Production technology of crinkled wiping paper

A production process and wiping paper technology, which is applied in the field of papermaking, paper processing and production, and wrinkle wiping paper production technology, can solve the problems of long delivery cycle and high price, and achieve the effect of improving wrinkle quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

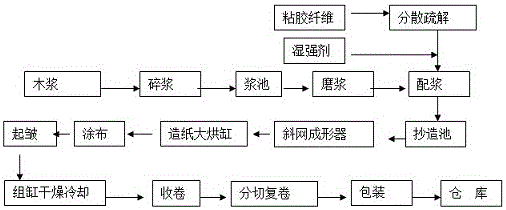

Image

Examples

Embodiment 1

[0035] Embodiment 1 (product specification 42g / ㎡):

[0036] A production process of wrinkled wiping paper, specifically comprising the steps of:

[0037] a. After the pure wood pulp is disintegrated by a hydropulper, it is subjected to disc grinding and beating to obtain a slurry with a concentration of 3.5 to 4.0 wt % and a degree of percussion of 18 to 20 ° SR;

[0038] B, the ultra-short viscose fibers are mixed with the slurry after being evacuated by a deflagging machine to obtain a mixed slurry, the mixed slurry contains 80wt% wood pulp and 20wt% ultra-short viscose fibers, and the slurry concentration is 2.5wt%;

[0039] c. Add paper softener, auxiliary agent and wet strength agent to the slurry, mix well, wet form through the inclined wire papermaking wire part former, press and dehydrate in the suction box, and enter the vat for pre-drying through the supporting roller. A large cylinder with a diameter of 3.5 meters is used for the pre-drying of the large cylinder. T...

Embodiment 2

[0053] Embodiment 2 (product specification 35g / ㎡):

[0054] A production process of wrinkled wiping paper, specifically comprising the steps of:

[0055] a. After the pure wood pulp is disintegrated by a hydropulper, it is subjected to disc grinding and beating to obtain a slurry with a concentration of 3.5 to 4.0 wt % and a degree of percussion of 18 to 20 ° SR;

[0056] B, ultra-short viscose fibers are mixed with the slurry after being evacuated by a deflagging machine to obtain a mixed slurry, the mixed slurry contains 85wt% wood pulp and 15wt% ultra-short viscose fibers, and the slurry concentration is 2.5wt%;

[0057] c. Add paper softener, auxiliary agent and wet strength agent to the slurry, mix well, wet form through the inclined wire papermaking wire part former, press and dehydrate in the suction box, and enter the vat for pre-drying through the supporting roller. Large cylinder pre-drying adopts a large cylinder with a diameter ≥ 3 meters. Two suction hoods are in...

Embodiment 3

[0071] Embodiment 3 (product specification 40g / ㎡):

[0072] A production process of wrinkled wiping paper, specifically comprising the steps of:

[0073] a. After the pure wood pulp is disintegrated by a hydropulper, it is subjected to disc grinding and beating to obtain a slurry with a concentration of 3.5 to 4.0 wt % and a degree of percussion of 18 to 20 ° SR;

[0074] B, the ultra-short viscose fiber is mixed with the slurry after being evacuated by a deflagging machine to obtain a mixed slurry, the mixed slurry contains 95wt% wood pulp and 5wt% ultra-short viscose fiber, and the slurry concentration is 2.0wt%;

[0075] c. Add paper softener, auxiliary agent and wet strength agent to the slurry, mix well, wet form through the inclined wire papermaking wire part former, press and dehydrate in the suction box, and enter the vat for pre-drying through the supporting roller. A large cylinder with a diameter of 3.5 meters is used for the pre-drying of the large cylinder. Two s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com