Direct drive type servo pump control electro-hydraulic combined driving hydraulic cylinder control system and control method

An electro-hydraulic mixing and control system technology, applied in fluid pressure actuation system components, servo motors, fluid pressure actuation devices, etc., can solve the problems of low cost performance, complex system control, low energy efficiency, etc., and achieve speed improvement and response, fast response, and shortened routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described below through a specific embodiment.

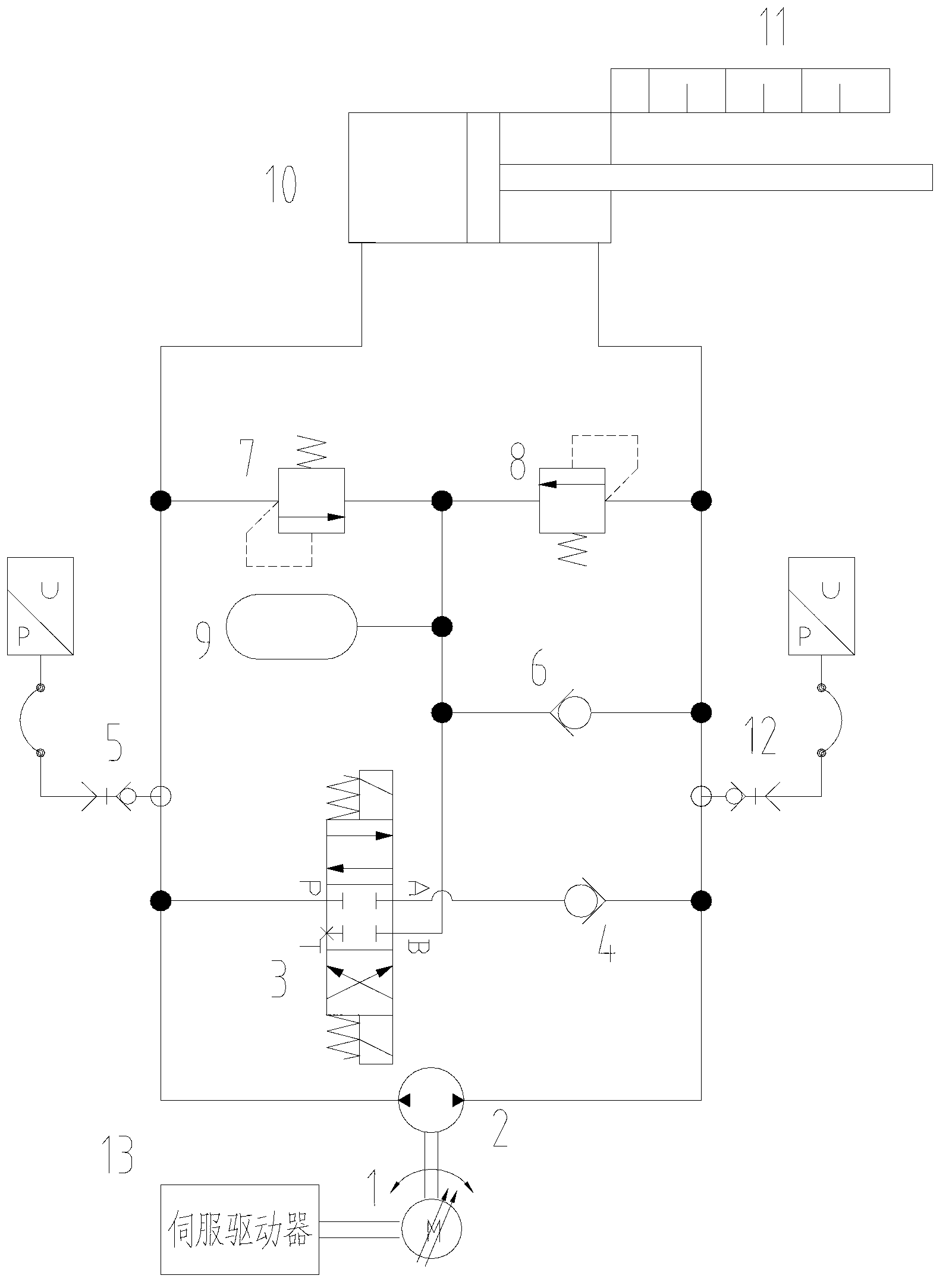

[0023] Such as figure 1 , the hydraulic cylinder control system of the present invention includes a servo motor 1, a bidirectional pump 2, a differential unloading valve 3, a first one-way valve 4, a second one-way valve 6, an oil tank 9, a hydraulic cylinder 10 and a servo driver 13, wherein The ratio of the annular cross-sectional area of the piston rod chamber of the hydraulic cylinder 10 to the cross-sectional area of the piston is not 1. The structure of the control system is: the servo drive 13 is connected to the servo motor 1, the output of the servo motor 1 is connected to the bidirectional pump 2, and the bidirectional pump 2 is divided into two circuits. Oil circuit, the first oil circuit is connected to the rodless chamber of the hydraulic cylinder 10, the second oil circuit is connected to the rod chamber of the hydraulic cylinder 10, and the two oil cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com