Movable arm potential energy recovery method and apparatus of hydraulic excavator

A potential energy recovery and maneuvering arm technology, which is applied to fluid pressure actuating devices, mechanically driven excavators/dredgers, circuit devices, etc., can solve problems such as low efficiency, large fluctuations in hydraulic oil pressure, and low energy recovery efficiency. To achieve the effect of reducing pressure fluctuation, improving efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

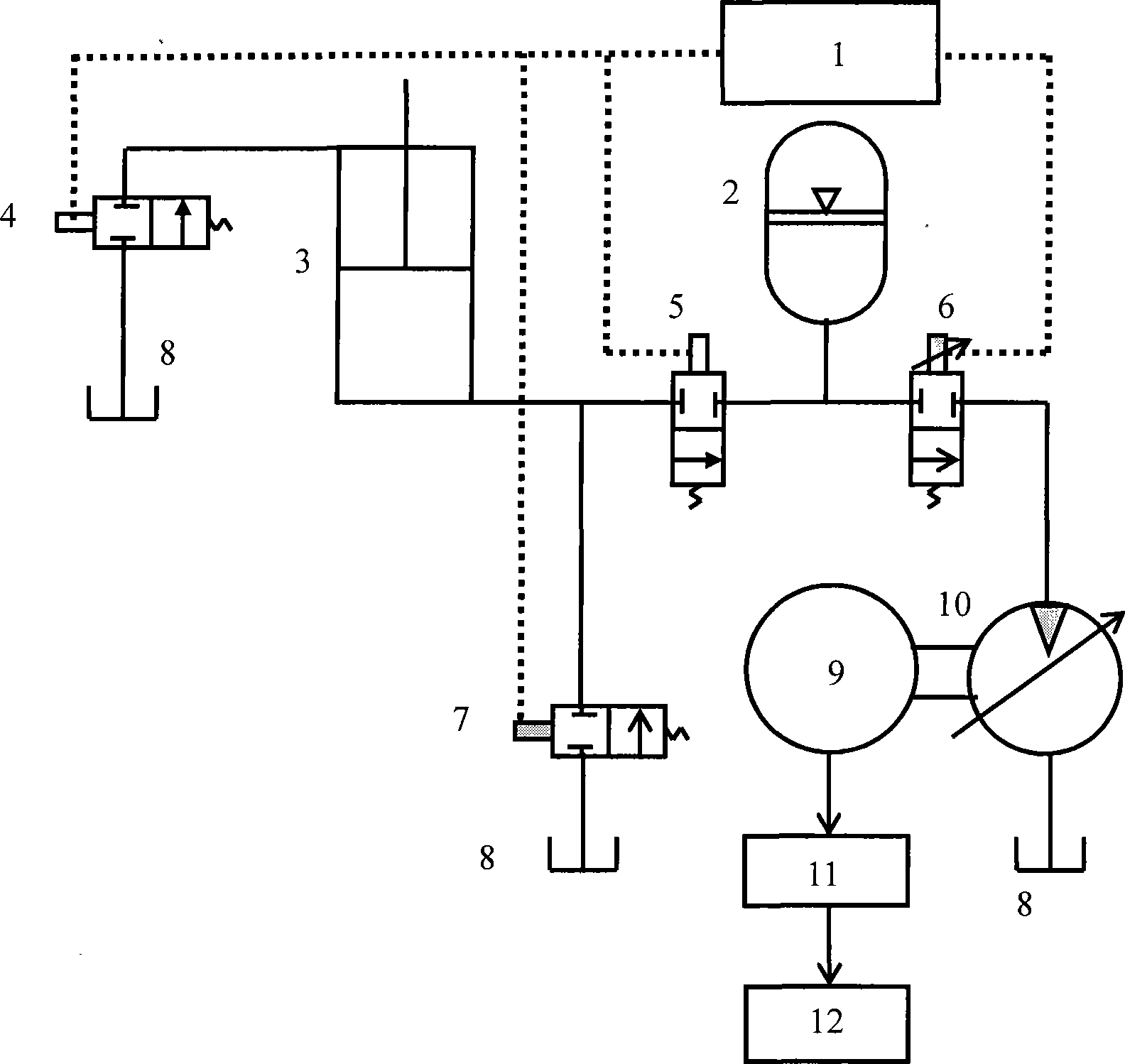

[0021] Such as figure 1 As shown, the oil-electric hybrid hydraulic excavator arm potential energy recovery device includes a hydraulic cylinder 3, a controller 1, an accumulator 2, a two-position two-way solenoid valve 4, 5 and 7, and a two-position two-way proportional valve 6 ( Wherein the two-position two-way solenoid valves 4, 7 and 5 and the two-position two-way proportional valve 6 respectively correspond to the first solenoid valve, the second solenoid valve, the third solenoid valve and the fourth solenoid valve) and the generator 9 , hydraulic motor 10, inverter 11, accumulator 12 and oil tank 8, two-position two-way solenoid valves 4, 5 and 7 are normally closed solenoid valves, two-position two-way proportional valve 6 is a normally closed proportional valve, two The two-position two-way solenoid valve 4 is installed between the oil port of the rod chamber of the hydraulic cylinder 3 and the fuel tank 8, the two-position two-way solenoid valve 7 is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com