Low idling energy consumption hydraulic power source

A hydraulic power source and energy consumption technology, which is applied in the direction of machines/engines, liquid variable displacement machinery, pump control, etc., can solve the problems of system complexity, high cost, slow dynamic response, etc., to reduce energy loss, reduce The volume and the effect of increasing the oil supply flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

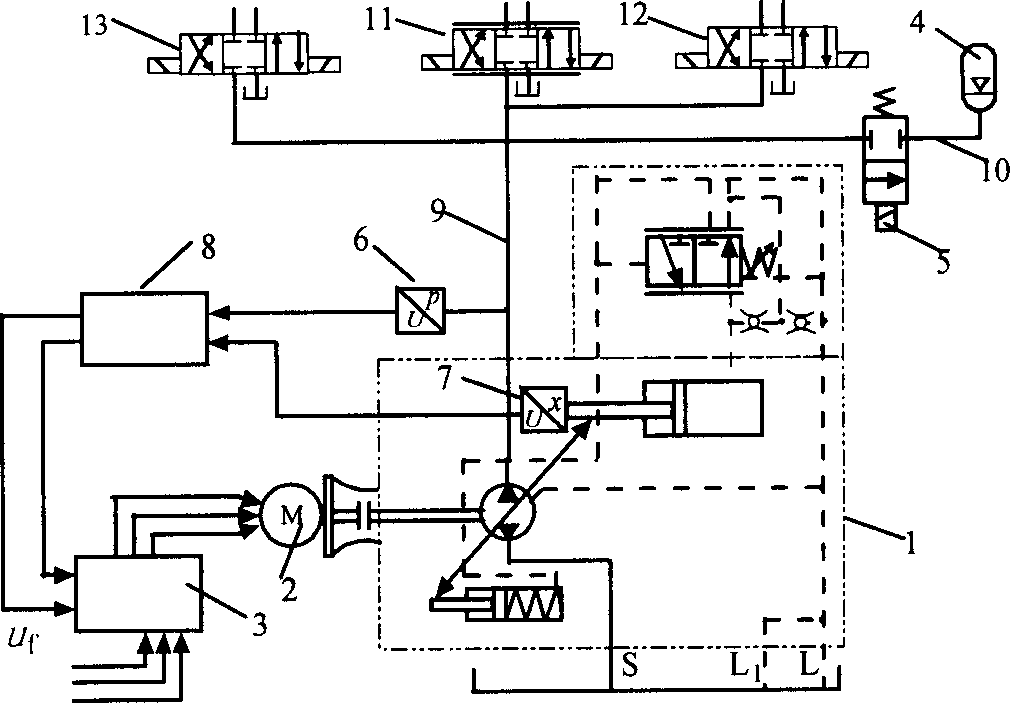

[0016] In the embodiment shown in Figure 1, the hydraulic pump 1 adopts a mechanically controlled pilot structure constant pressure variable pump, the motor 2 adopts an AC asynchronous motor, the motor speed controller 3 adopts a vector control frequency converter, and the accumulator adopts a bladder type The structure of the solenoid valve 5 is a 10-way 2-position two-way solenoid valve, and the pressure sensor has a measuring range of 0-35MPa and is integrated with a pre-amplification stage. The displacement sensor 7 adopts the principle of differential transformer, and the controller 8 is composed of a single-chip calculator.

Embodiment approach 2

[0018] The difference between this embodiment and Embodiment 1 is that the mechanically controlled constant pressure variable pump in Mode 1 is changed to an electronic proportional controlled constant pressure variable pump, the motor speed controller 3 uses a soft starter, and the rest are the same.

Embodiment approach 3

[0020] The difference between this embodiment and embodiment 1 is that the AC asynchronous motor used in the mode 1 is changed to an AC servo motor, and the rest are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com