Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Lobe pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lobe pump, or rotary lobe pump, is a type of positive displacement pump. It is similar to a gear pump except the lobes are designed to almost meet, rather than touch and turn each other. An early example of a lobe pump is the Roots Blower, patented in 1860. to blow combustion air to melt iron in blast furnaces, but now more commonly used as an engine supercharger.

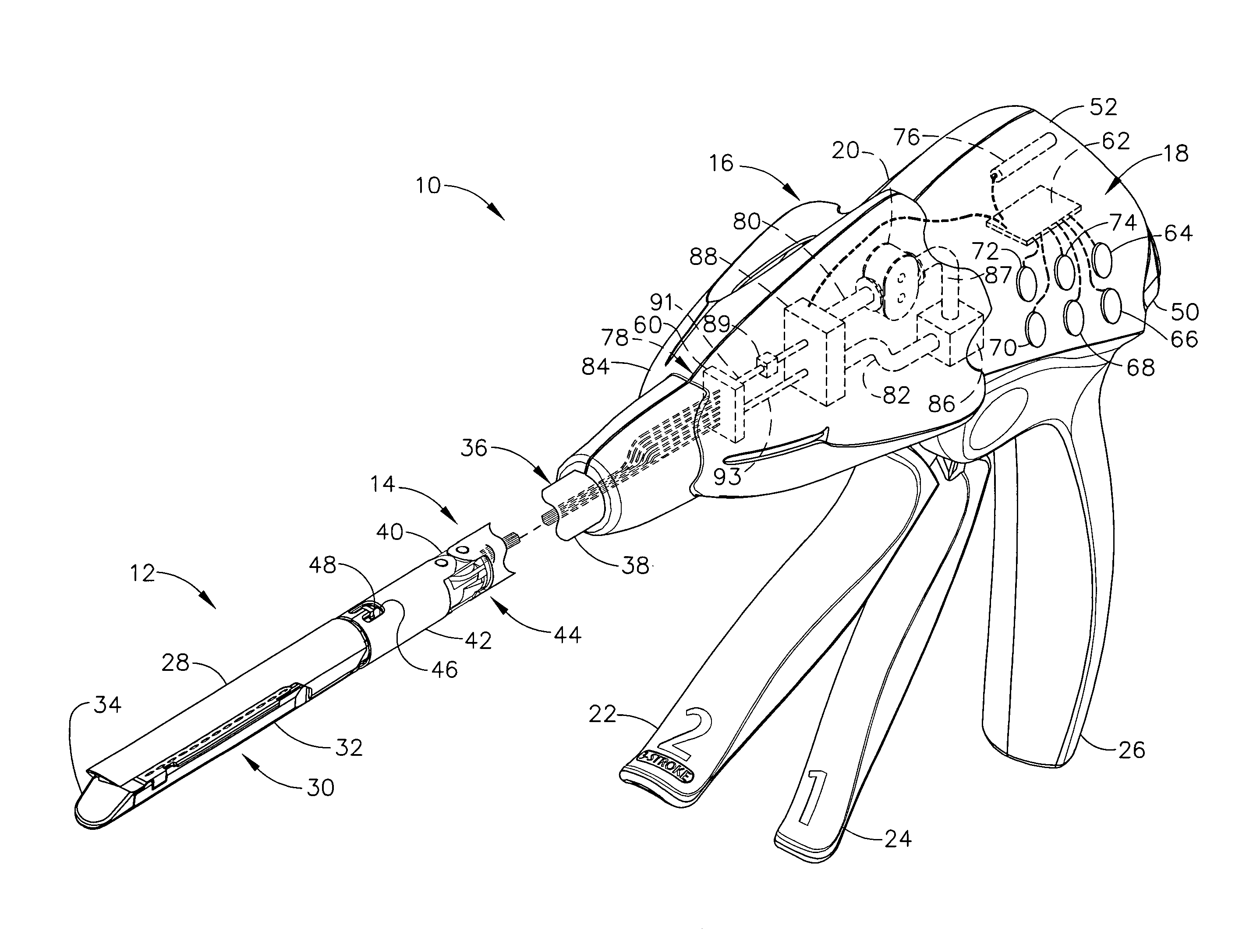

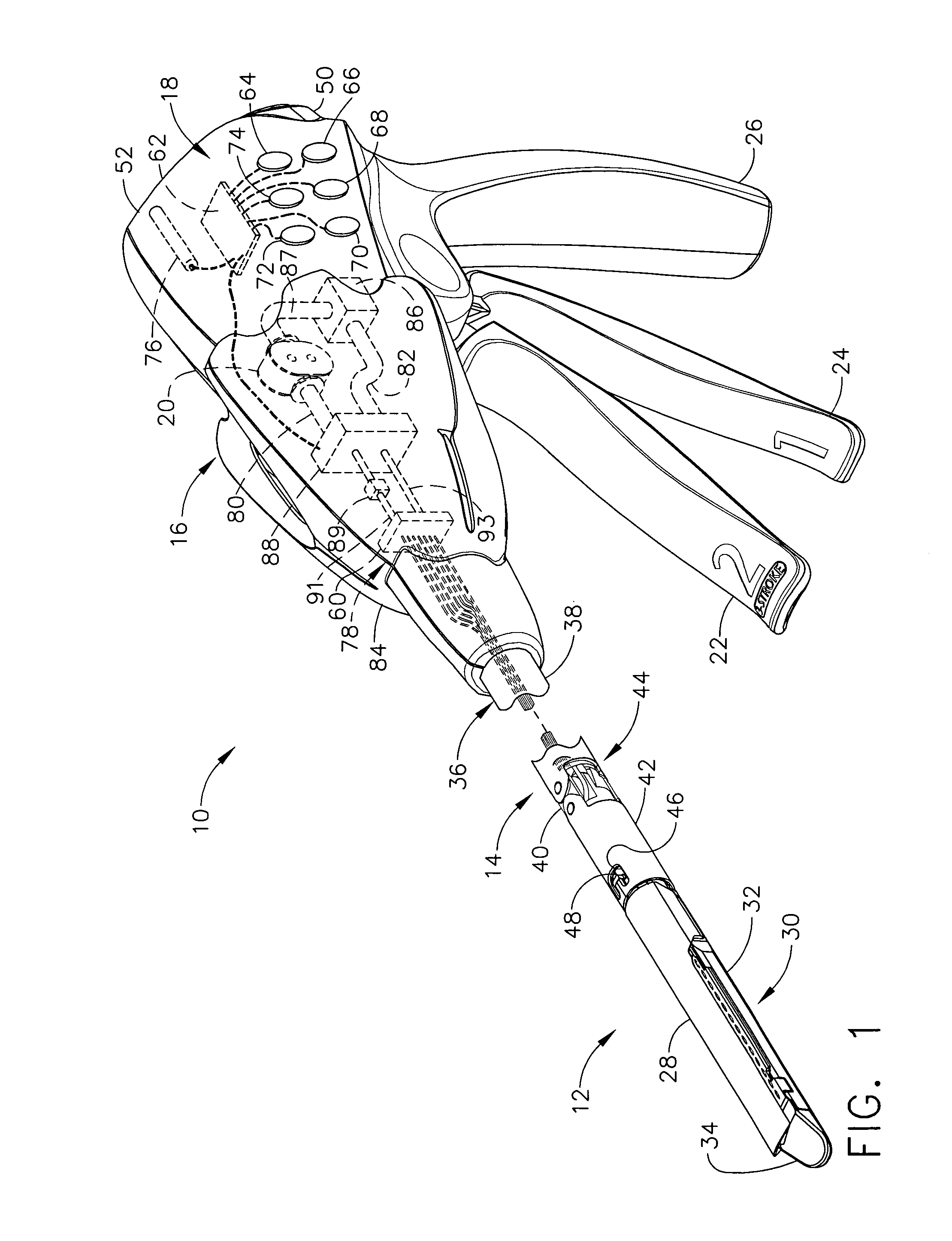

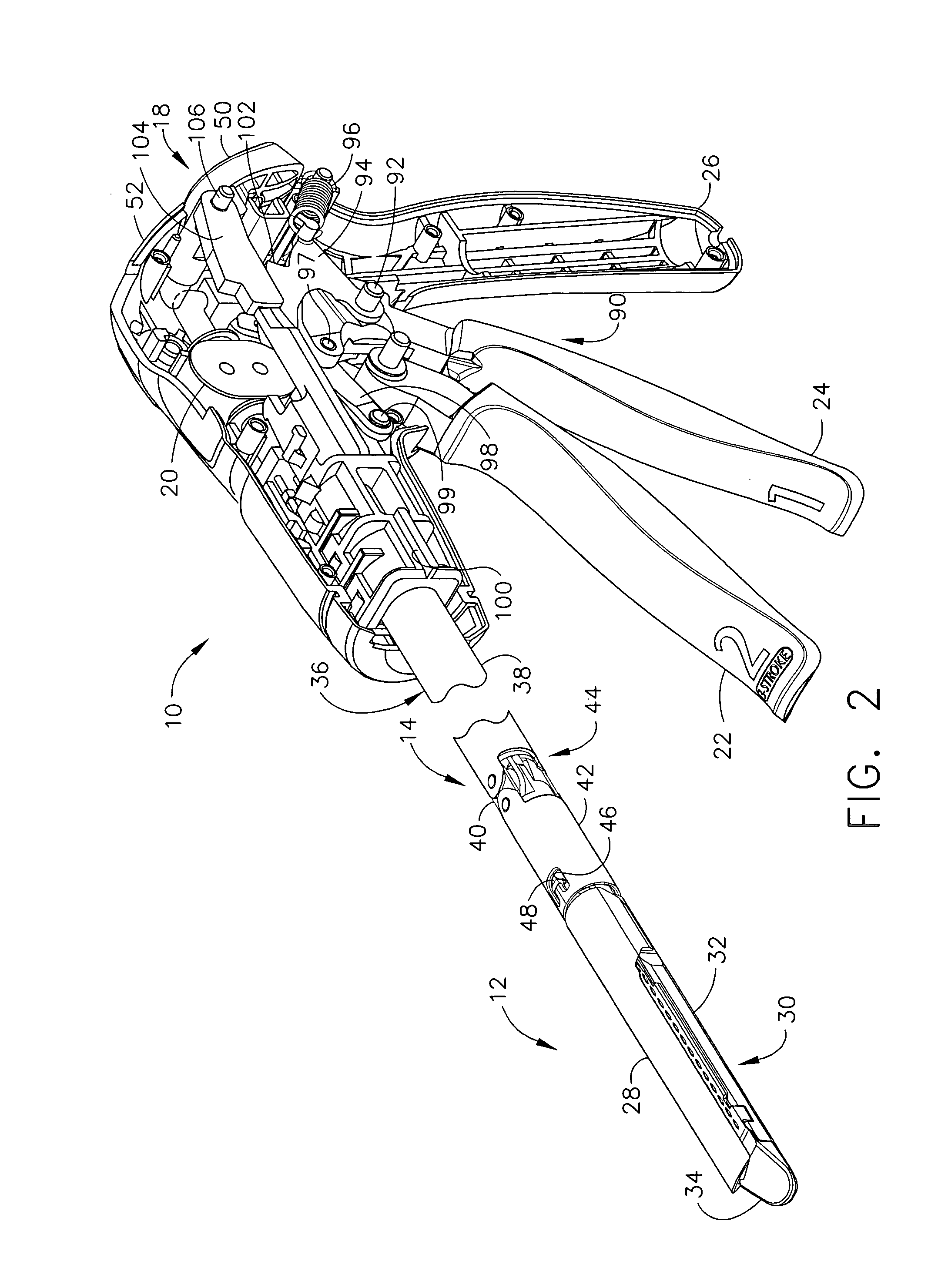

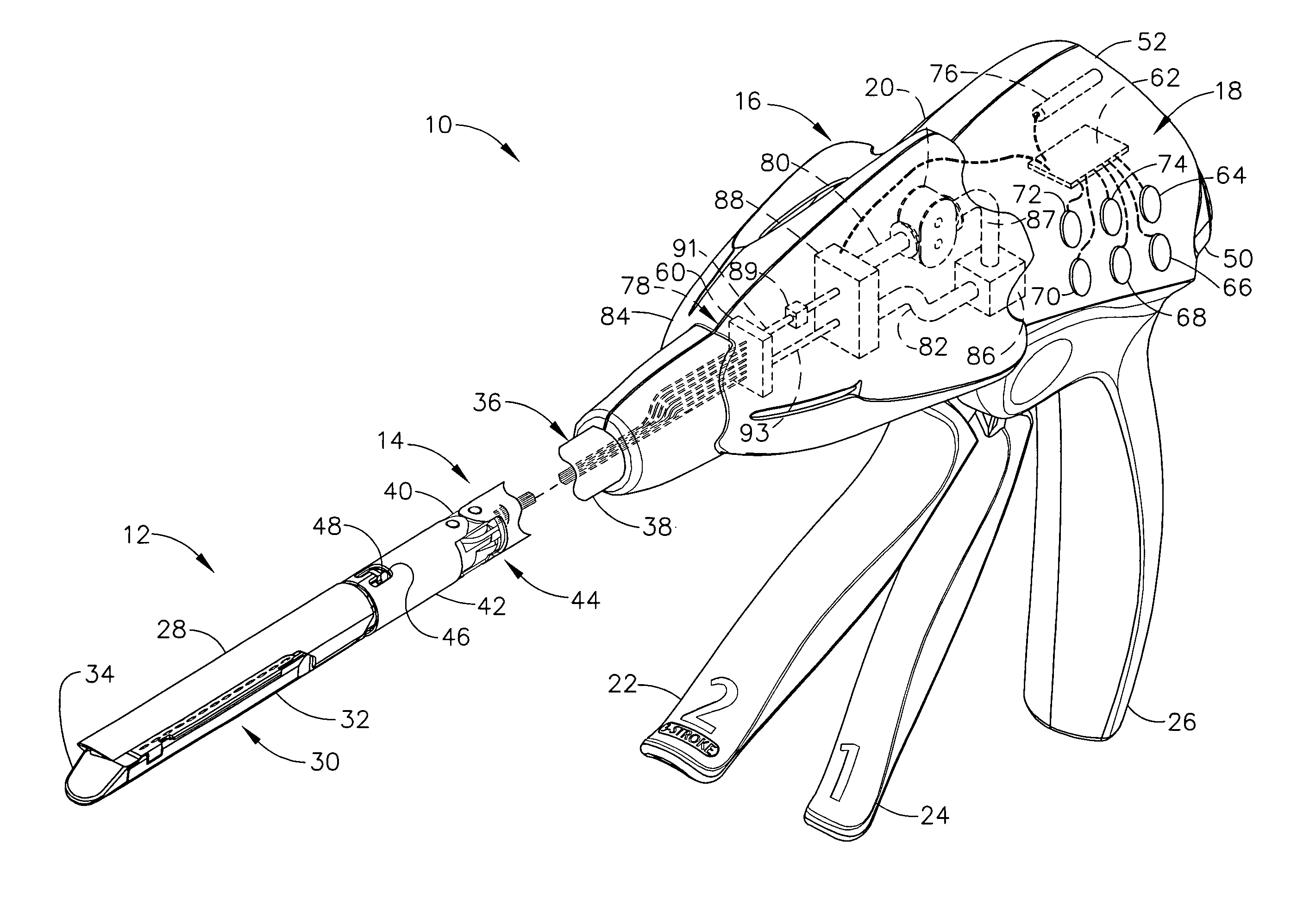

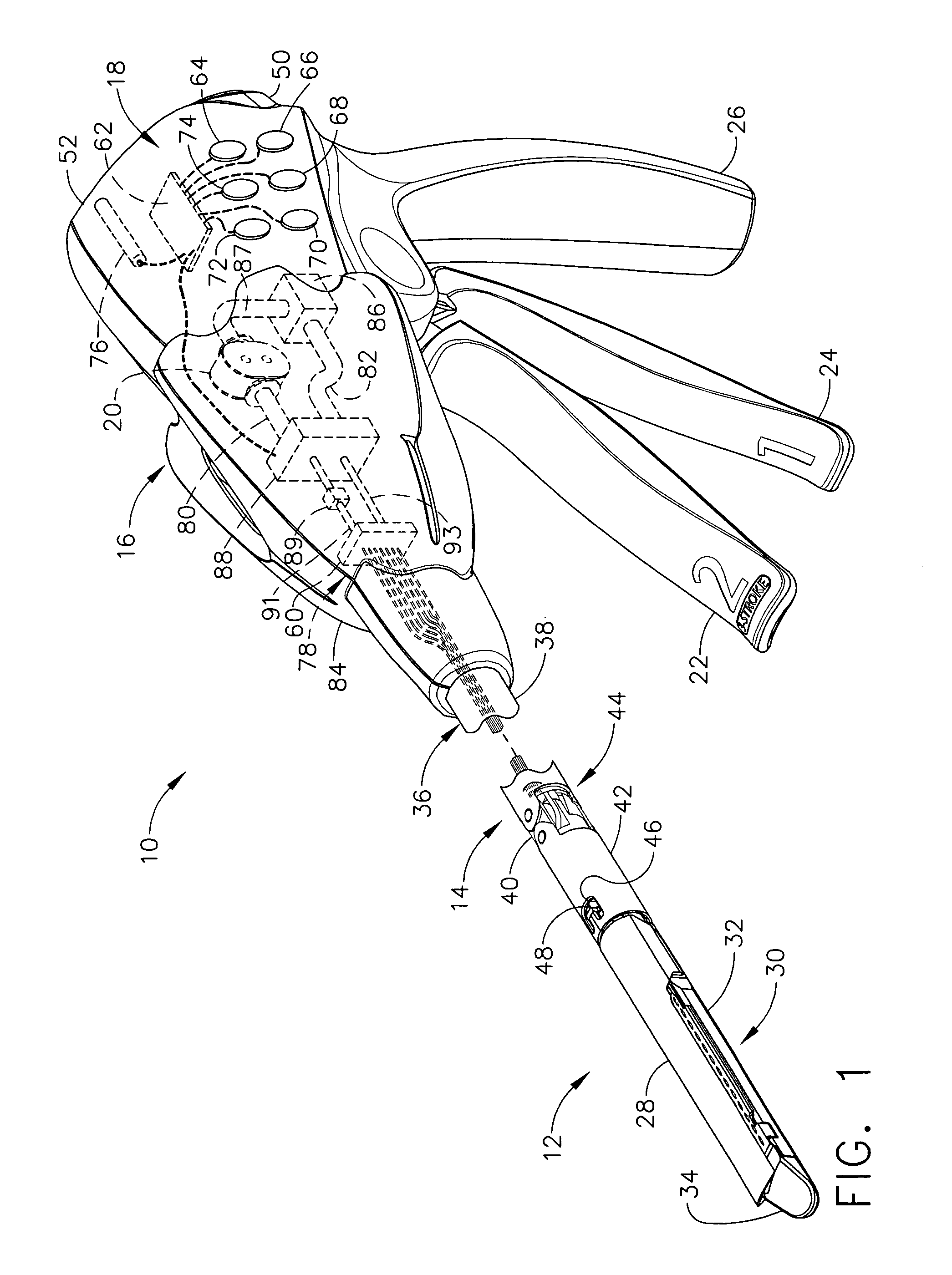

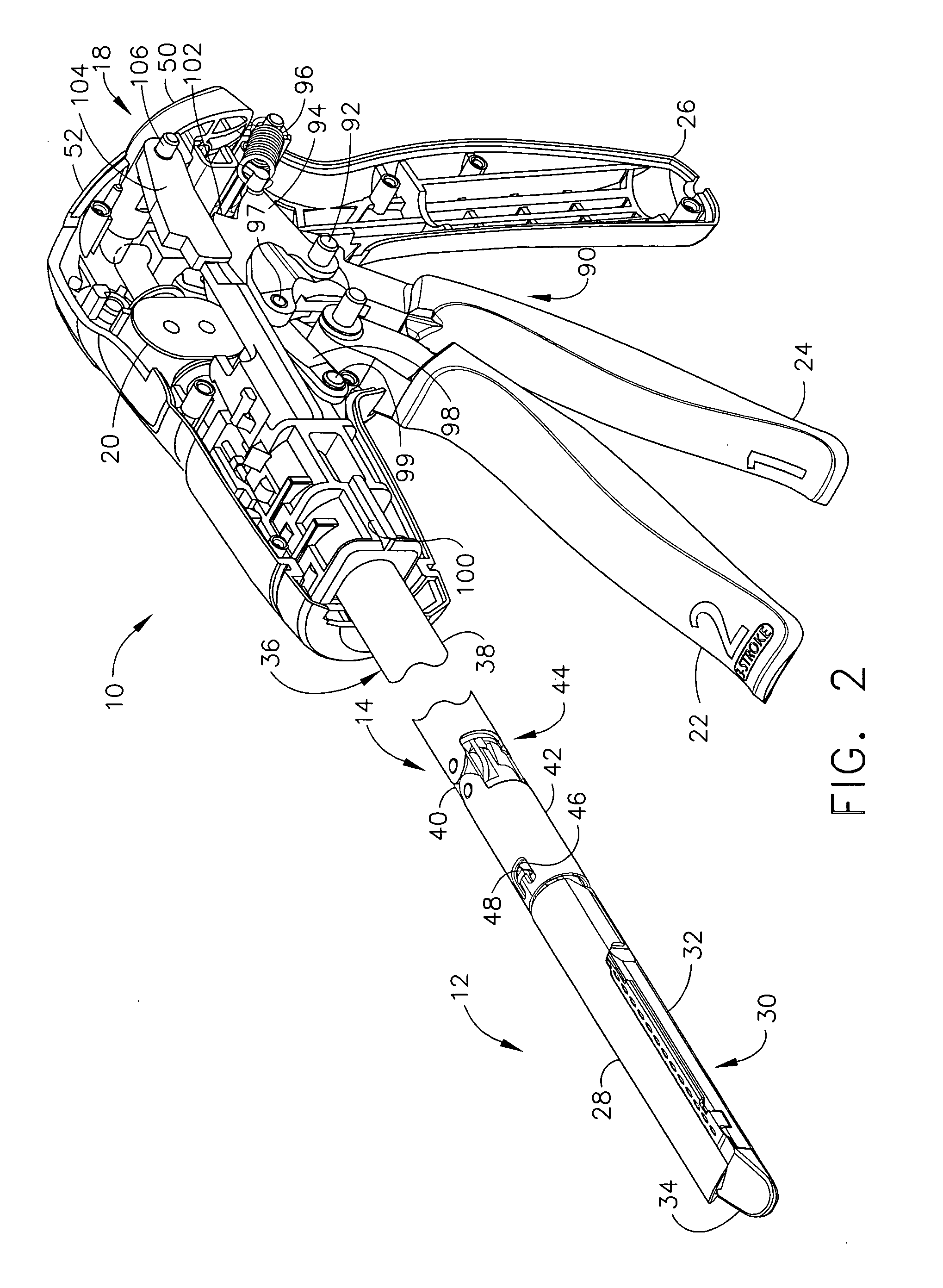

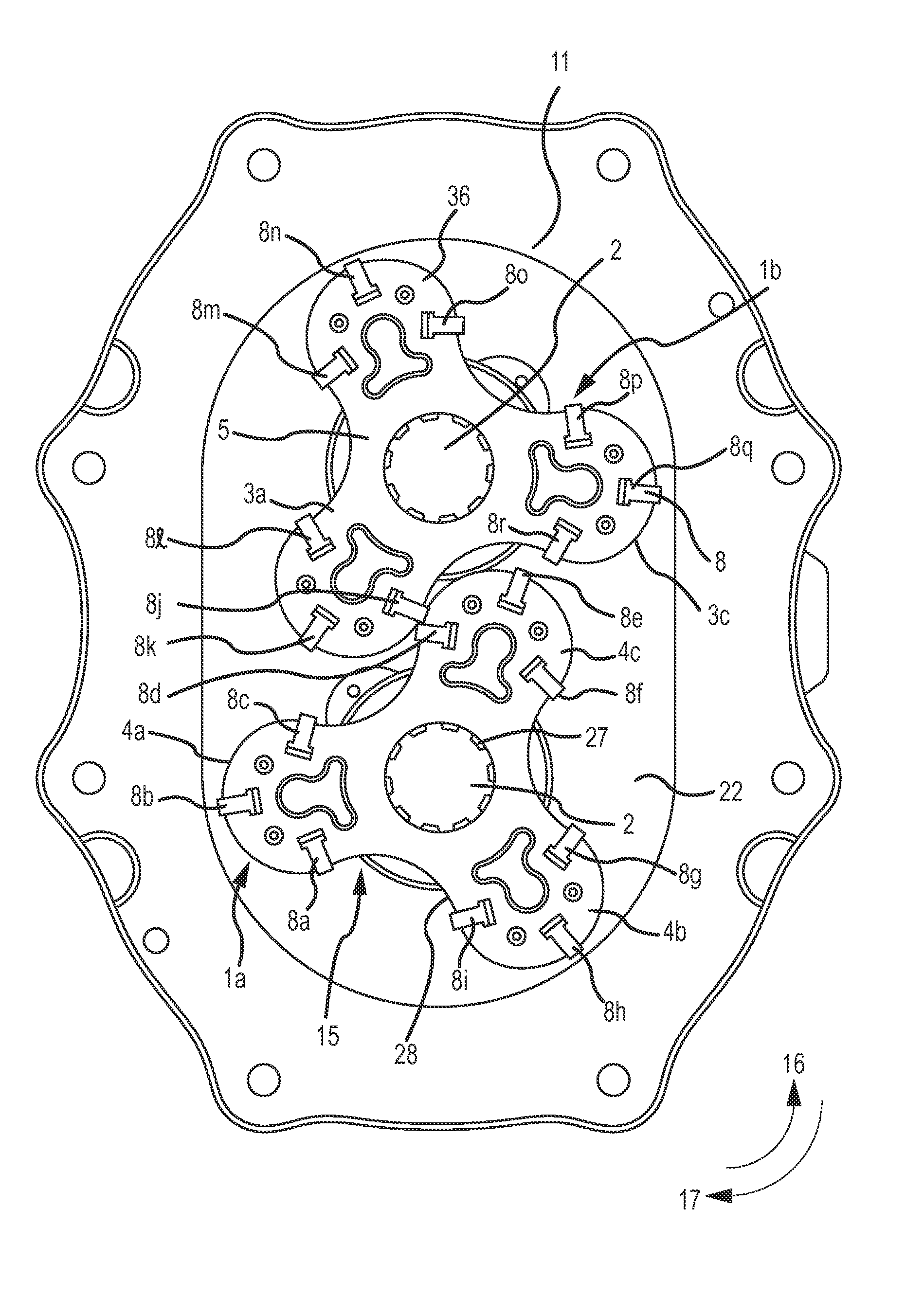

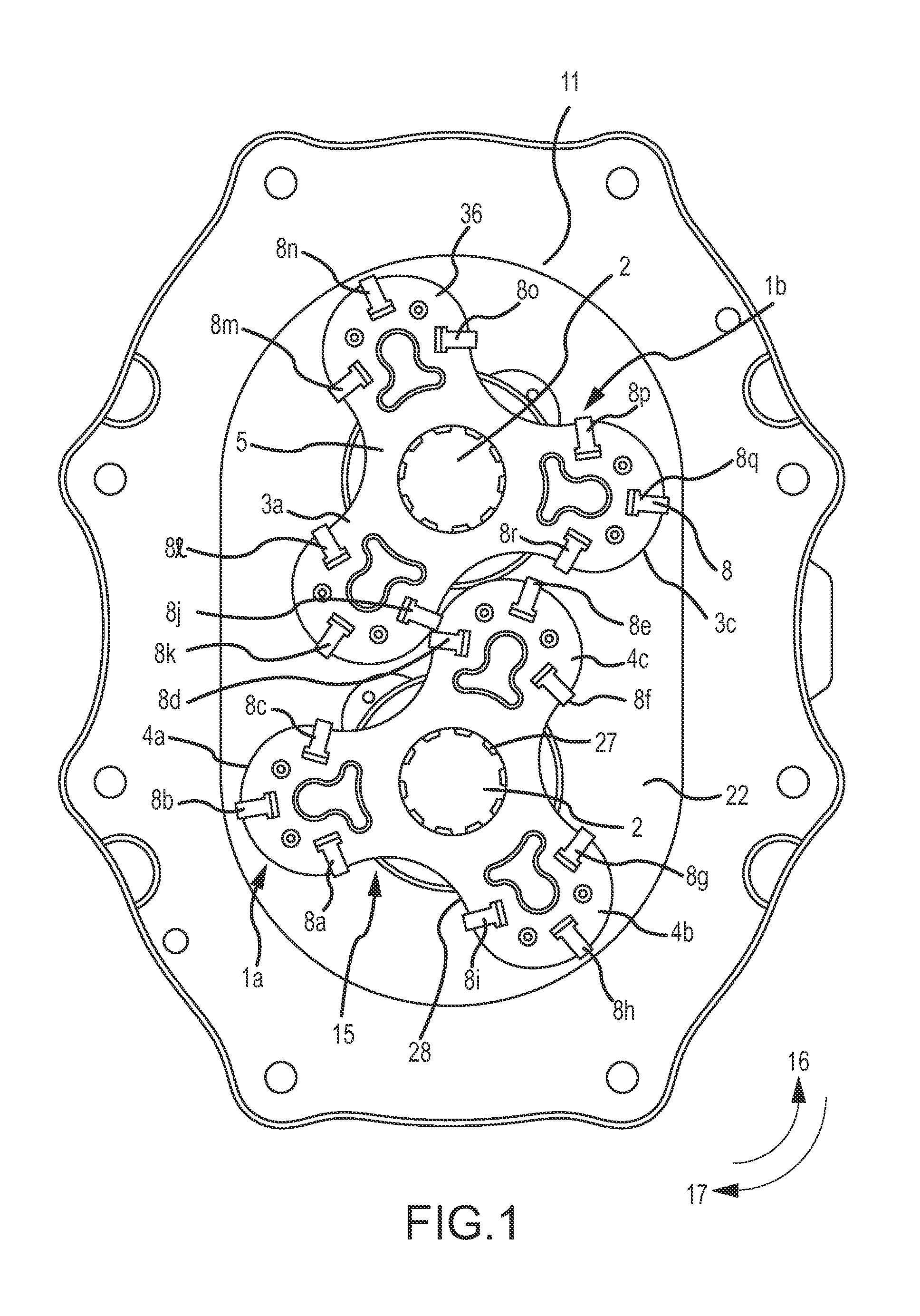

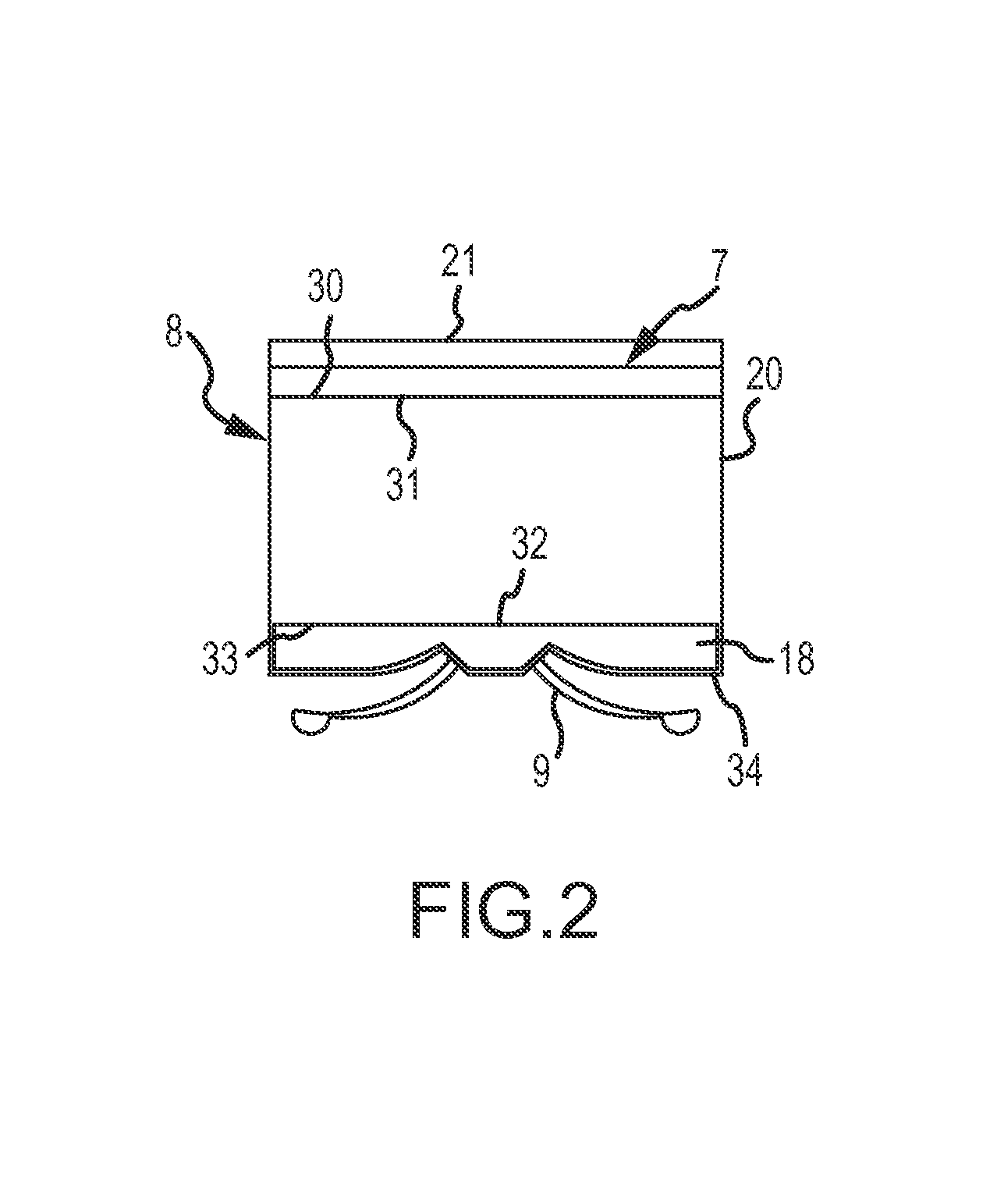

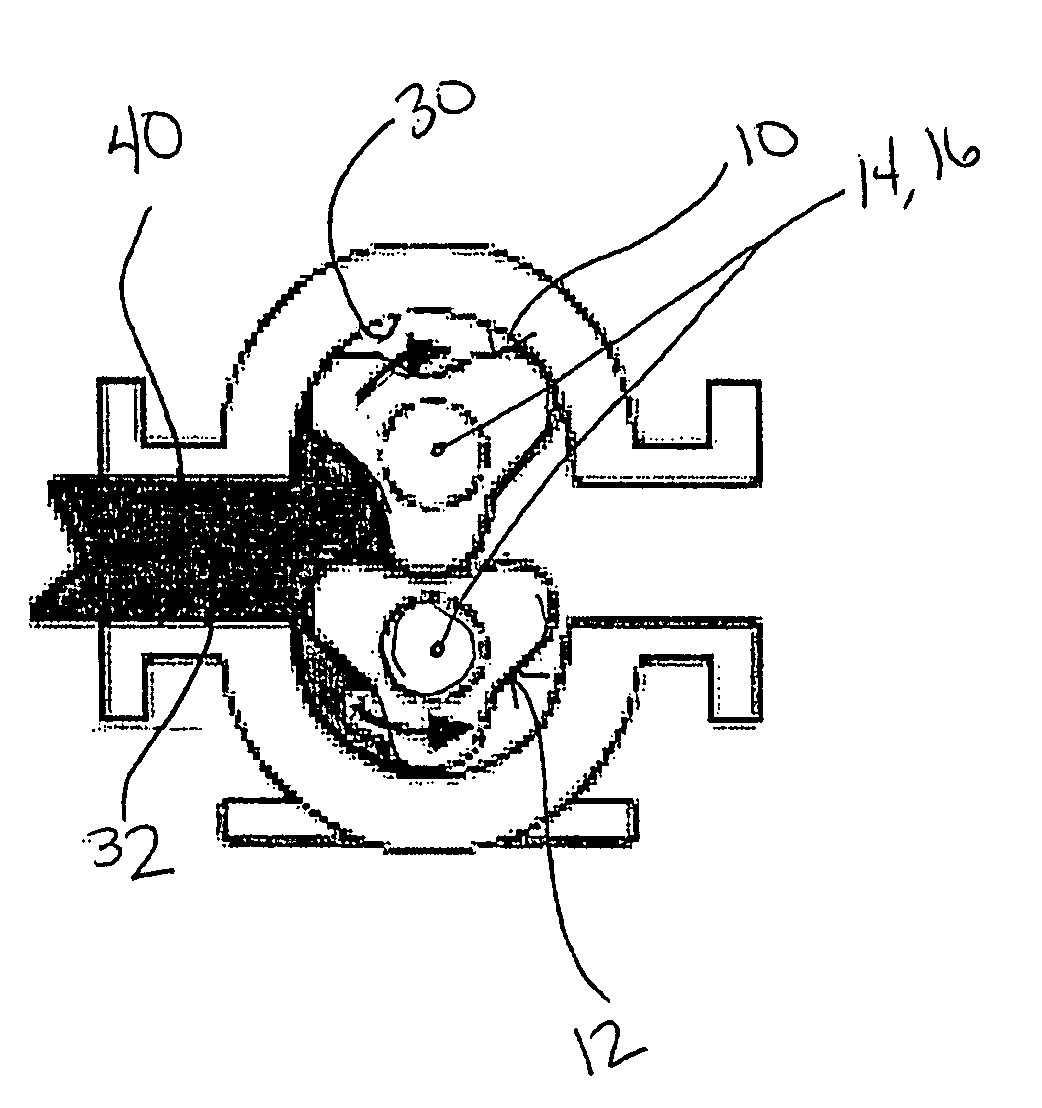

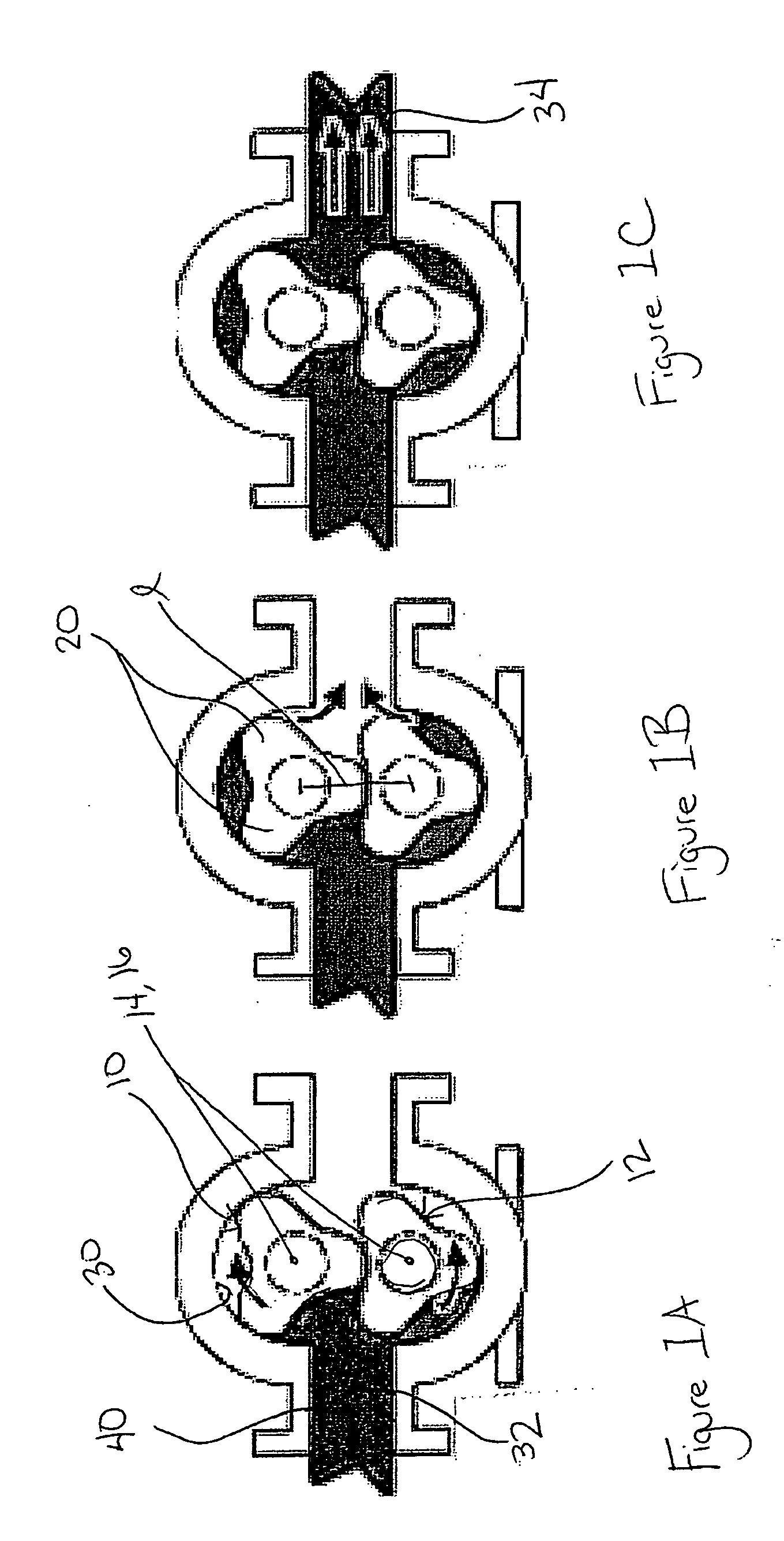

Rotary hydraulic pump actuated multi-stroke surgical instrument

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

Rotary hydraulic pump actuated multi-stroke surgical instrument

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

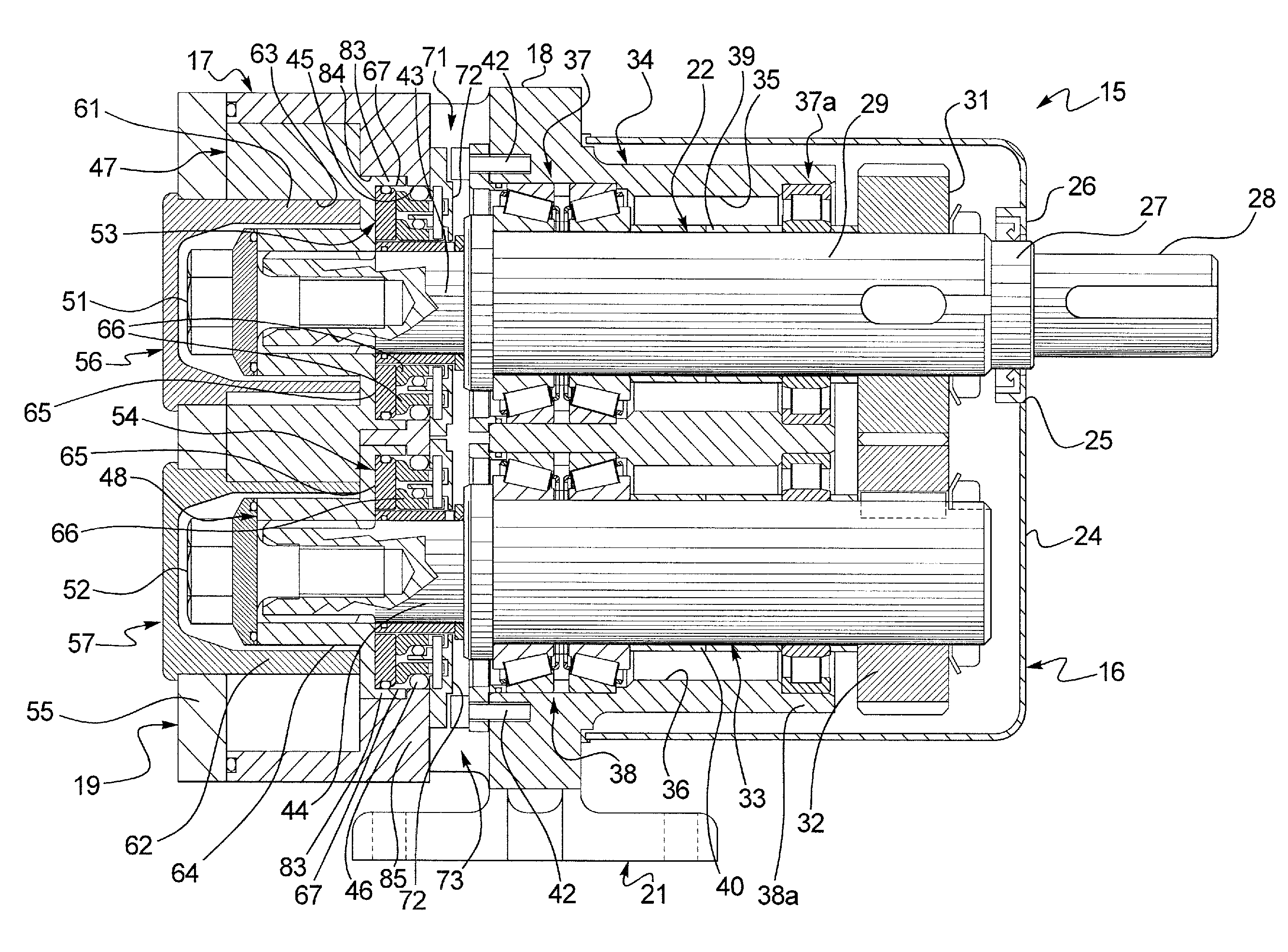

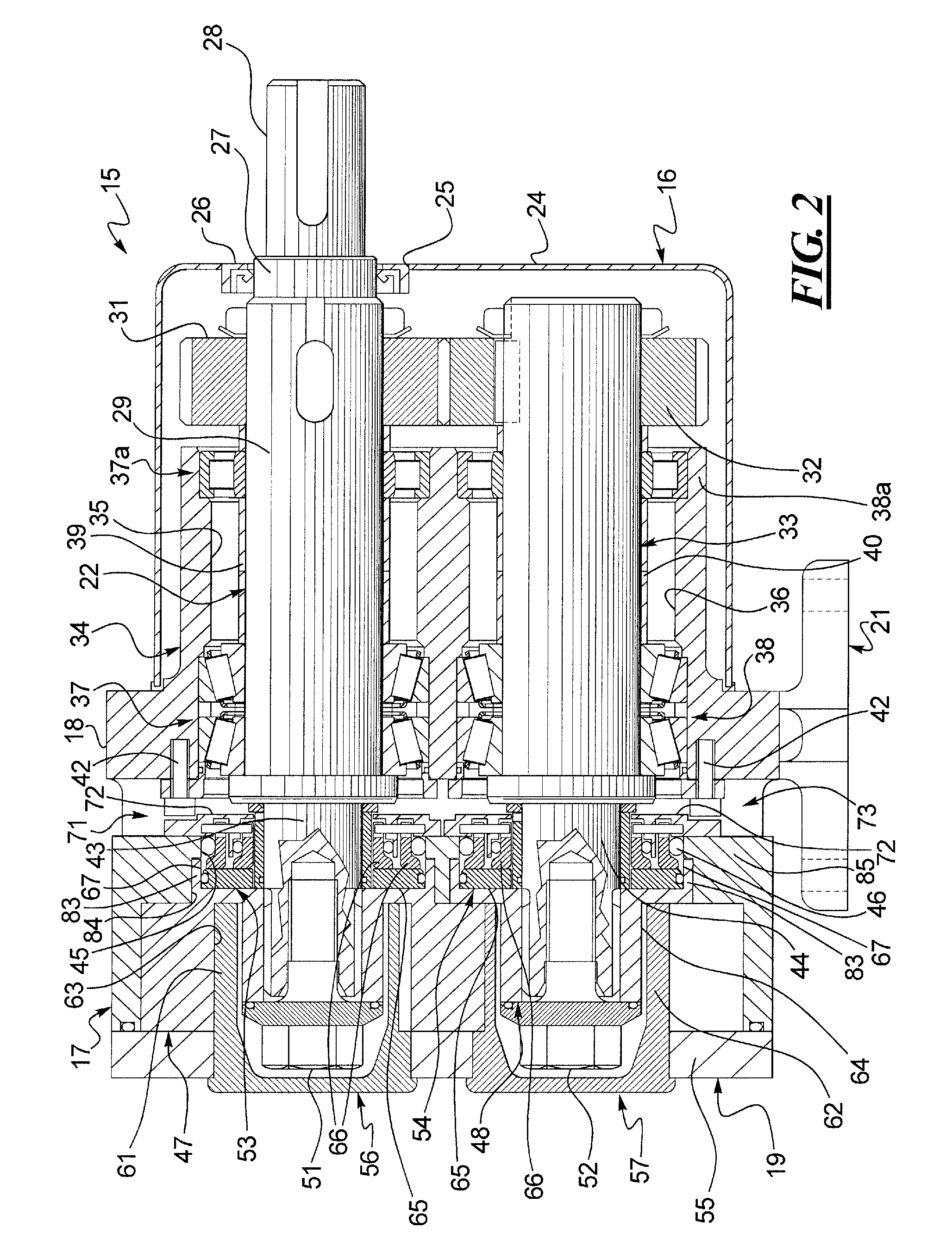

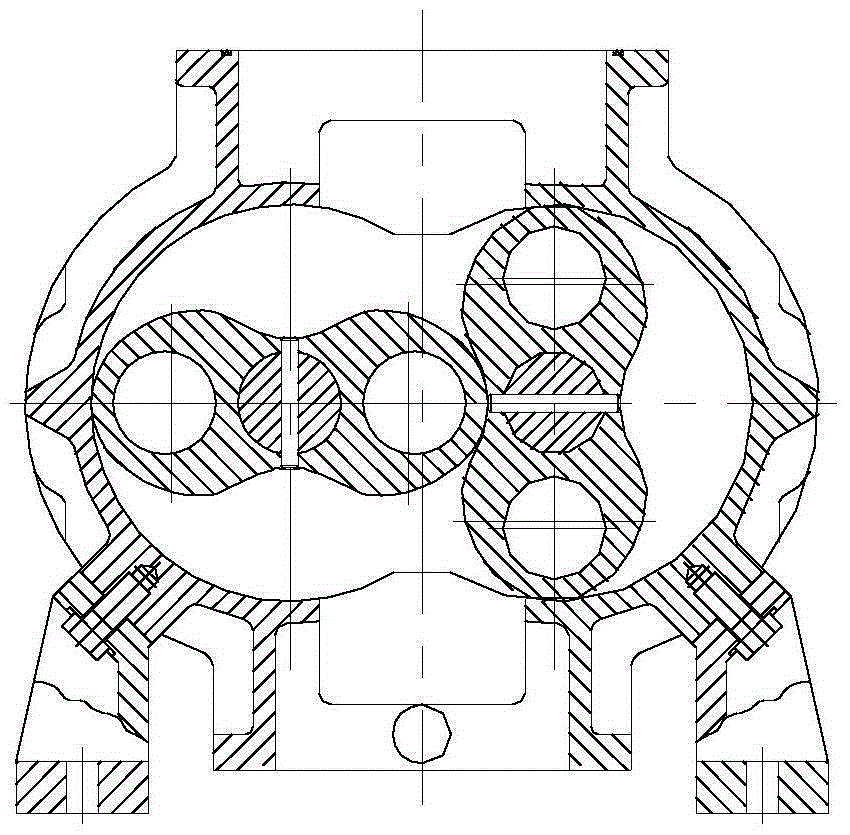

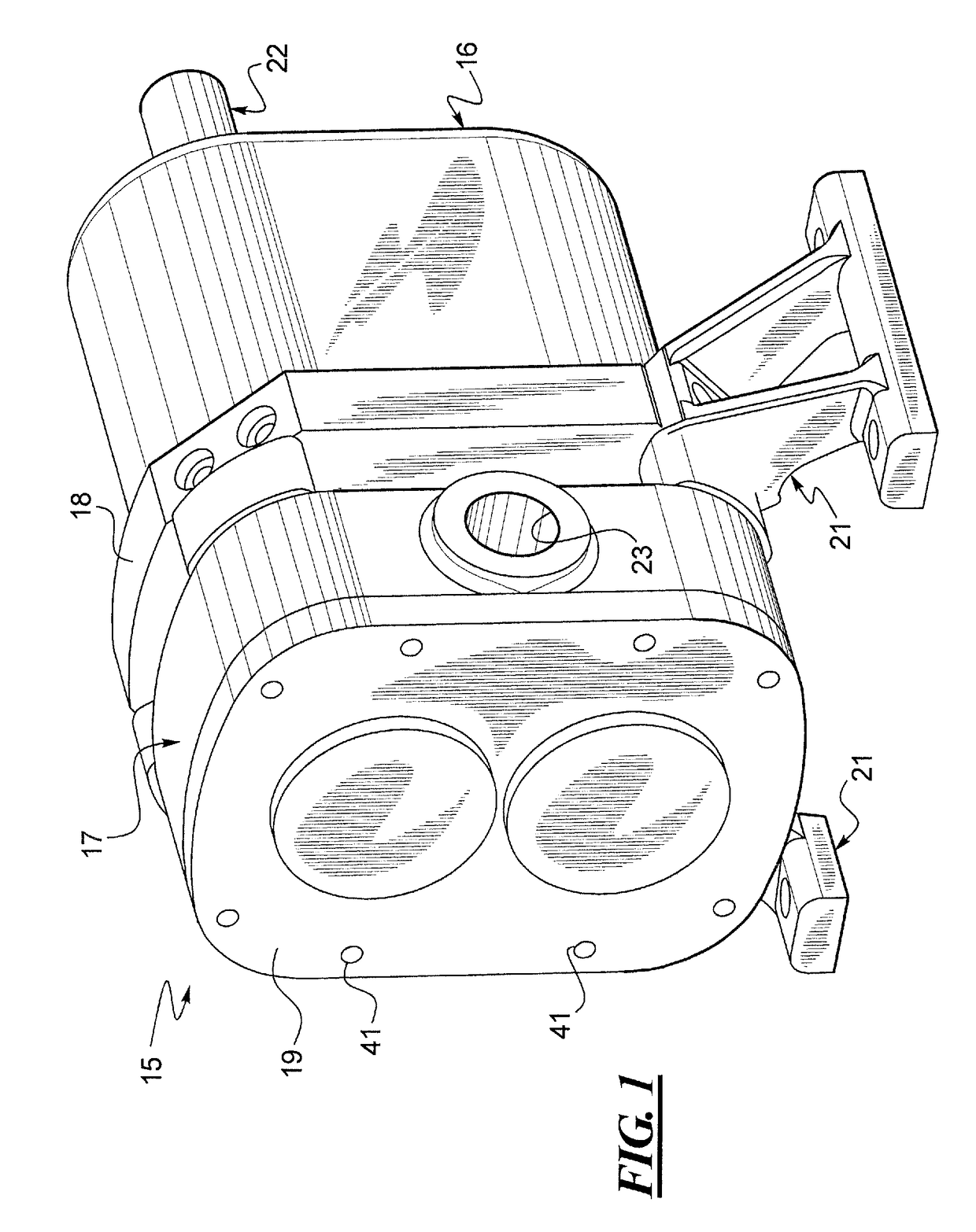

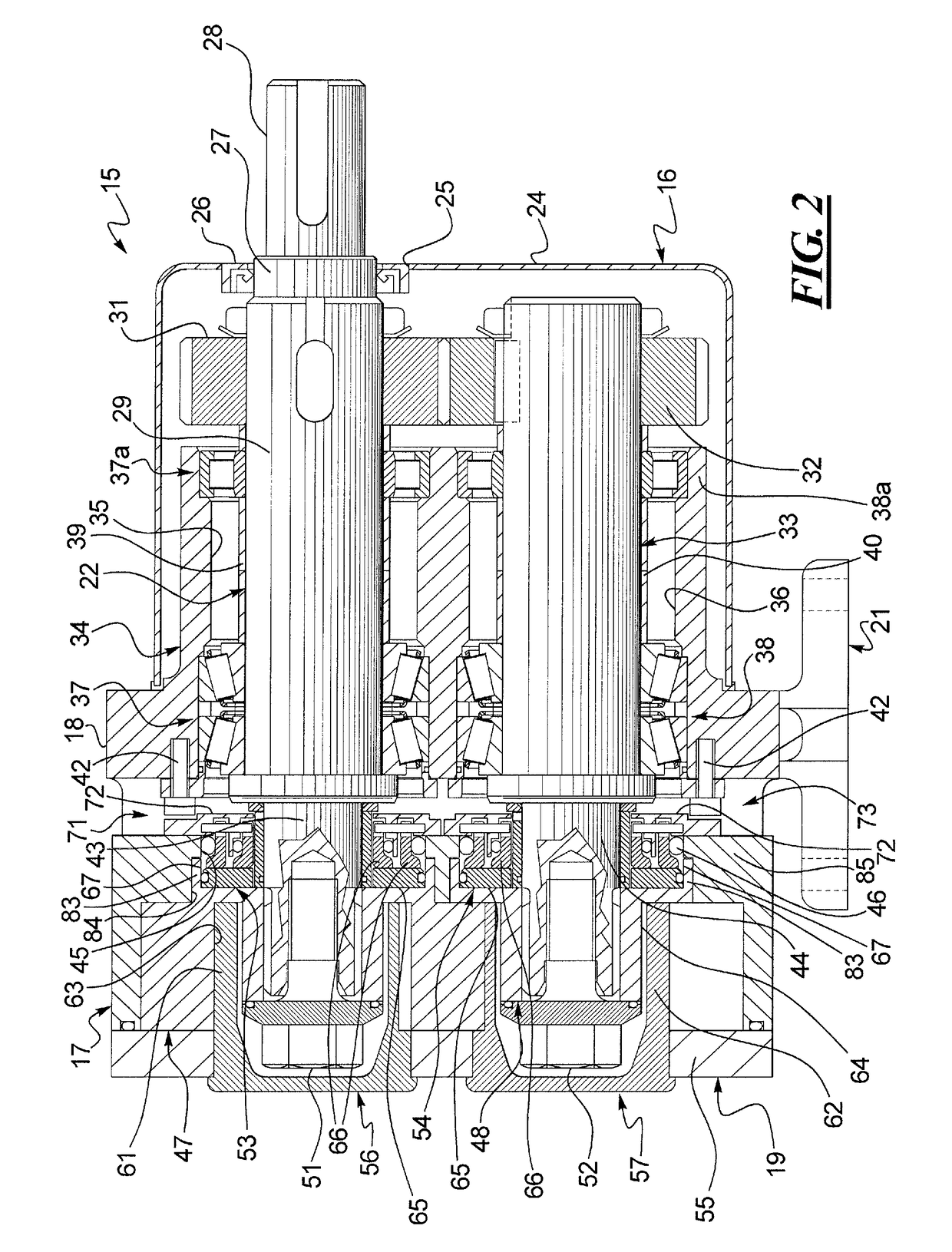

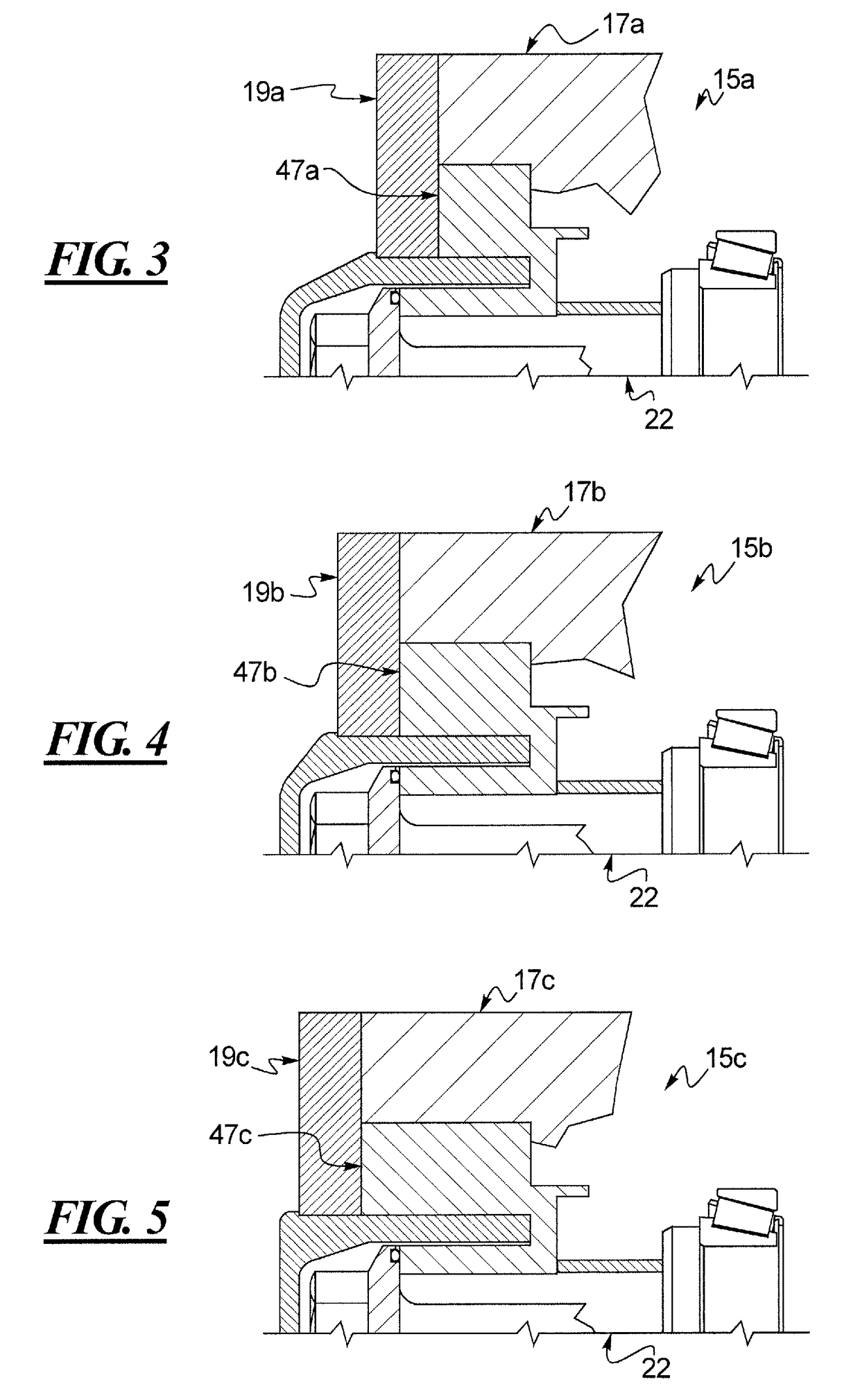

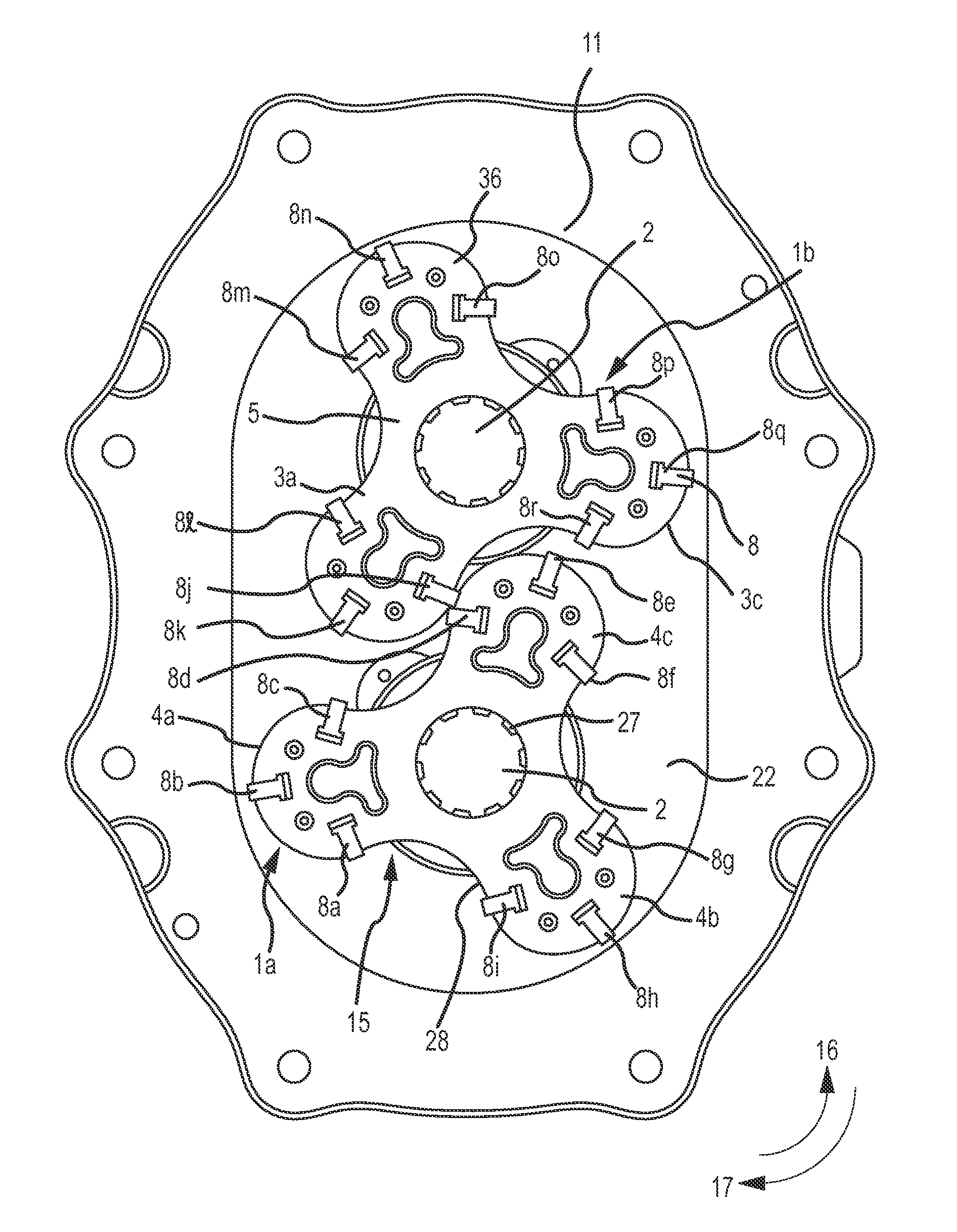

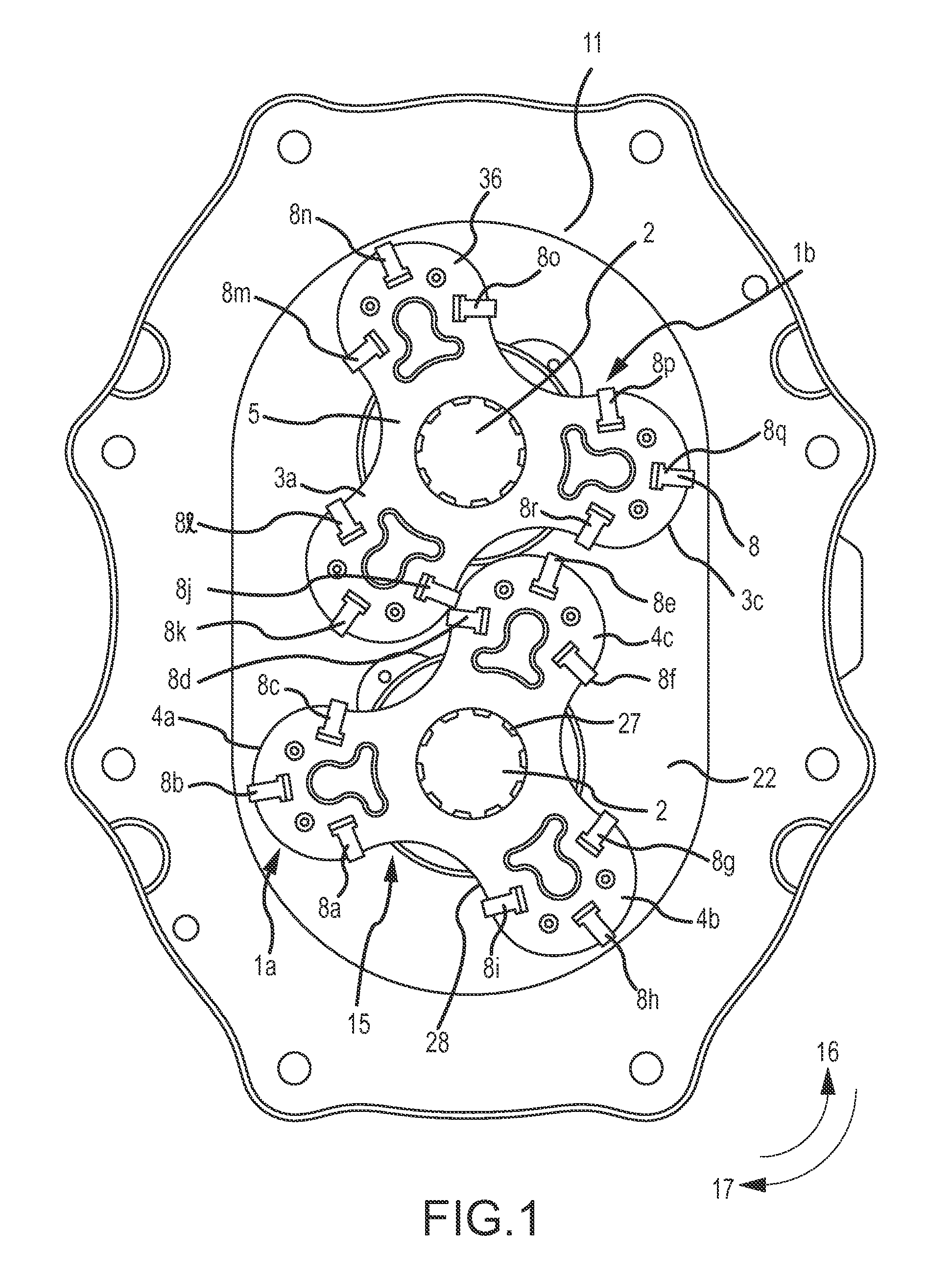

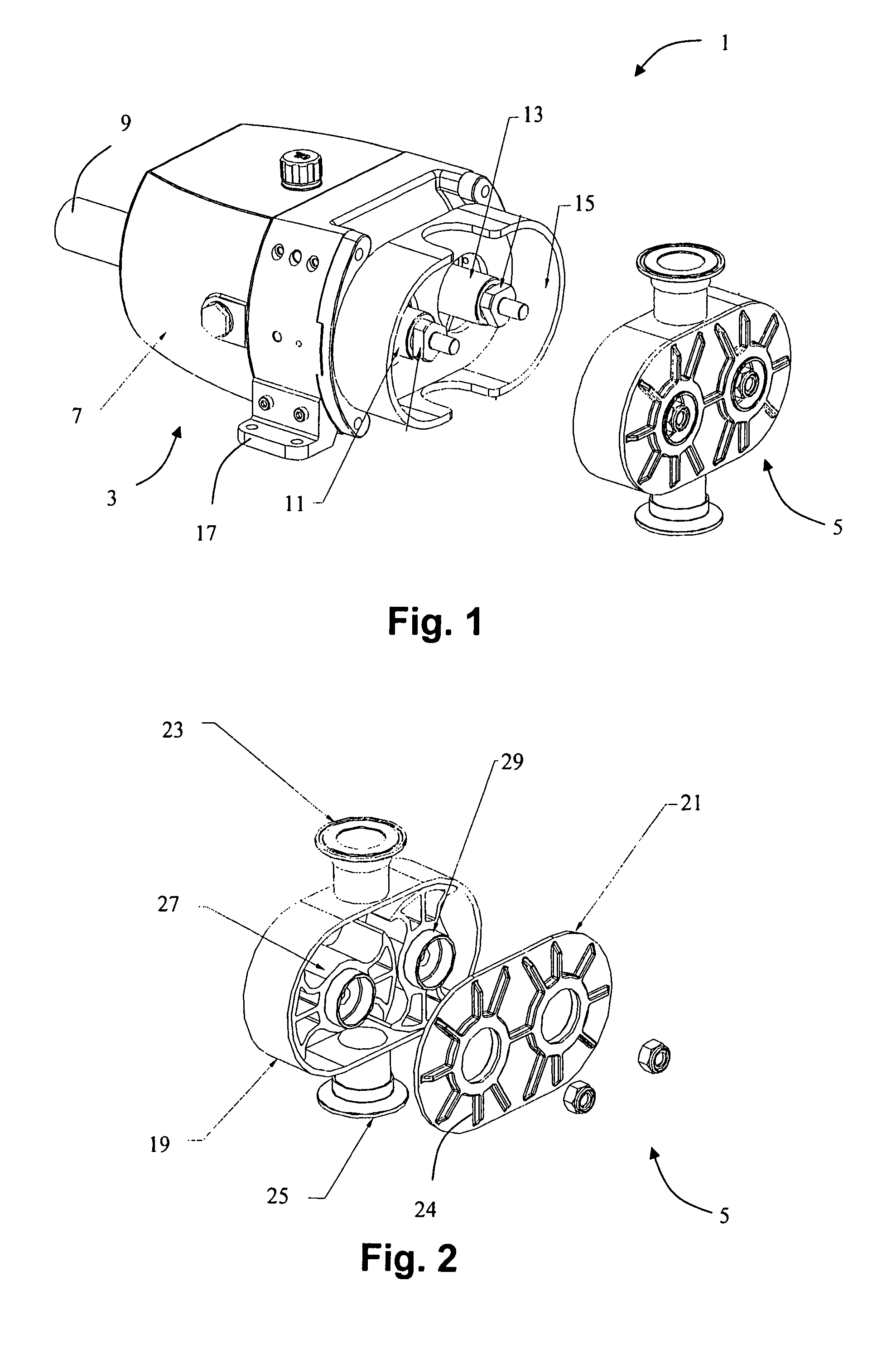

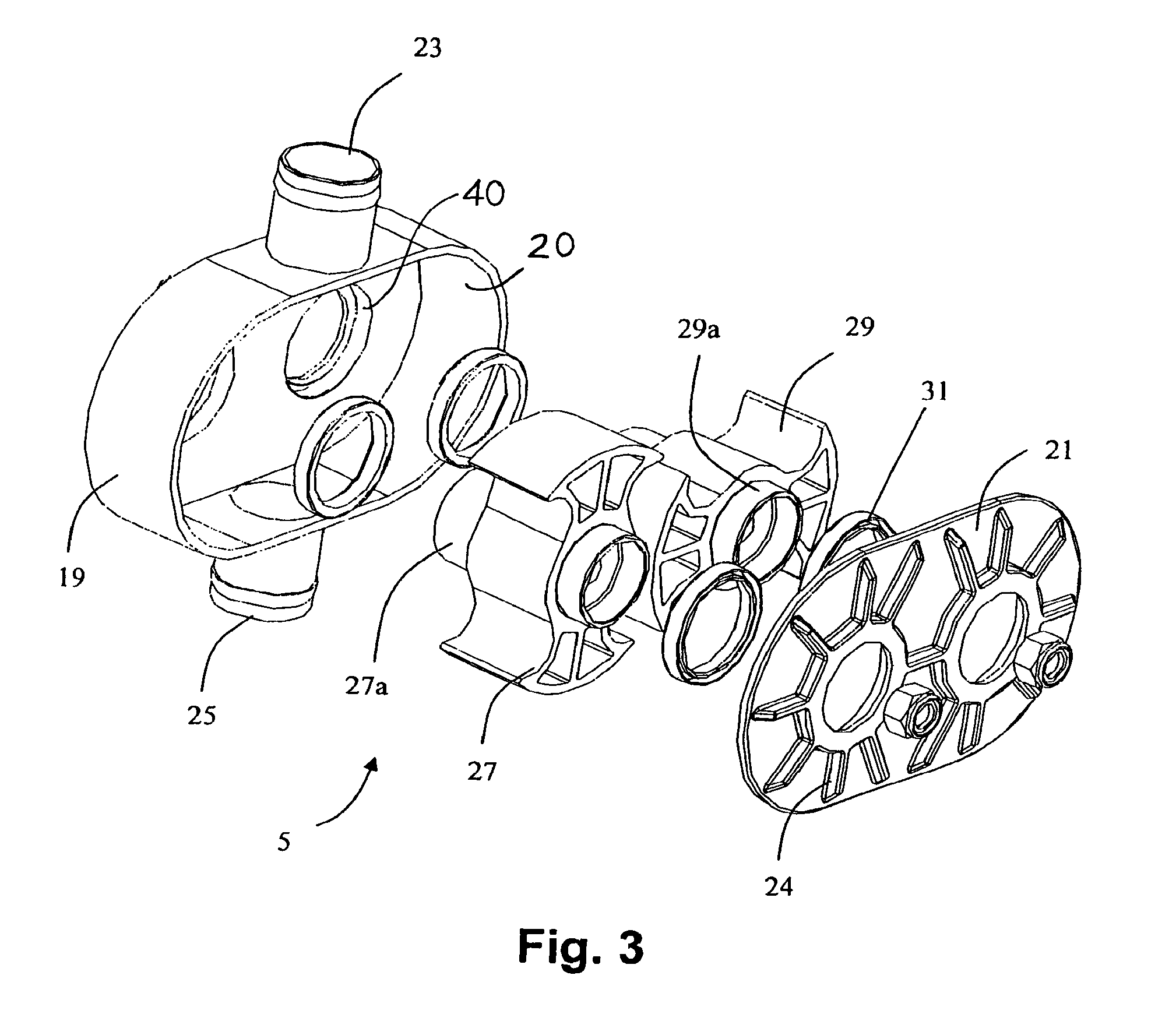

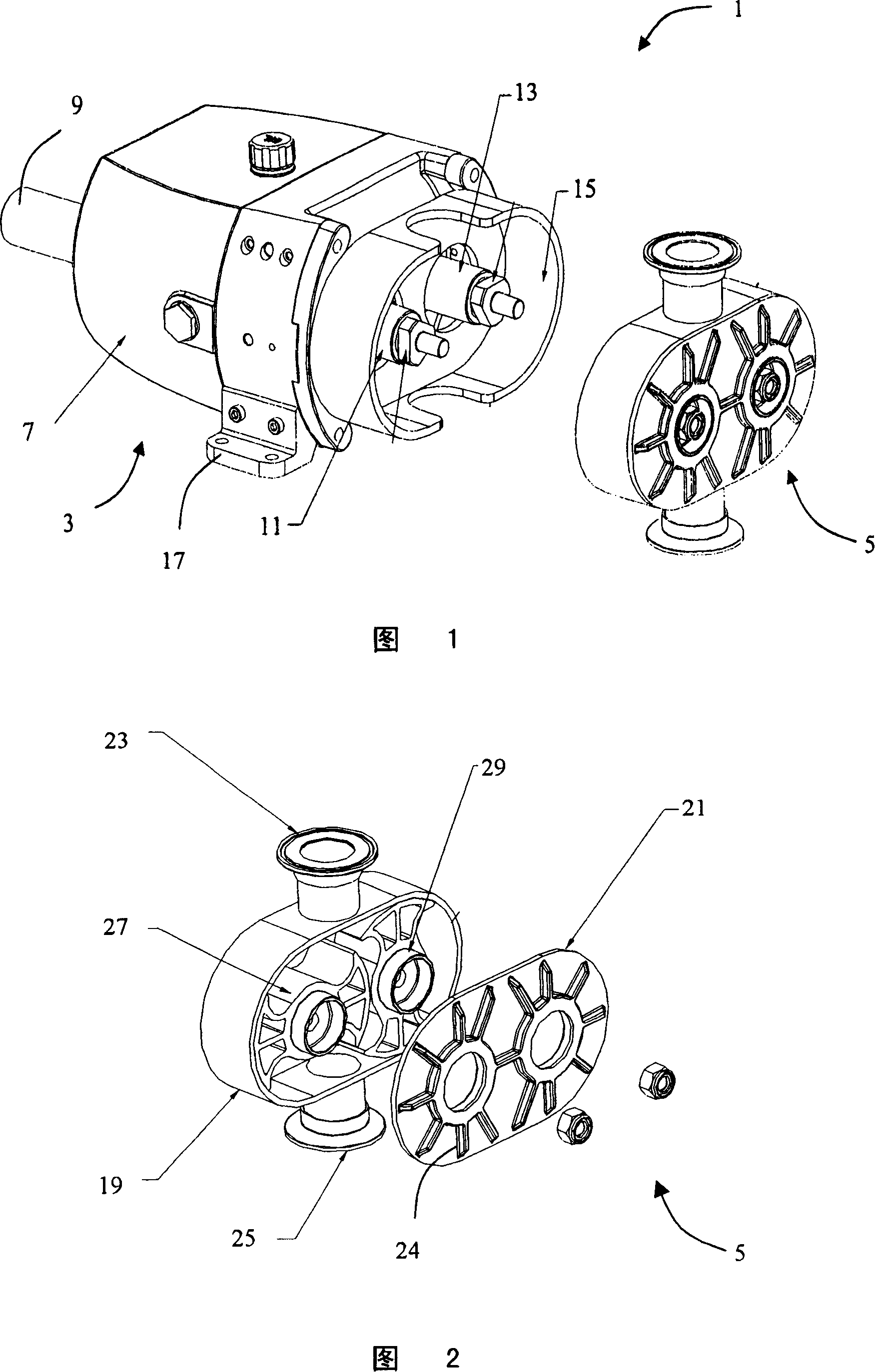

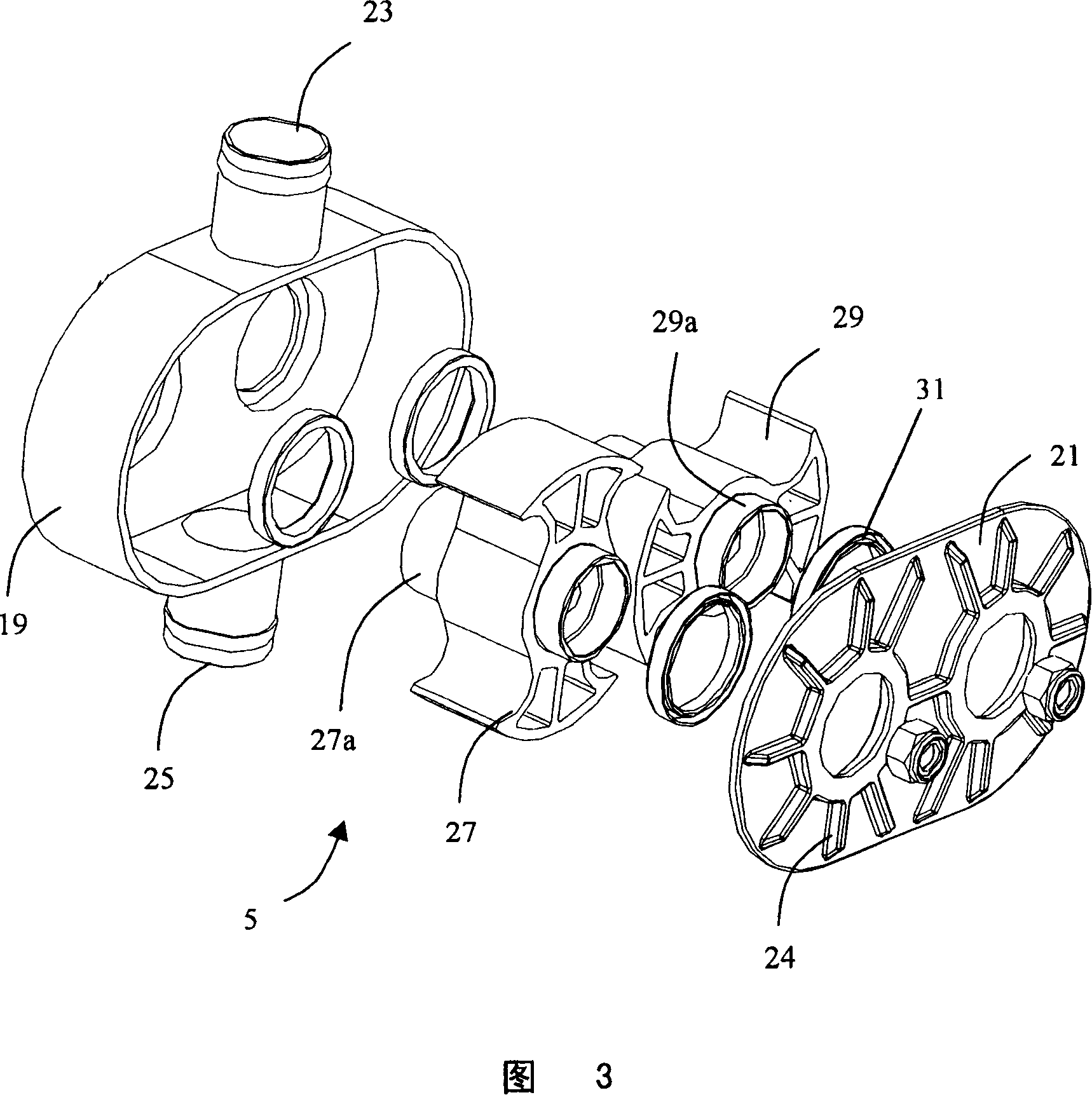

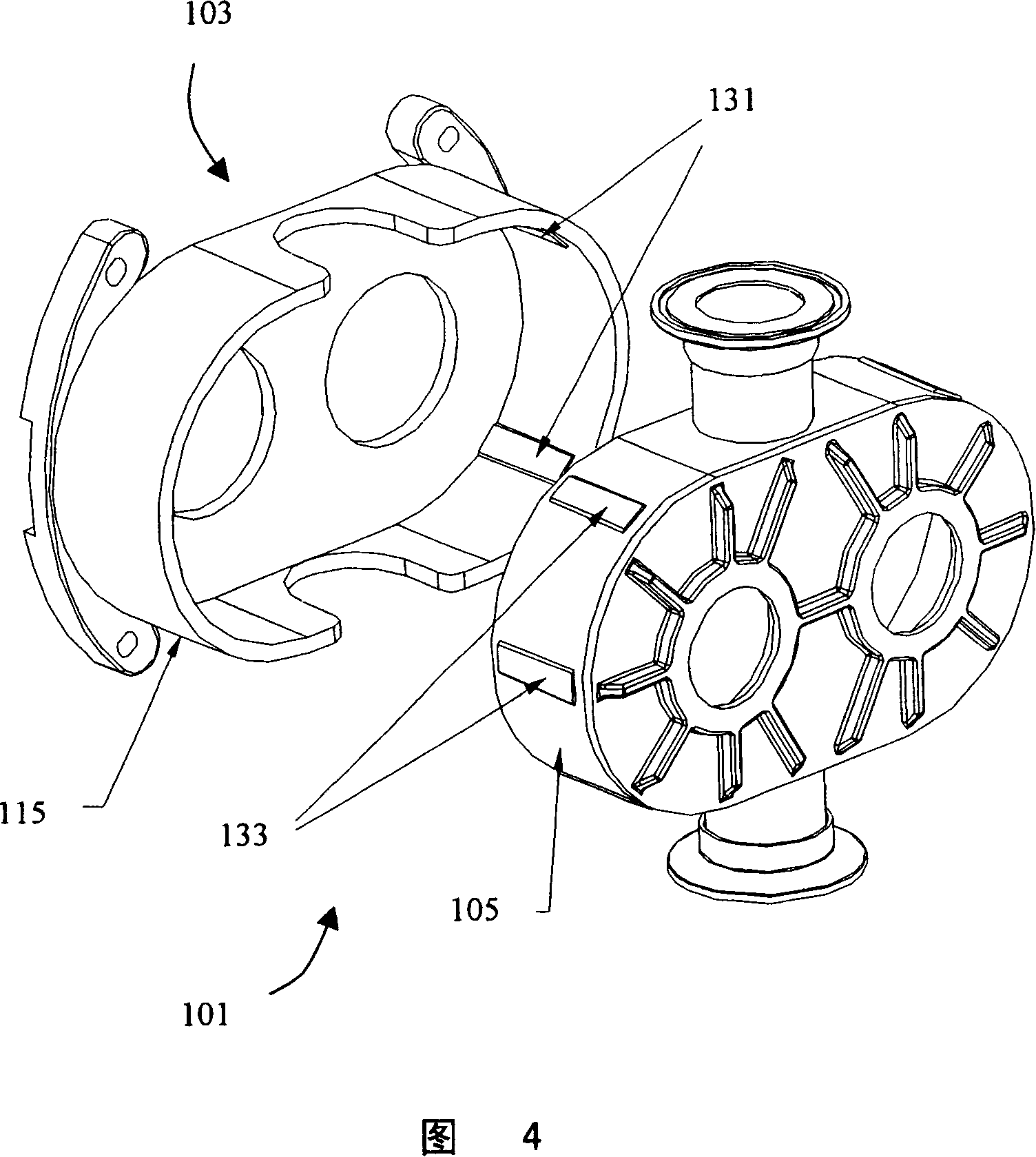

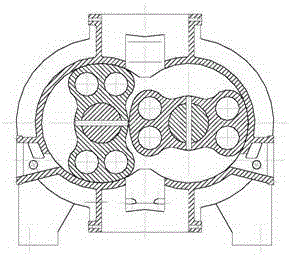

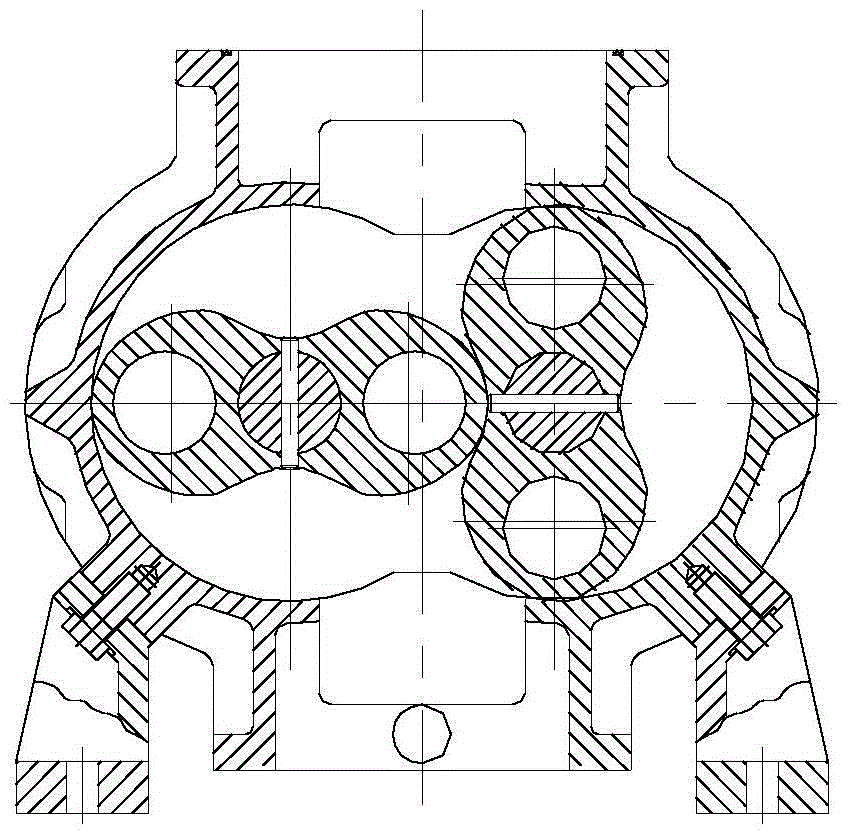

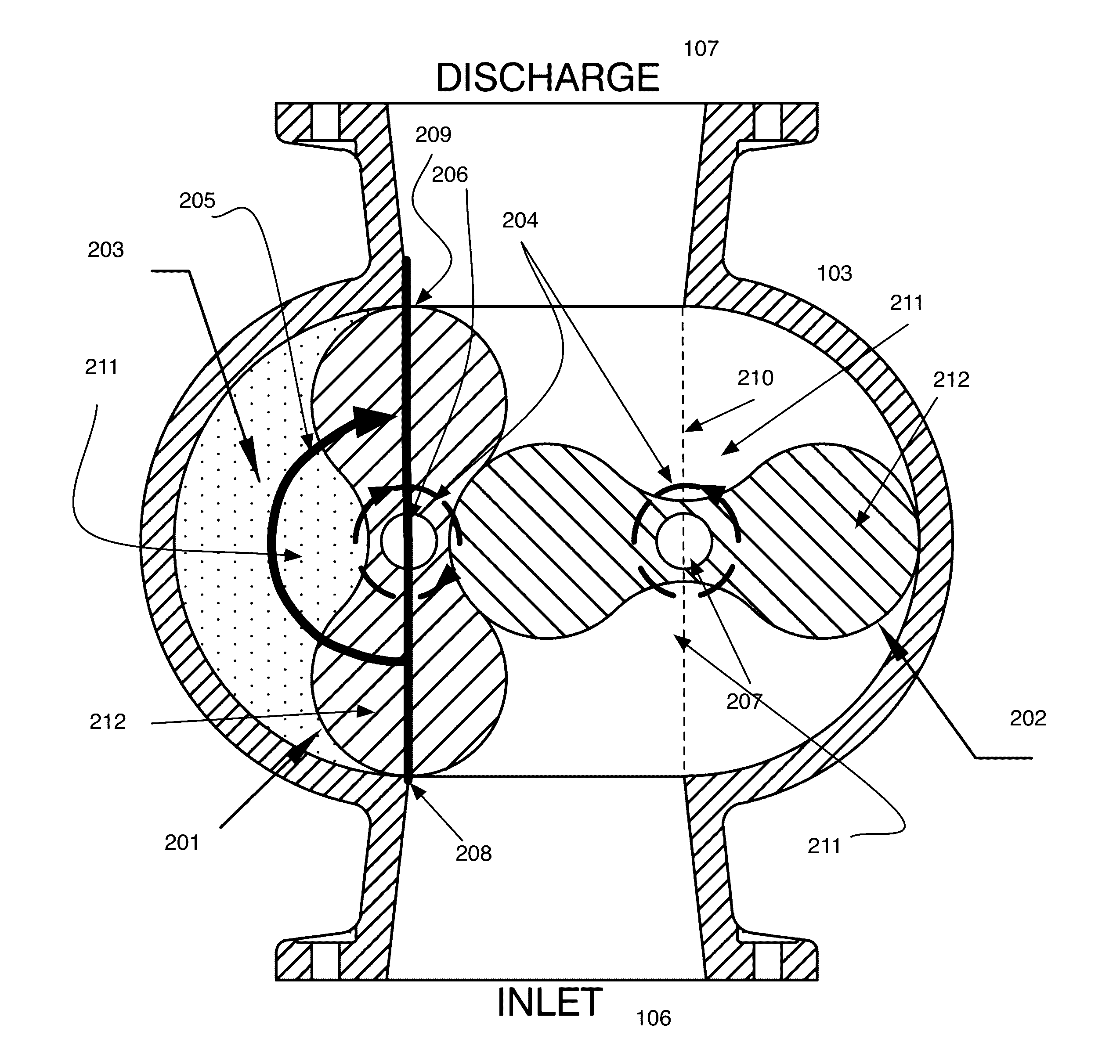

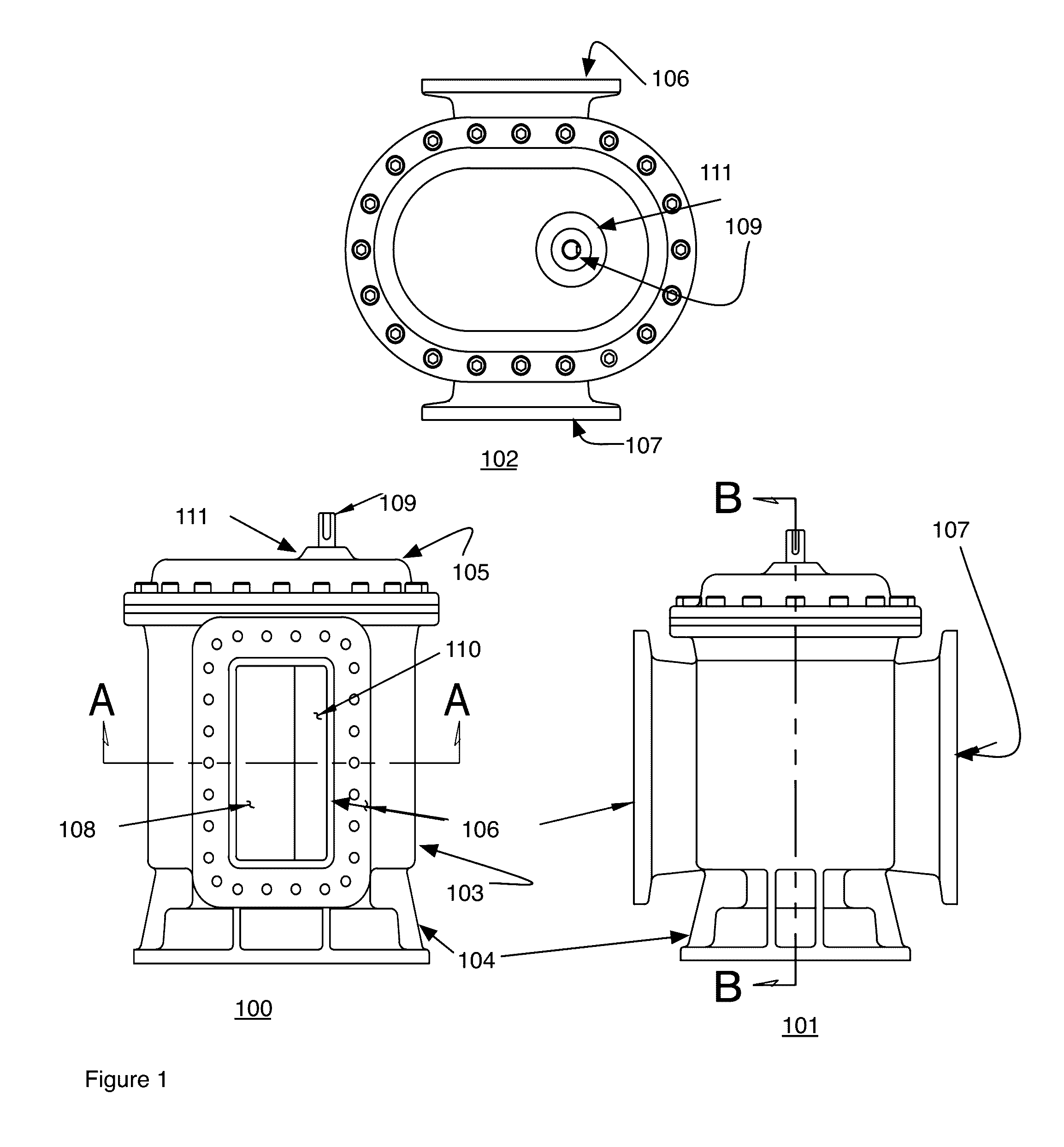

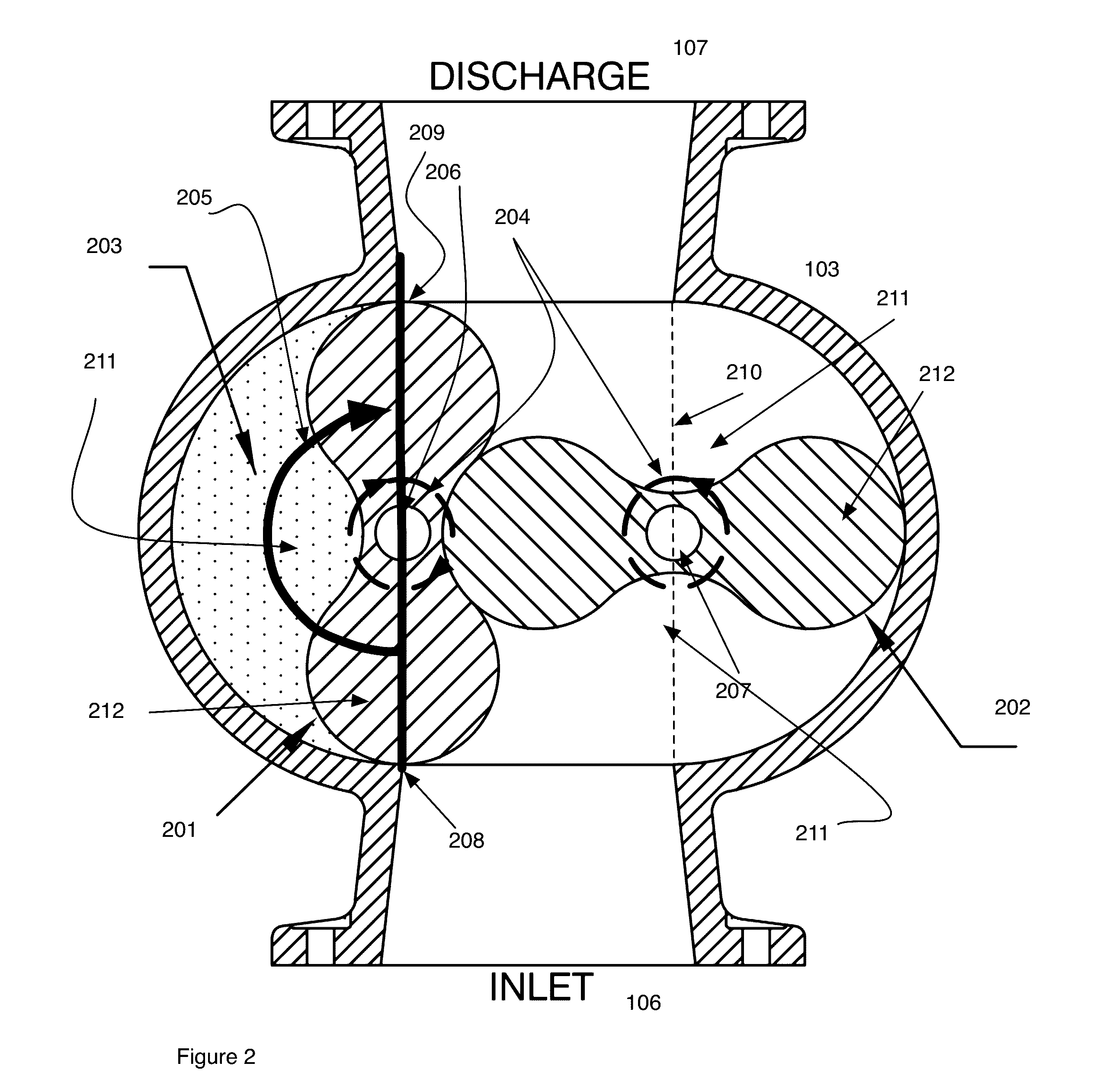

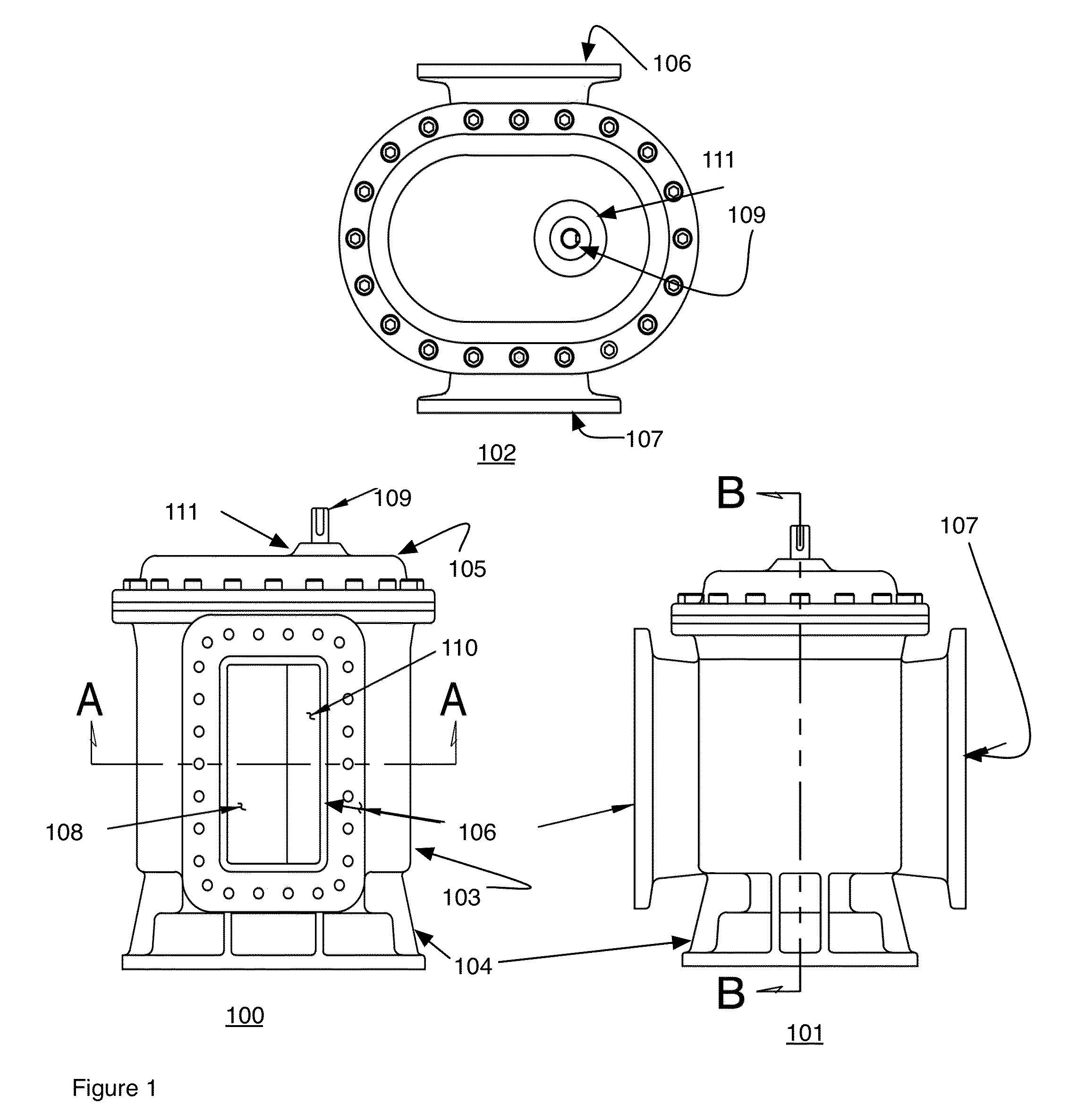

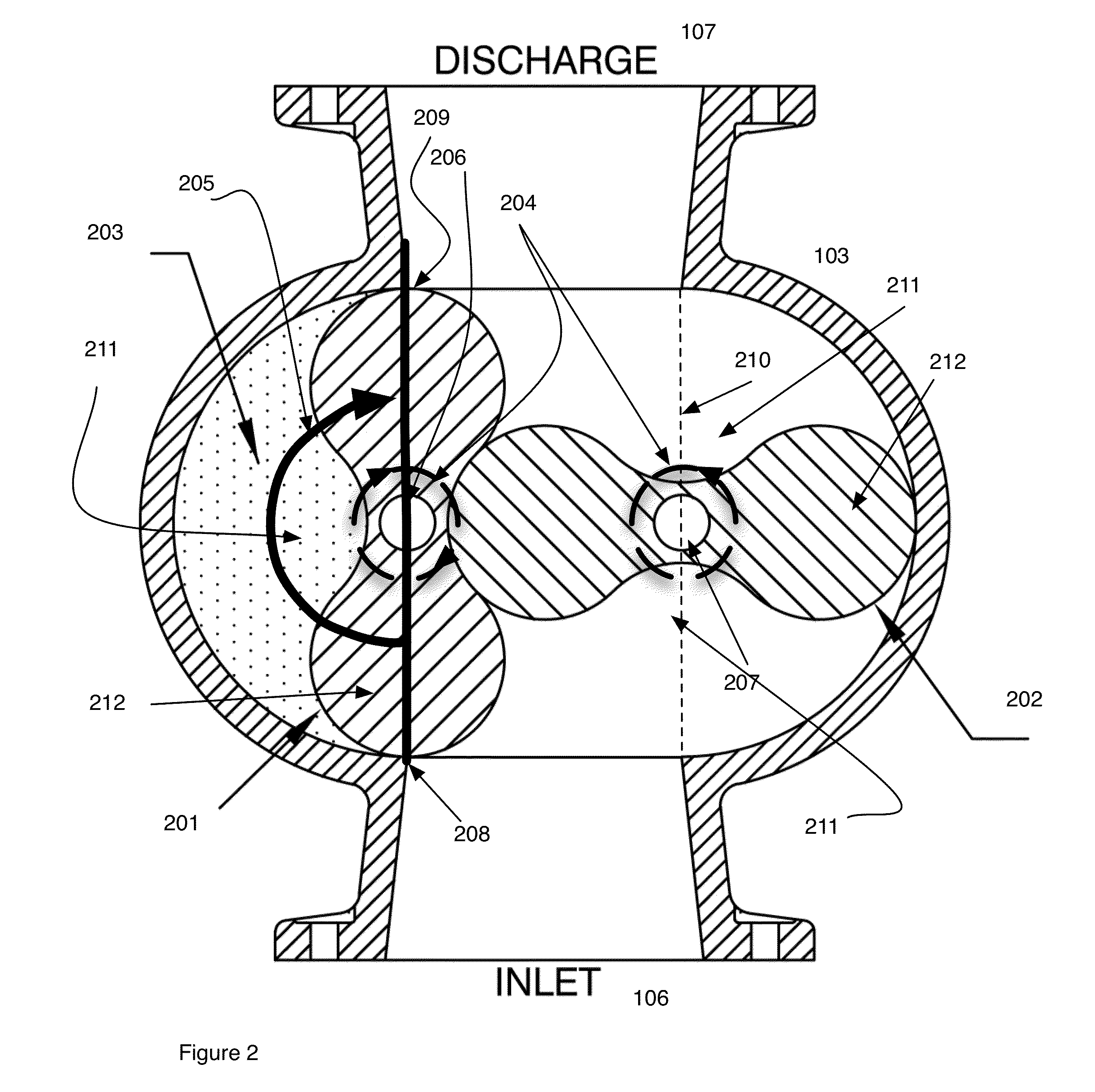

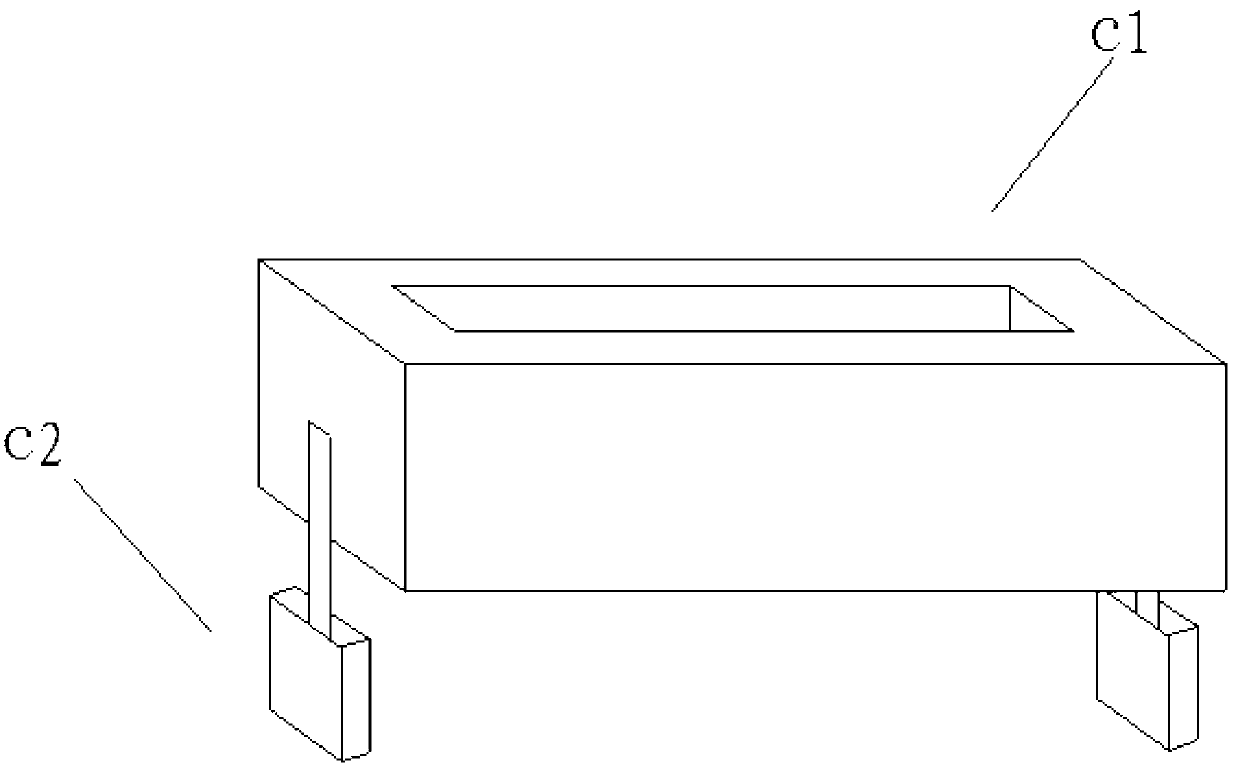

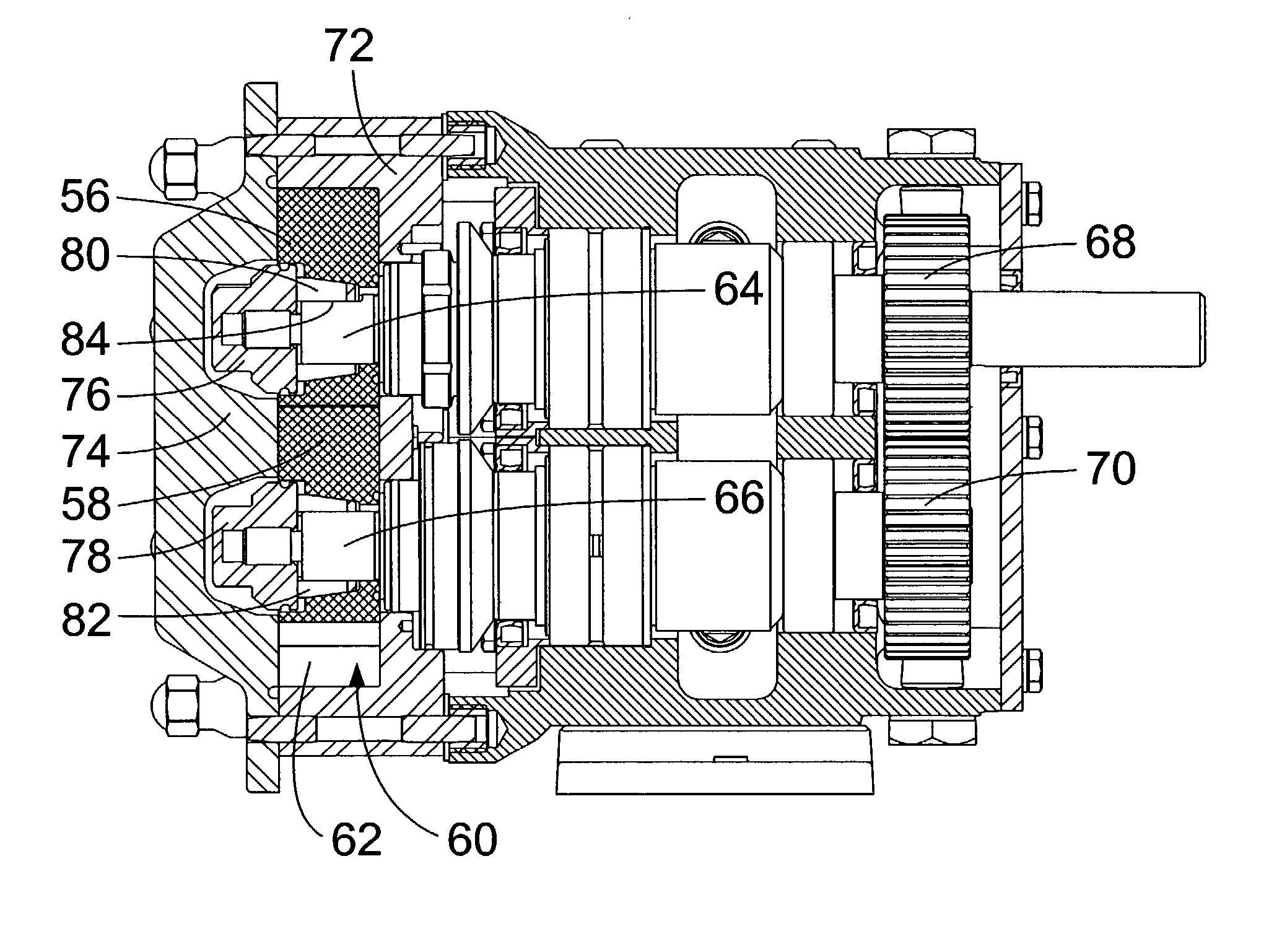

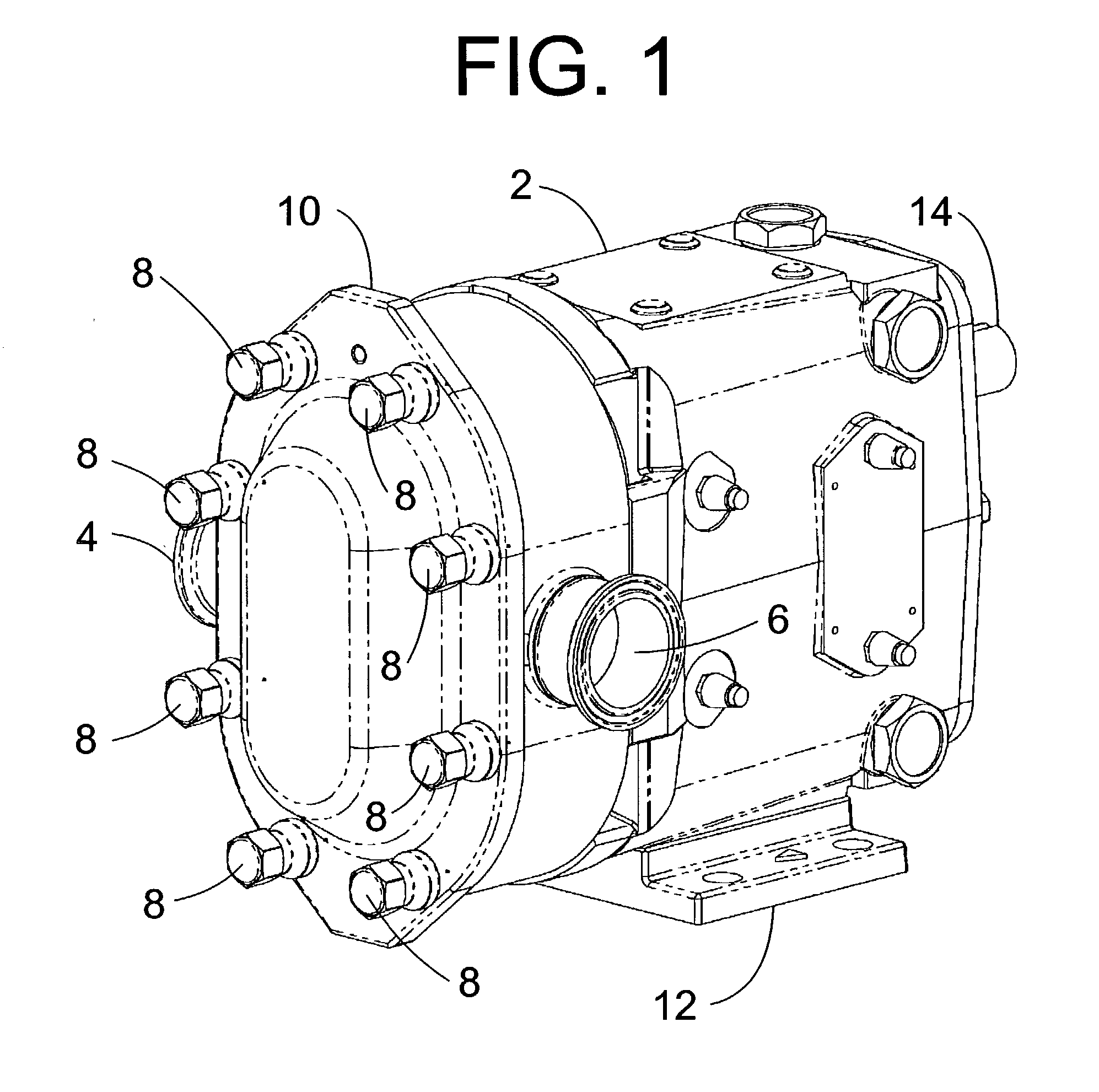

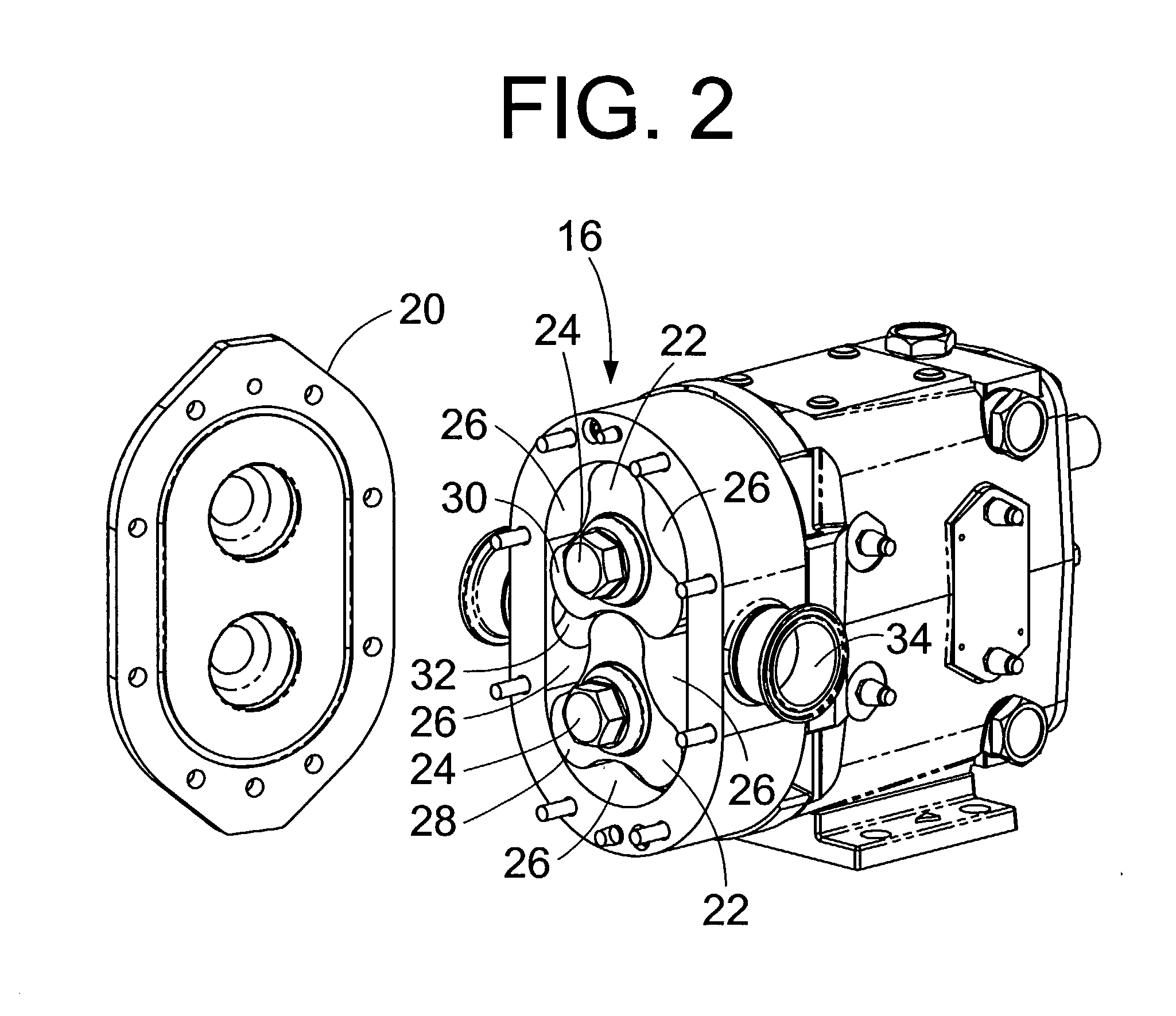

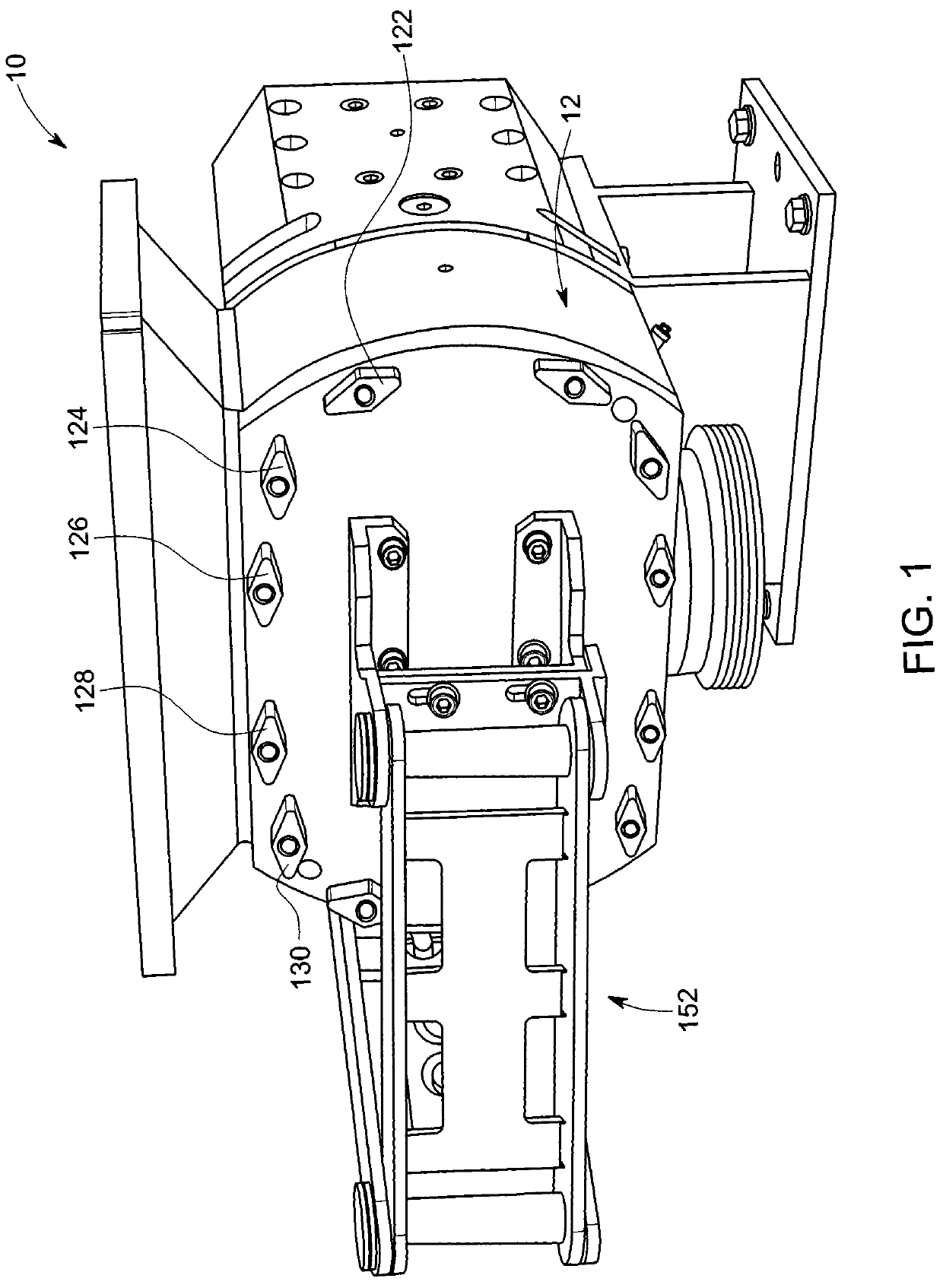

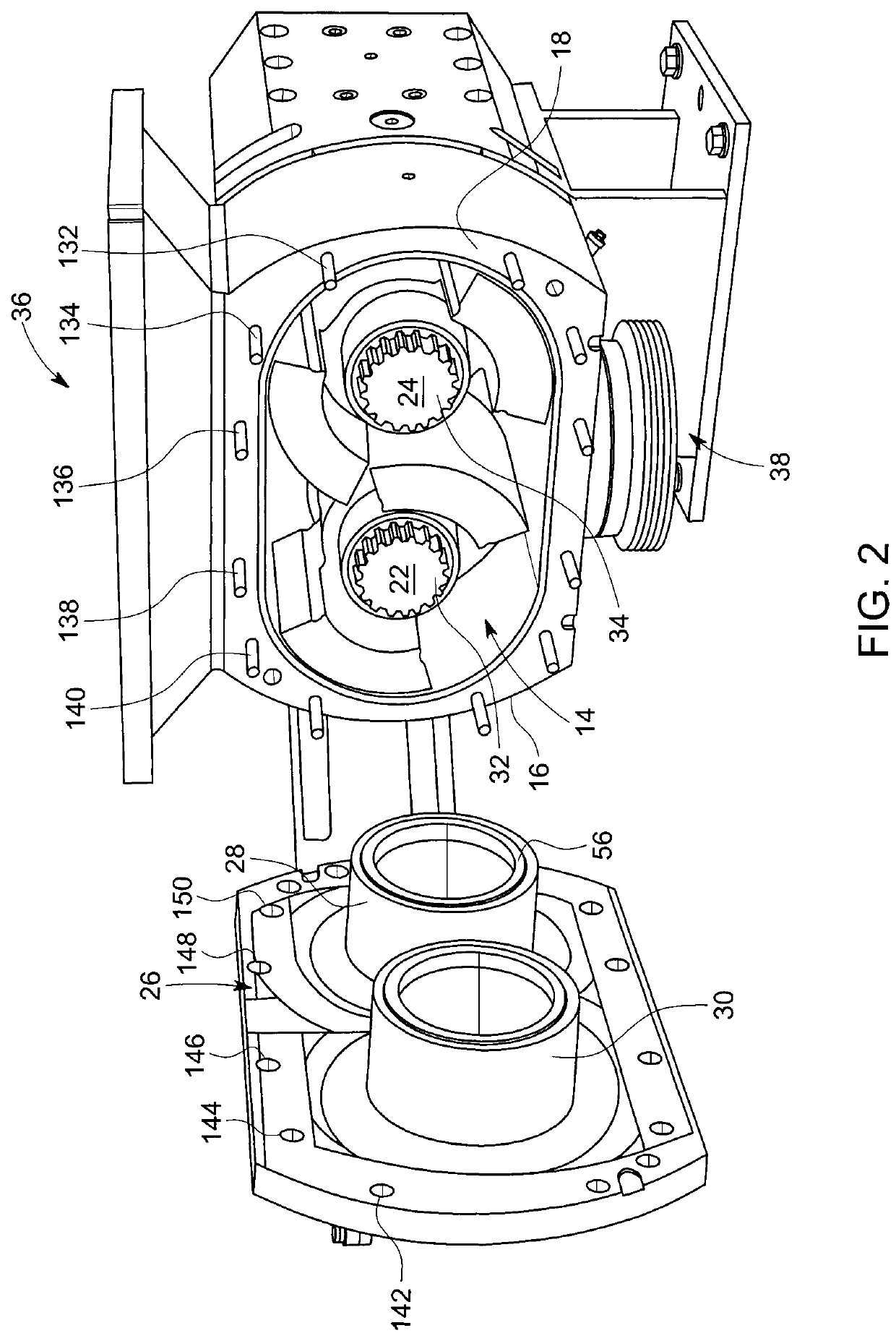

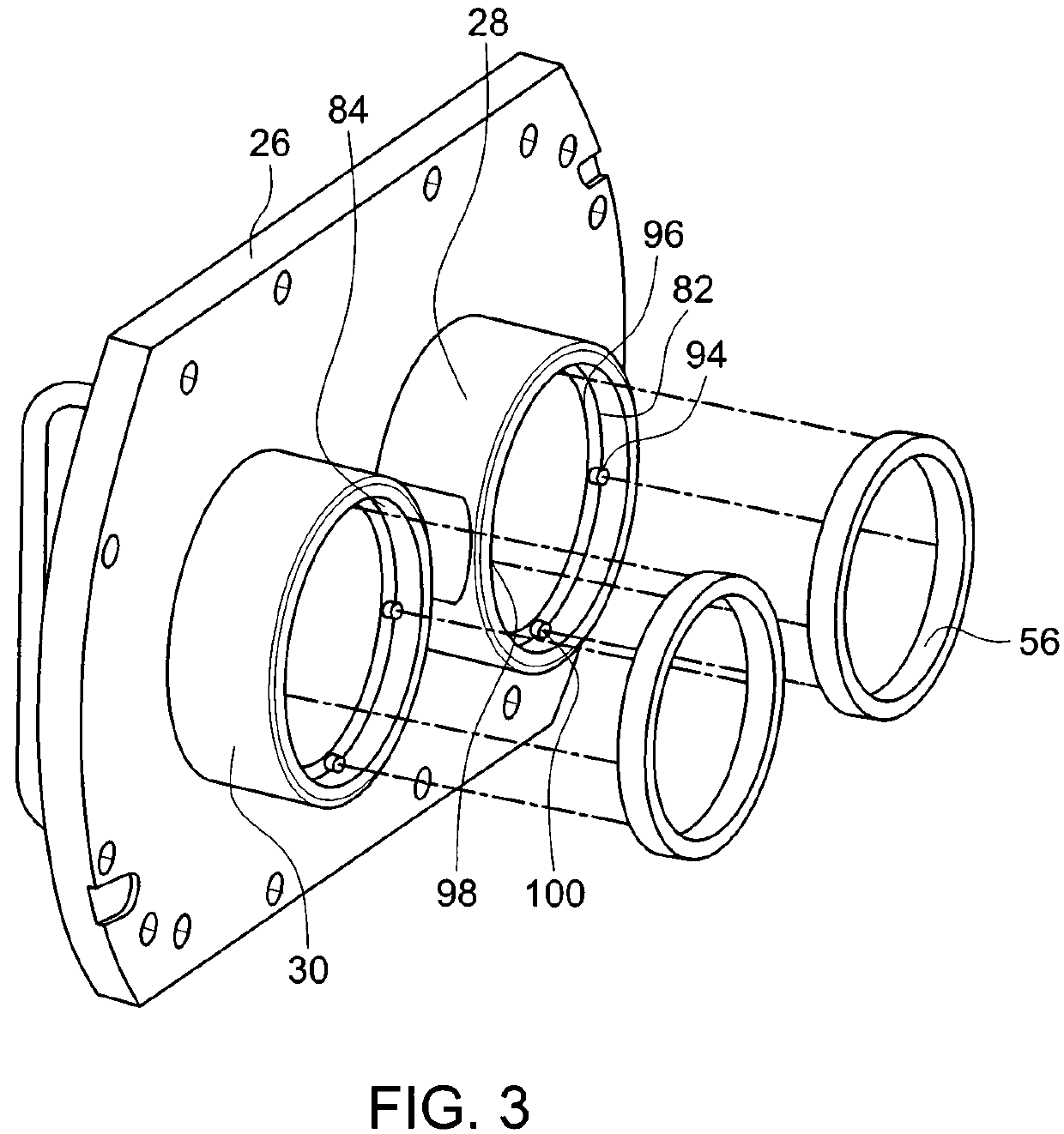

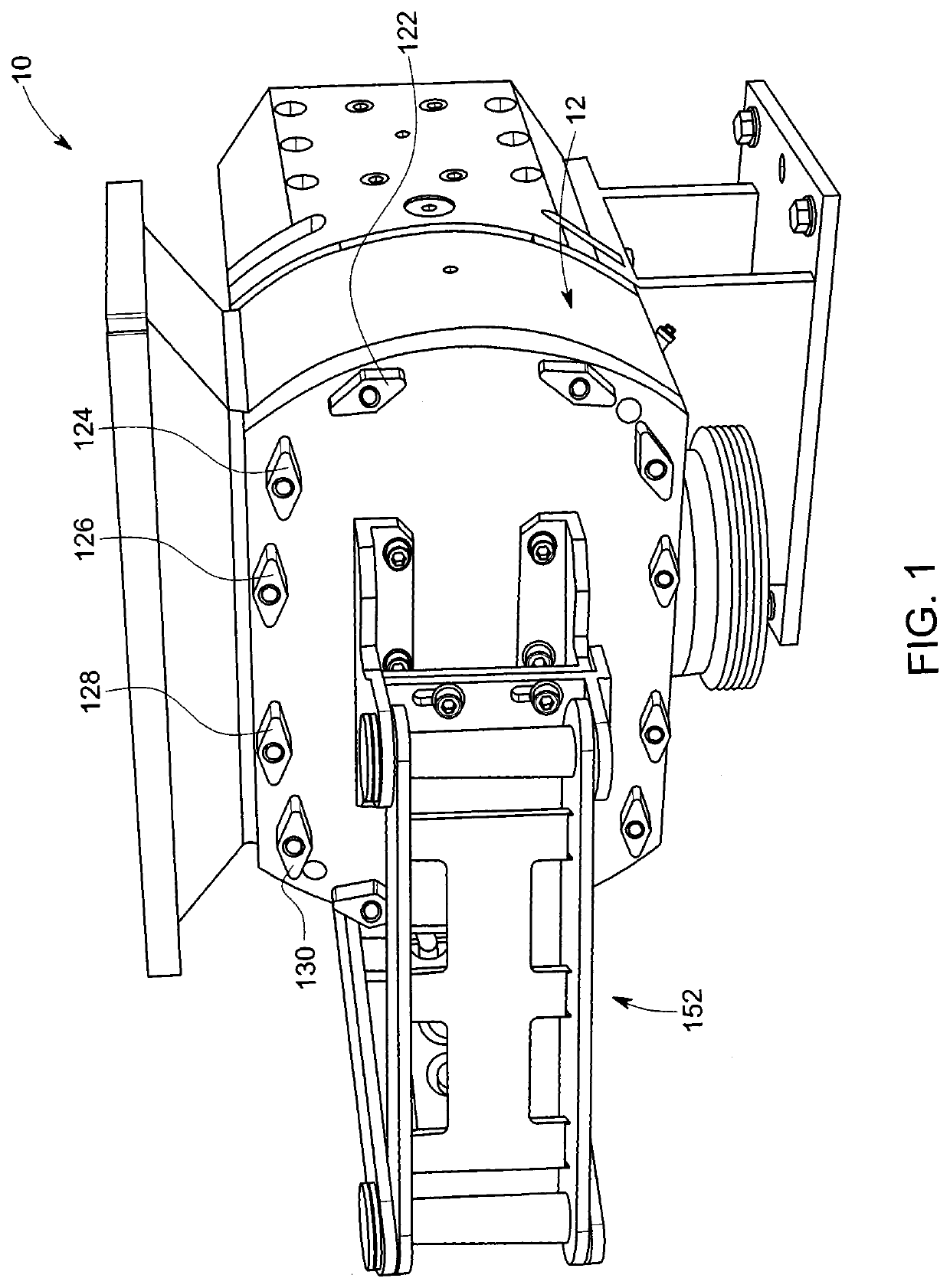

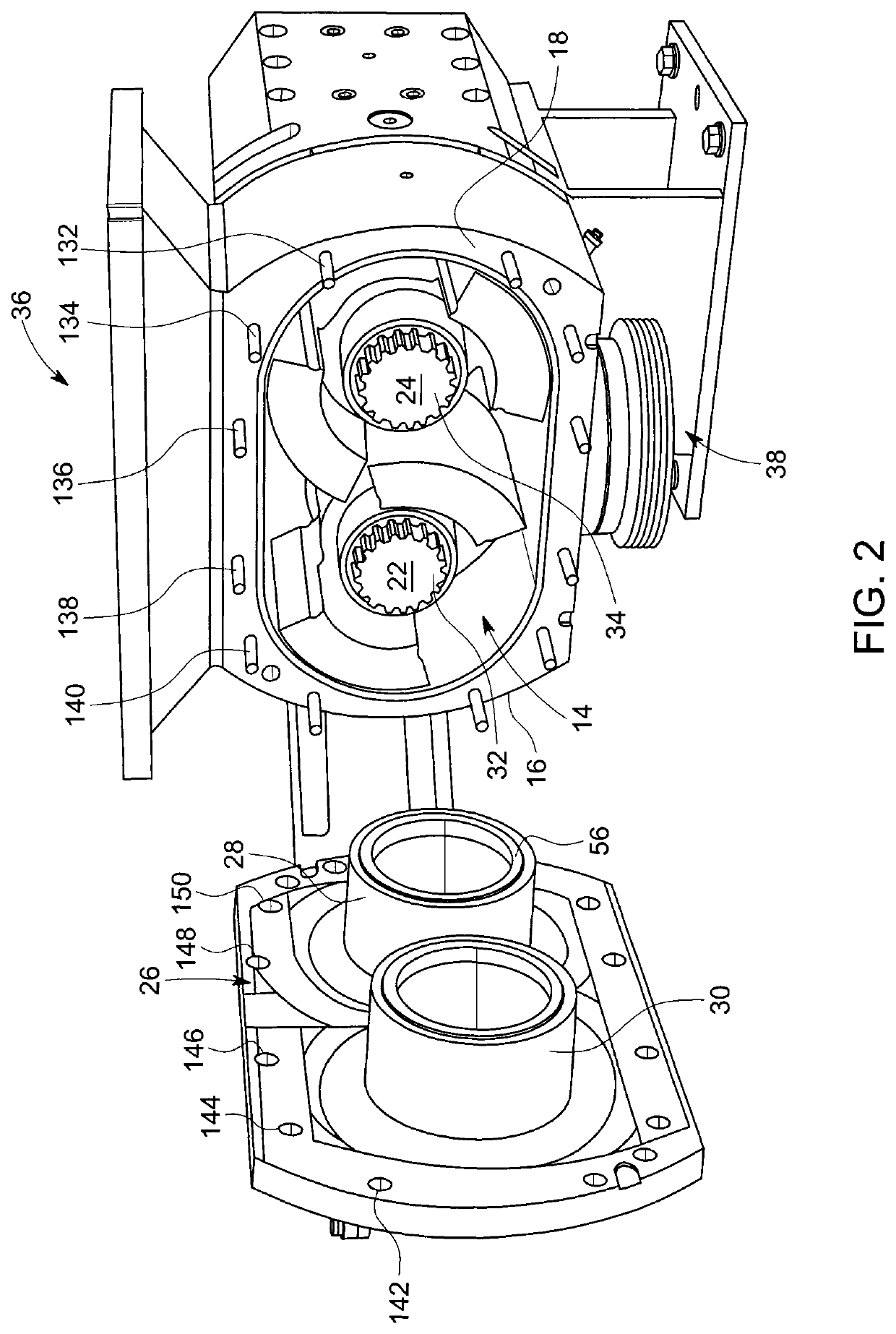

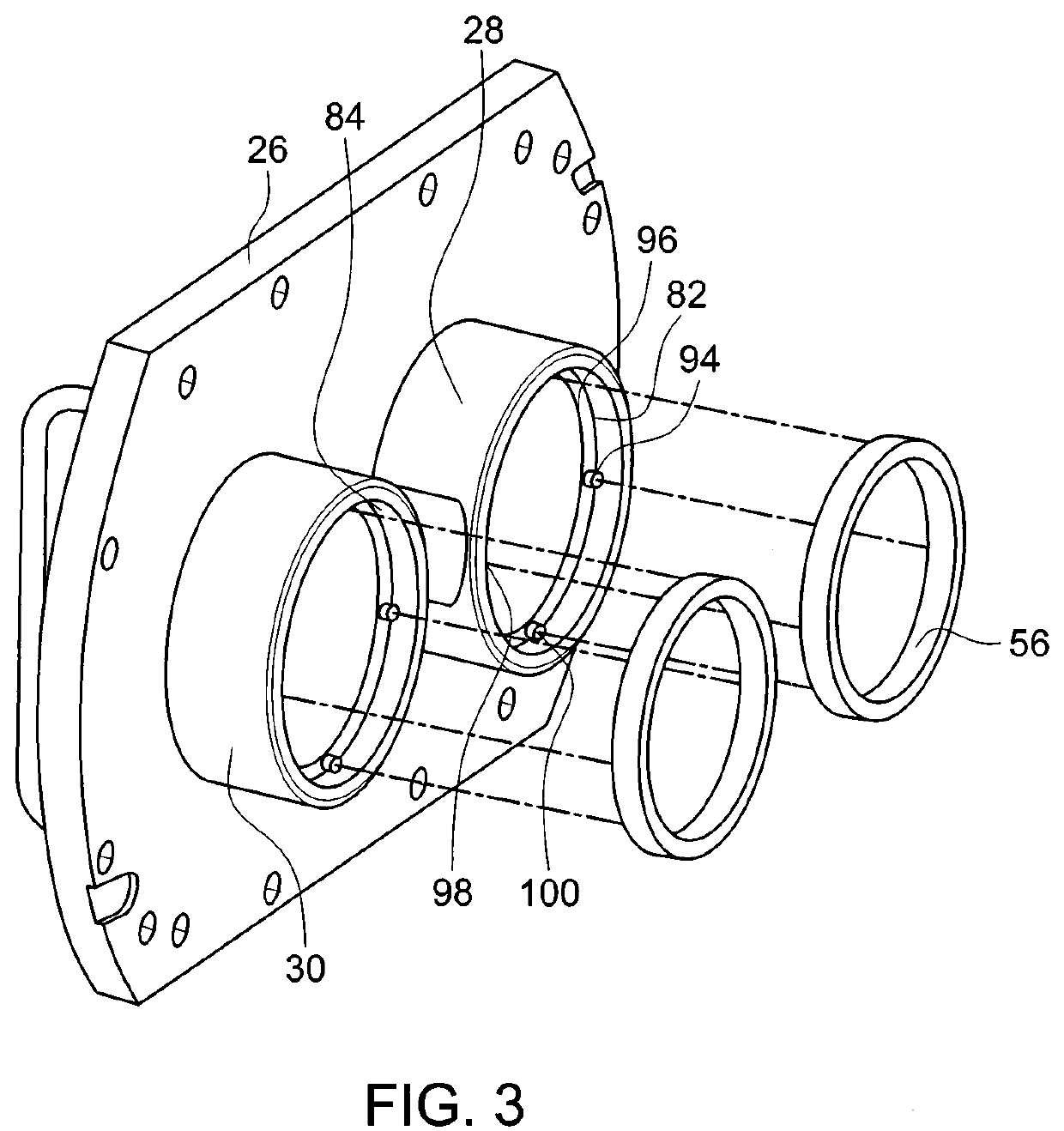

PD Pumps with a Common Gearbox Module and Varying Capacities and Easy Access to Mechanical Seals

ActiveUS20090304540A1Ease in which the seals can be serviced or replacedOscillating piston enginesSealing arrangement for pumpsDrive shaftEngineering

Rotary lobe pump and circumferential piston pump designs are disclosed where the drive and driven shafts are detachably connected to their respective rotors. The rotors are disposed in a pump or rotor casing, which is sandwiched between a head cover and a gearbox. The drive and driven shafts pass through mechanical seal assemblies, which are sandwiched between the first and second rotors and the gear box respectively. The seal assemblies can be serviced or replaced by simply removing the head cover and removing the rotors from the drive and driven shafts. The pump casing does not need to be removed to replace or service the seal assemblies. Further, the capacities of the disclosed rotary lobe and circumferential piston pumps can be modified without changing the gearboxes or shaft length. To modify a pump capacity, all that needs to be changed are the rotors, the pump or rotor casing and, in some designs, the head cover or cover plate. In some designs, the cover plate is universal to the gearbox so that only the rotors and pump casing need to be changed to modify the pump capacity.

Owner:VIKING PUMP HYGIENIC LTD

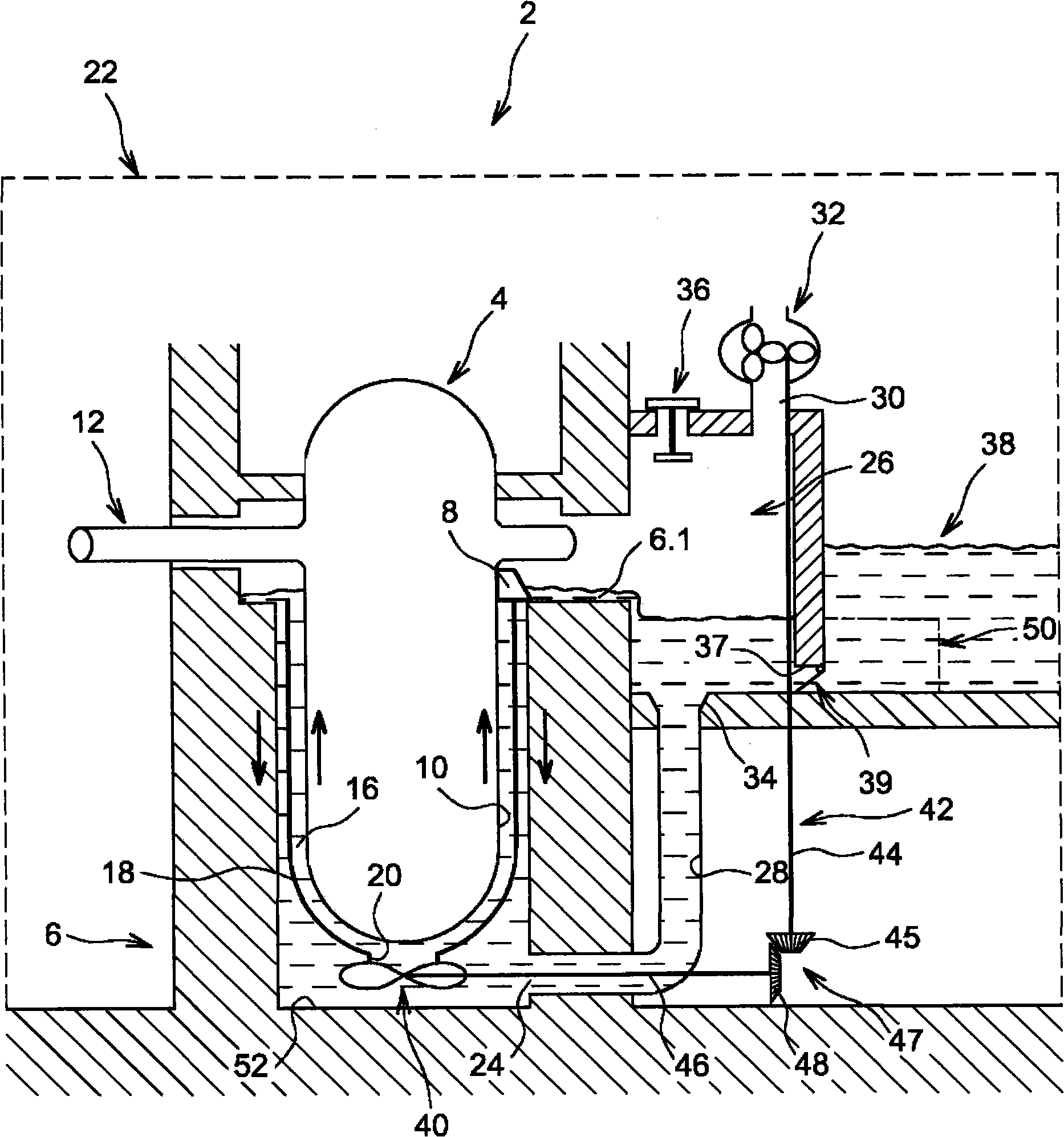

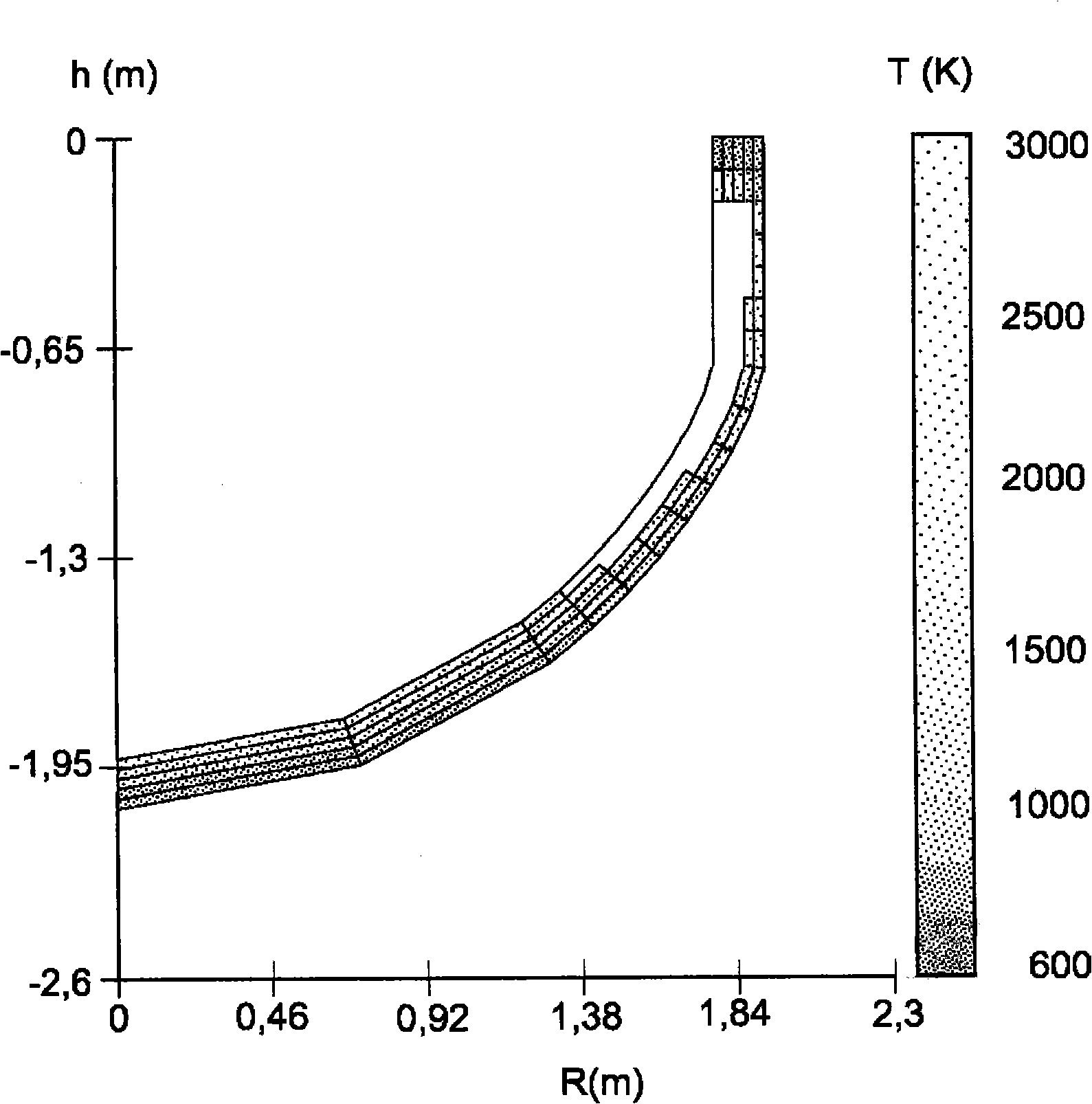

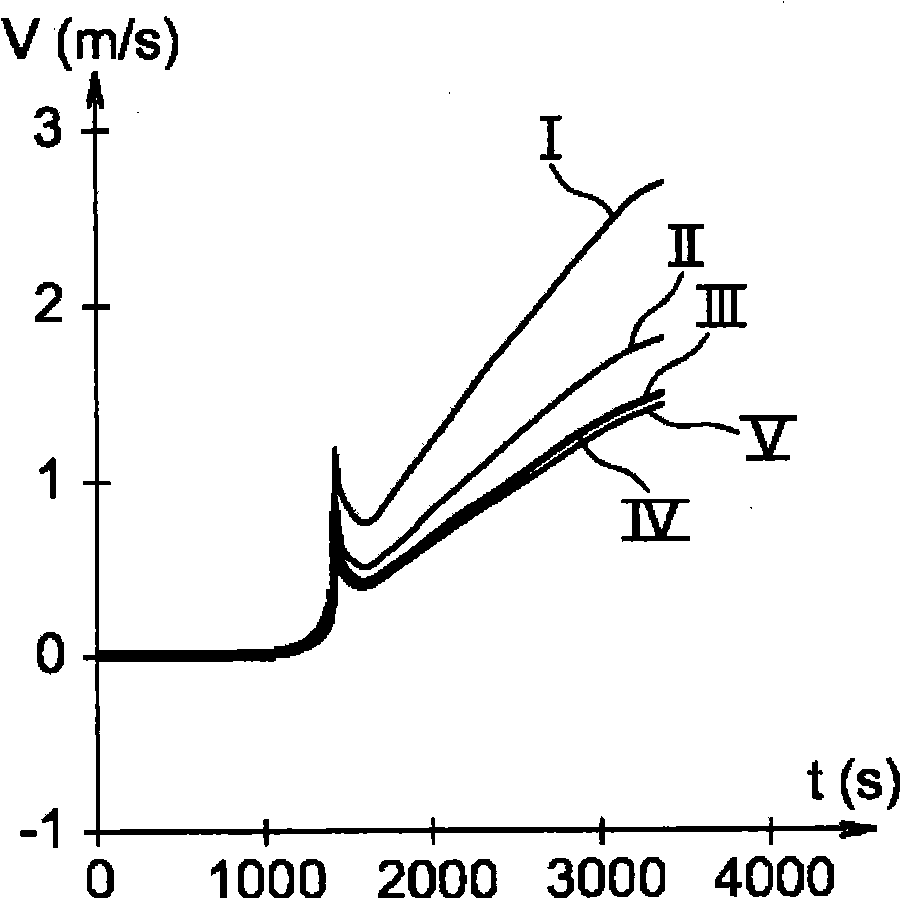

Nuclear reactor with improved cooling in an accident situation

InactiveCN101836262ARobustGuaranteed uptimeNuclear energy generationNuclear engineering problemsNuclear reactorForce convection

Nuclear reactor comprising: a reactor vessel (4) designed to hold a reactor core; a primary system for cooling the reactor; a reactor pit (6) in which the vessel (4) is placed; an annular channel (16) surrounding a lower portion of the reactor vessel (4) in the reactor pit (6), said channel (16) being intended to act as a thermal shield in normal operation and intended for the ascending flow of a liquid in the event of an accident; a reserve of liquid capable of filling the reactor pit; a reactor containment (22, not drawn); a manifold (26) for collecting the steam generated at an upper end of the reactor pit (6), said manifold being separate from the containment (22); a circulating pump (40) capable of generating a forced convection of the liquid in the annular channel (16); and a lobe pump or steam piston machine or turbine (32) for actuating the circulating pump (40) and capable of generating forced convection by means of said collected steam.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

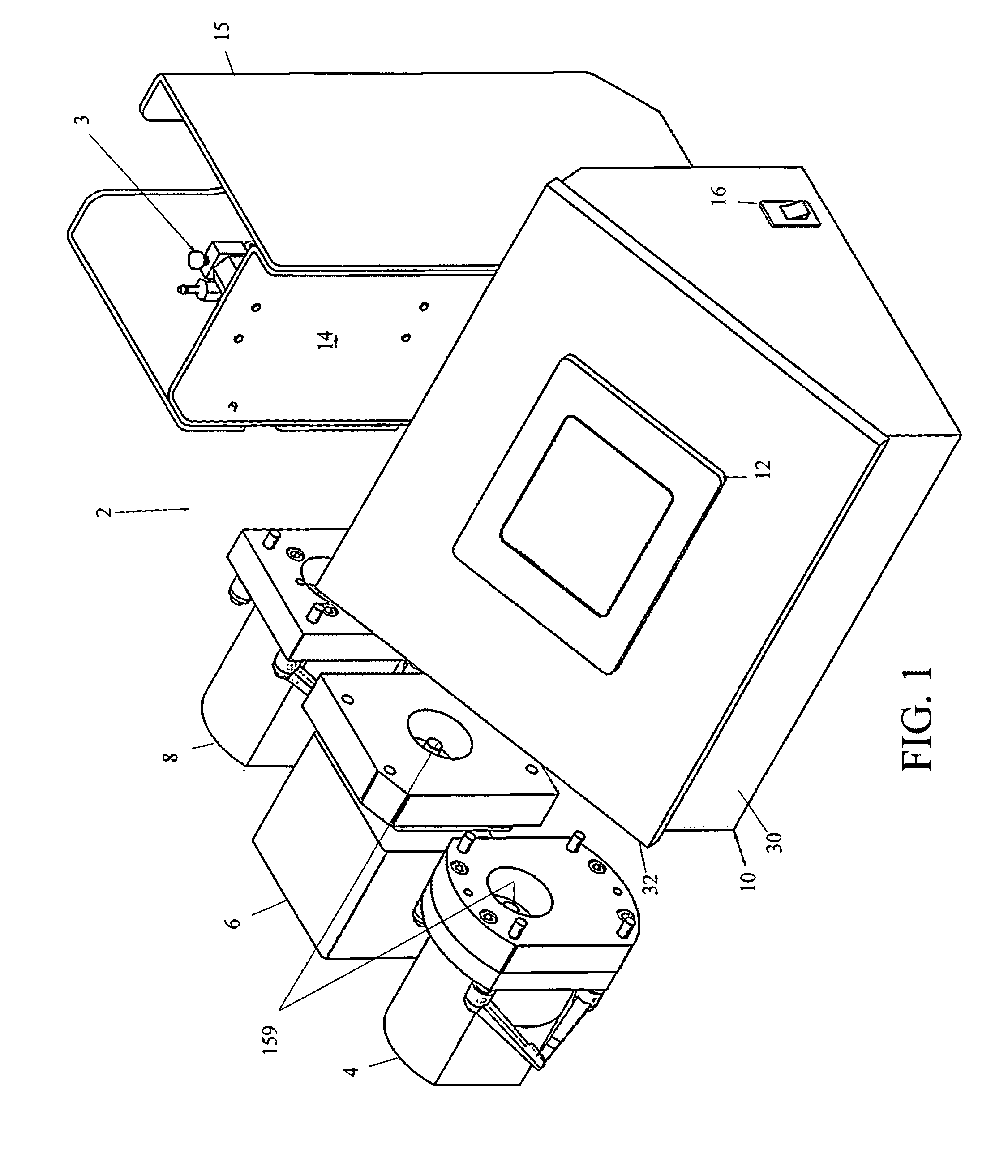

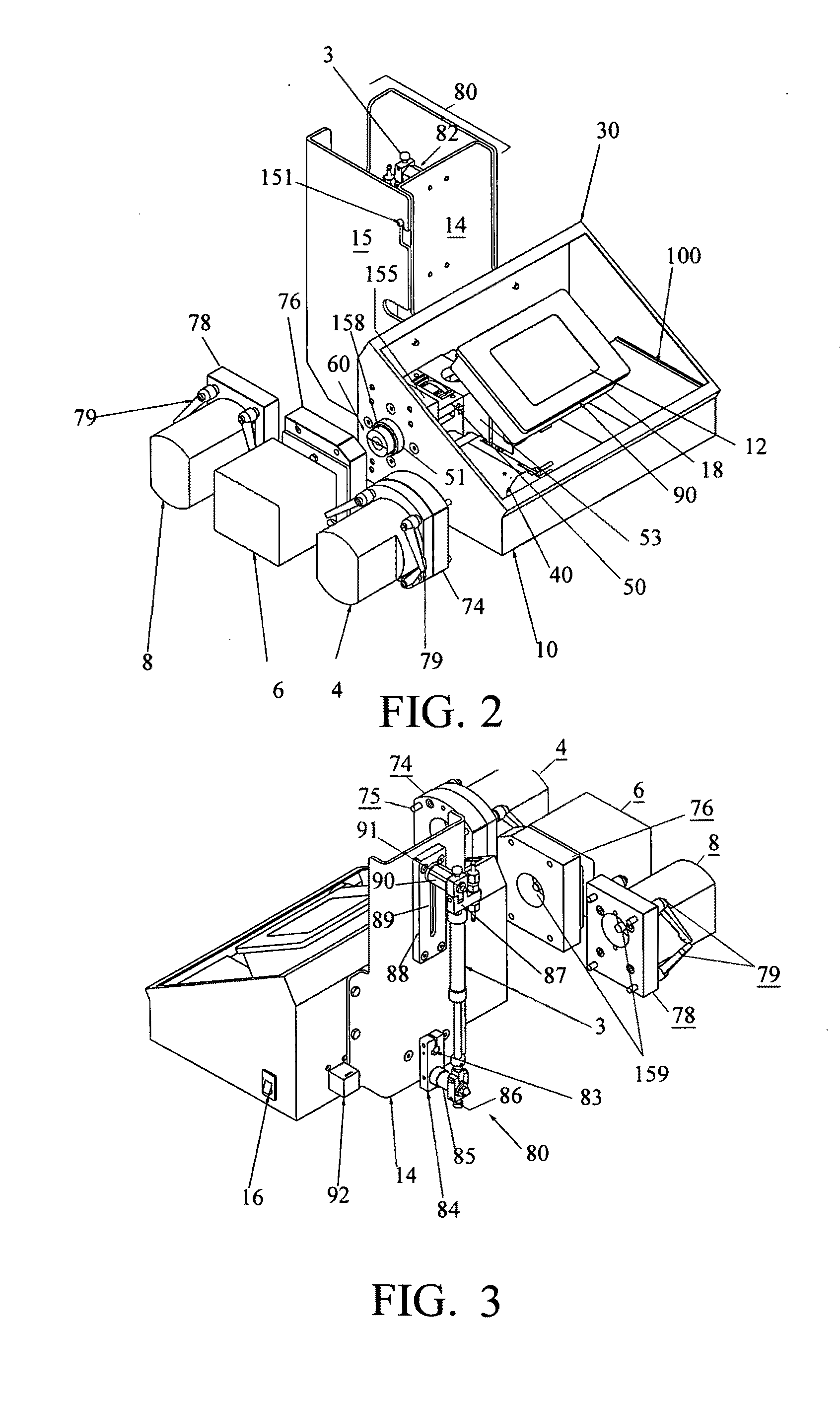

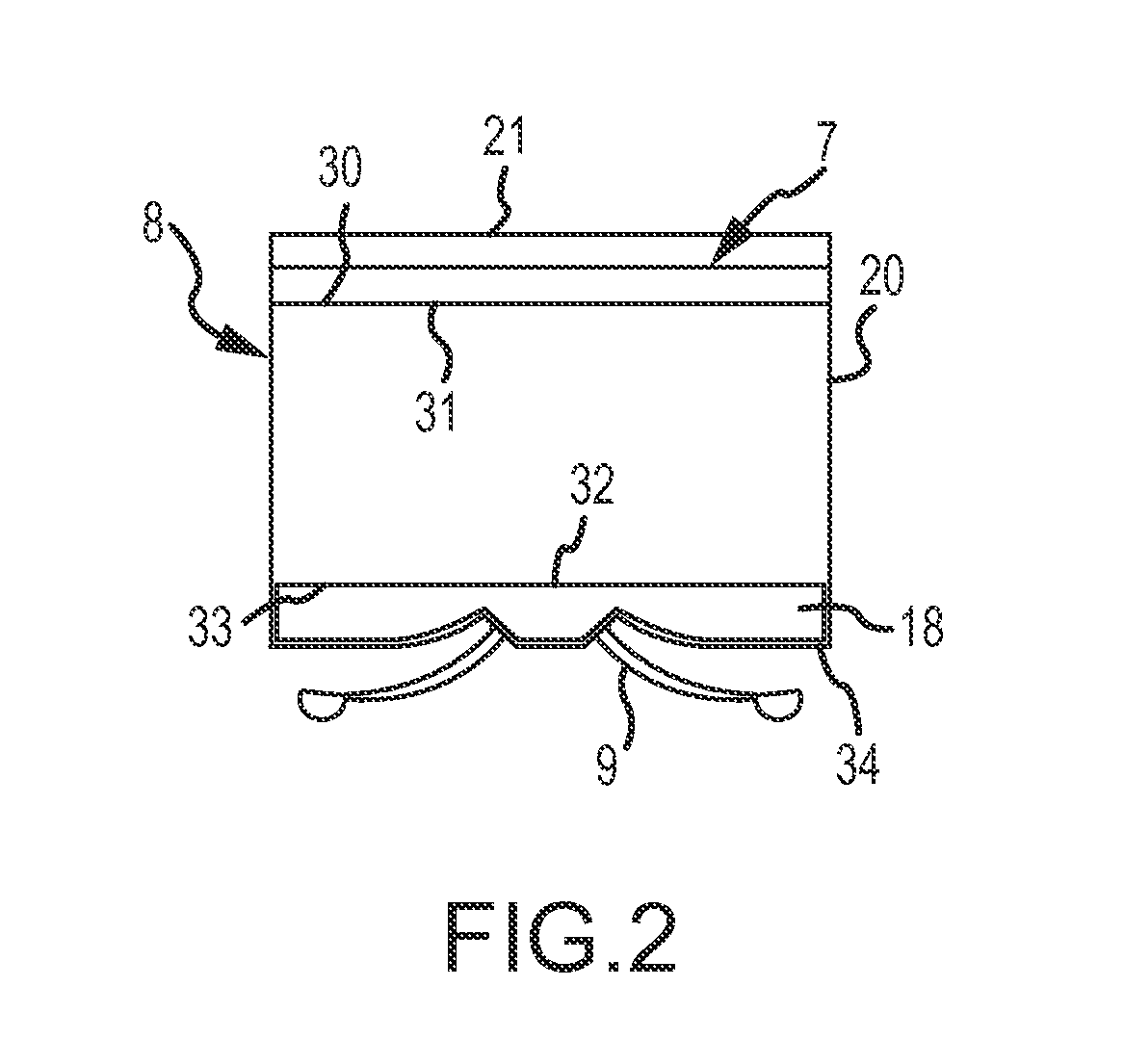

Adaptable bench top filling system

InactiveUS8561656B2Convenient user-setupMaximum flexibilityLiquid fillingPositive displacement pump componentsSystems designGear pump

A semi-automatic benchtop filling system that allows the user to switch between pump technologies while utilizing one base unit. The base unit is outfitted to accommodate peristaltic, lobe, gear, and piston pumps providing a maximum amount of flexibility and versatility in one unit. The base unit employs a computerized servo motor control system and docking hardware for driving any of the four different pump types. The system is designed to automate the filling of sample containers regardless of which pump is mounted by tare weighting, and the drive will adjust itself to dispense the correct weight. The pump drive includes appropriate reduction gearing and quick disconnect flexible couplings for each of the different pump types, a side-mounted adapter for connecting any of the peristaltic, gear and lobe pumps, and a separate piston drive assembly and dock-connector at the rear for a piston pump. The device includes a touch-screen interface with control software for user-setup, establishing different fill recipes, and run time.

Owner:EGINTON MICHAEL +1

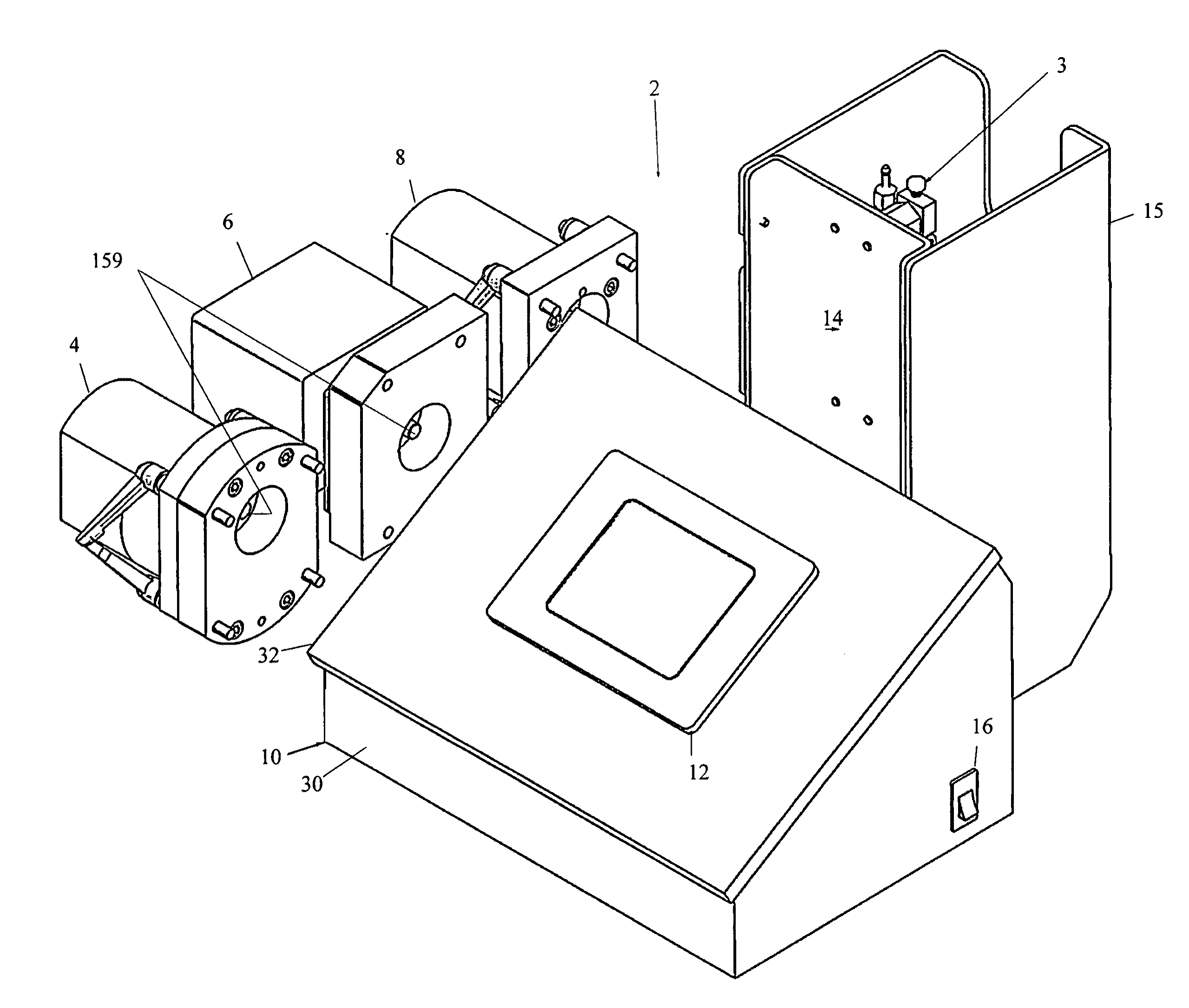

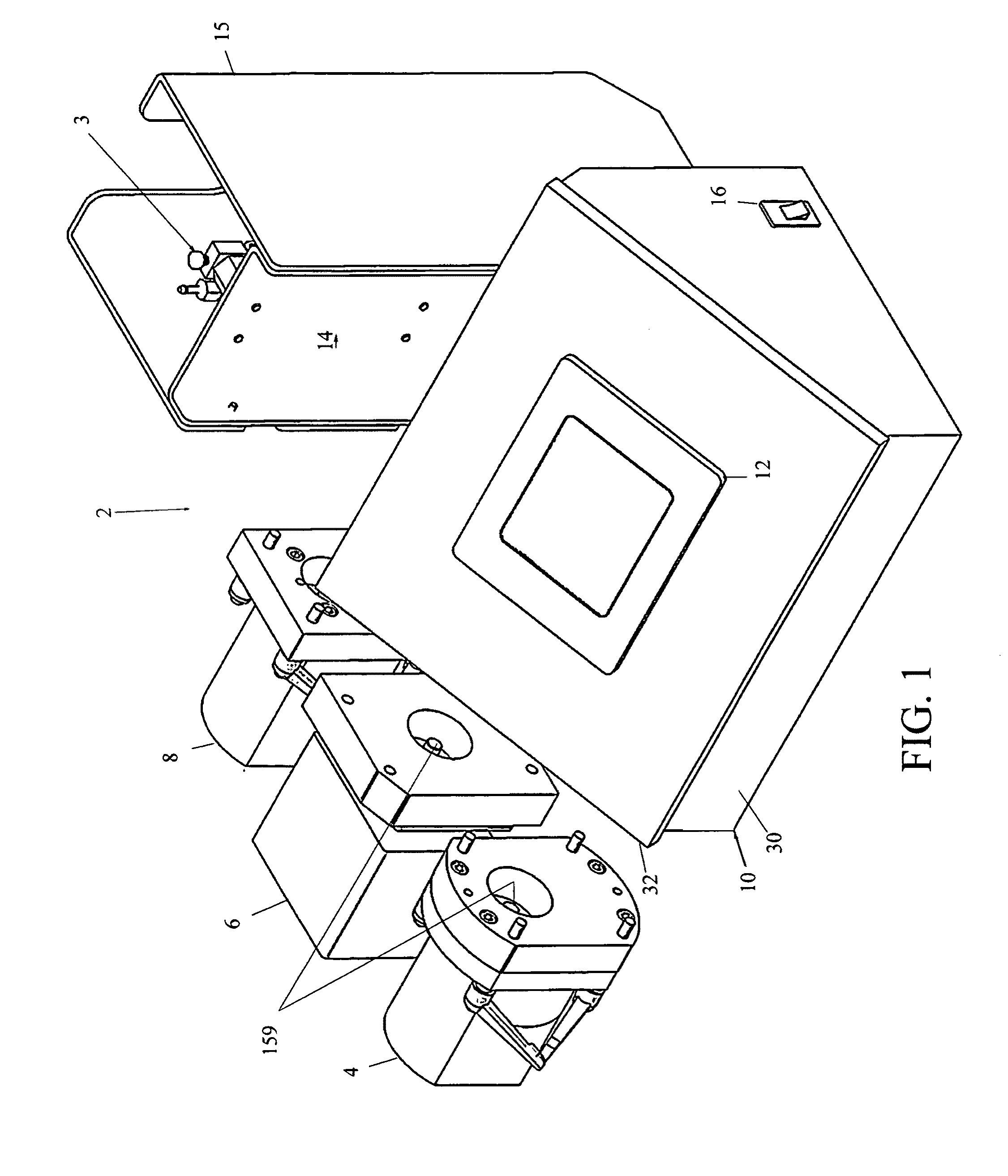

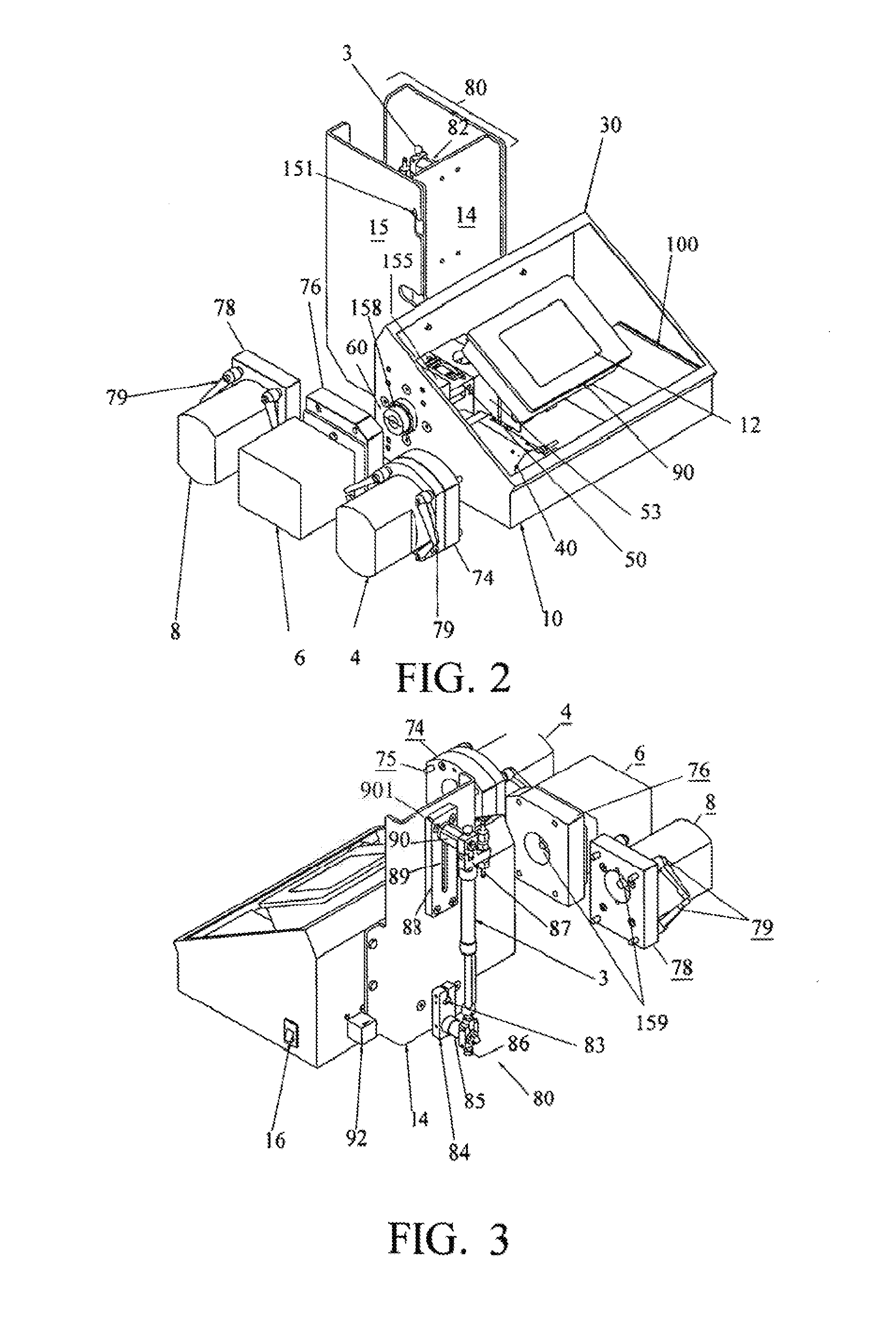

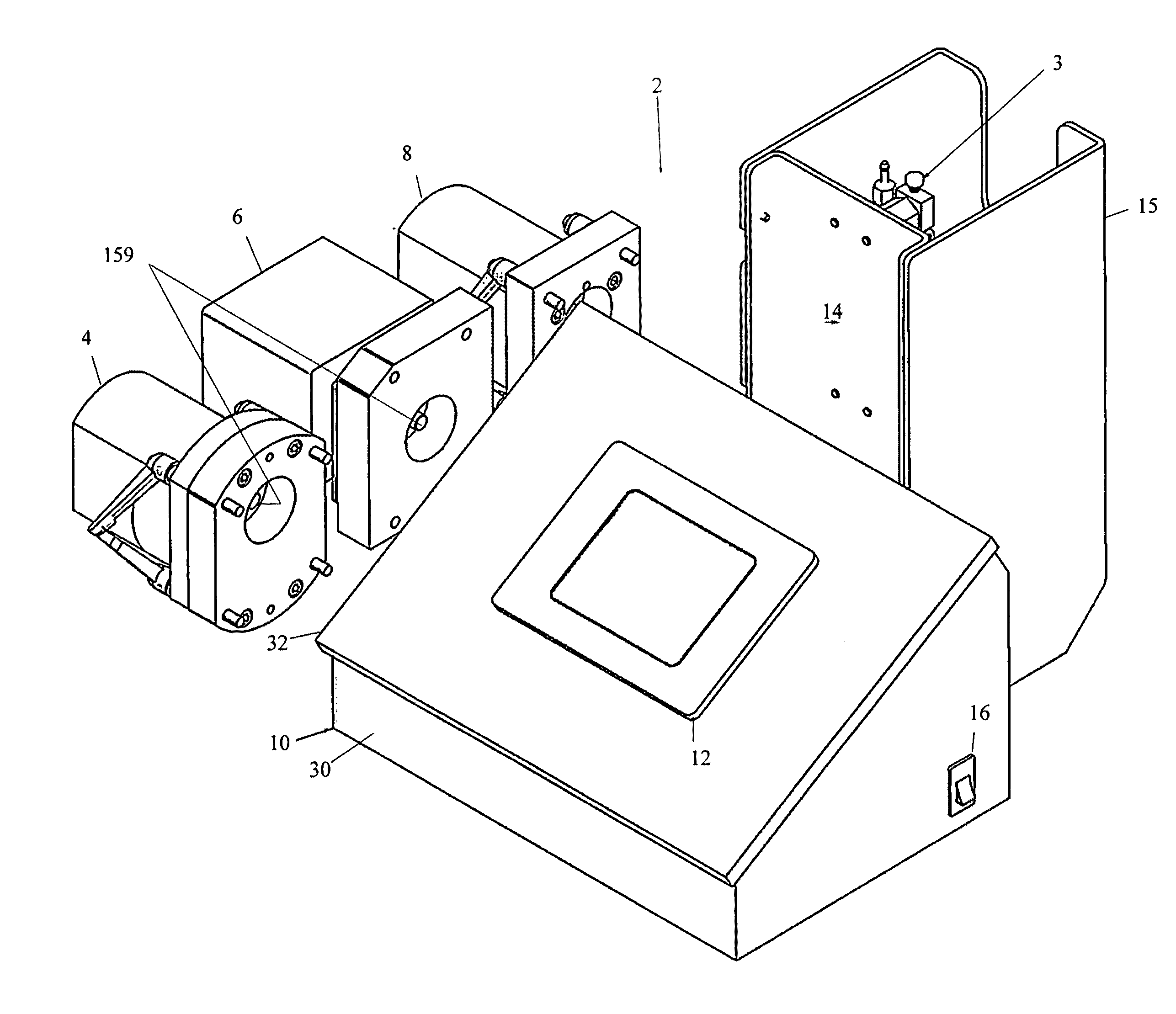

Adaptable bench top filling system

InactiveUS20100116375A1Convenient user-setupMaximum flexibilityLiquid fillingPositive displacement pump componentsSystems designGear wheel

A semi-automatic benchtop filling system that allows the user to switch between pump technologies while utilizing one base unit. The base unit is outfitted to accommodate peristaltic, lobe, gear, and piston pumps providing a maximum amount of flexibility and versatility in one unit. The base unit employs a computerized servo motor control system and docking hardware for driving any of the four different pump types. The system is designed to automate the filling of sample containers regardless of which pump is mounted by tare weighting, and the drive will adjust itself to dispense the correct weight. The pump drive includes appropriate reduction gearing and quick disconnect flexible couplings for each of the different pump types, a side-mounted adapter for connecting any of the peristaltic, gear and lobe pumps, and a separate piston drive assembly and dock-connector at the rear for a piston pump. The device includes a touch-screen interface with control software for user-setup, establishing different fill recipes, and run time.

Owner:EGINTON MICHAEL +1

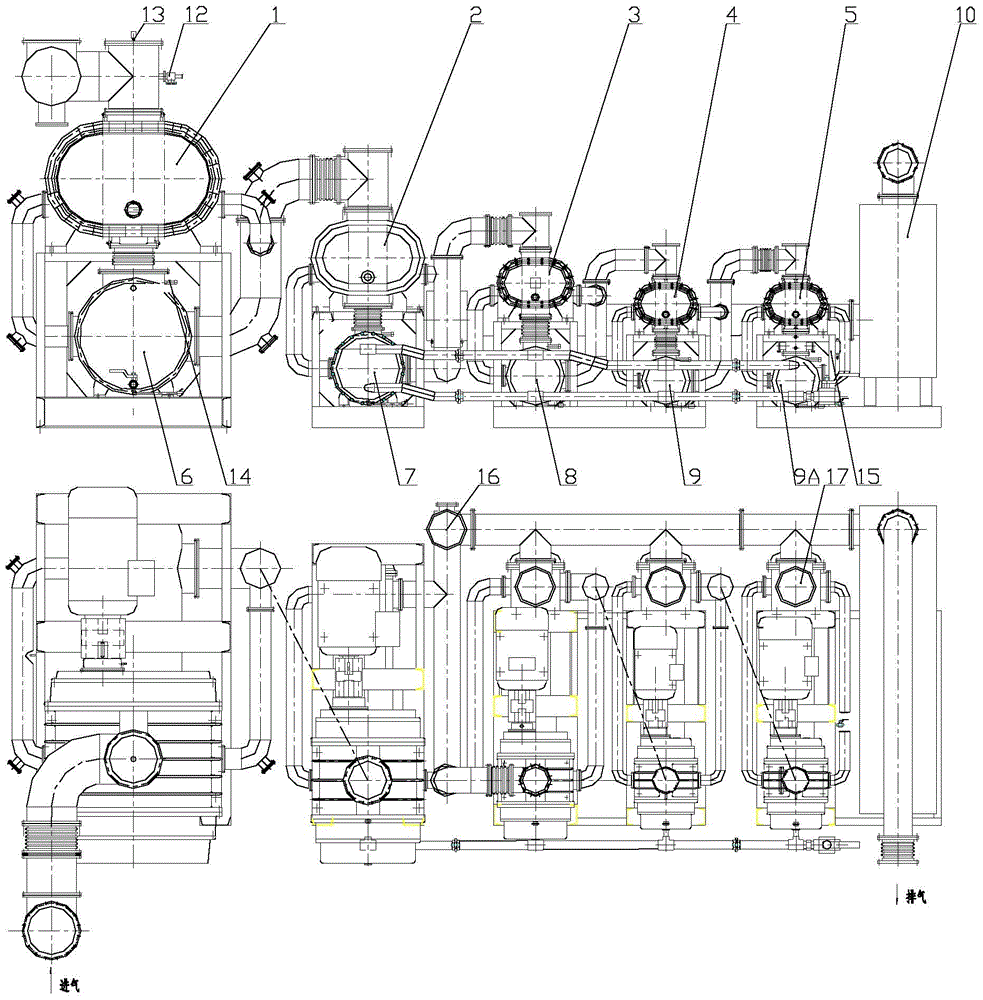

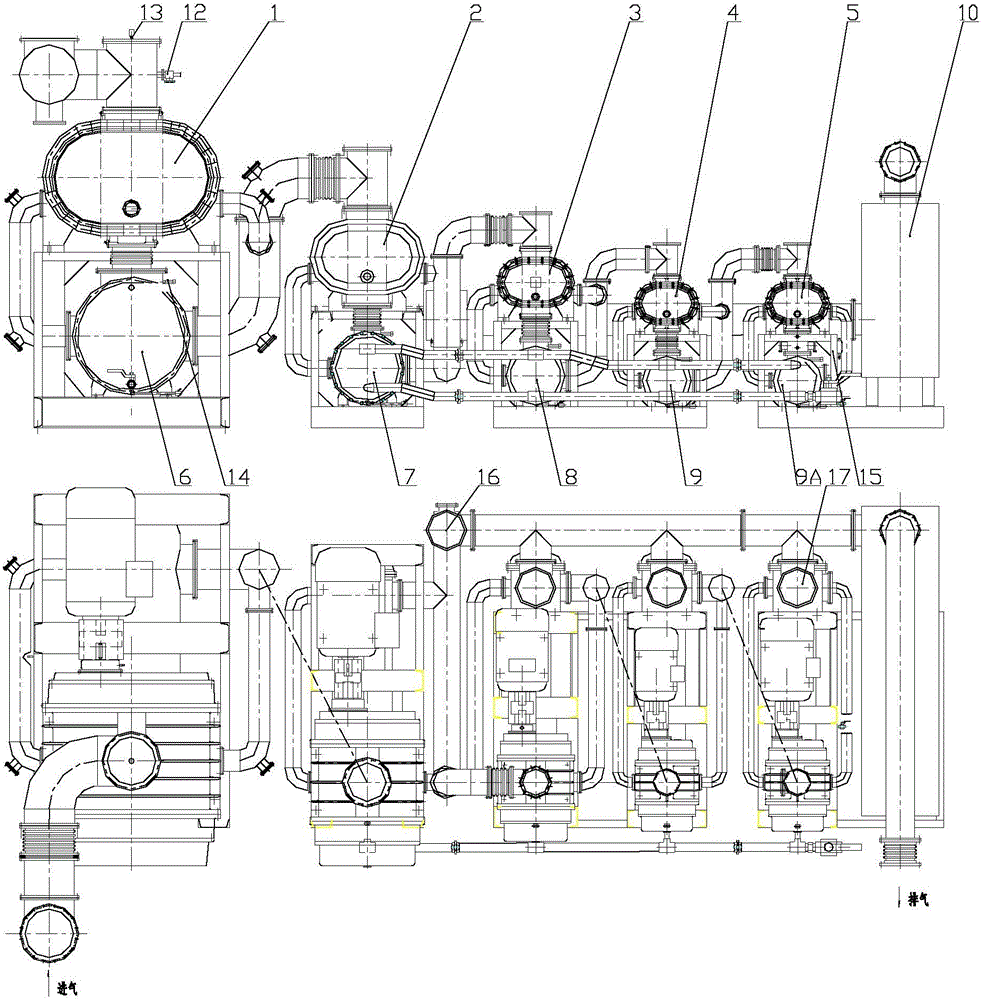

Vacuum-pumping system for wind tunnel body

ActiveCN105222980AImprove the noise reduction effectSimple structureAerodynamic testingVacuum pumpingReflux valve

The invention relates to a vacuum-pumping system for a wind tunnel body. The vacuum-pumping system includes a multi-level air cooled lobe pump assembly, a set of heat exchangers, a silencer, an overflow valve, and a check valve; the upper part of each air cooled lobe pump is provided with an air inlet, and the lower part of each air cooled lobe pump is provided with an air outlet; two sides of each air cooled lobe pump are provided with a cool air returning opening respectively, so that heat balance of a pump body can be maintained when the pump operates under a high pressure difference; when the pressure of an air inlet connected to the back end of the lobe pump system is greater than the discharge pressure of the lobe pump assembly, a part of pumped air can be directly discharged into the silencer via the overflow valve, and then is discharged into the atmosphere via the silencer; the other part of the pumped air is discharged into the atmosphere via the overflow valve and the silencer. Each vacuum heat exchanger of the system mainly includes a housing, heat exchanger tubes, and an anti-reflux valve. A PLC control technology and a frequency converter technology are adopted by the system, so that the vacuum-pumping system can automatically adjust the pumping speed according to the pressure of an entrance.

Owner:ZHEJIANG VACUUM EQUIP GROUP

Rotary lobe pump with wiper blades

InactiveUS20130216417A1Improve efficiencyReduce manufacturing costOscillating piston enginesSealing arrangement for pumpsImpellerRotary pump

A positive displacement rotary pump with an improved impeller design integrating replaceable wiper inserts. The impeller generally has or more lobes and an equal number of conjugate surfaces. Each lobe has an arcuate peripheral end comprising a plurality of wiper blades. The wiper blades improve efficiency by making a seal with a pump chamber or the conjugate surface on the other impeller as it rotates. The wiper blades are arranged such that constant and successive contact between wiper blades and impellers is achieved.

Owner:PMC LIQUIFLO EQUIP

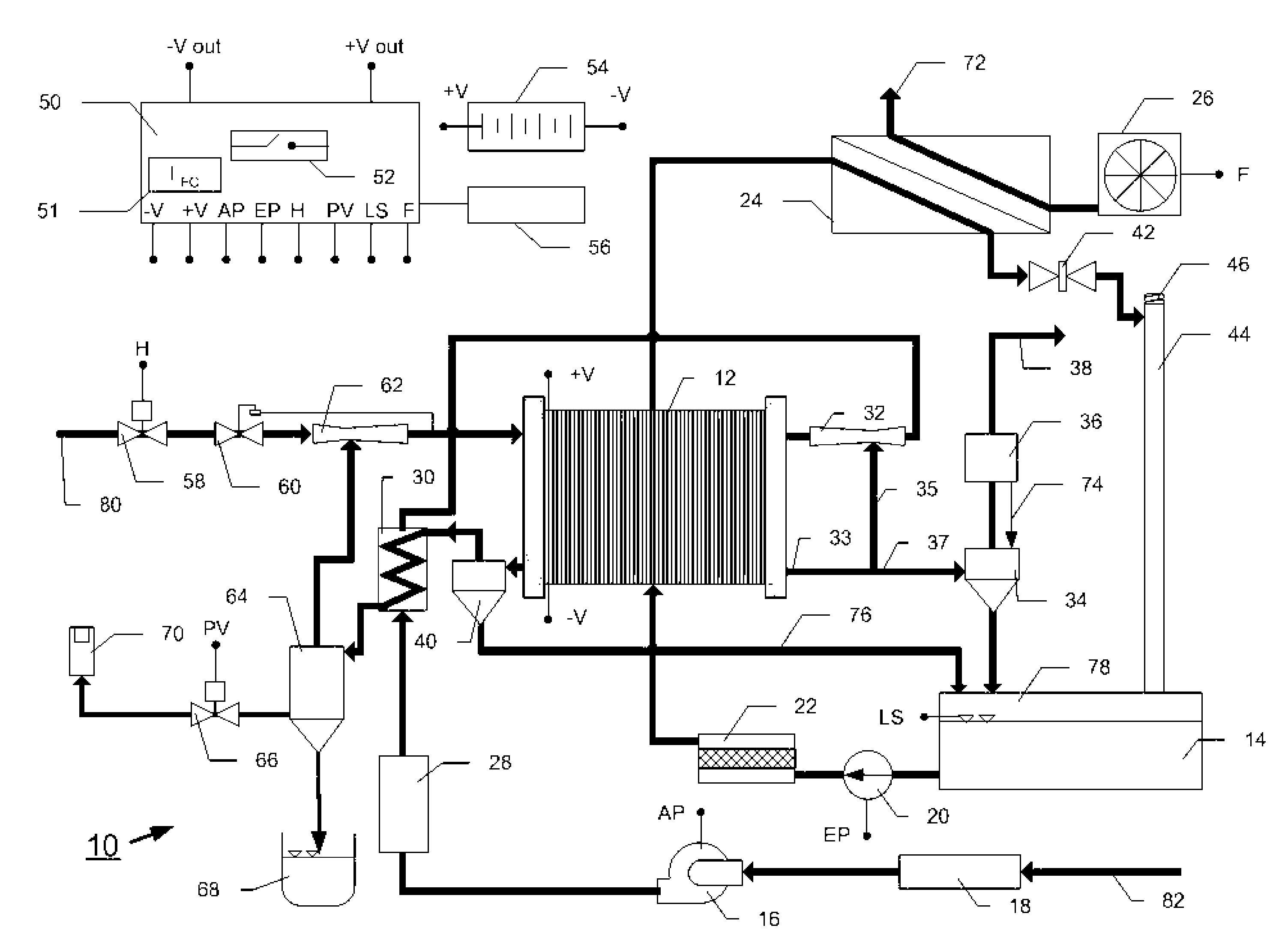

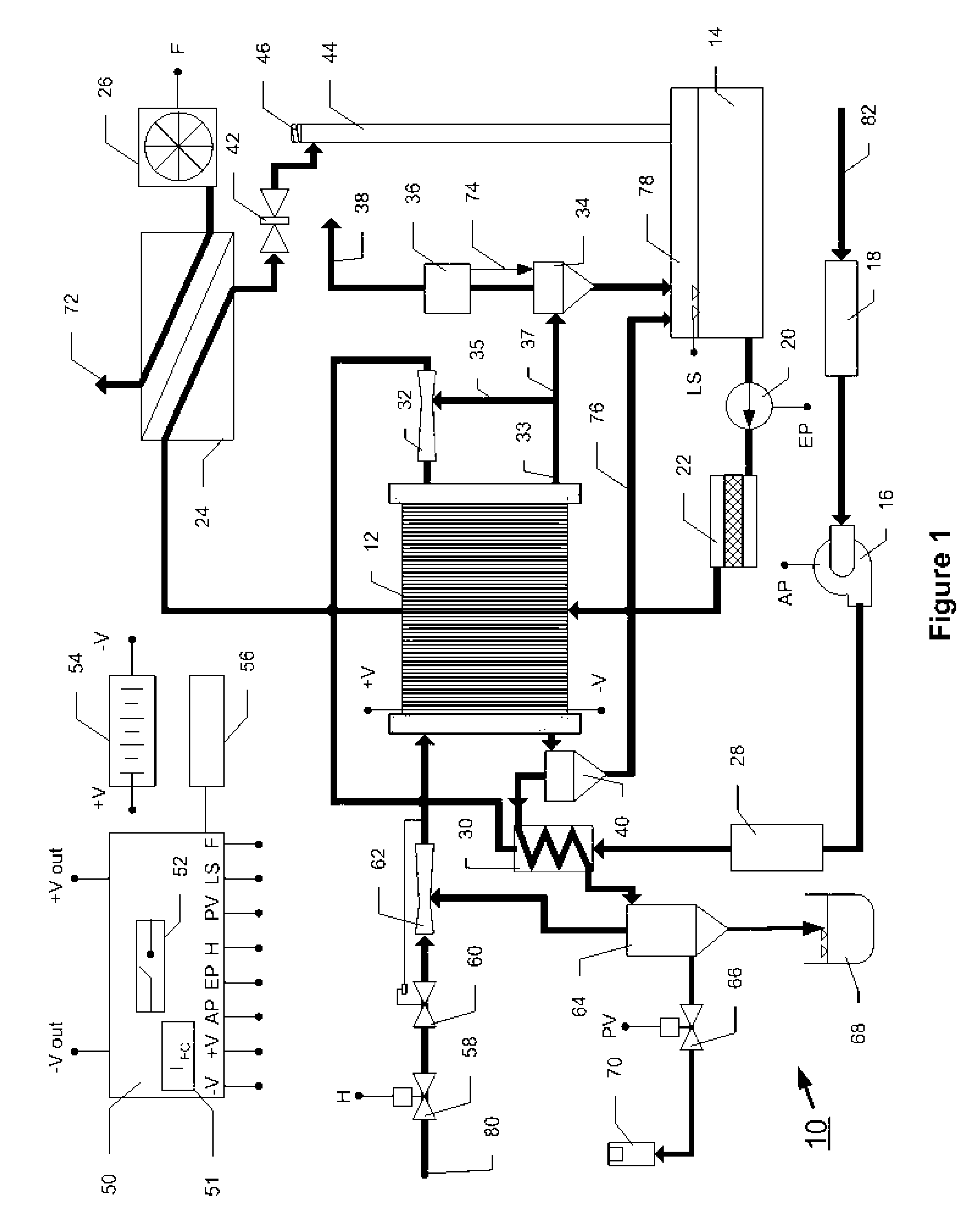

Alkaline fuel cell system

InactiveUS20090325012A1Minimal flowFuel cell heat exchangeReactant parameters controlElectricityElectronic controller

An alkaline fuel cell system includes an alkaline fuel cell stack, a source of fuel gas, an oxidizer gas pump for oxidizer gas, an electrolyte tank, an electrolyte pump, an auxiliary electric storage device, and an electronic controller. The oxidizer gas pump is controlled by the electronic controller to deliver an oxidizer gas flow to the alkaline fuel cell stack which varies proportionately with the amount of electrical current drawn from the stack under any load conditions. At zero load, a minimal oxidizer gas flow is delivered to the fuel cell stack. The oxidizer gas pump may be a positive displacement pump such as a vane pump, a lobe pump, or a screw pump; or it may be a controlled blower. Also provided is a back pressure valve in the electrolyte flow circuit to maintain positive pressure in the electrolyte if the electrolyte is flowed through the fuel stack.

Owner:ASTRIS ENERGI

PD pumps with a common gearbox module and varying capacities and easy access to mechanical seals

ActiveUS7905717B2Ease in which the seals can be serviced or replacedOscillating piston enginesSealing arrangement for pumpsDrive shaftEngineering

Rotary lobe pump and circumferential piston pump designs are disclosed where the drive and driven shafts are detachably connected to their respective rotors. The rotors are disposed in a pump or rotor casing, which is sandwiched between a head cover and a gearbox. The drive and driven shafts pass through mechanical seal assemblies, which are sandwiched between the first and second rotors and the gear box respectively. The seal assemblies can be serviced or replaced by simply removing the head cover and removing the rotors from the drive and driven shafts. The pump casing does not need to be removed to replace or service the seal assemblies. Further, the capacities of the disclosed rotary lobe and circumferential piston pumps can be modified without changing the gearboxes or shaft length. To modify a pump capacity, all that needs to be changed are the rotors, the pump or rotor casing and, in some designs, the head cover or cover plate. In some designs, the cover plate is universal to the gearbox so that only the rotors and pump casing need to be changed to modify the pump capacity.

Owner:VIKING PUMP HYGIENIC LTD

Toothed-Lobed Gear Pump

InactiveUS20140271313A1Well formedCombination enginesEngine of intermeshing engagement typeGear pumpEngineering

Toothed gears and lobed gears intermesh to create large volume pockets in gear sets of a given size. The pockets are larger than the pockets that exist in current tooth or lobe pumps and provide the benefit of a pump that better handles shear sensitive liquids. Preferably, the profiles of the teeth and of the lobes are involute-shaped to provide rolling contact and a fixed pressure angle between the teeth and lobes during engagement. The toothed gears and lobe gears improve upon standard spur and helical gear designs by omitting alternate teeth on the standard toothed gears and filling in corresponding gaps on the mating standard lobed gears. Additional tooth and lobed gear rotors may be added in tandem as additional pairs of gears to the shafts and circumferentially offset to provide driving tooth engagement between at least one pair of the toothed and lobed rotors at every point around the rotational circumference of the rotors. This spur gear or helical gear configuration eliminates the need for separate driving / synchronizing gears.

Owner:ROPER PUMP CO

Rotary lobe pump with wiper blades

InactiveUS9062675B2Improve efficiencyReduce manufacturing costOscillating piston enginesSealing arrangement for pumpsImpellerRotary pump

A positive displacement rotary pump with an improved impeller design integrating replaceable wiper inserts. The impeller generally has or more lobes and an equal number of conjugate surfaces. Each lobe has an arcuate peripheral end comprising a plurality of wiper blades. The wiper blades improve efficiency by making a seal with a pump chamber or the conjugate surface on the other impeller as it rotates. The wiper blades are arranged such that constant and successive contact between wiper blades and impellers is achieved.

Owner:PMC LIQUIFLO EQUIP

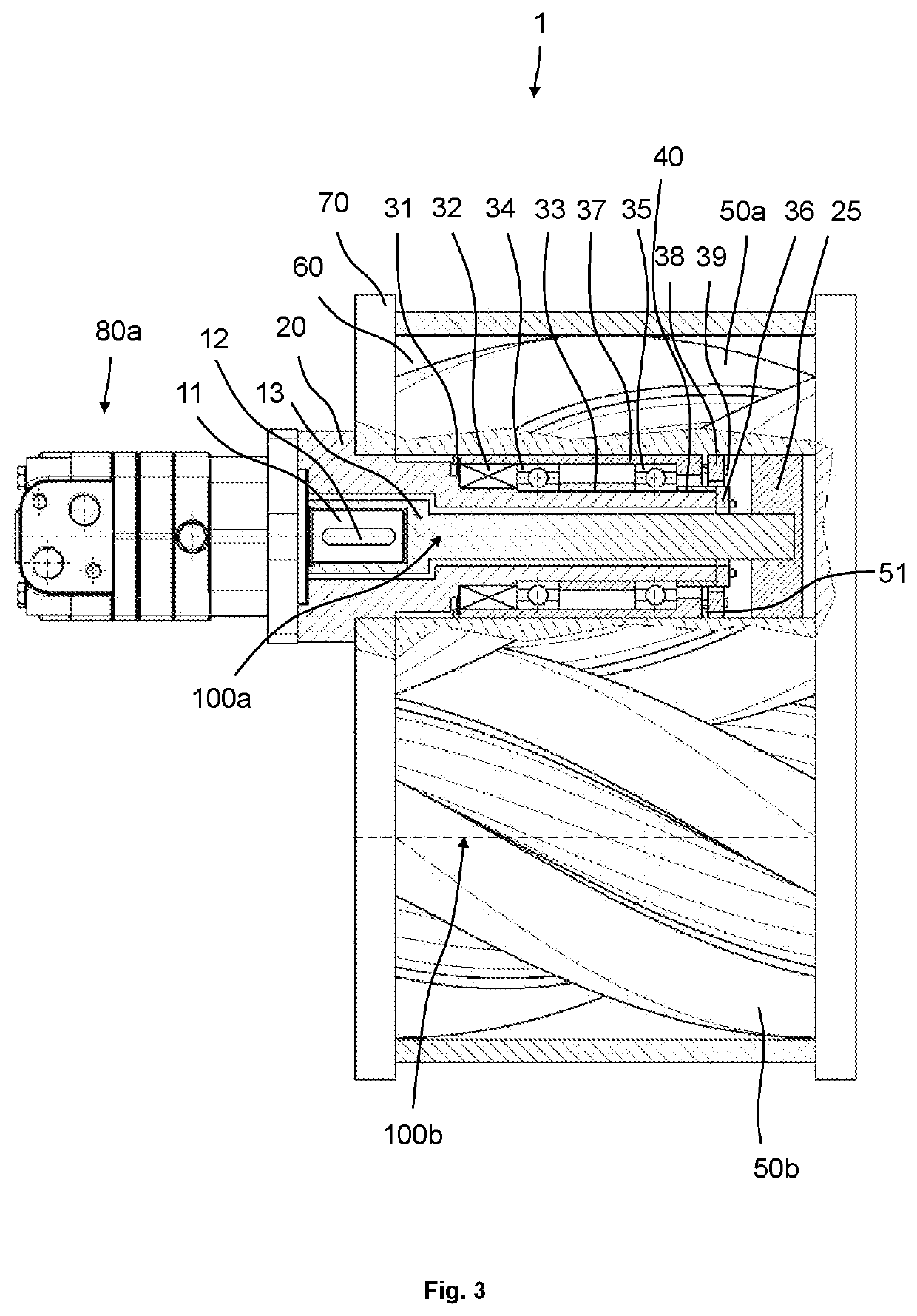

Rotary lobe pump

ActiveUS7857607B2Accurate dimensional accuracyReduce frictionOscillating piston enginesEngine of counter-engagement typePlastic materialsPump chamber

A rotary lobe pump comprises a pump body having a driving means and an outer casing, and an insert that can be replaced. The replaceable insert comprises a housing formed of a plastic material and having an inlet port, an outlet port and internal surfaces defining a pumping chamber. The replaceable insert also includes a pair of lobed rotors arranged for rotation within the pumping chamber. The housing includes apertures through which the lobed rotors may be rotationally driven, so that the lobed rotors mesh together for pumping a fluid from the inlet port to the outlet port.

Owner:ITT MFG ENTERPRISES LLC

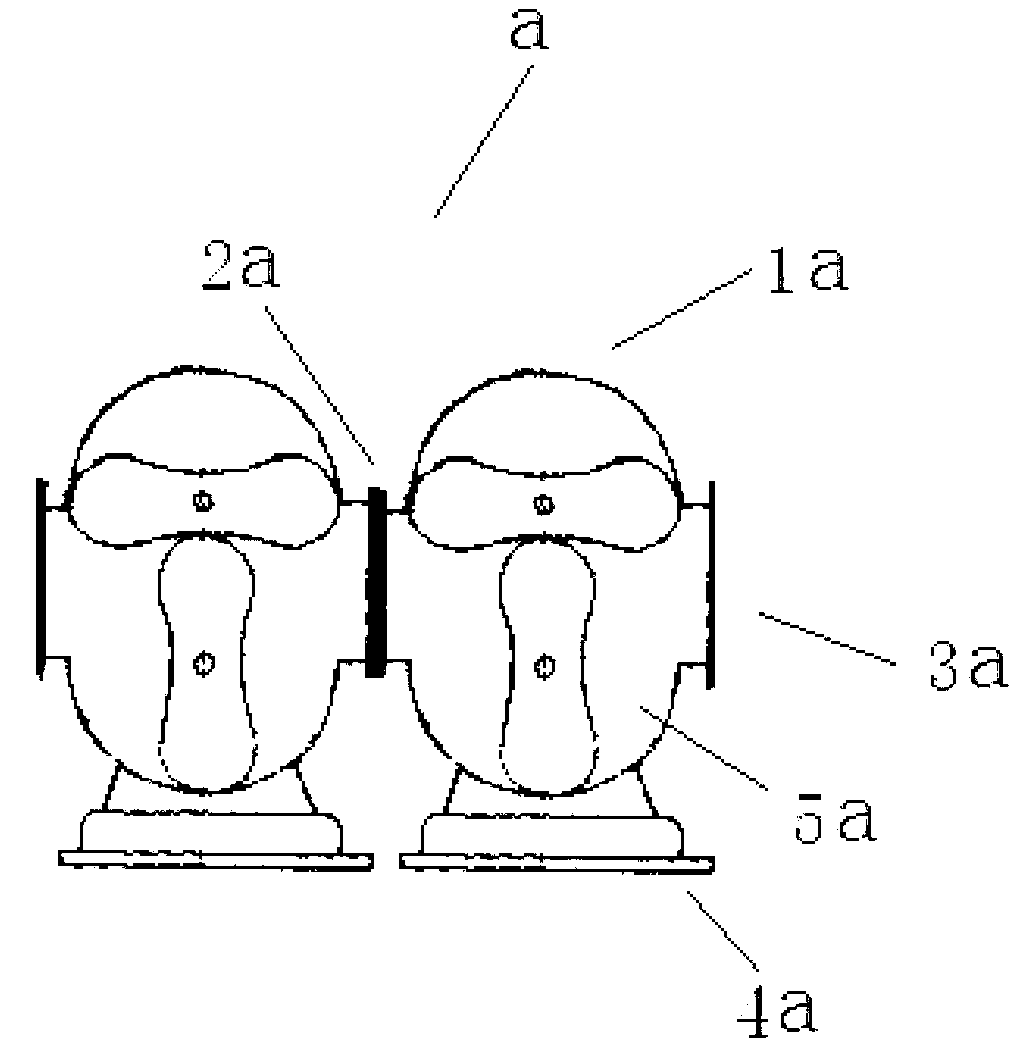

Rotary lobe pump

The invention proposes a rotary cam pump which includes a pump body with a drive device and an outer pump housing, as well as a replaceable insert. The insert includes a box made of plastic material having an inlet end, an outlet end and an inner surface defining a pump chamber; and a pair of cam rotors configured for rotation within the pump chamber. The casing includes a bore through which the cam rotor can be rotationally driven such that the cam rotors mesh together for pumping fluid from the inlet end to the outlet end.

Owner:ITT MFG ENTERPRISES LLC

A vacuum pumping system for a wind tunnel body

ActiveCN105222980BIncrease pumping speedReduce current shockAerodynamic testingVacuum pumpingReflux valve

The invention relates to a vacuum-pumping system for a wind tunnel body. The vacuum-pumping system includes a multi-level air cooled lobe pump assembly, a set of heat exchangers, a silencer, an overflow valve, and a check valve; the upper part of each air cooled lobe pump is provided with an air inlet, and the lower part of each air cooled lobe pump is provided with an air outlet; two sides of each air cooled lobe pump are provided with a cool air returning opening respectively, so that heat balance of a pump body can be maintained when the pump operates under a high pressure difference; when the pressure of an air inlet connected to the back end of the lobe pump system is greater than the discharge pressure of the lobe pump assembly, a part of pumped air can be directly discharged into the silencer via the overflow valve, and then is discharged into the atmosphere via the silencer; the other part of the pumped air is discharged into the atmosphere via the overflow valve and the silencer. Each vacuum heat exchanger of the system mainly includes a housing, heat exchanger tubes, and an anti-reflux valve. A PLC control technology and a frequency converter technology are adopted by the system, so that the vacuum-pumping system can automatically adjust the pumping speed according to the pressure of an entrance.

Owner:ZHEJIANG VACUUM EQUIP GROUP

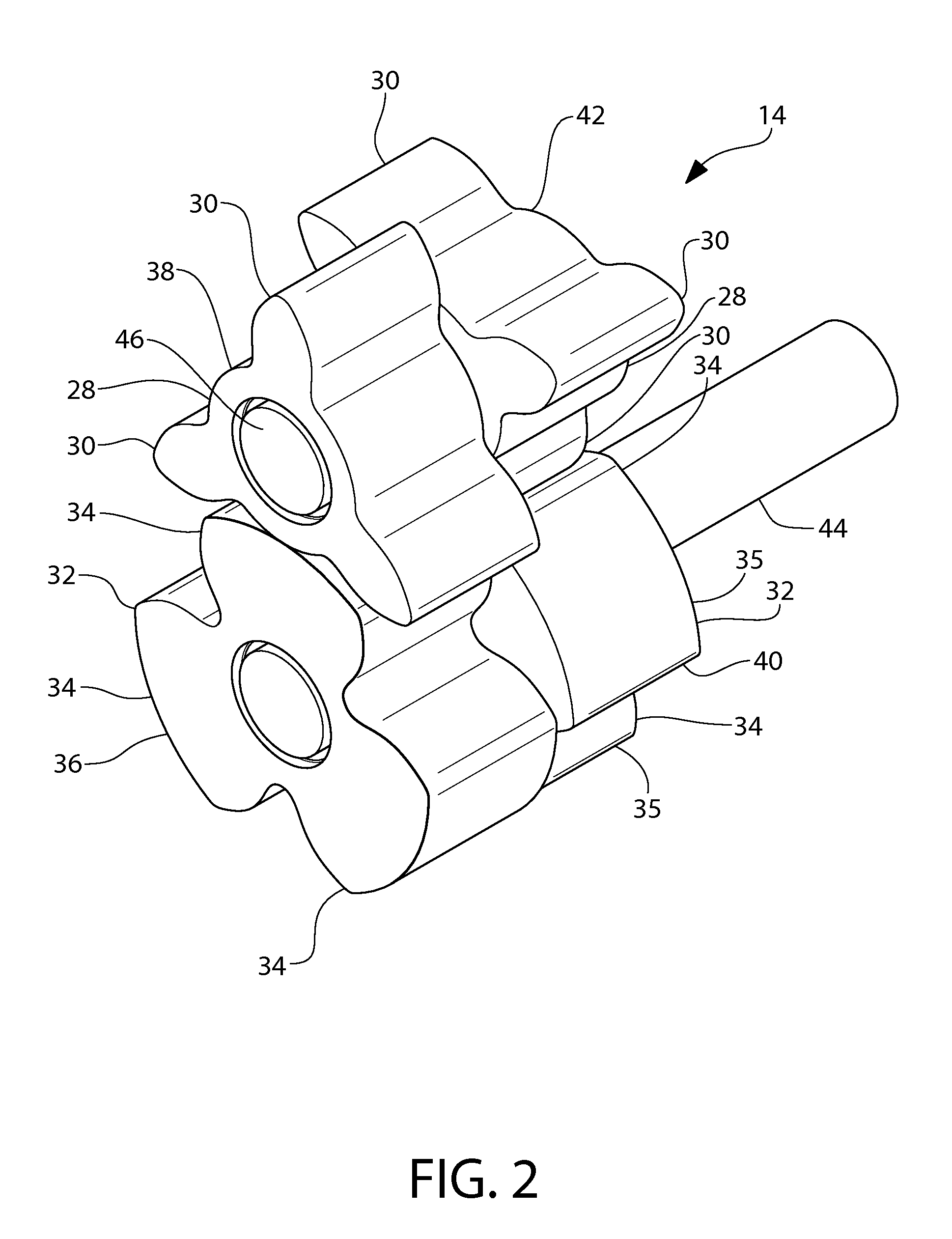

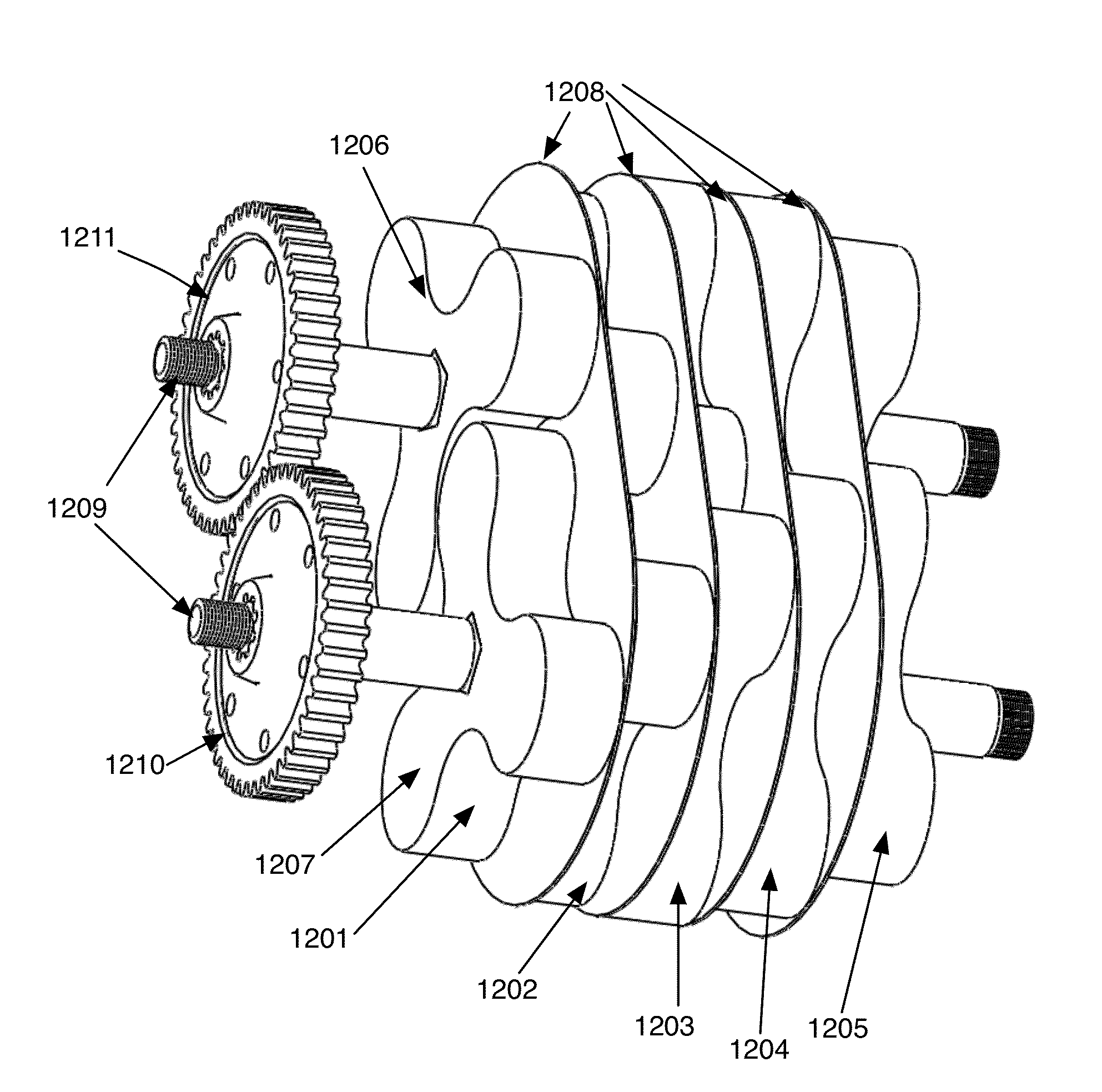

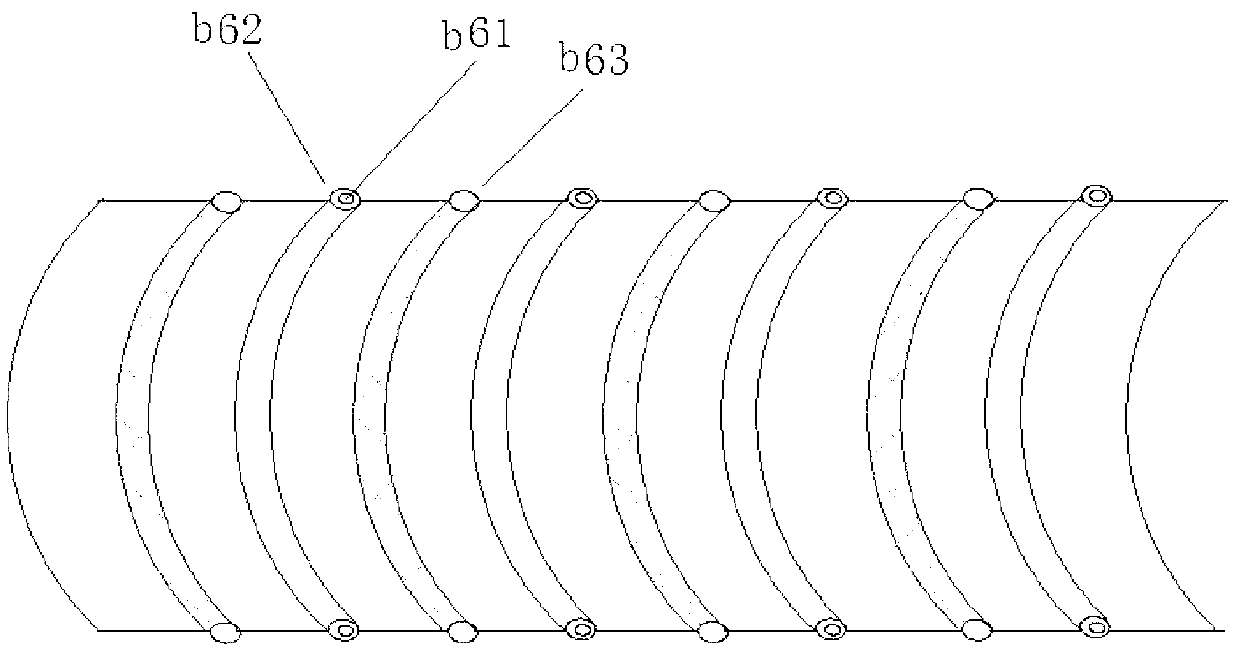

Multiple Segment Lobe Pump

ActiveUS20160281709A1Eliminates cyclic variationReduces flow pulsationRotary piston pumpsRotary/oscillating piston combinationsEngineeringLobe pump

Designs for multiple segment lobe pumps are shown. The designs include pumps using rotors having two lobes to a plurality of lobes and segments that include two segments to a plurality of segments. Designs for both vertical, or straight walled conventional lobed rotors, as well as helical lobe rotors are shown. The designs are applicable to a variety of rotors and number of segments. In one particular case the designs enable a three lobe helical pump. Designs are also shown for separator plates used between the multiple segments. The separator float between the pairs of lobes in a segment and can also have a fixed position between the lobes by inclusion of end pieces that enable clamping of the separator plates in position.

Owner:OCOR CORP

Multiple Segment Lobe Pump

ActiveUS20140010698A1Eliminates cyclic variationReduces flow pulsationOscillating piston enginesEngine of counter-engagement typeEngineeringLobe pump

Designs for multiple segment lobe pumps are shown. The designs include pumps using rotors having two lobes to a plurality of lobes and segments that include two segments to a plurality of segments. Designs for both vertical or straight walled conventional lobed rotors as well as helical lobe rotors are shown. The designs are applicable to a variety of rotors and number of segments. In one particular case the designs enable a three lobe helical pump.

Owner:OCOR CORP

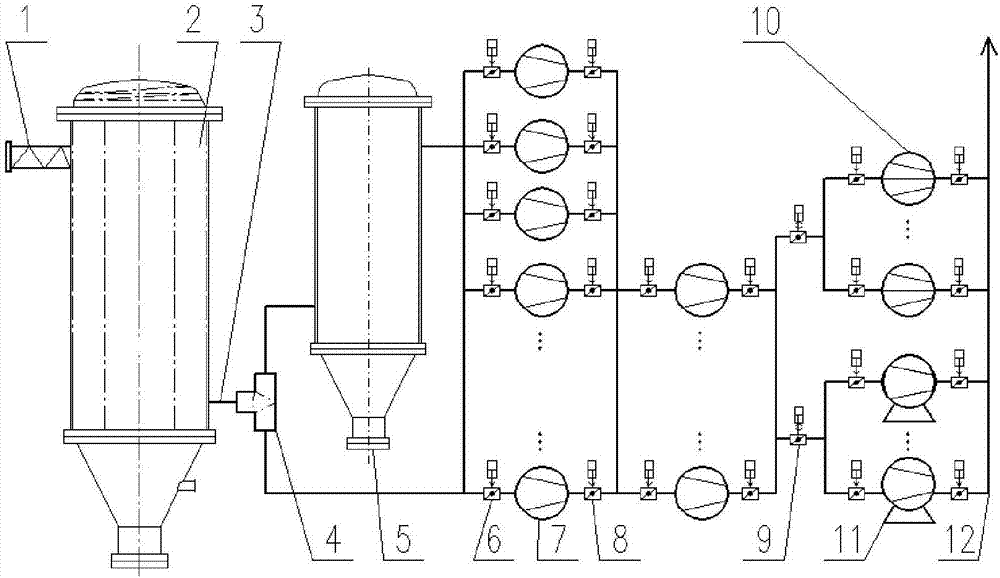

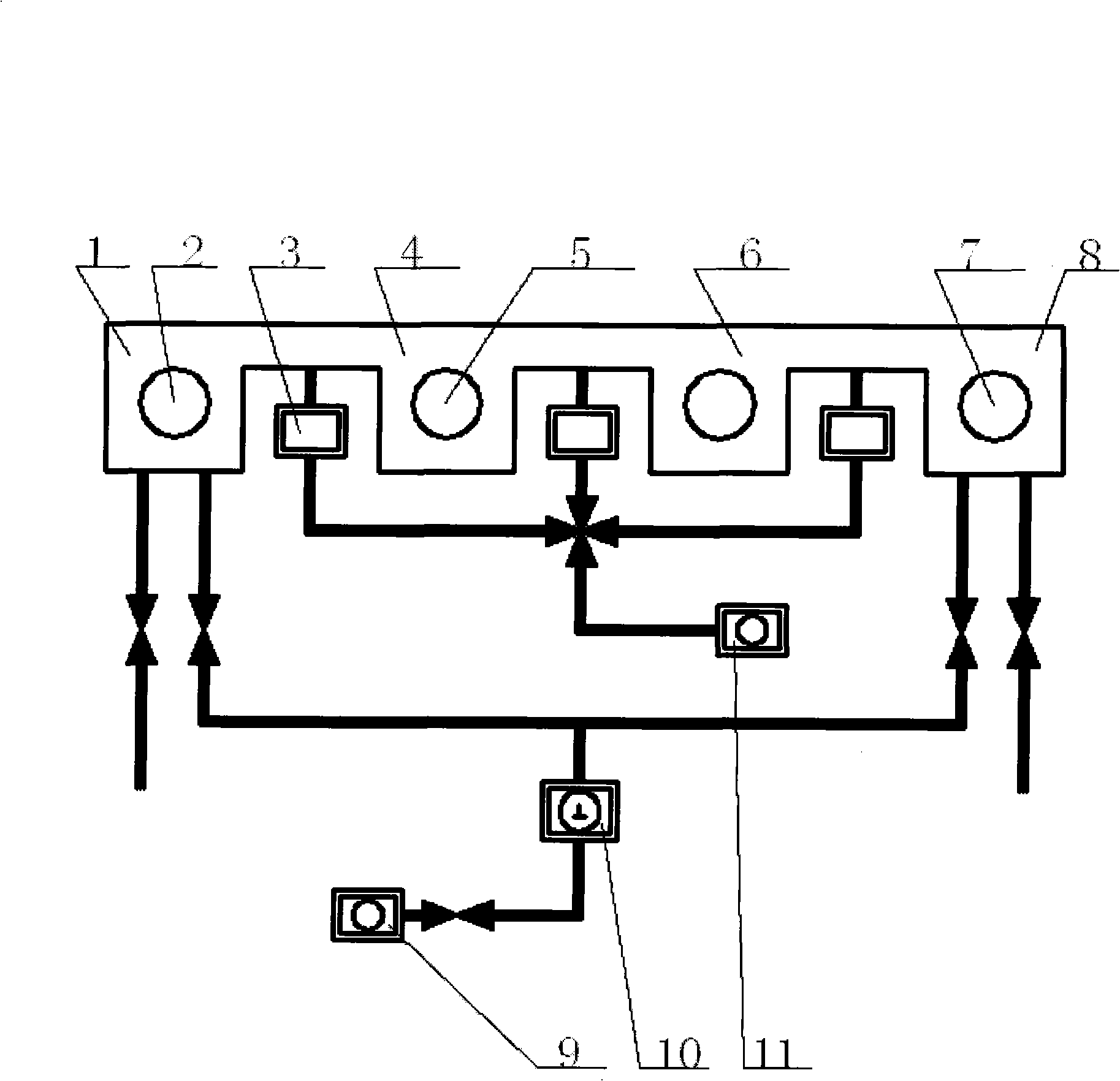

Switchable mechanical pump air-exhausting device for vacuum refining of molten steel

PendingCN107326151ASolve fever problemSolve efficiency problemsRotary/oscillating piston combinations for elastic fluidsMachines/enginesMolten steelLobe pump

The invention provides a switchable mechanical pump air-exhausting device for vacuum refining of molten steel and belongs to the technical field of external refining of steel-making furnaces. The switchable mechanical pump air-exhausting device comprises a water-cooled air exhausting pipe (1), an air cooler (2), an air exhausting pipe (3), a vacuum fast switching box (4), a high-temperature dust filter (5), a front pump valve (6), a lobe pump unit (7), a rear pump valve (8), a switching valve (9), a screw pump unit (10), a water ring pump unit (11) and an emptying pipeline (12). According to the switchable mechanical pump air-exhausting device, four different combination modes can be achieved through the vacuum fast switching box (4) and the switching valve (9) so as to adapt to different working conditions in the vacuum treatment process. The switchable mechanical pump air-exhausting device for vacuum refining of molten steel has the advantages that the air exhausting efficiency of a mechanical pump is high, the service life of equipment is long, and the operating cost is low.

Owner:BEIJING SHOUGANG INT ENG TECH

Ceramic high barrier film apparatus of continuous winding type magnetron sputtering manufacture

InactiveCN101353783ADense microstructureImprove efficiencyVacuum evaporation coatingSputtering coatingHigh resistanceVacuum extraction

The invention provides a ceramic high-resistance film device manufactured by a continuous coiling type magnetic-control sputtering method, which comprises a settling chamber, a unwinding device, a winding device, a radio frequency AC power source, and a butterfly valve, a mechanical pump, a lobe pump and a molecular pump which are arranged at the exterior of the settling chamber. In the middle of the settling chamber, a coating roller is installed, while at the lower part thereof, a rectangular silicon target is provided and at two ends thereof, end sockets are provided; at least one observation window is arranged on the settling chamber; and the lower part of the settling chamber is respectively connected with the mechanical pump, the lobe pump and the molecular pump via the butterfly valve and conduits. The ceramic high-barrier film device of the invention is characterized by continuous production, can better solve the problems of bell-typed or vertical-typed sedimentation device where the continuous production is unavailable, the production capacity is low and vacuum extraction needs to be conducted again for every time; and the utilization of the rectangular silicon target can fully utilize the space of the settling chamber and the large-scale industrialized production is convenient.

Owner:HARBIN UNIV OF COMMERCE

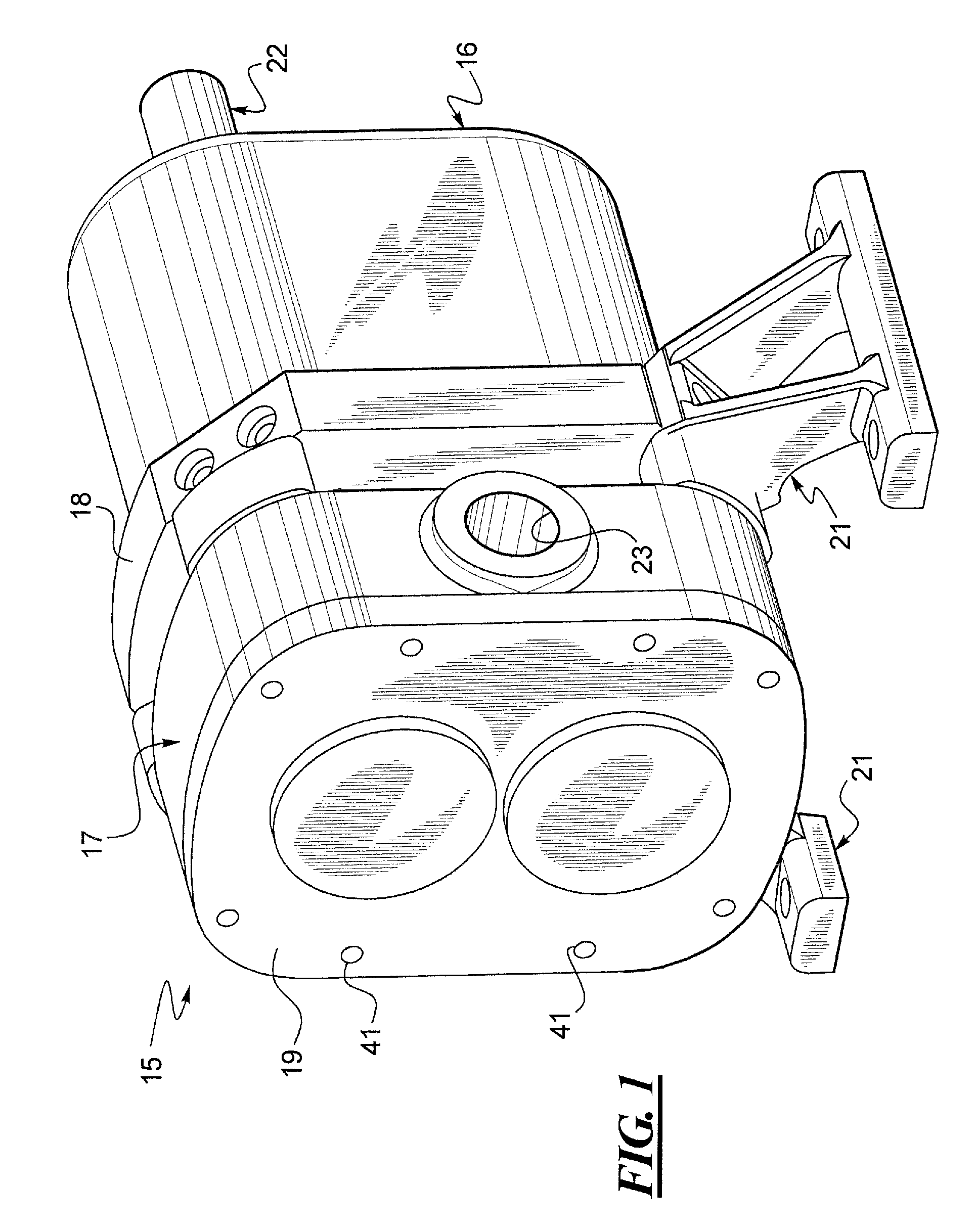

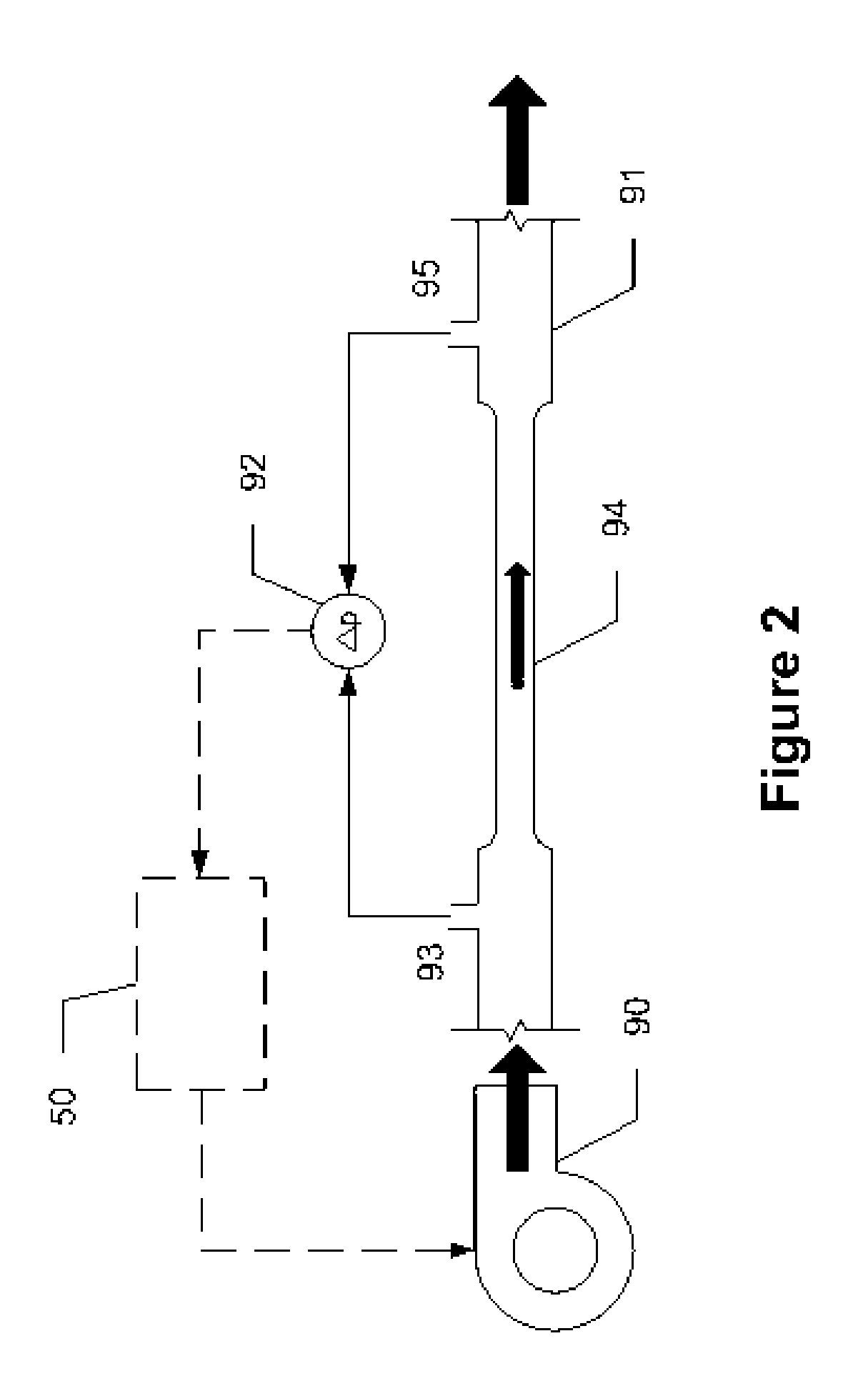

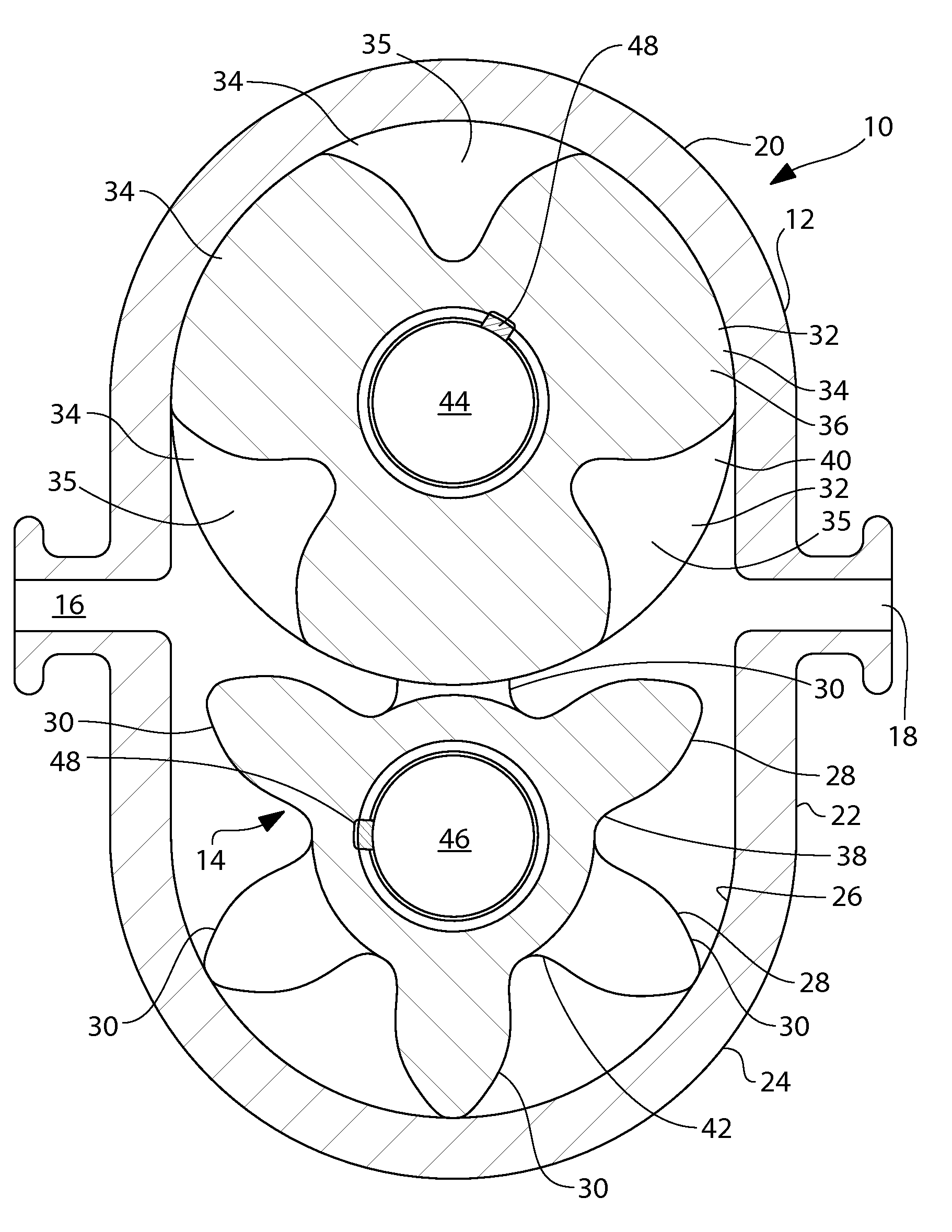

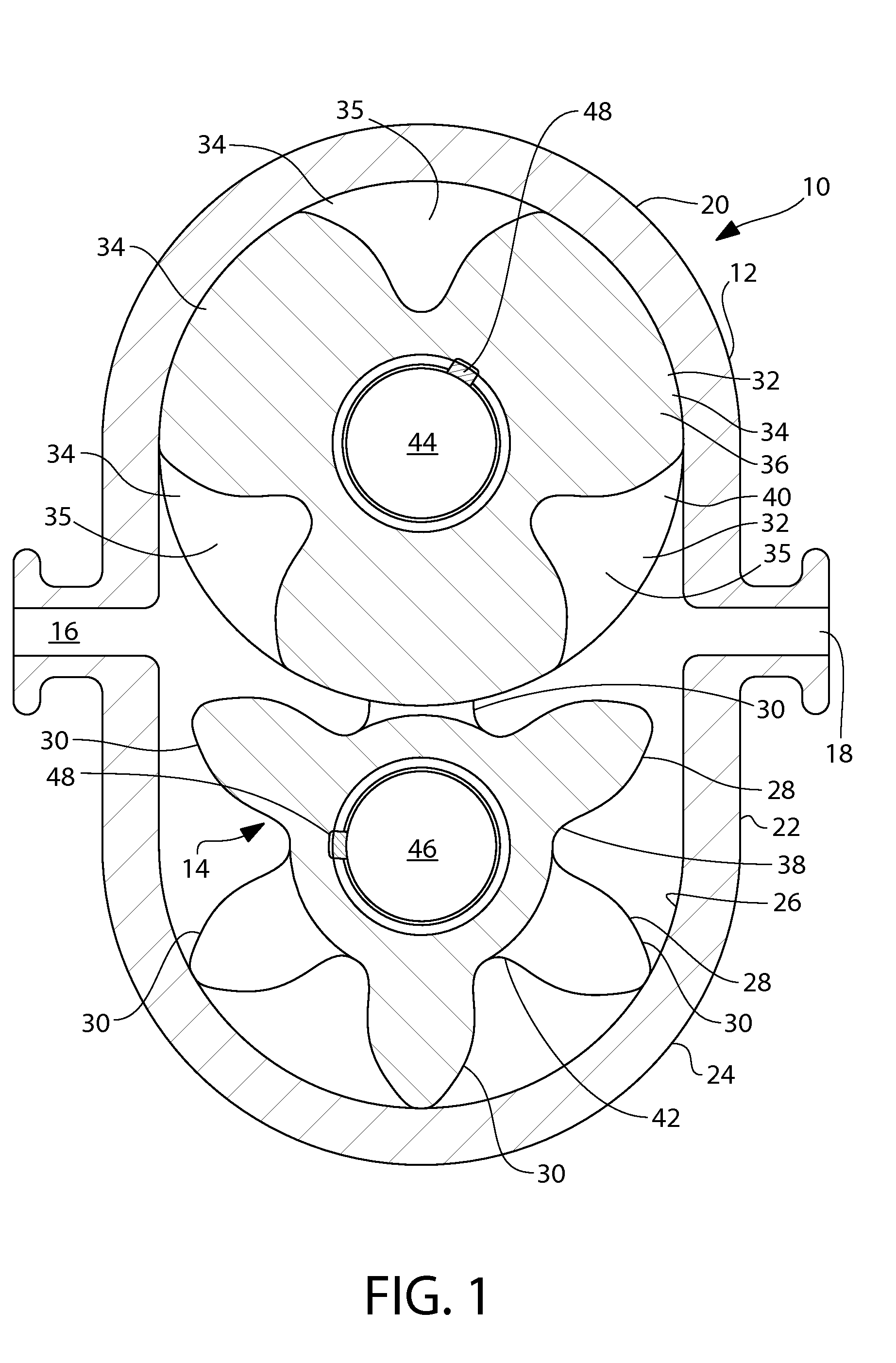

Lobe pump system and method of manufacture

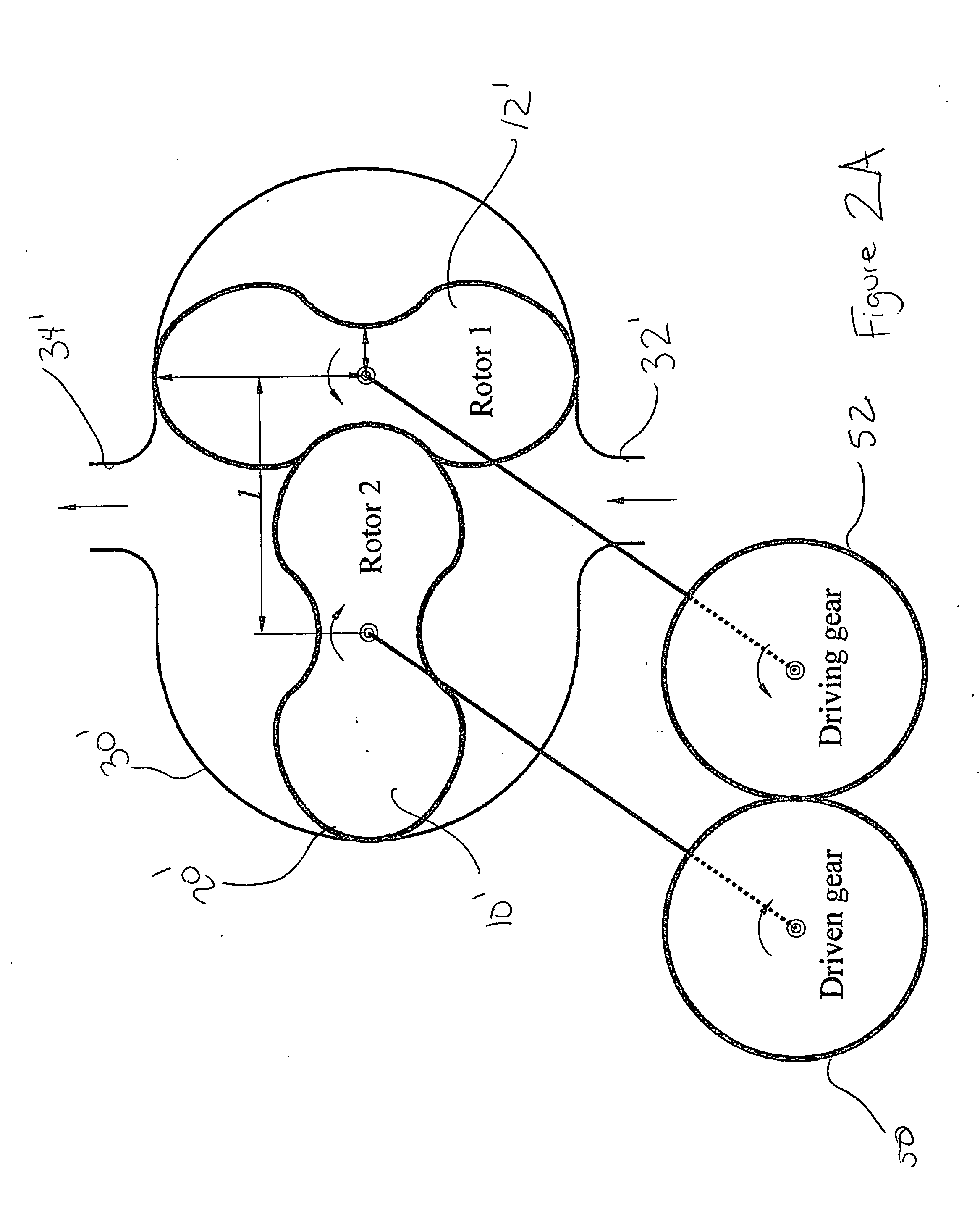

ActiveUS7553143B2Oscillating piston enginesEngine of counter-engagement typeLobe pumpMechanical engineering

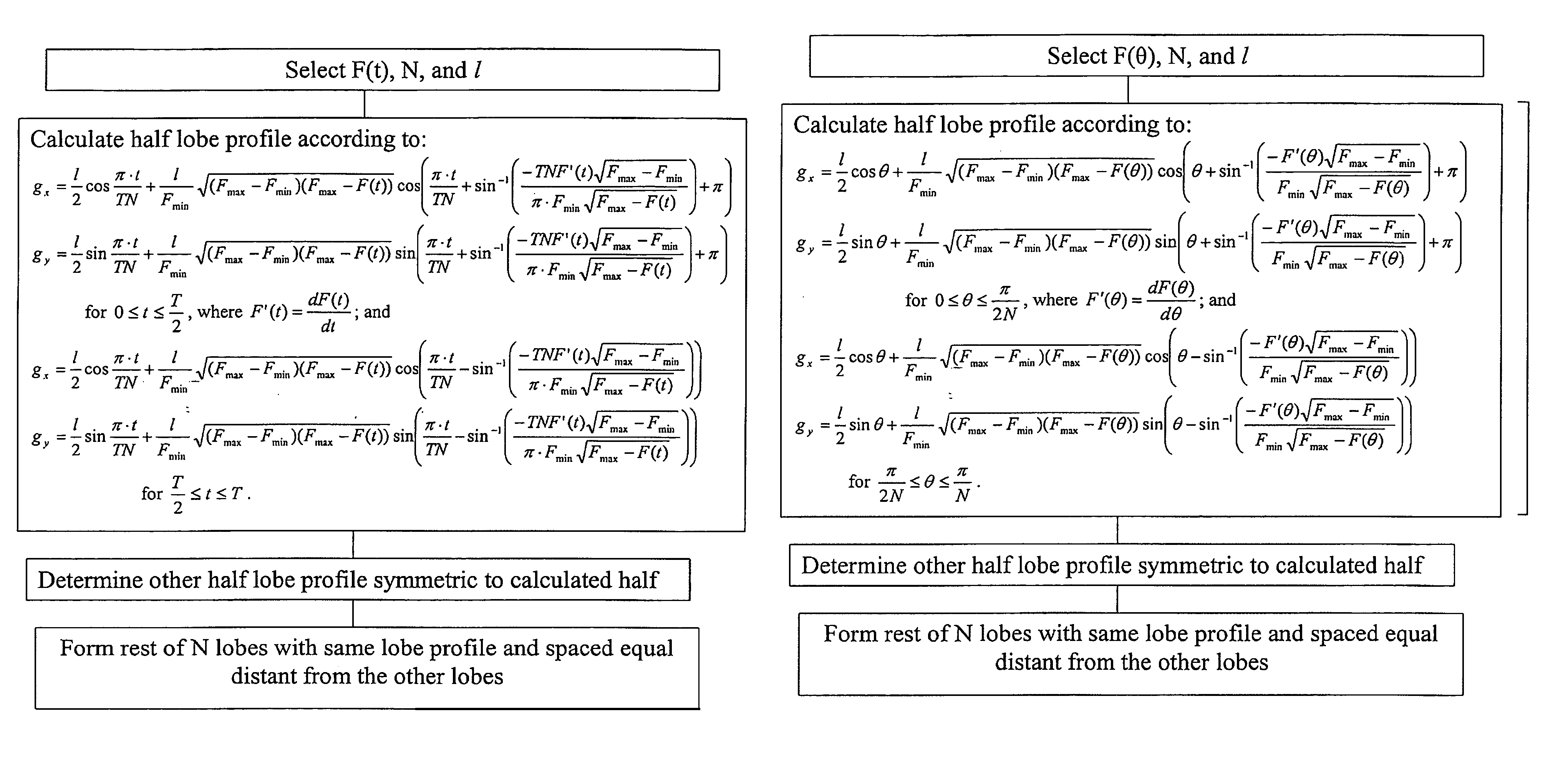

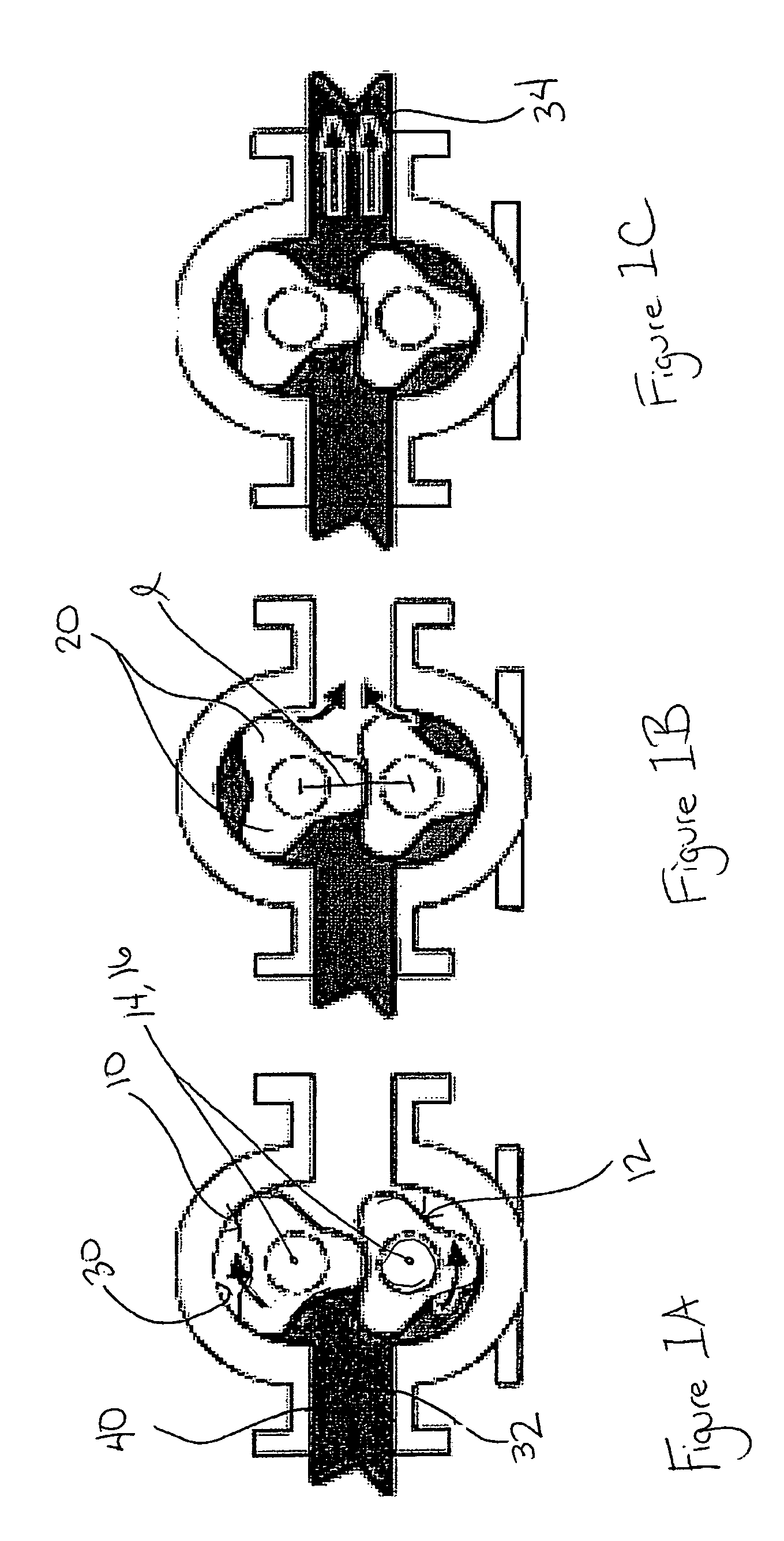

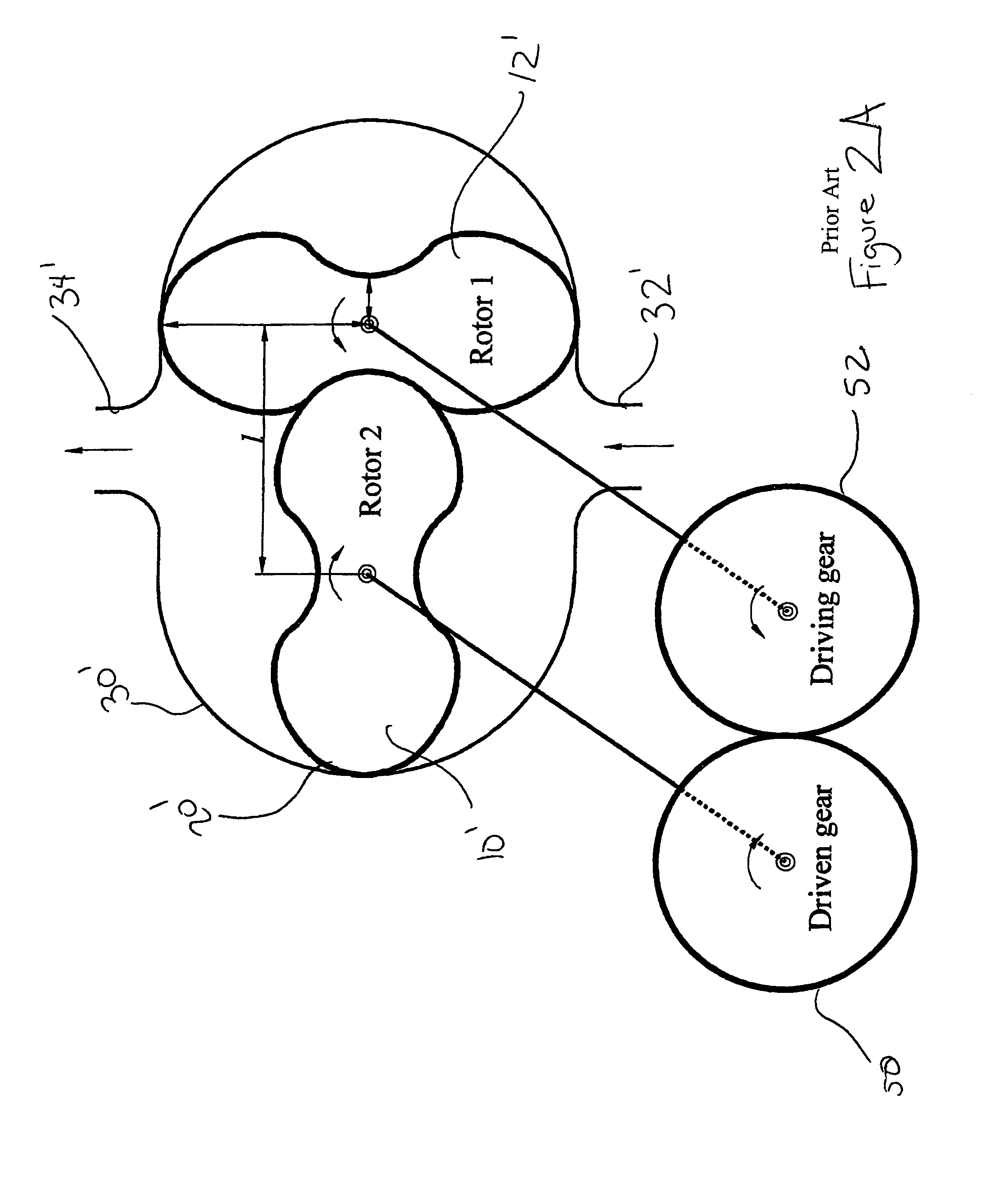

A method of manufacturing a rotor to be used in a dual-rotor lobe pump system for pumping a material at a periodic rate is provided. The method includes selecting a desired periodic flow rate for the material, selecting a number of lobes for the rotor, and selecting either a thickness of the rotor or a spacing between the dual-rotors' axes of rotation in the lobe pump. The method also includes determining the profile for the rotor based on the desired periodic flow rate, so that when the rotor is operated within the dual-rotor lobe pump system, the material can be pumped at substantially the desired periodic flow rate. In another embodiment of the invention, a lobe pump rotor profile is formed by the method described above.

Owner:RGT UNIV OF CALIFORNIA

No-diffusion-pump type coating machine for composite films

InactiveCN102994957AReduce energy consumptionImprove performanceVacuum evaporation coatingSputtering coatingLobe pumpDiffusion pump

The invention relates to the technical field of heating and in particular relates to vacuum coating equipment. A no-diffusion-pump type coating machine for composite films comprises a vacuum-pumping system and a coating chamber, wherein the vacuum-pumping system is connected with the coating chamber for carrying out vacuum-pumping on the coating chamber; a vacuum pump system is arranged in the vacuum -pumping system; and the vacuum pump adopts a lobe pump system. Compared with a conventional diffusion pump, the lobe pump has advantages of low energy consumption, stable performances, a good vacuum-pumping effect, instant starting and the like, is beneficial to improving the performable stability of the no-diffusion-pump type coating machine for composite films, and the coating quality, and greatly reducing energy consumption. The lobe pump system adopts a high-vacuum multi-stage lobe system which is formed by connecting at least two lobe systems stage by stage.

Owner:SHANGHAI HONGHAO ENTERPRISE DEV

Lobe pump system and method of manufacture

ActiveUS20050257371A1Oscillating piston enginesEngine of counter-engagement typeLobe pumpMechanical engineering

A method of manufacturing a rotor to be used in a dual-rotor lobe pump system for pumping a material at a periodic rate is provided. The method includes selecting a desired periodic flow rate for the material, selecting a number of lobes for the rotor, and selecting either a thickness of the rotor or a spacing between the dual-rotors' axes of rotation in the lobe pump. The method also includes determining the profile for the rotor based on the desired periodic flow rate, so that when the rotor is operated within the dual-rotor lobe pump system, the material can be pumped at substantially the desired periodic flow rate. In another embodiment of the invention, a lobe pump rotor profile is formed by the method described above.

Owner:RGT UNIV OF CALIFORNIA

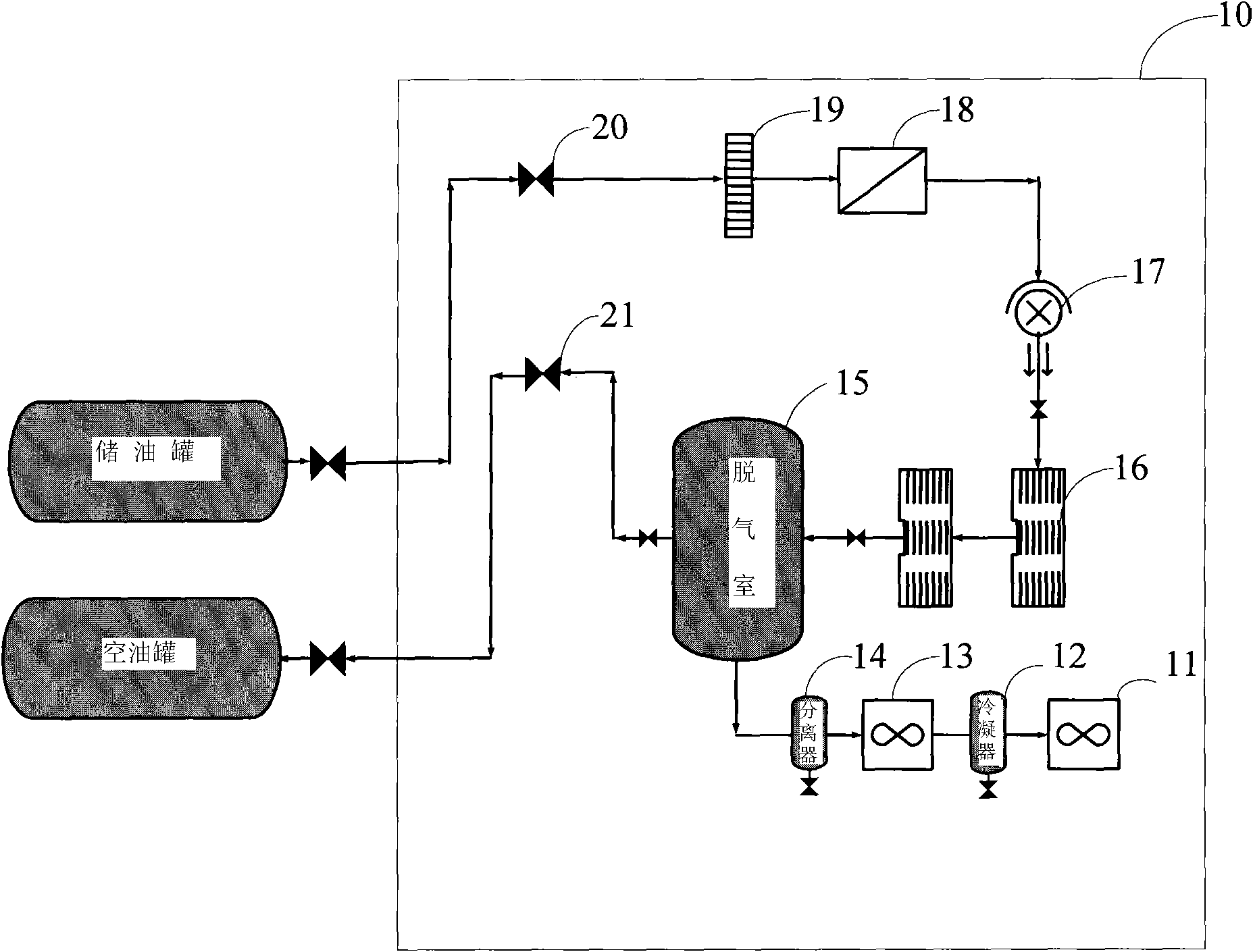

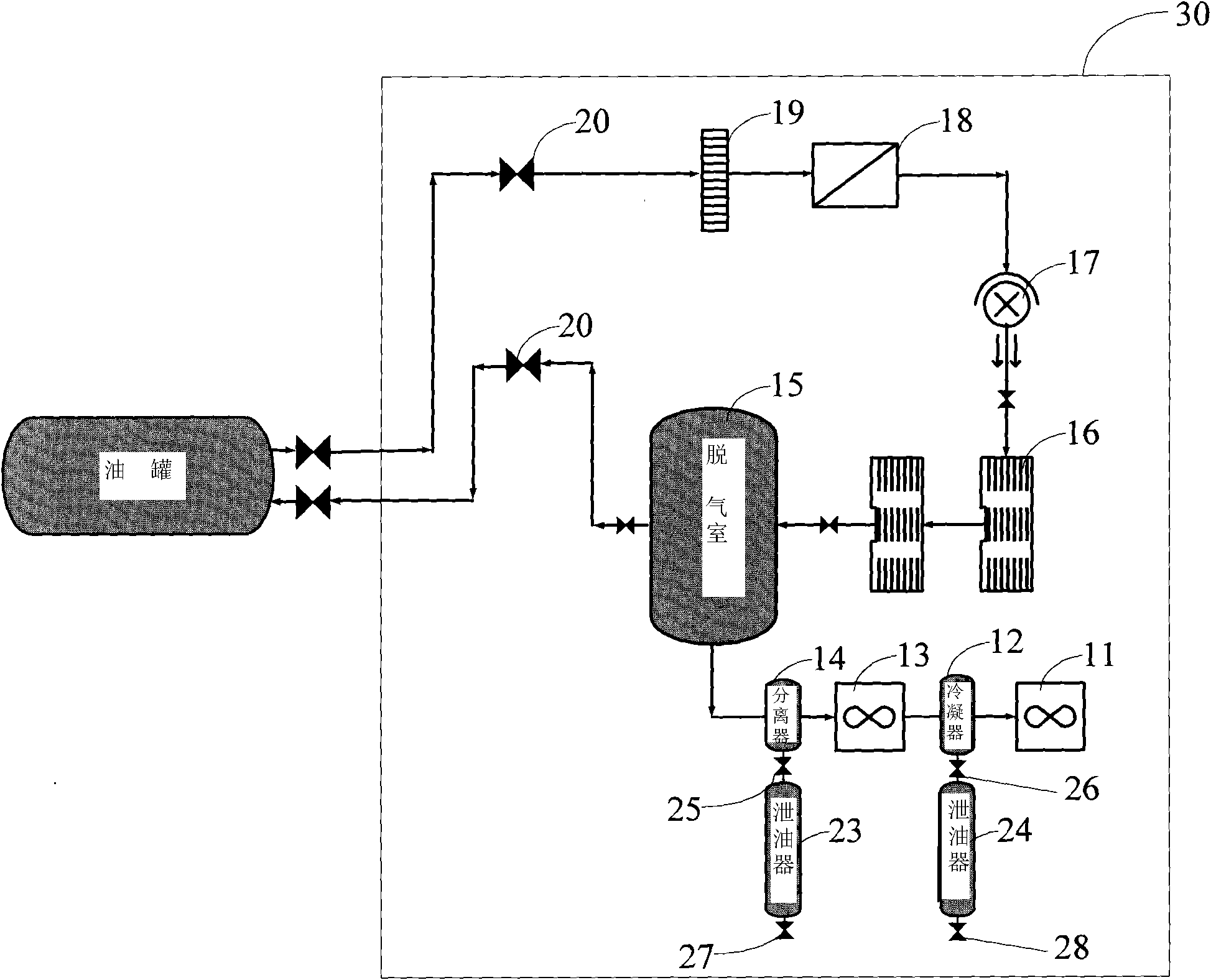

Vacuum oil filter

The invention relates to a vacuum oil filter. A coarse filter, a gear pump, a heater, a fine filter and a degassing chamber are sequentially connected between a filling valve and a delivery valve of the vacuum oil filter, wherein the degassing chamber is communicated with a separator, a lobe pump, a condenser, and a vacuum pump in turn; a first oil drainer and a second oil drainer are respectively rearranged below the separator and the condenser; a first oil drain valve is arranged between the first oil drainer and the separator and is provided with a third oil drain valve; a second oil drain valve is arranged between the second oil drainer and the condenser; and the second oil drainer is provided with a fourth oil drain valve. With the first oil drainer and the second oil drainer, the vacuum oil filter realizes the continuous operation, simultaneously prevents humidity in the air from entering the vacuum oil filter, and ensures the quality of filtered oil.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

Method and apparatus for timing rotors in a rotary lobe pump

InactiveUS20030059330A1Oscillating piston enginesEngine of counter-engagement typeEngineeringLobe pump

A rotary lobe pump includes two geared-together, counter-rotating shafts, to which are affixed rotors with interdigital lobes. Adjustment of the angular relationship of the rotors uses a clamping device within each rotor. The clamping device consists of a tapered, slotted bushing that is forced between a mating taper on the rotor and a locking device on the shaft by means of a flanged fastener mated to each pump shaft's threads.

Owner:SPX CORP +1

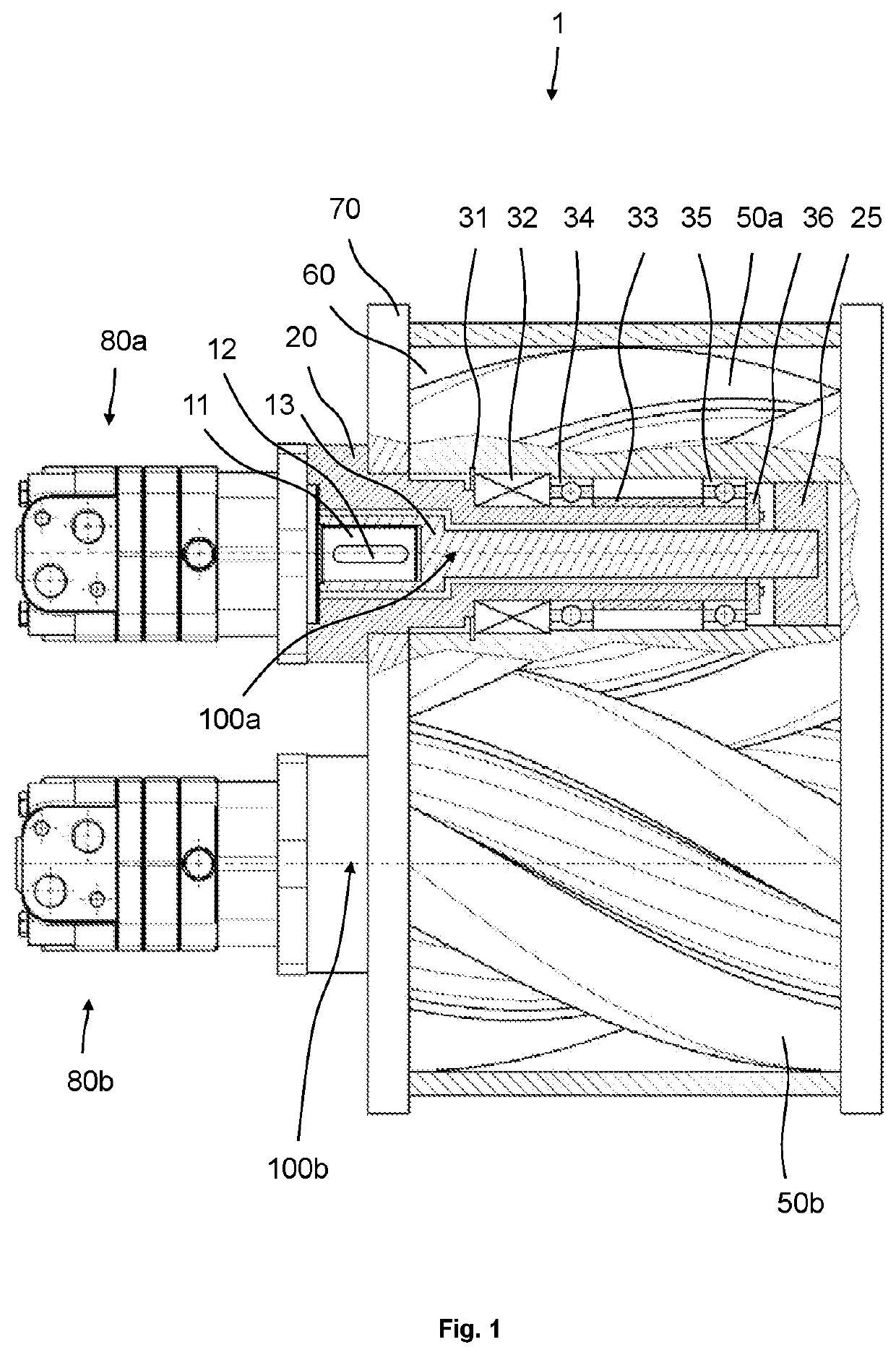

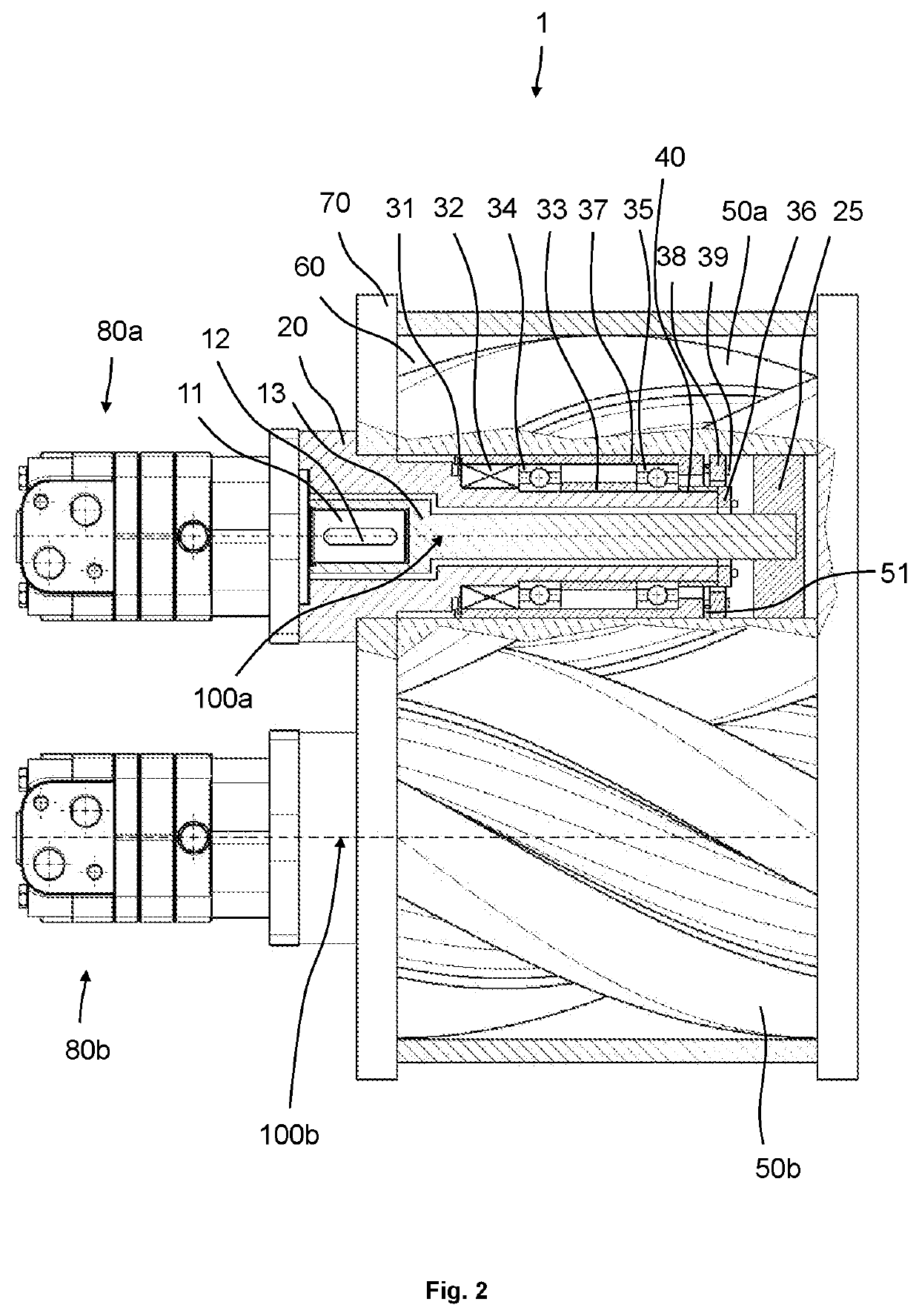

Rotary lobe pump with internal bearing

PendingUS20220025883A1Easy to manufactureIncrease spaceRotary piston pumpsRotary piston liquid enginesRotational axisPump chamber

A rotary lobe pump having a pump housing with a pump room, an inlet opening and an outlet opening, a first multi-lobe rotary piston, which is arranged in the pump room and is rotatably mounted about a first axis of rotation, a second multi-lobe rotary piston, which is arranged in the pump room and is rotatably mounted about a second axis of rotation spaced apart from the first axis of rotation and meshingly engages in the first rotary piston, wherein the first and second rotary pistons are drivable in opposite directions and are designed to generate a flow of a conveyed medium from the inlet opening through the pump room to the outlet opening by counter-rotation about the first and second axis of rotation, respectively, and a drive device, which is mechanically coupled to the rotary pistons for driving the rotary pistons.

Owner:VOGELSANG GMBH & CO KG

Rotary pump with rotor bearing ring

ActiveUS11353019B2Improve sealing propertiesQuickly and efficiently openRotary piston pumpsRotary piston liquid enginesRotary pumpClassical mechanics

Owner:THE BRICKS GRP

Rotary pump with rotor bearing ring

ActiveUS20220065246A1Improve sealing propertiesMaintain performanceRotary piston pumpsRotary piston liquid enginesRotary pumpClassical mechanics

Owner:THE BRICKS GRP

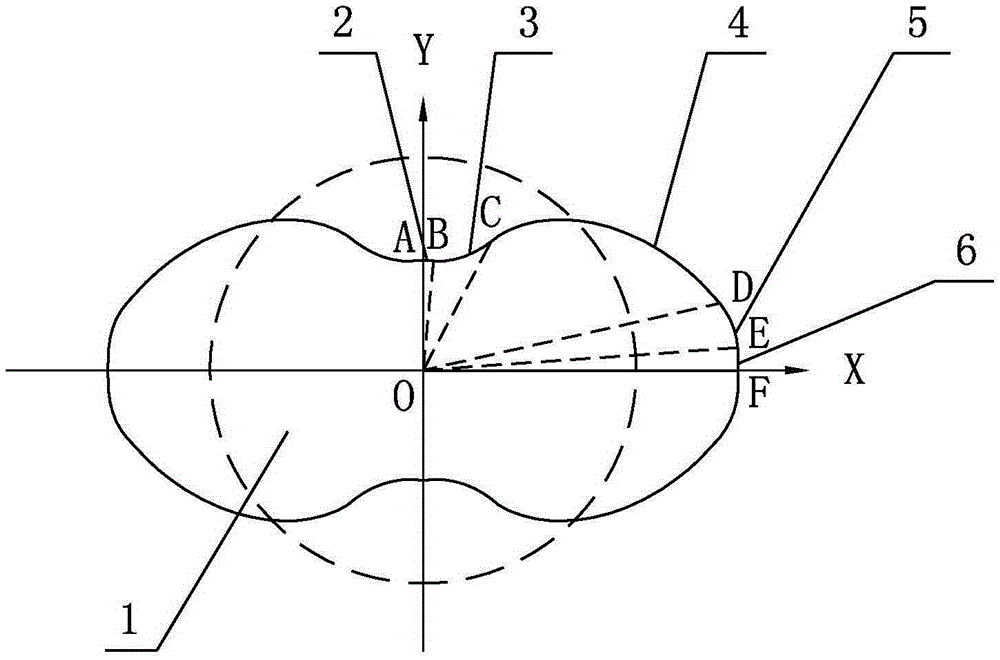

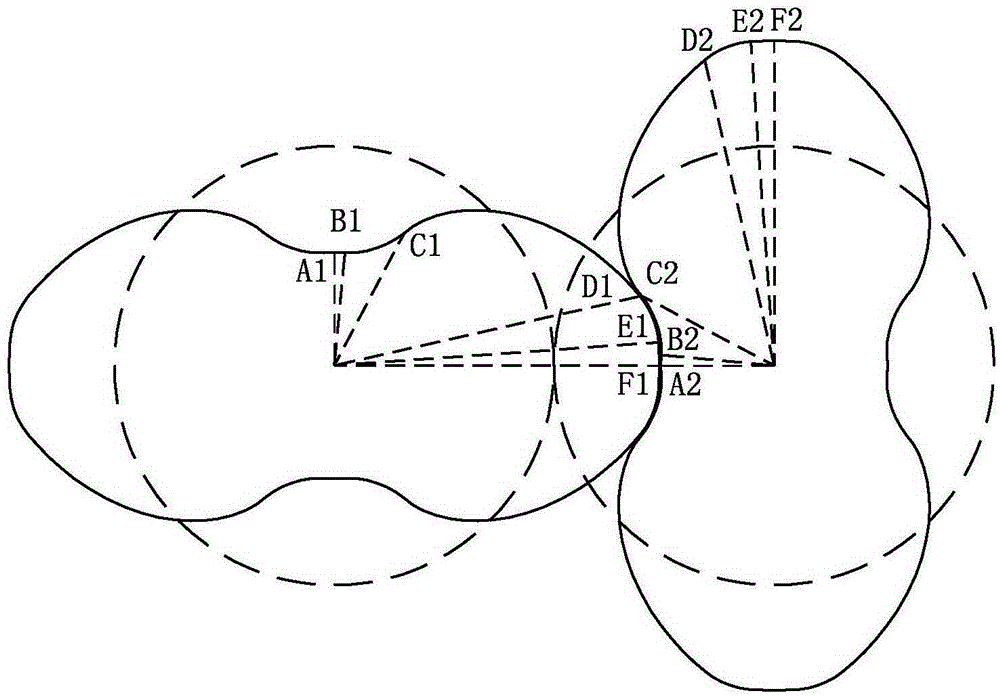

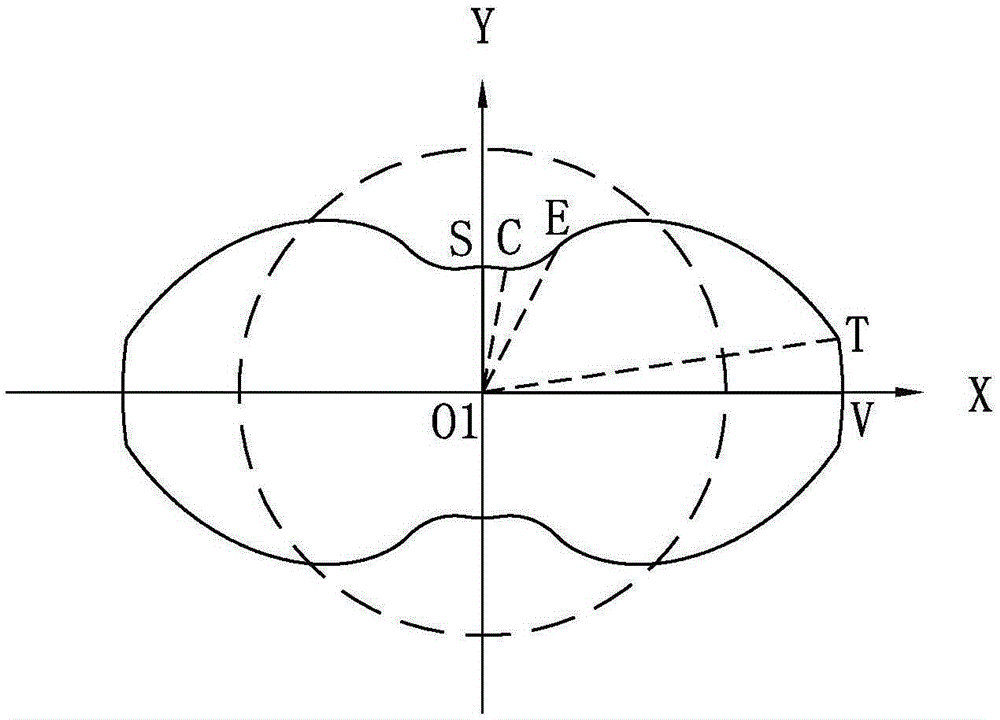

Roots pump rotor

ActiveCN103486041BReduce the chance of interferenceReduce reflux rateRotary piston pumpsRotary piston liquid enginesLobe pumpPoint counting

The invention relates to a lobe pump, and in particular relates to a lobe pump rotor. The lobe pump rotor comprises a body, wherein the body is of two-leaf-type, body molded lines comprise a first circular arc segment, a conjugate curve segment, an involute segment, a second circular arc segment and a third circular arc segment which are arranged in sequence, and the first circular arc segment, the conjugate curve segment, the involute segment, the second circular arc segment and the third circular arc segment are in smooth connection. According to the lobe pump rotor, by arranging the involute segment and the second circular arc segment, meshing points are greatly reduced, so that the interference probability of the rotor molded lines is greatly reduced, the rotor cannot be stuck, and processing and assembly are easier.

Owner:伯仲(山东)工业设备有限公司

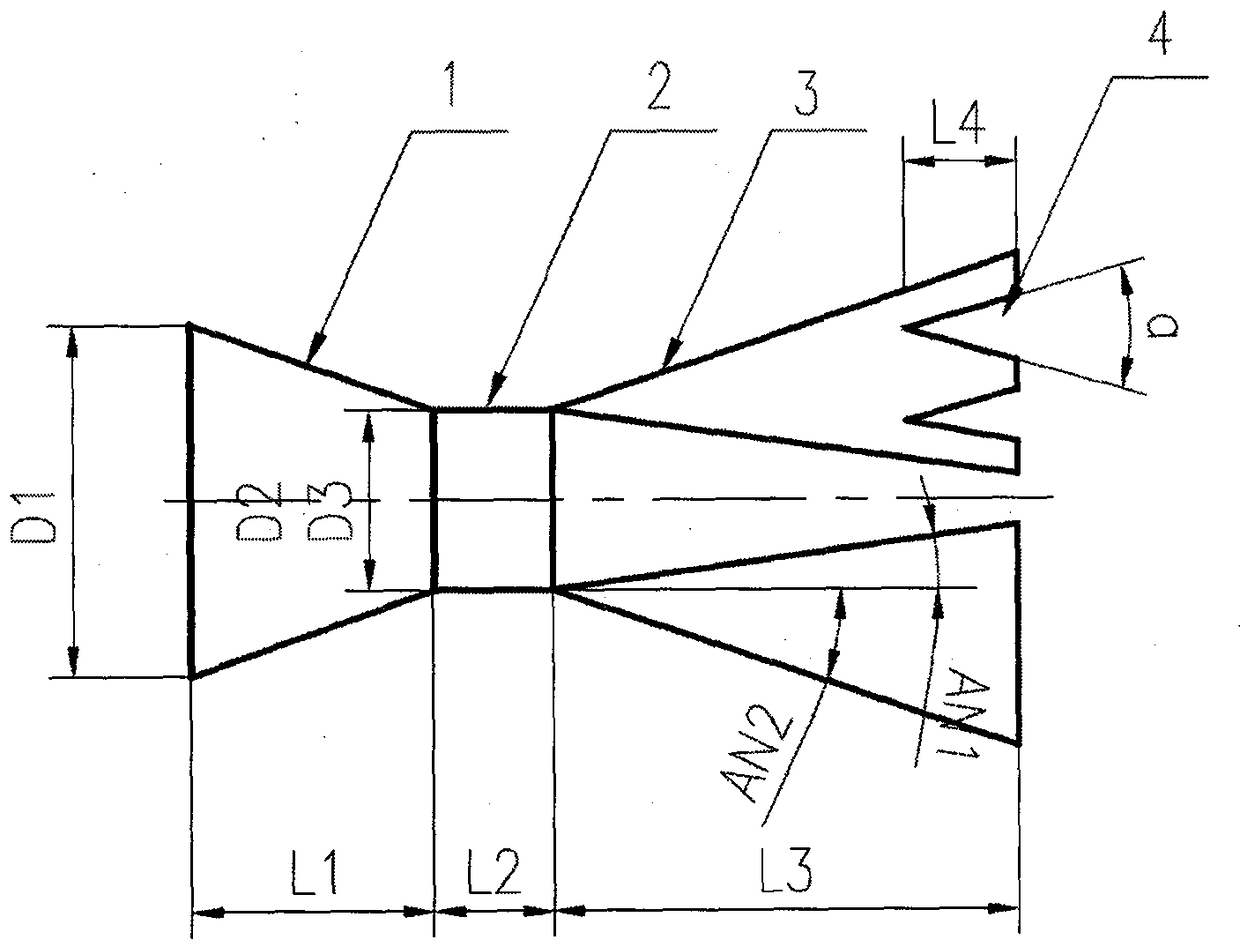

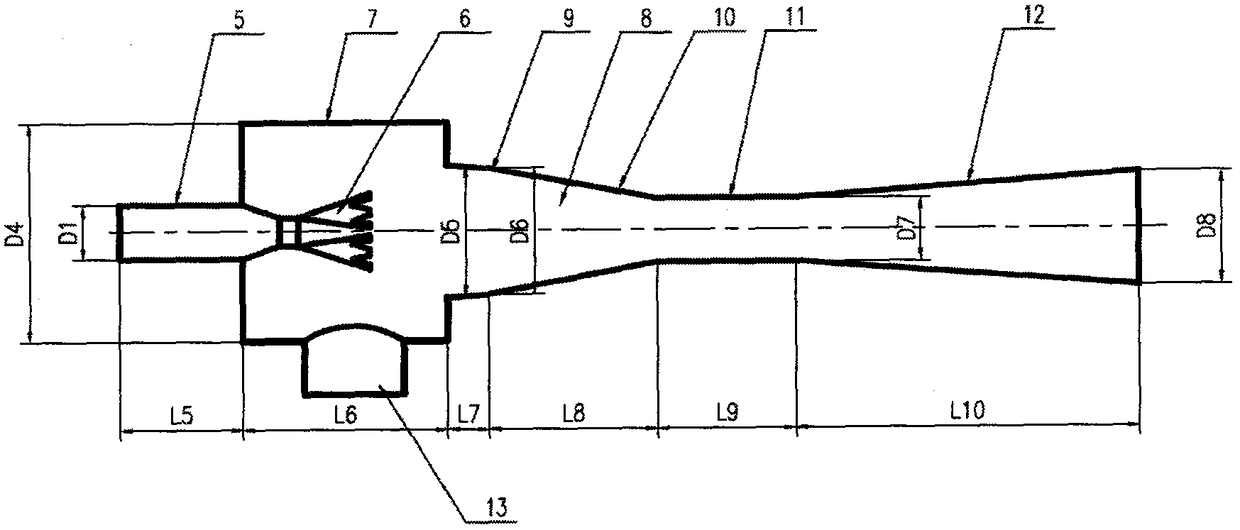

lobe evacuator

InactiveCN106286420BIncrease the effective contact areaIncrease forceJet pumpsMachines/enginesEngineeringNozzle throat

The invention discloses a supersonic speed lobe nozzle and a lobe pumping-out device with the nozzle. The supersonic speed lobe nozzle comprises an inlet segment, a nozzle throat portion and a nozzle outlet segment, and nozzle outlet tail edge modification is carried out. The lobe pumping-out device with the supersonic speed lobe nozzle comprises a main current fluid pipeline inlet segment, the supersonic speed lobe nozzle, a suction chamber, a secondary flow inlet connected with the suction chamber and a mixed pressure expanding chamber. The mixed pressure expanding chamber comprises a mixing segment composed of an inlet portion and a convergence portion, a throat portion and a pressure expanding segment. The high injection coefficient and the high work efficiency are thoroughly and mechanically achieved, energy can be greatly saved, and consumption can be greatly reduced.

Owner:苏州中尧节能环保设备有限公司

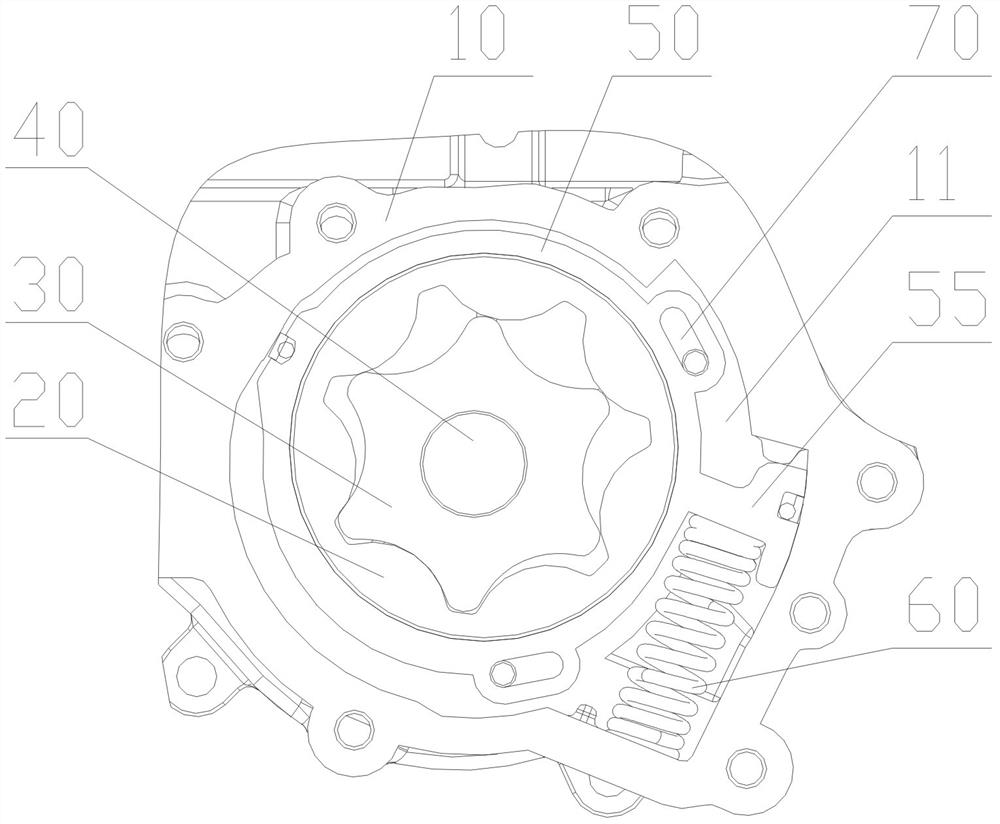

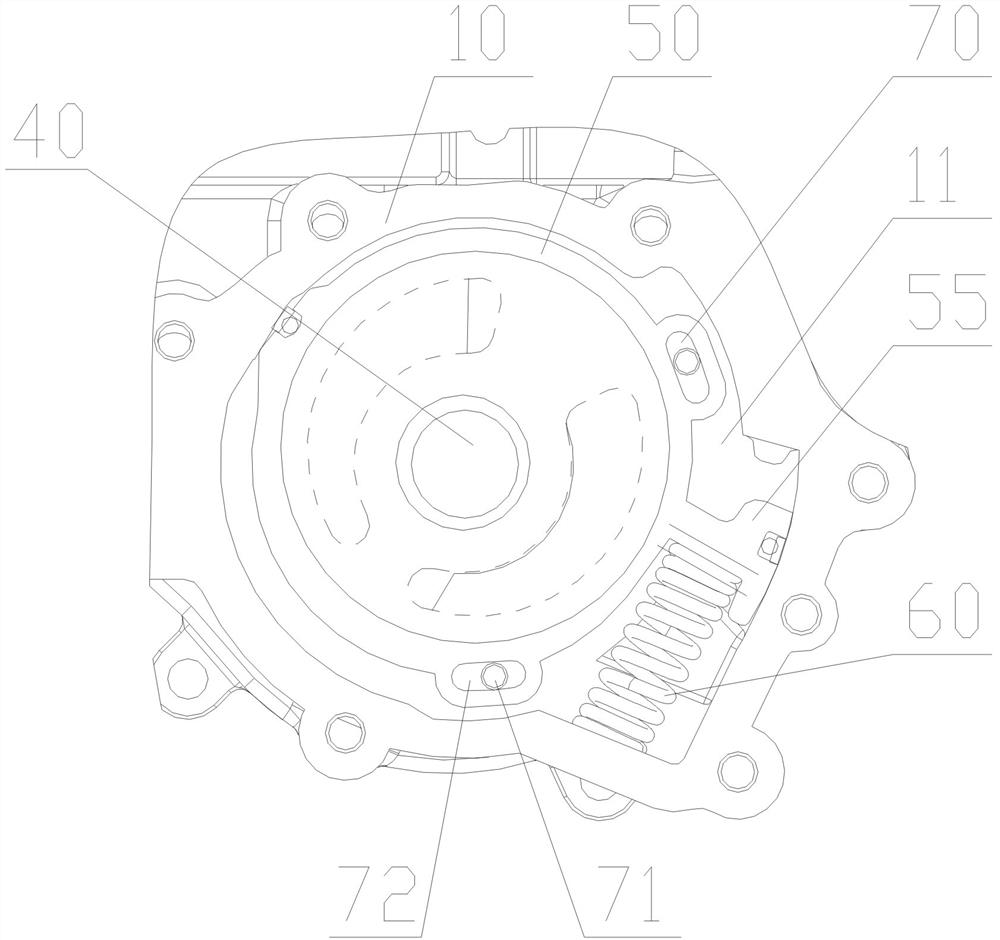

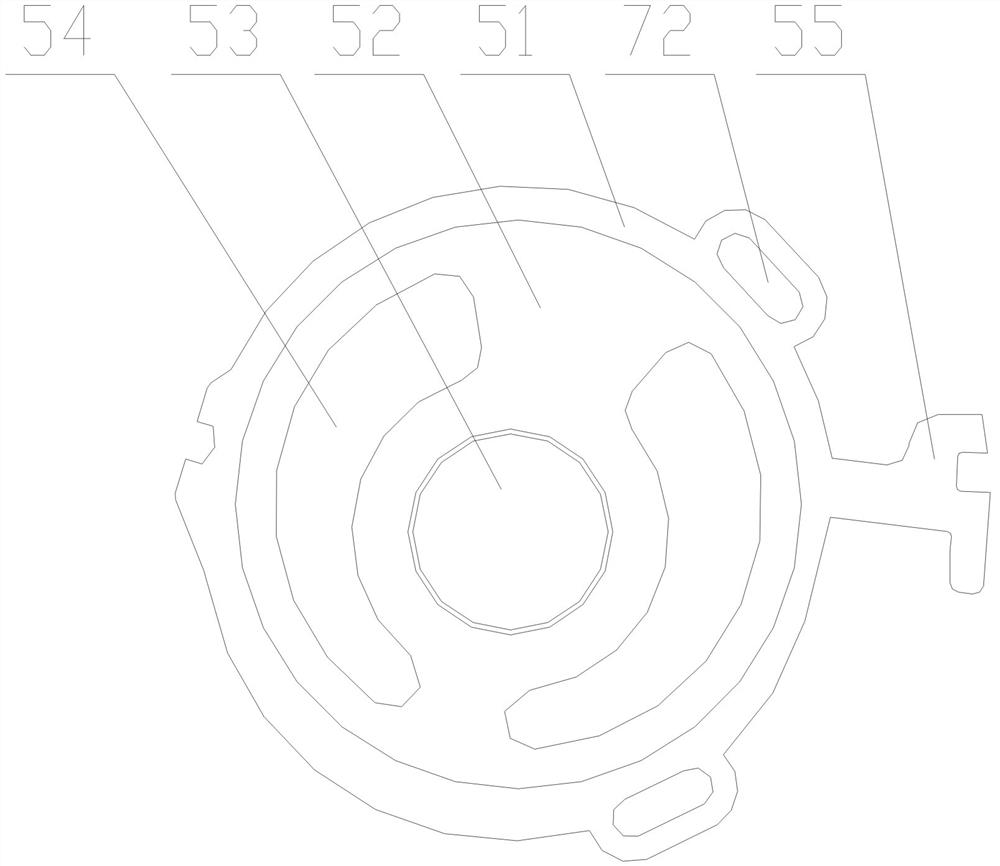

A variable displacement rotor pump

ActiveCN107061972BImprove anti-interference abilityDisplacement flexibleRotary piston pumpsLubricating pumpsDrive shaftEngineering

The invention provides a variable displacement rotor pump, which includes a pump body, an outer rotor, an inner rotor, and a drive shaft. The pump body is provided with a shaft hole and a cavity, and the bottom wall of the cavity is provided with an oil inlet cavity and oil outlet cavity, the cavity of the pump body is equipped with an inner casing and a variable spring, the inner casing is composed of a ring-shaped wall plate and a bottom plate, and the bottom plate is provided with an eccentric circular hole and two two arc-shaped through holes, the positions of the two arc-shaped through holes correspond to the oil inlet chamber and the oil outlet chamber respectively; the hollow part in the middle of the inner housing is the rotor chamber, and the outer rotor and inner rotor are installed in the rotor chamber Inside; the wall plate of the inner casing is provided with an outwardly protruding spring pressing block, one side of the spring pressing block is in contact with the variable spring, and the other side is in contact with the cavity side wall of the pump body A variable control cavity is formed between them; at least two sets of movement limit mechanisms are arranged between the inner casing and the pump body, and the movement limit mechanism can control the rotation range of the inner casing in the cavity of the pump body. Limit.

Owner:HUNAN OIL PUMP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com