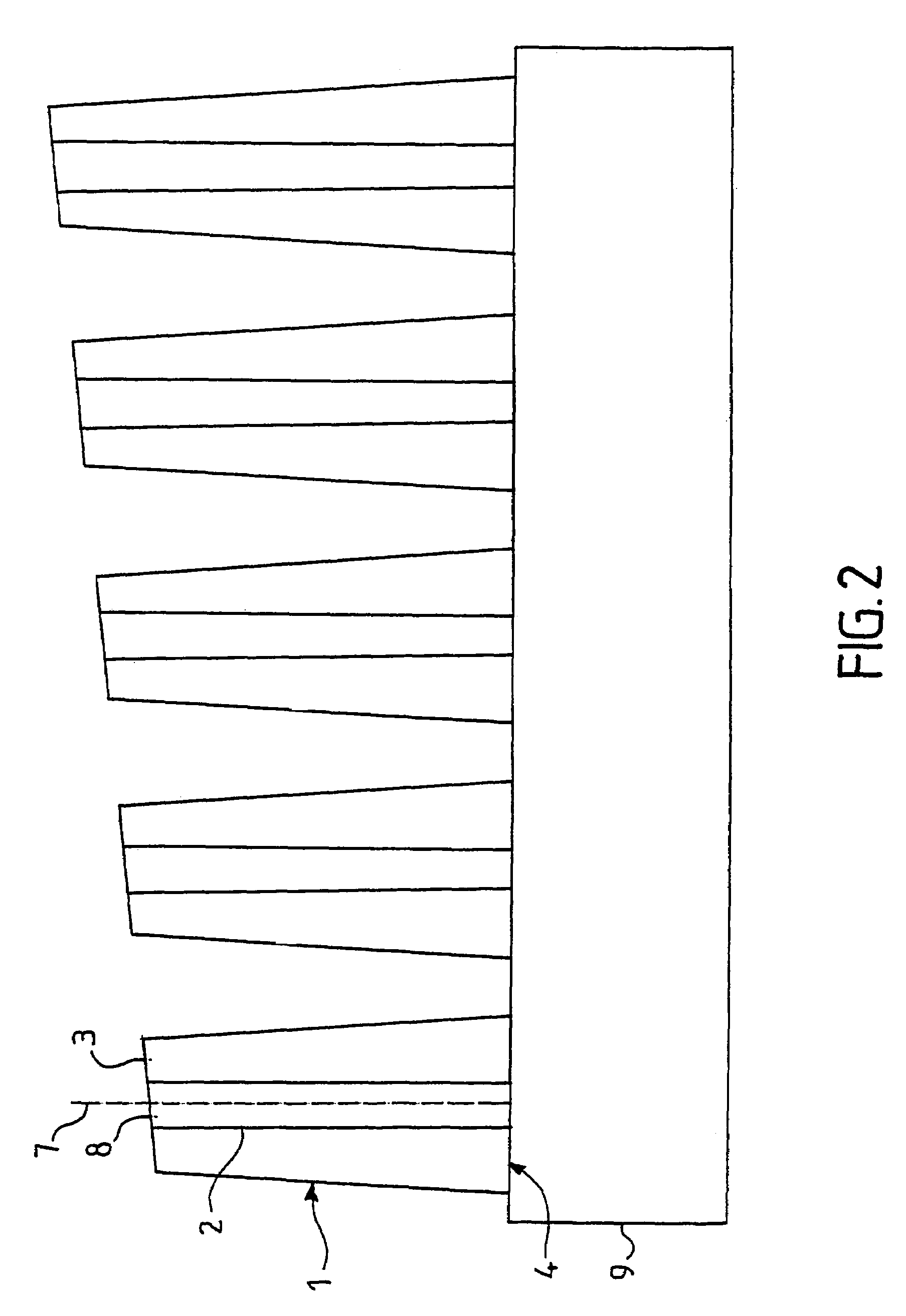

Noise abatement wall

A noise-absorbing device includes a substantially flat base and embossed and / or hollow elements each including at least one recess. This base reveals with the embossed and / or hollow elements, a configuration exhibiting a fractality zone of between 1 cm and 50 cm, of fractal dimension greater than 2.5 enabling the localization of the waves over the sound frequency range, in the vicinity of the elements.

Owner:ECOLE POLYTECHNIQUE +1

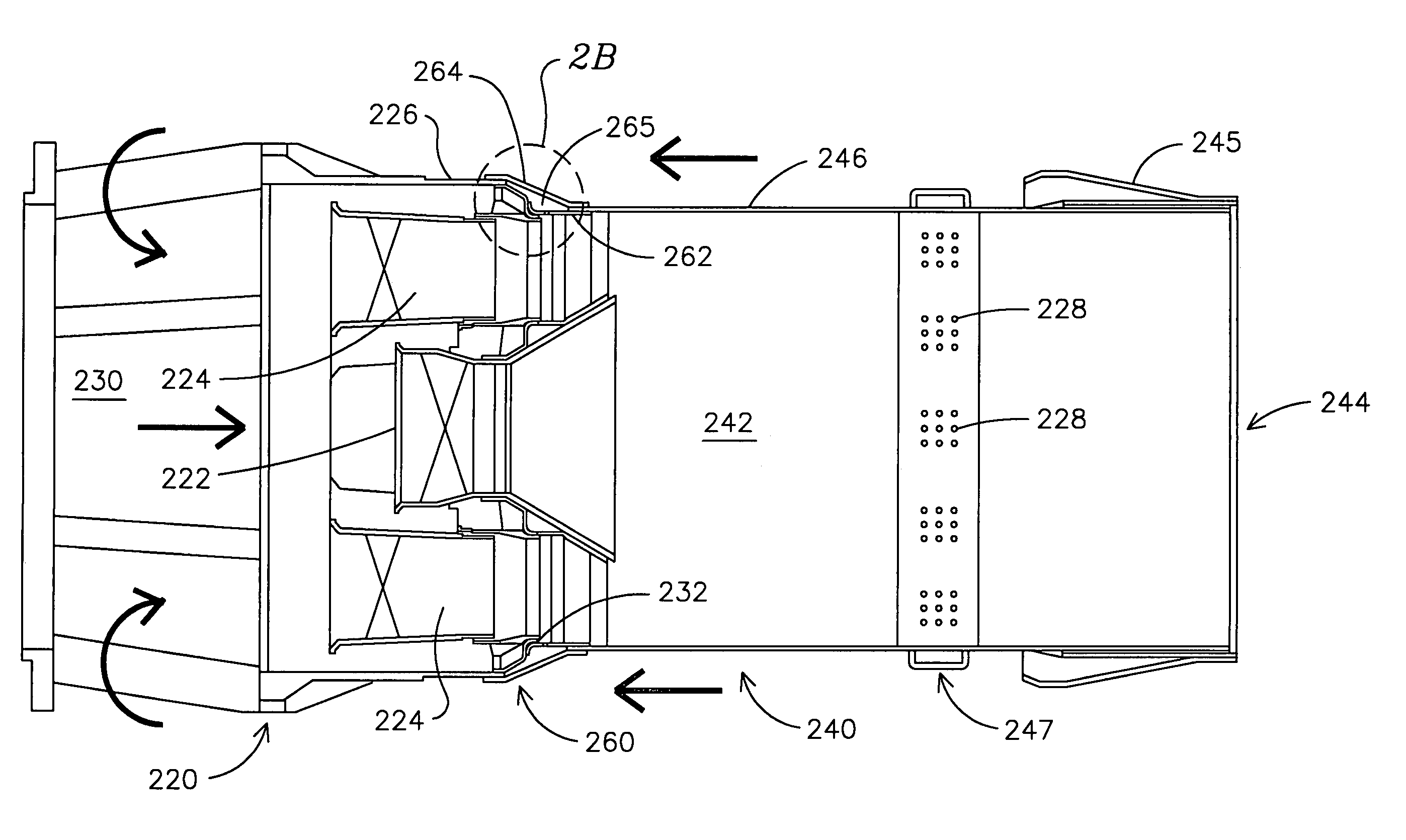

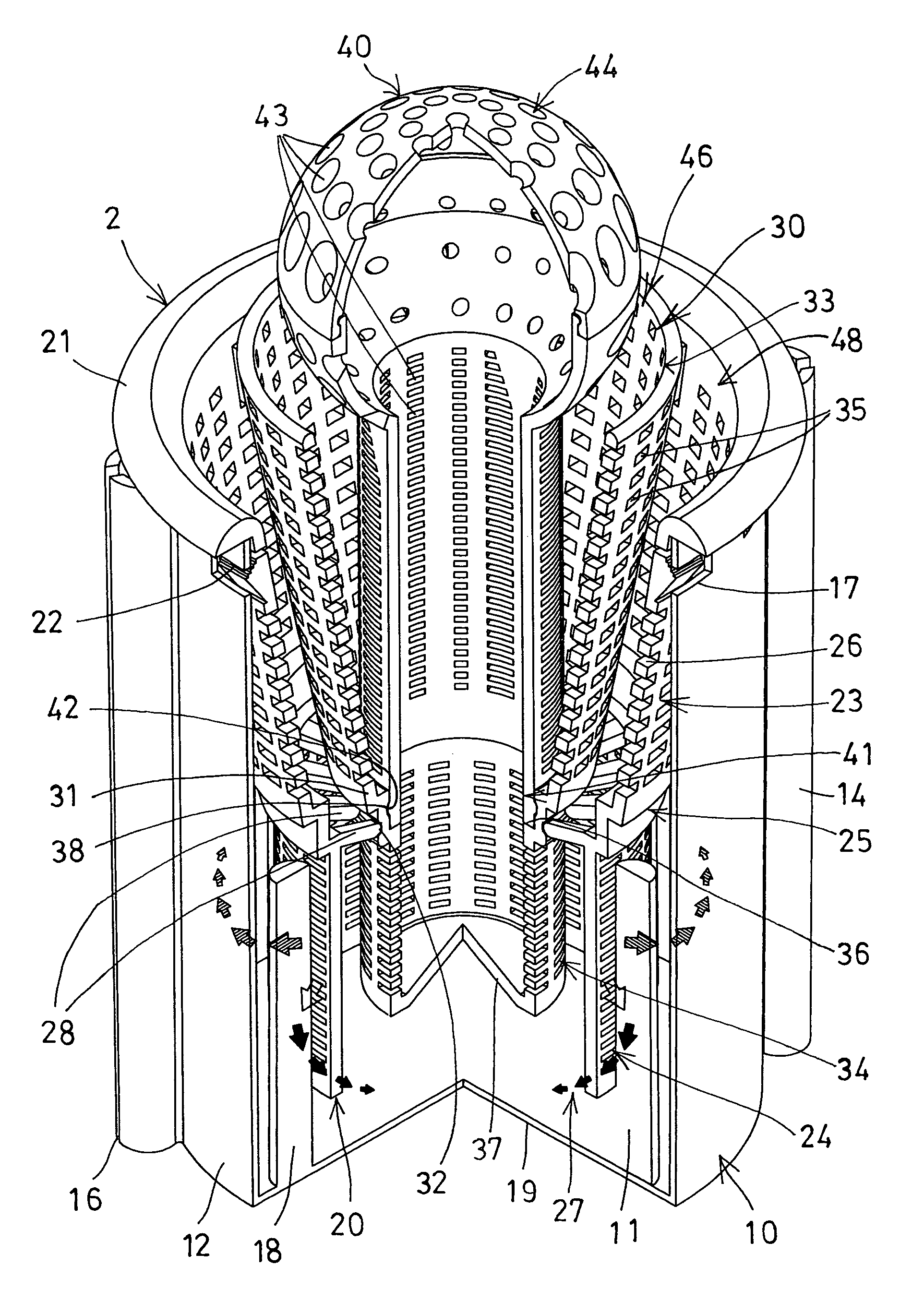

Resonator device at junction of combustor and combustion chamber

InactiveUS7788926B2Noise reduction installationsContinuous combustion chamberCombustion chamberCombustor

One or more Helmholtz-type resonators (270) is / are provided at the junction (260) of a combustor (220) and a combustion chamber (240) of a gas turbine engine (100). In one embodiment, adjacent Helmholtz-type resonators (290, 291, 292), which may be separated by respective baffles (285), have different volumes that help provide for damping different undesired combustion-generated acoustic pressure waves. In some embodiments, a structural member (435) may be provided between adjacent Helmholtz-type resonators (425, 426, 427, 428) at the junction. At least one of the plurality of Helmholtz-type resonators comprises one or more inlet openings (480), and one or more exit openings (482). Embodiments (370, 425-429) are described in which Helmholtz-type resonators provided at the junction are enlarged in size using various approaches. The positioning at the junction, upstream of the space (242) in which combustion occurs, and providing a plurality of differently sized resonators, provides for improved flexibility and resonator damping efficiencies.

Owner:SIEMENS ENERGY INC

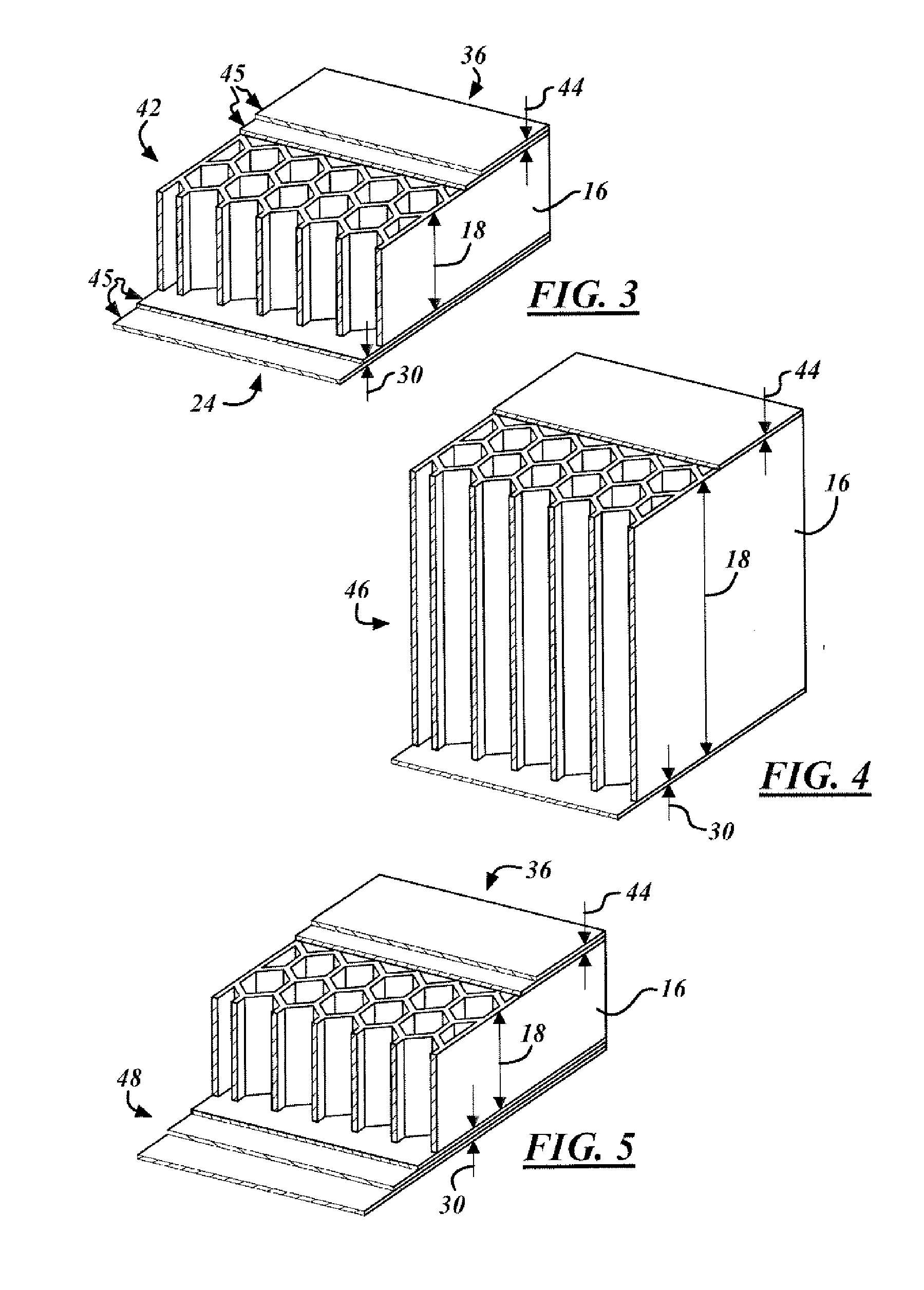

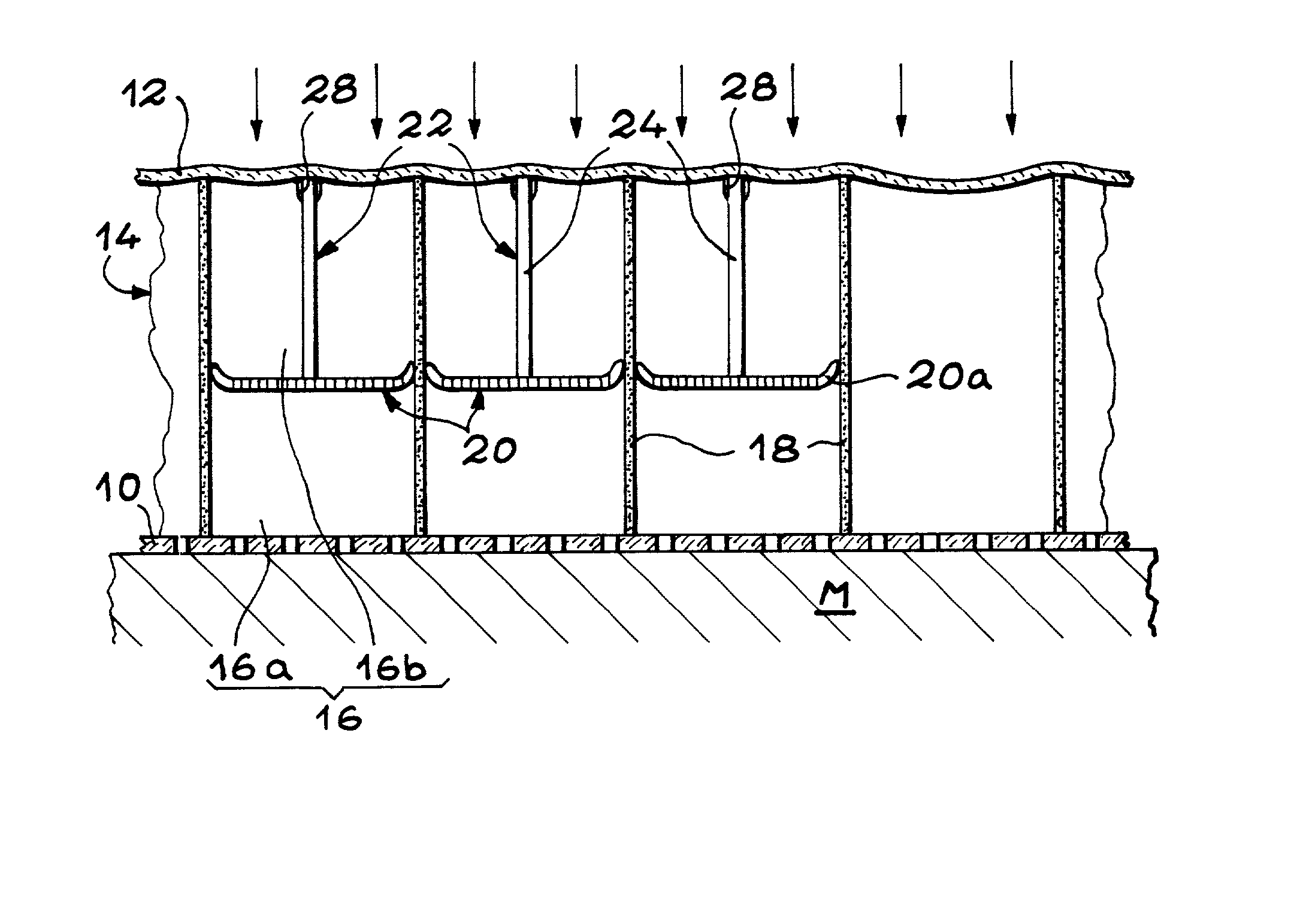

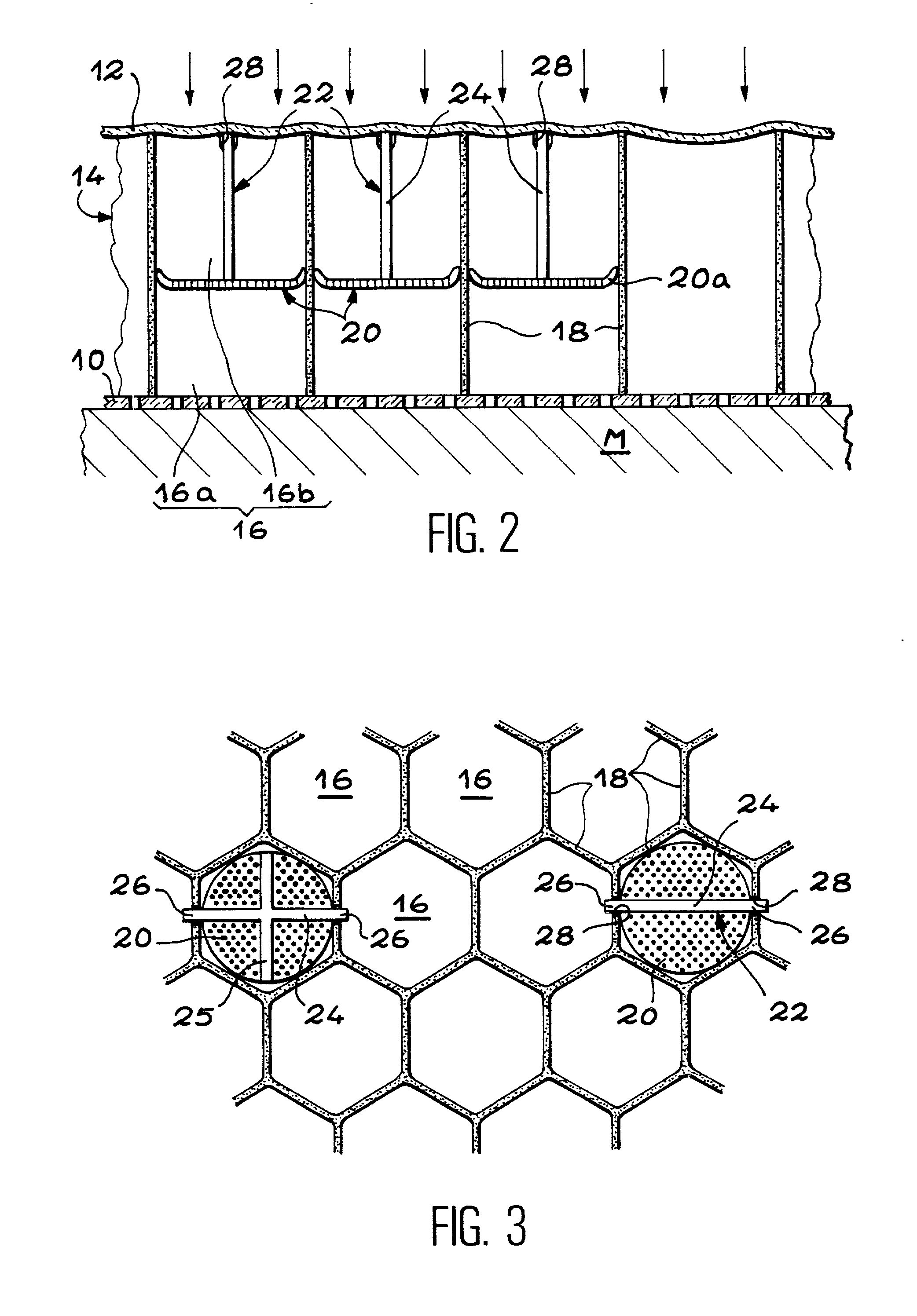

Noise reduction sandwich panel, notably for aircraft turbojet engine

InactiveUS20020050420A1The process is convenient and fastEasy and quick to placeNoise reduction installationsCeilingsRelative displacementJet engine

Noise reduction sandwich panel, notably for an aircraft turbojet engine. In order to produce a noise reduction sandwich panel having a structure with two degrees of freedom, inserted separative components (20) are placed into the hexagonal cells (16) of the unique waffle core of the panel. More specifically, the separative components (20) have an substantially circular external peripheral edge, which allows them to be easily assembled, in spite of the deformations of the walls (18) of the cells (16) due to manufacturing tolerances and to the optional forming of the waffle core. Advantageously, several separative components (20) are supported by a same positioning unit (22), which then allows relative displacement between the separative components.

Owner:AIRBUS OPERATIONS (SAS)

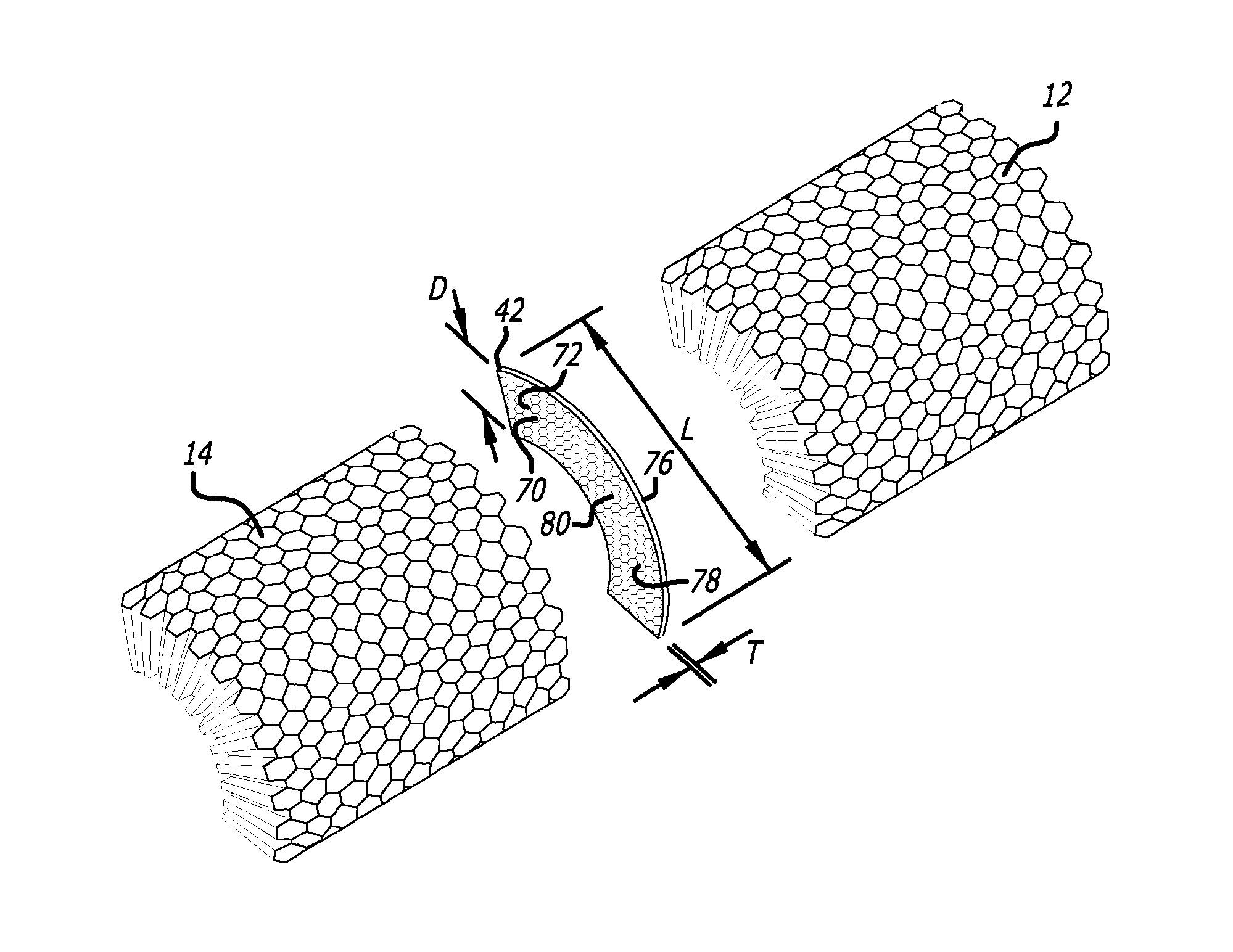

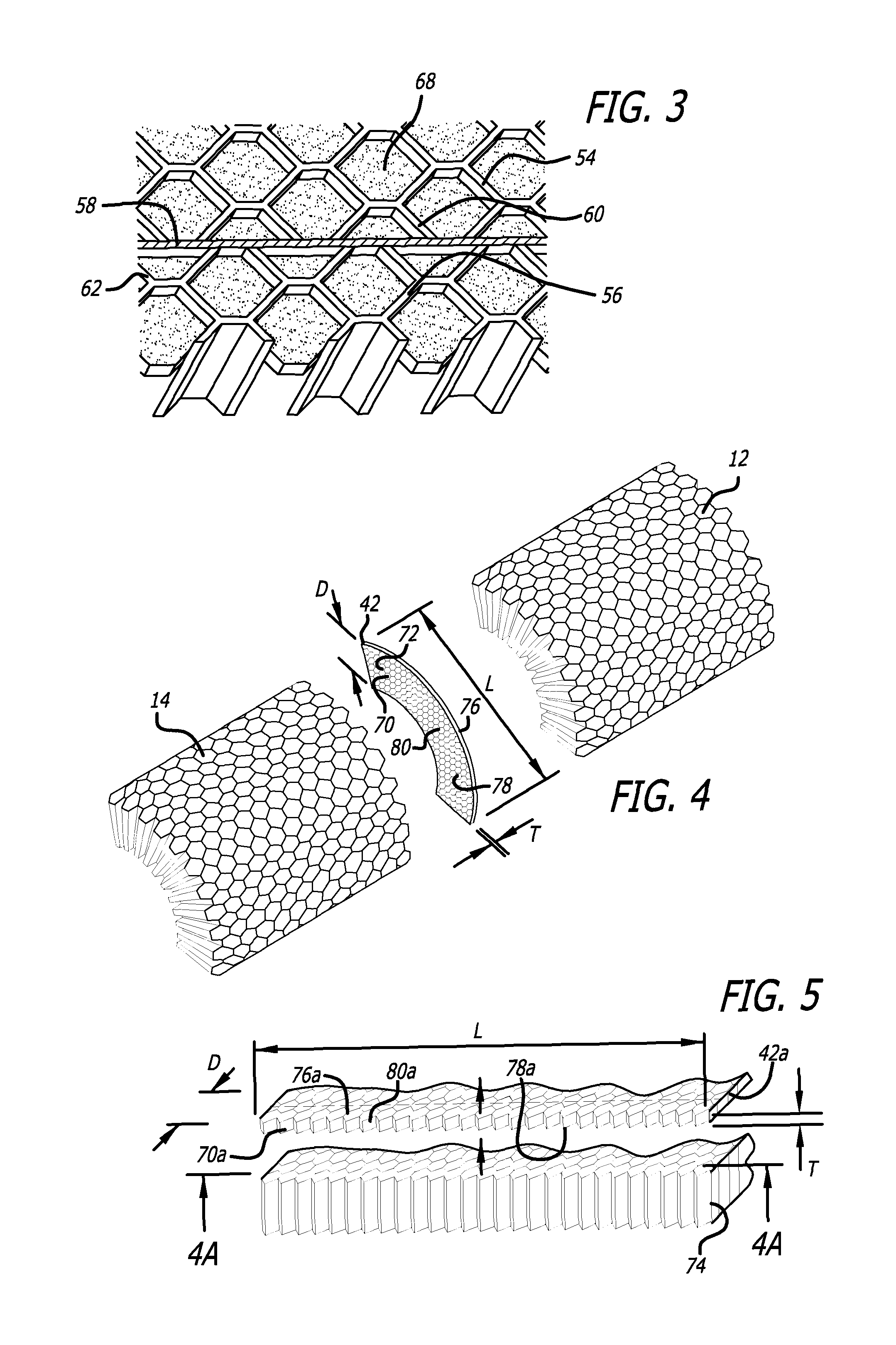

Splicing of curved acoustic honeycomb

ActiveUS8579076B2Interference minimizationThinner seamNoise reduction installationsEngine manufactureNacelleHoneycomb

Honeycomb sections are bonded together with seams made up of an adhesive that is carried by a honeycomb seam support or a linked-segment seam support. The seams are particularly useful for splicing together curved honeycomb sections that contain acoustic septum. The curved acoustic honeycomb sections are spliced or seamed together to form engine nacelles and other acoustic dampening structures.

Owner:HEXCEL

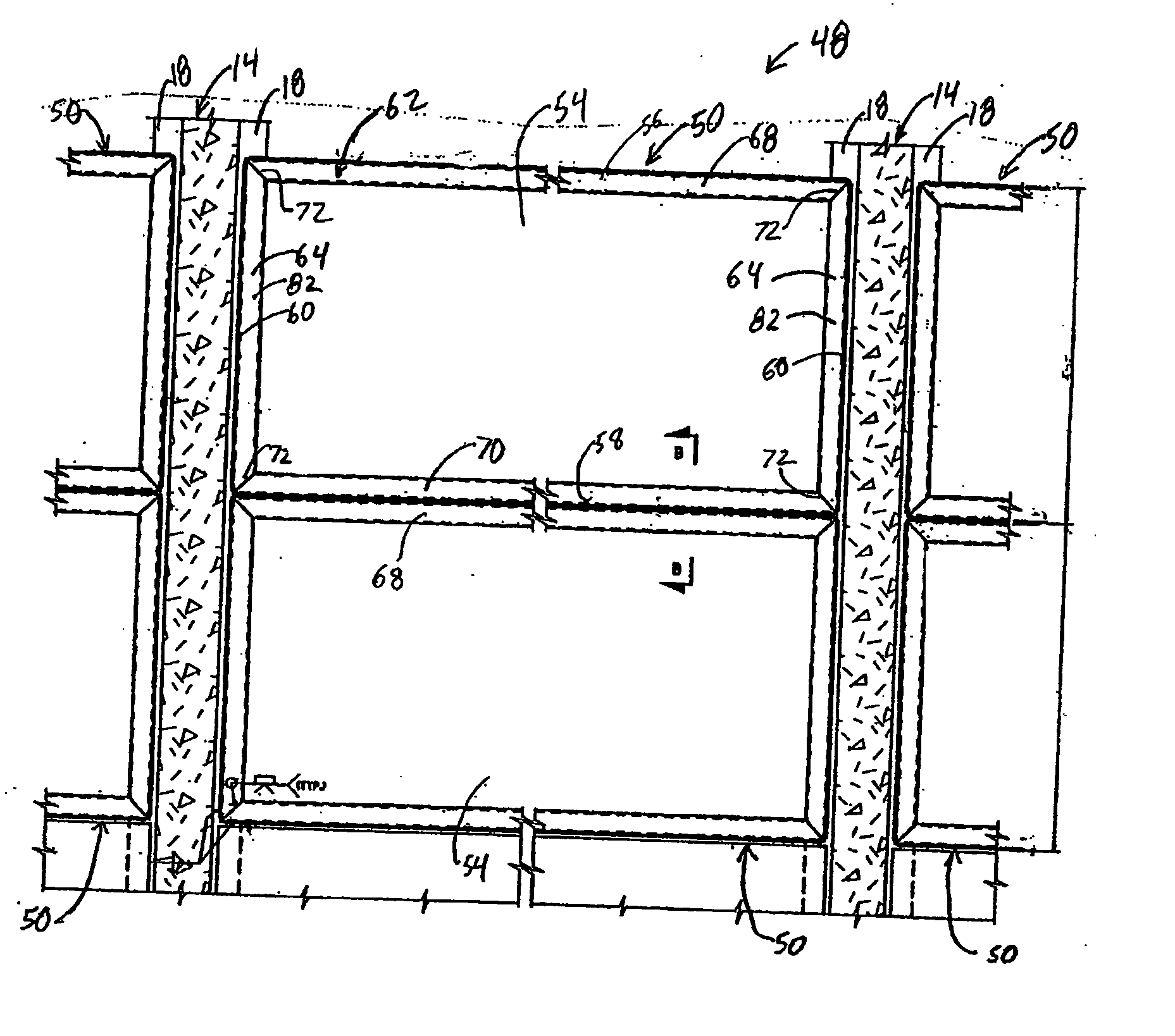

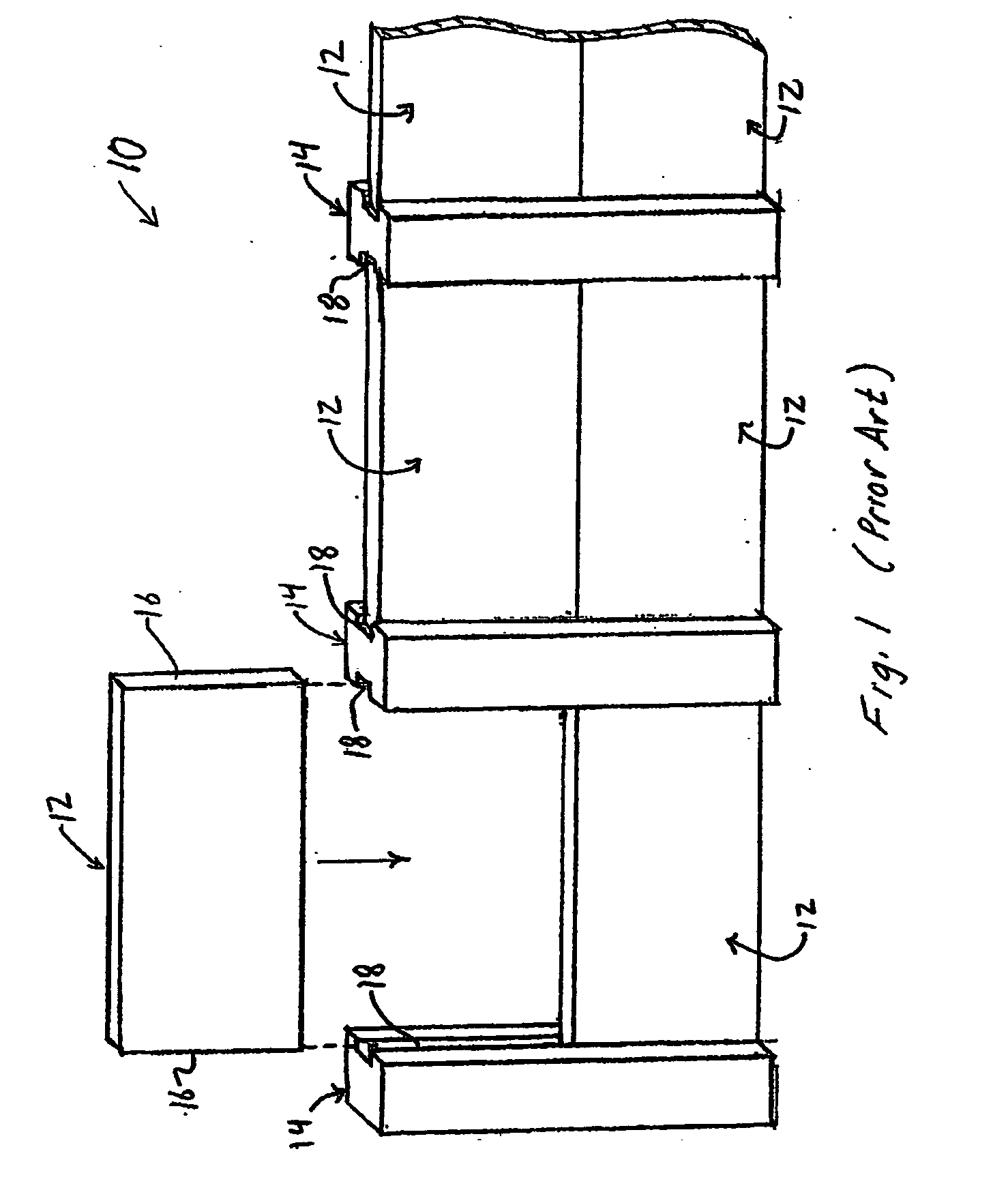

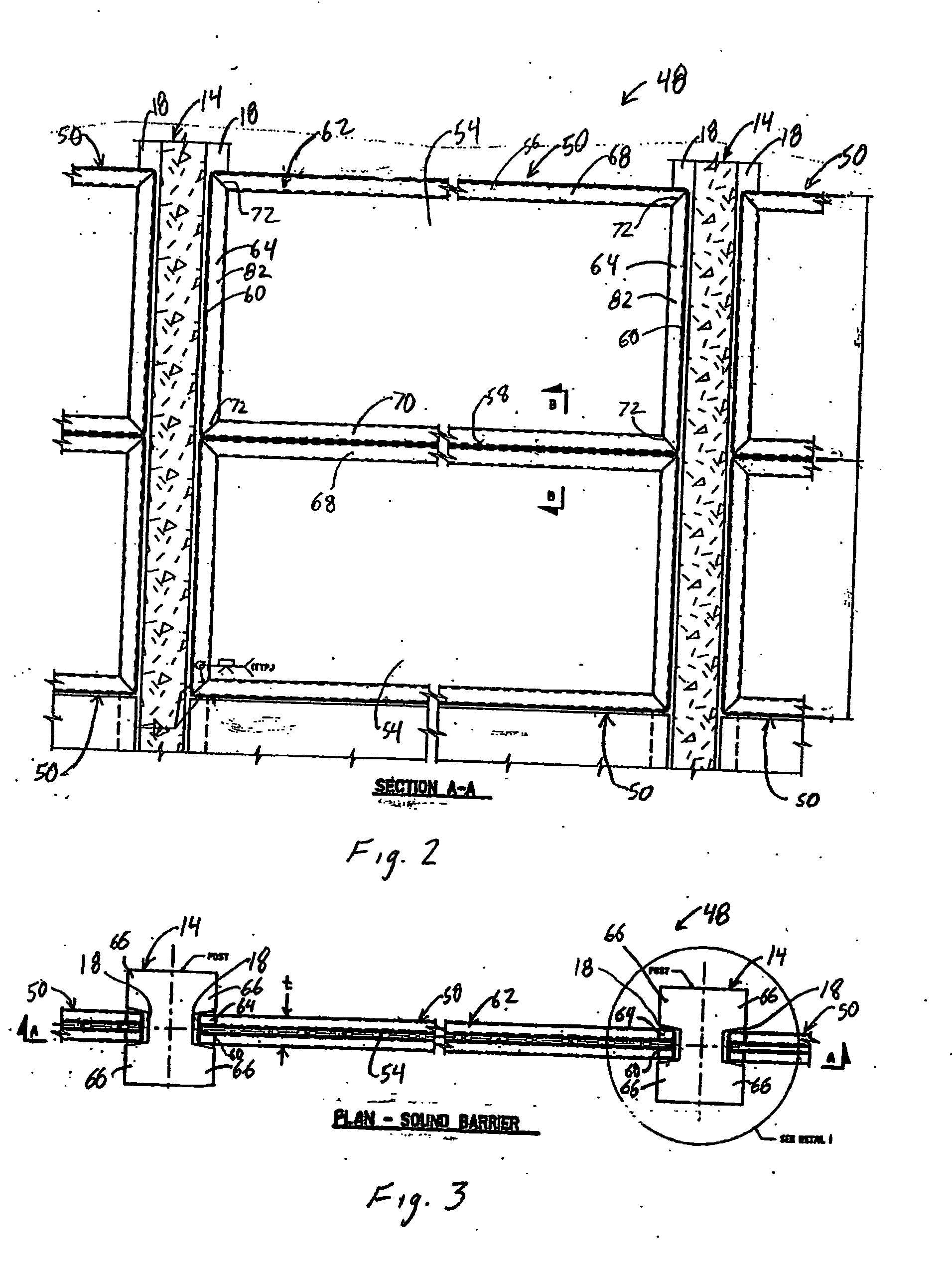

Panel assembly for traffic noise barrier wall

A panel assembly for a traffic noise barrier wall of the type including opposing slots formed in pairs of vertically-mounted posts is described. The panel assembly includes a sheet, which may be transparent, and a frame disposed along at least a portion of the perimeter of the sheet. Side portions of the frame capture at least a portion of the side edges of the sheet and are received within the opposing slots in drop-down fashion.

Owner:EVONIK CYRO

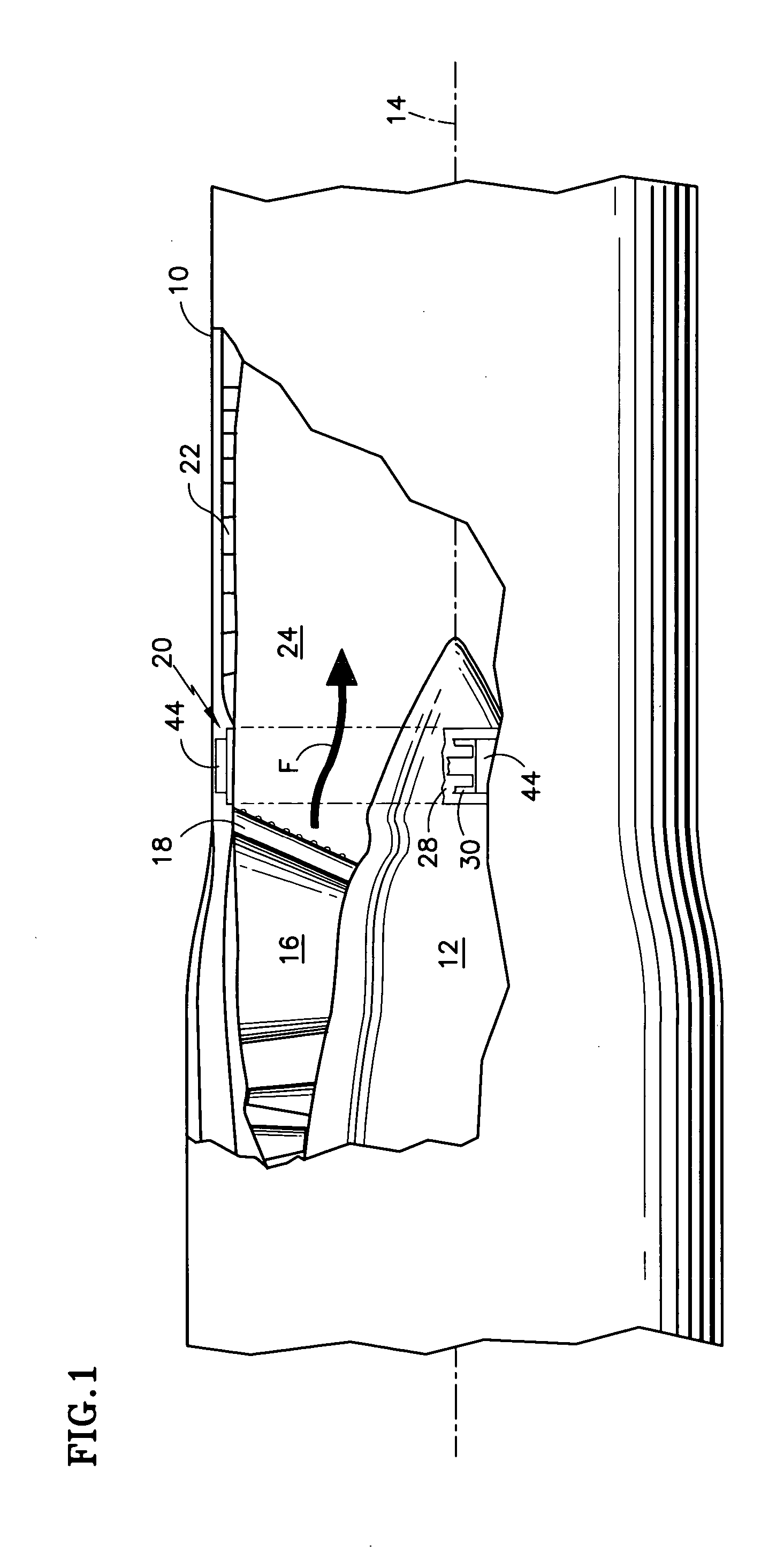

Annular acoustic panel

ActiveUS20050082112A1Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

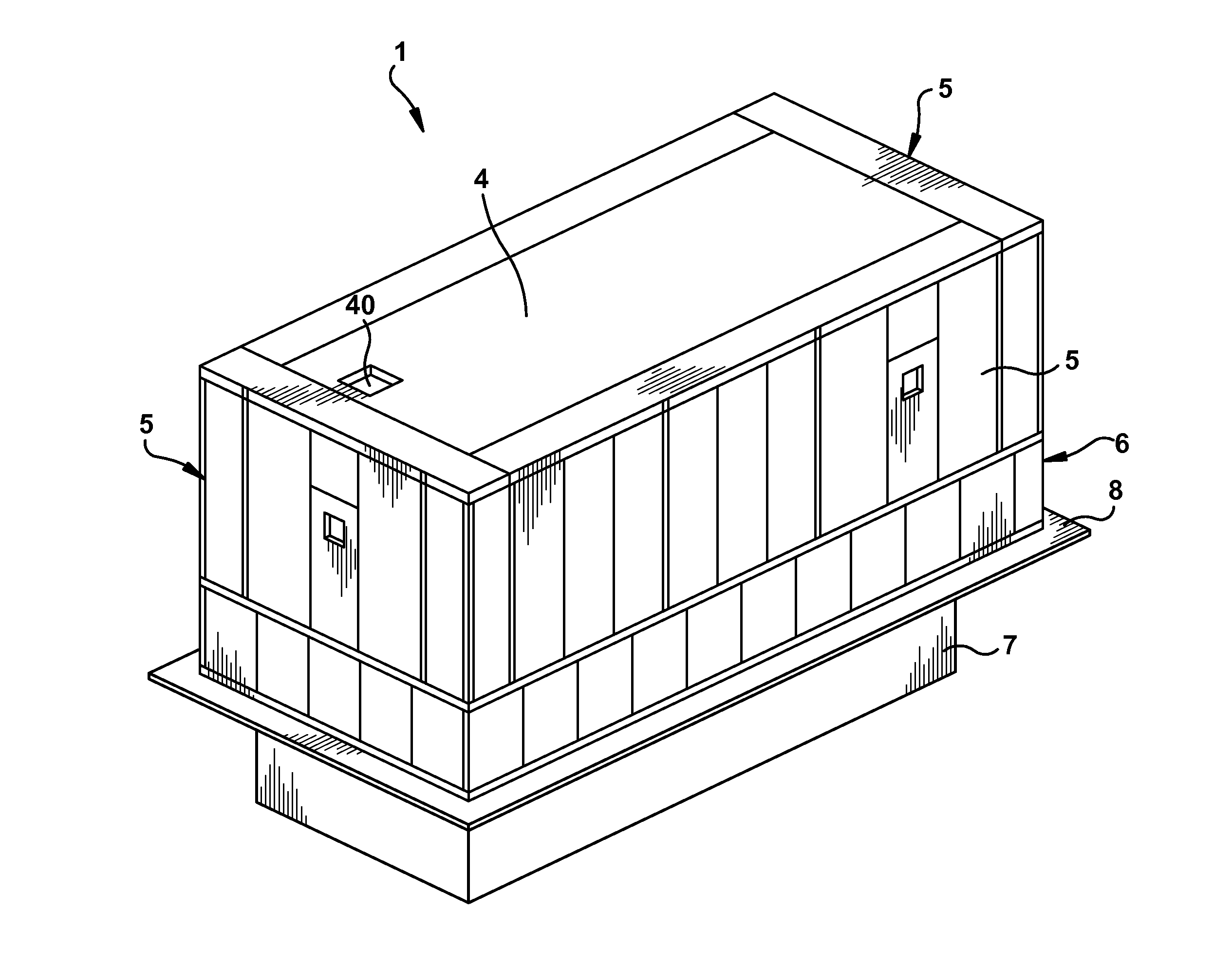

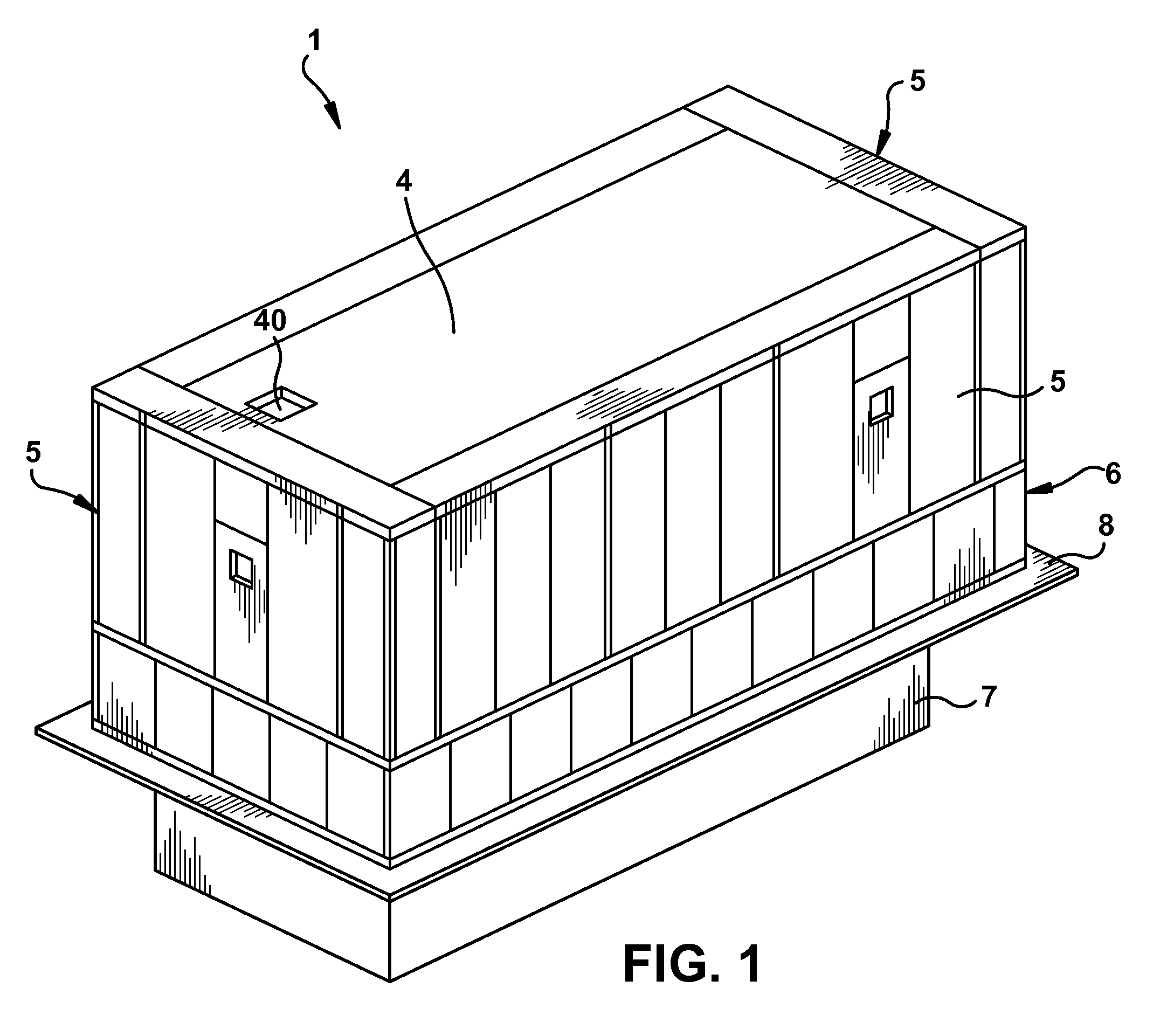

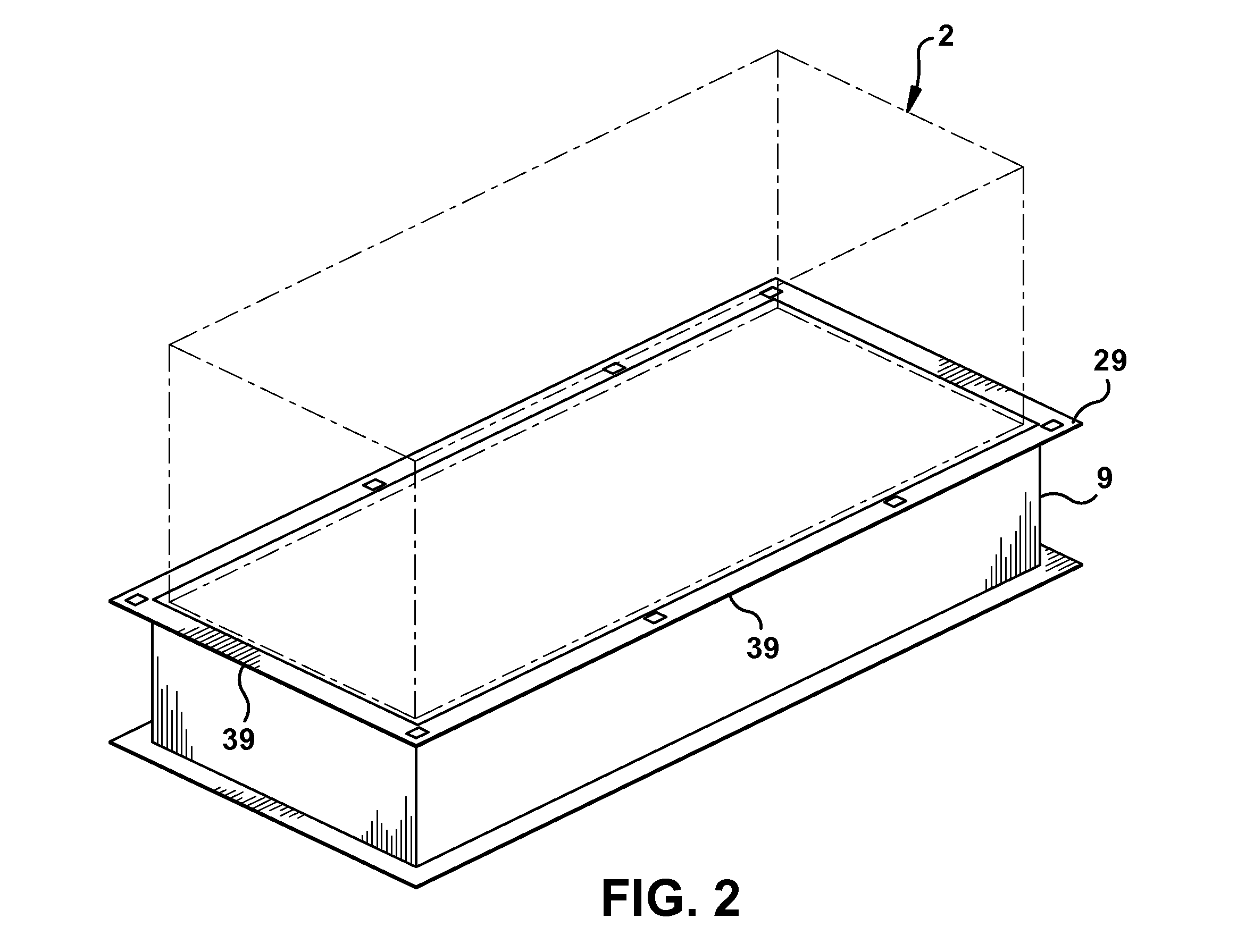

On-base enclosure

InactiveUS8689932B2Increase surface areaMore roomNoise reduction installationsSpraying apparatusWaste management

An on-base enclosure for equipment is disclosed. The on-base enclosure has walls attached to a base for equipment such that the walls are attached to the base at a distance away from the base. By providing the walls away from the base, more room is provided around the equipment within the enclosure.

Owner:GENERAL ELECTRIC CO

Acoustic absorbing device

ActiveUS7451855B2Easily and quickly secured and attachedEffective noiseNoise reduction installationsCeilingsCouplingEngineering

An acoustic absorbing device includes a housing having a chamber formed by an outer peripheral wall and a bottom wall, a hood engaged into the housing, an absorbing member engaged into the hood, and a silencer engaged into the absorbing member, the silencer and the absorbing member may be selectively attached to the hood or may be easily replaced with the other ones or new or different ones according to different environment. The silencer may include an outer cap extended into or out of the absorbing member. The housing includes one or more couplers for selectively coupling the housing to the other coupling or supporting members.

Owner:WISWONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com