Method of controlling secondary gummy substances by using lipase

A technology for stickies and lipase, which is applied in the field of pulping and papermaking of waste paper, and achieves the effect of low production cost, improved quality and genuine product rate, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 Rhizopus sinica lipase

[0037] Rhizopus sinensis was selected as the fermentation strain; the solid slant medium was 5 po malt juice agar medium, pH 7, and the liquid fermentation medium was 30% soybean milk, 1% glucose, 1% olive oil, 2% K2HPO4, 0.5% MgSO4 , pH7; first inoculate the slant medium by streaking, incubate at 30°C for 3 days until black spores are formed, then gently wash the spores with sterile water, shake well to make a spore suspension, and put it in a sterile Erlenmeyer flask save.

[0038] Then carry out the fermentation culture of Rhizopus chinensis, inoculate the sterilized liquid medium, culture on a shaking table, 220 r / min, 30 ℃ for 60 h (to allow the bacteria to fully grow), to obtain flocculent cells, wash with water, and filter to obtain wet The liquid Rhizopus sinensis lipase is obtained from the thalline, the enzyme activity of the obtained Rhizopus sinensis lipase is 20000U / mL, and the pH value is 8.0.

Embodiment 2

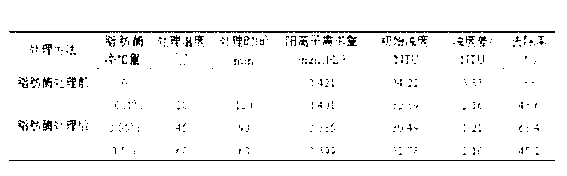

[0040] Control of secondary stickies in waste paper pulp production using Rhizopus sinensis lipase.

[0041] Take 30g of DIP and OCC dry pulp respectively, dilute the pulp with a concentration of 3%, and treat the old newsprint DIP pulp and OCC pulp under different additions of Rhizopus sinensis lipase. It is 0.001-0.5% of the weight of DIP and OCC dry pulp, the temperature is 20-60°C, and the time is 60-120min.

[0042] According to the document Sarja T, Zabihian M and Kourunen P. Control of Potential Secondary Stickies in Deinked Pulp. 2003 TAPPI Fall Technical Conference, Paper 22-2., when the pH of the water sample decreases, the resin and other dissolved The turbidity value of the system increases, and the turbidity difference is the change value between the turbidity and the initial turbidity when the pH is adjusted to 4 by sulfuric acid, and the colloidal substances such as resin acid and styrene-butadiene latex in the system There is a positive phase relationship betw...

Embodiment 3

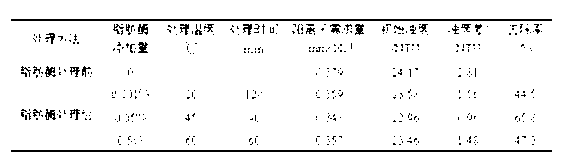

[0050] Control of secondary stickies in papermaking white water by Rhizopus sinica lipase.

[0051] 200mL old newsprint DIP pulp and OCC pulp machine white water samples were taken respectively, and treated with different amounts of Rhizopus sinensis lipase. The lipase activity of Rhizopus sinensis is 20000U / mL, the amount added is 0.001-0.5% of the weight of old newsprint DIP pulp and OCC pulp machine white water sample, the temperature is 20-60°C, and the time is 60-120min.

[0052] Centrifuge the treated white water of the paper machine at 2000r / min for 15 minutes to remove fine fibers and other components; test the cation demand and turbidity of the centrifuged white water, then use sulfuric acid to adjust the pH to 4, then measure the turbidity, and calculate the pH before and after adjustment difference in turbidity. The test results when the enzyme dosage is 0.001%, 0.05%, and 0.5% are as follows, and the removal rate of secondary stickies is calculated by the change o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com