Machine vision automatic detection system for rivets

An automatic detection and machine vision technology, applied in instruments, measuring devices, optical devices, etc., can solve problems such as unfavorable factory automation level requirements, low work efficiency, and high worker requirements, to improve the level of automation equipment and save labor. The effect of testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the concept, specific structure and technical effects of the present invention will be further described in conjunction with the accompanying drawings to fully understand the purpose, features and effects of the present invention.

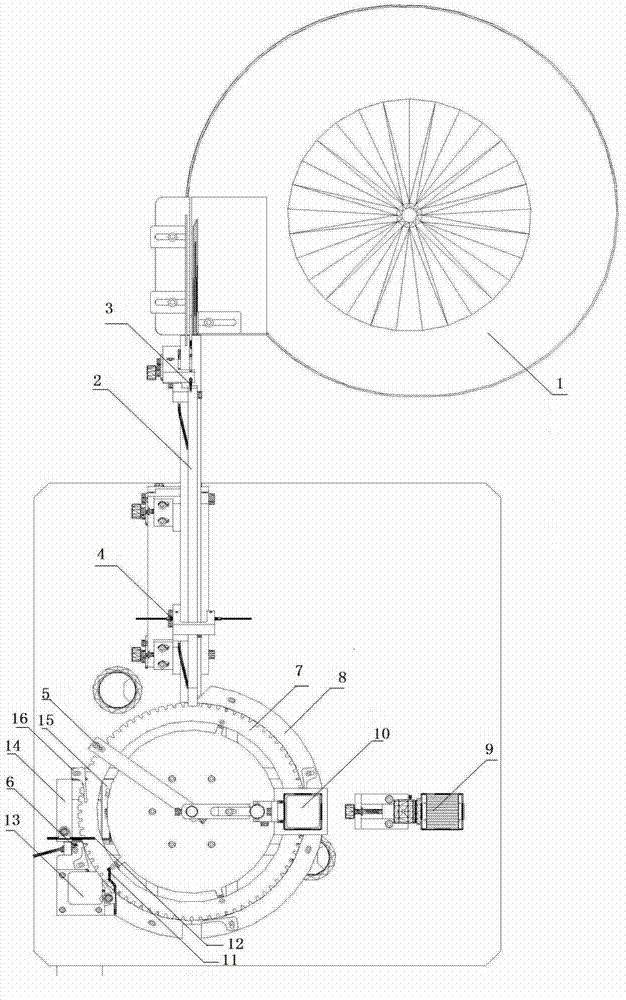

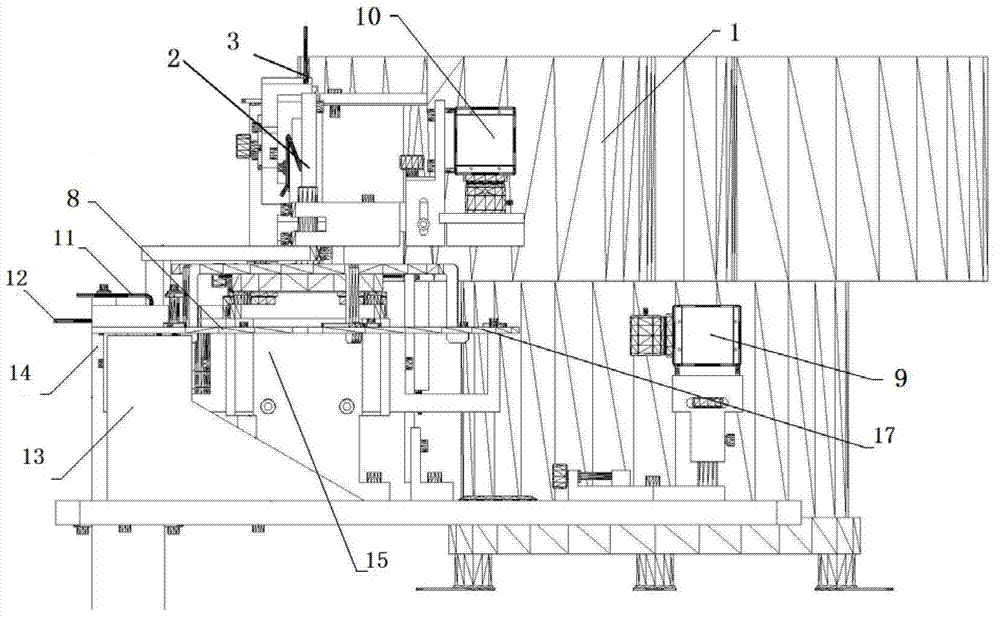

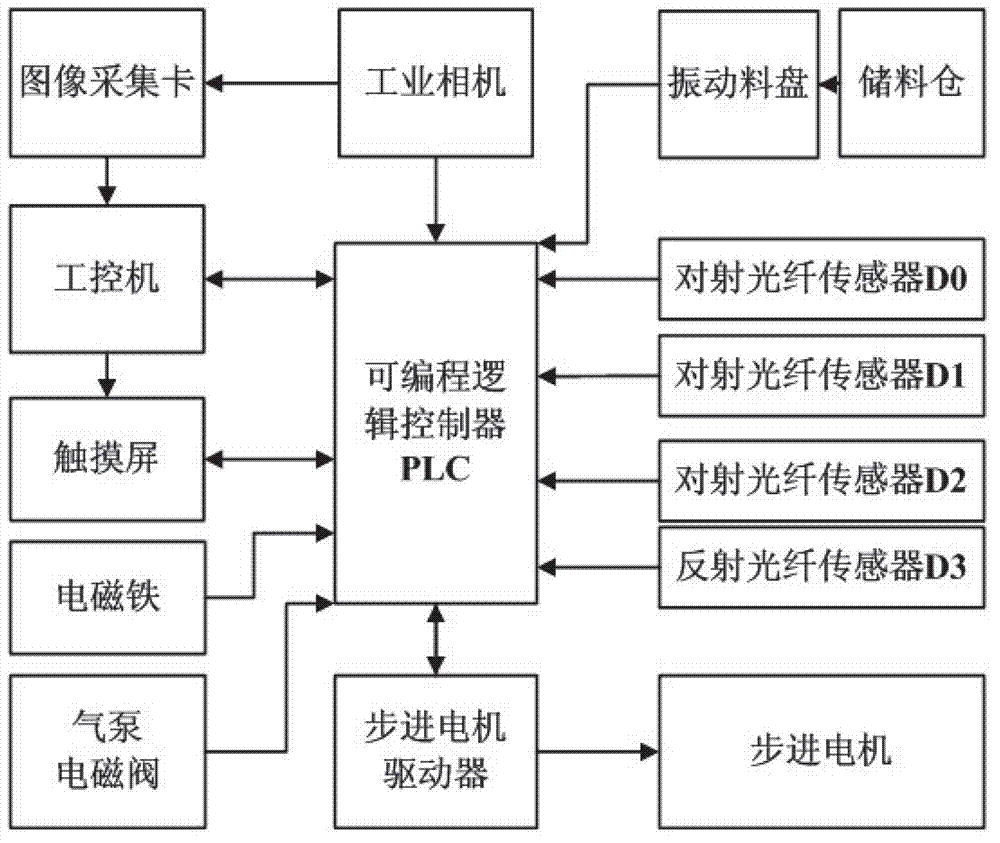

[0035] In the rivet machine vision automatic detection system of the present invention, the rivets to be tested can be stacked in the storage bin in batches, the rivets in the storage bin fall into the vibrating tray at a uniform speed, and the output port of the rivet track of the vibrating tray is connected with the upper end of the linear track , The rivets are placed in the tooth openings on the mechanical turntable in an orderly manner via a linear track, and the operation of the vibrating tray and the stepping motor are controlled by the PLC and sensors at various positions. When the rivet passes through the detection positions of the two cameras, the photos are taken, and the photos are transmitted to the industrial comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com