Test board for flow rate pressure of pressure regulating valve

A technology of flow pressure and pressure regulating valve, which is applied in the field of test equipment for automotive pressure regulating valves, which can solve problems such as recording and printing, heavy workload, and inability to calculate, and achieve high efficiency, high automation and intelligent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

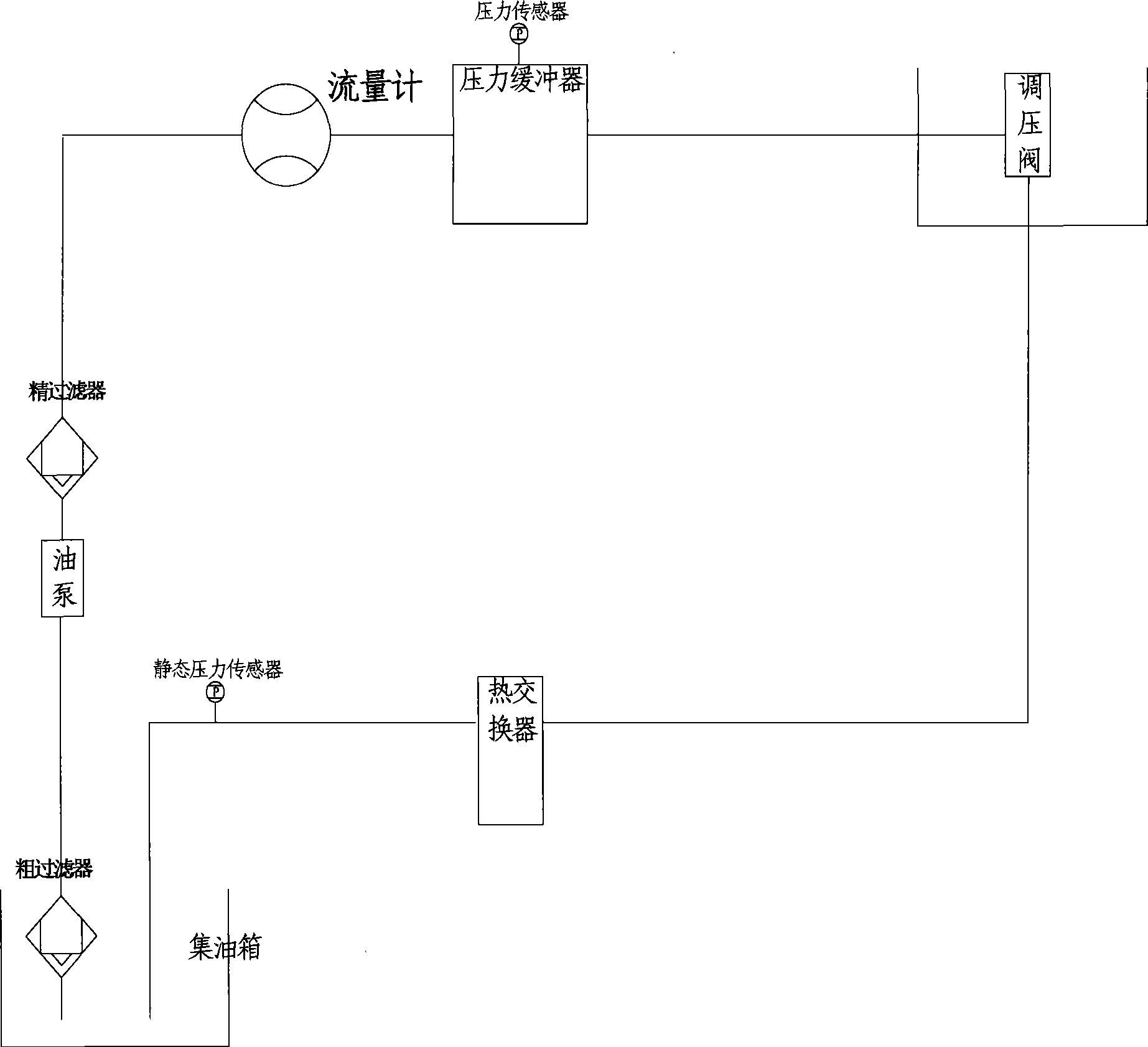

[0009] Such as figure 1 As shown, the present invention can test the corresponding system pressure according to a set of designated flow parameters. Including: oil tank, the oil tank is connected with an oil inlet pipeline; the oil inlet pipeline is connected with an oil pump, which is used to provide a certain flow rate of test fluid to the pressure regulating valve under test; The test fluid flow rate of the valve; a pressure sensor is connected to the oil inlet to collect the test fluid pressure flowing to the pressure regulating valve under test; the oil inlet pipeline is connected to the pressure regulating valve under test, and the oil return pipeline is connected to the pressure regulating valve under test The oil return pipeline is connected with a pressure sensor to collect the test fluid pressure flowing out of the pressure regulating valve under test; the oil return pipeline is connected to the oil return tank; the data acquisition control device is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com