Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

238 results about "Diffusion pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diffusion pumps use a high speed jet of vapor to direct gas molecules in the pump throat down into the bottom of the pump and out the exhaust. They were the first type of high vacuum pumps operating in the regime of free molecular flow, where the movement of the gas molecules can be better understood as diffusion than by conventional fluid dynamics. Invented in 1915 by Wolfgang Gaede, he named it a diffusion pump since his design was based on the finding that gas cannot diffuse against the vapor stream, but will be carried with it to the exhaust. However, the principle of operation might be more precisely described as gas-jet pump, since diffusion plays a role also in other high vacuum pumps. In modern textbooks, the diffusion pump is categorized as a momentum transfer pump.

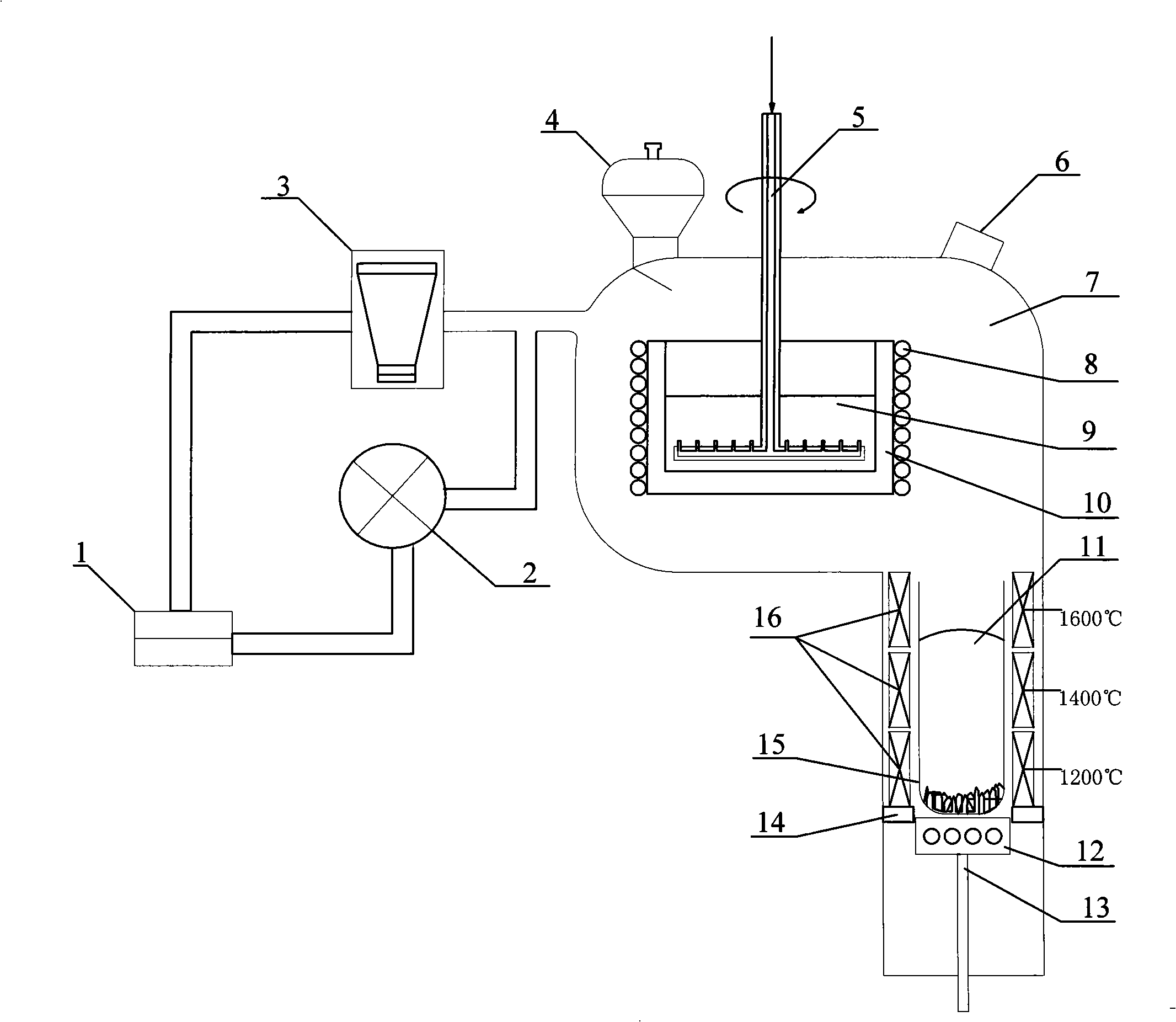

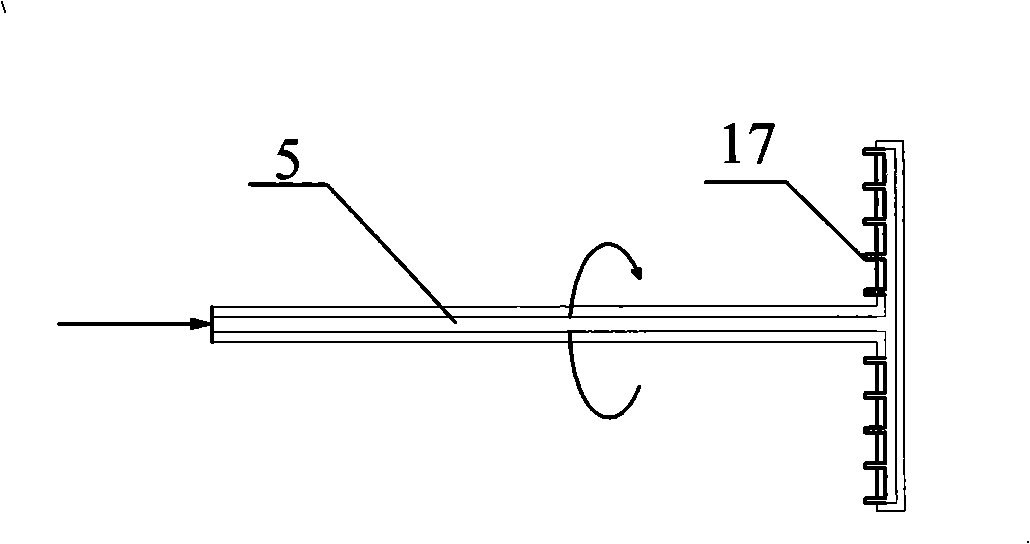

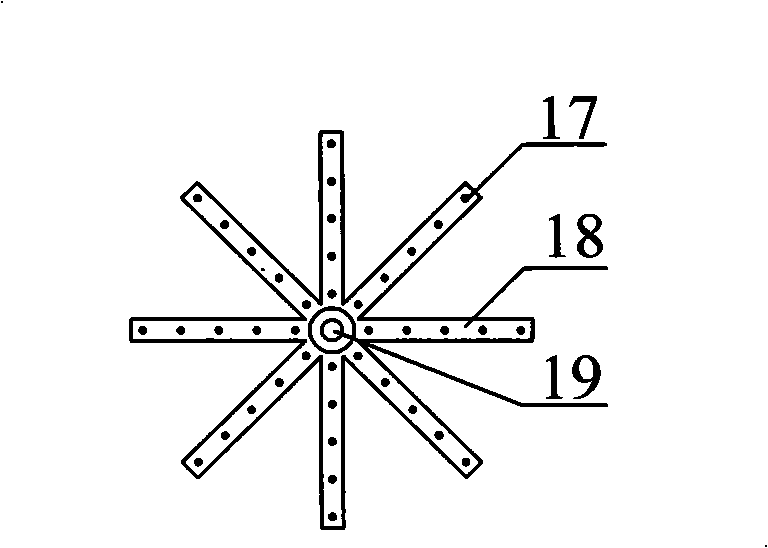

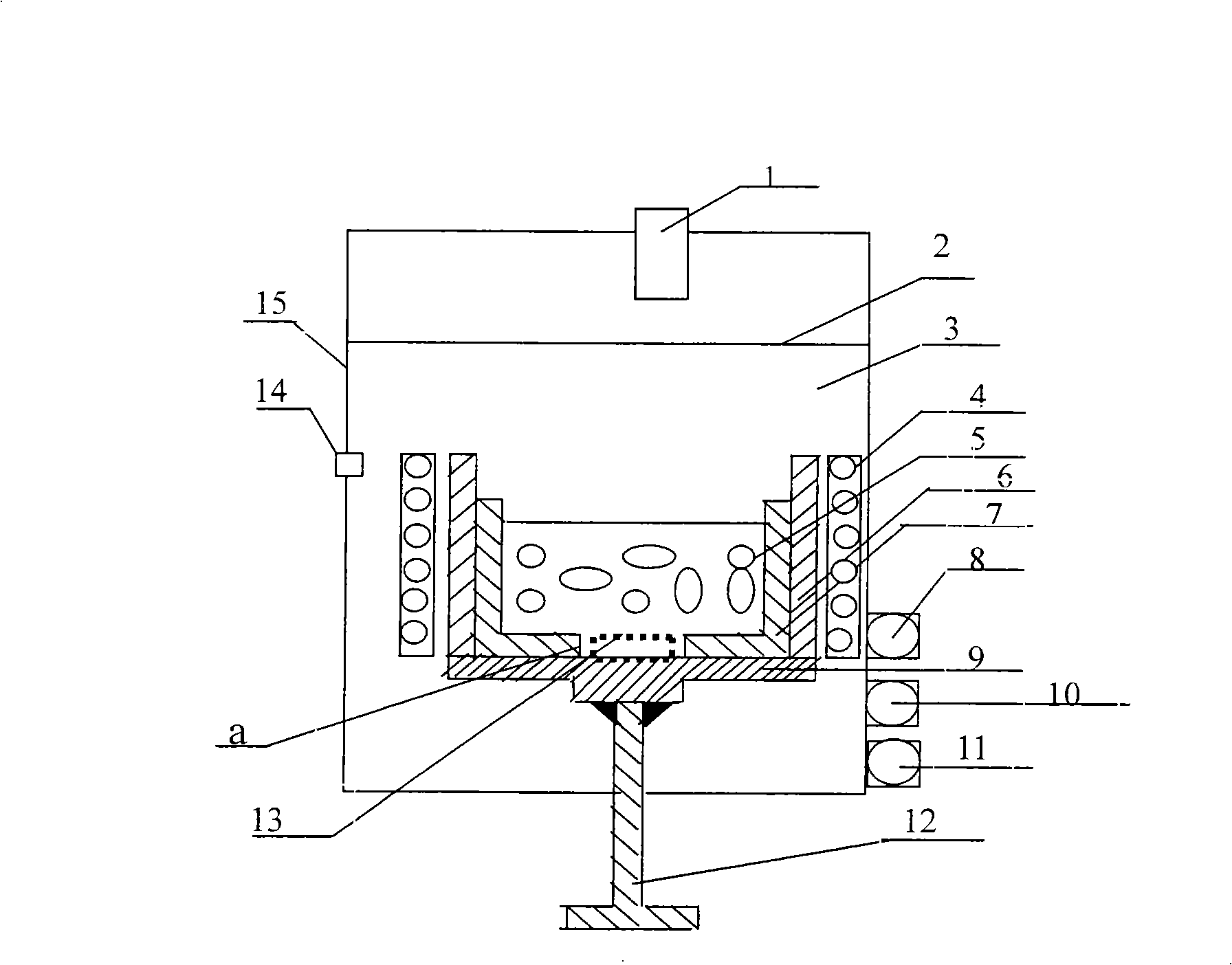

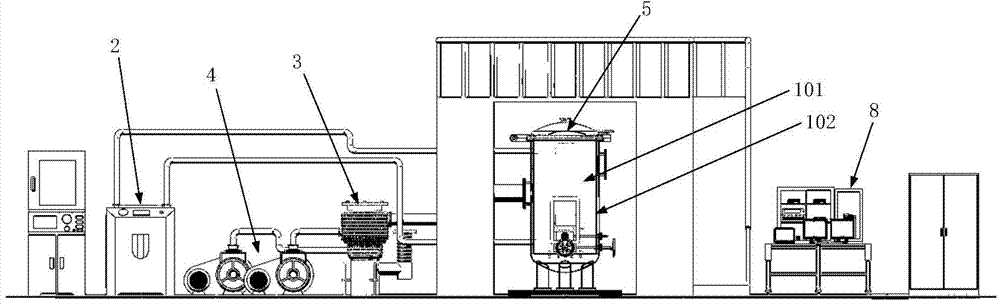

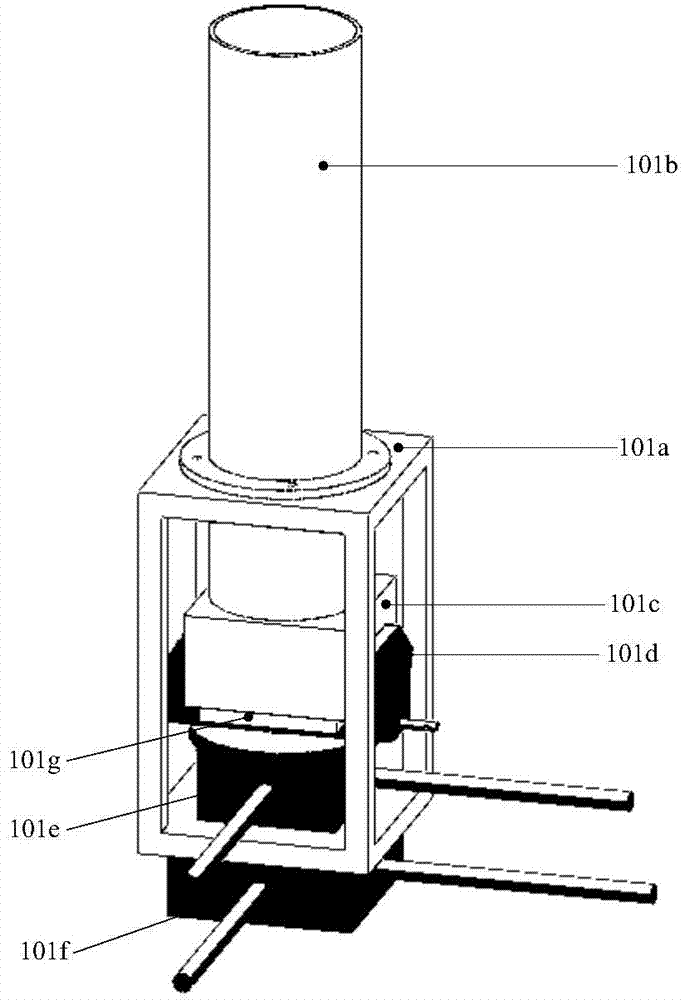

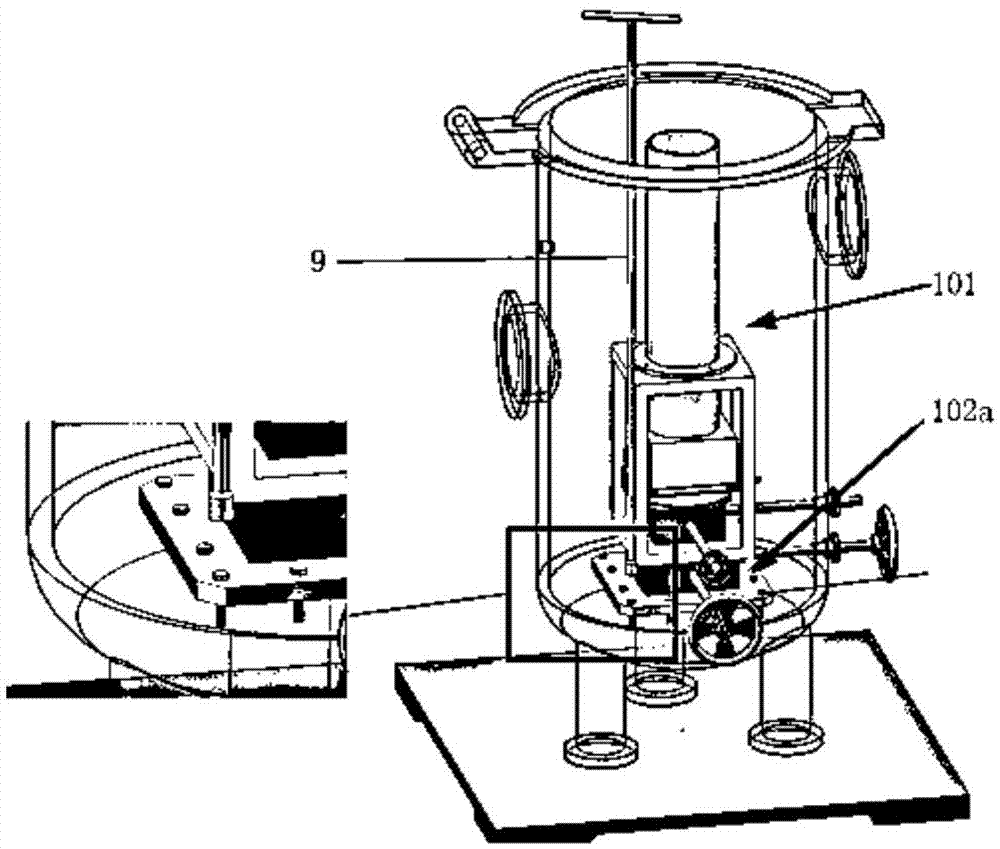

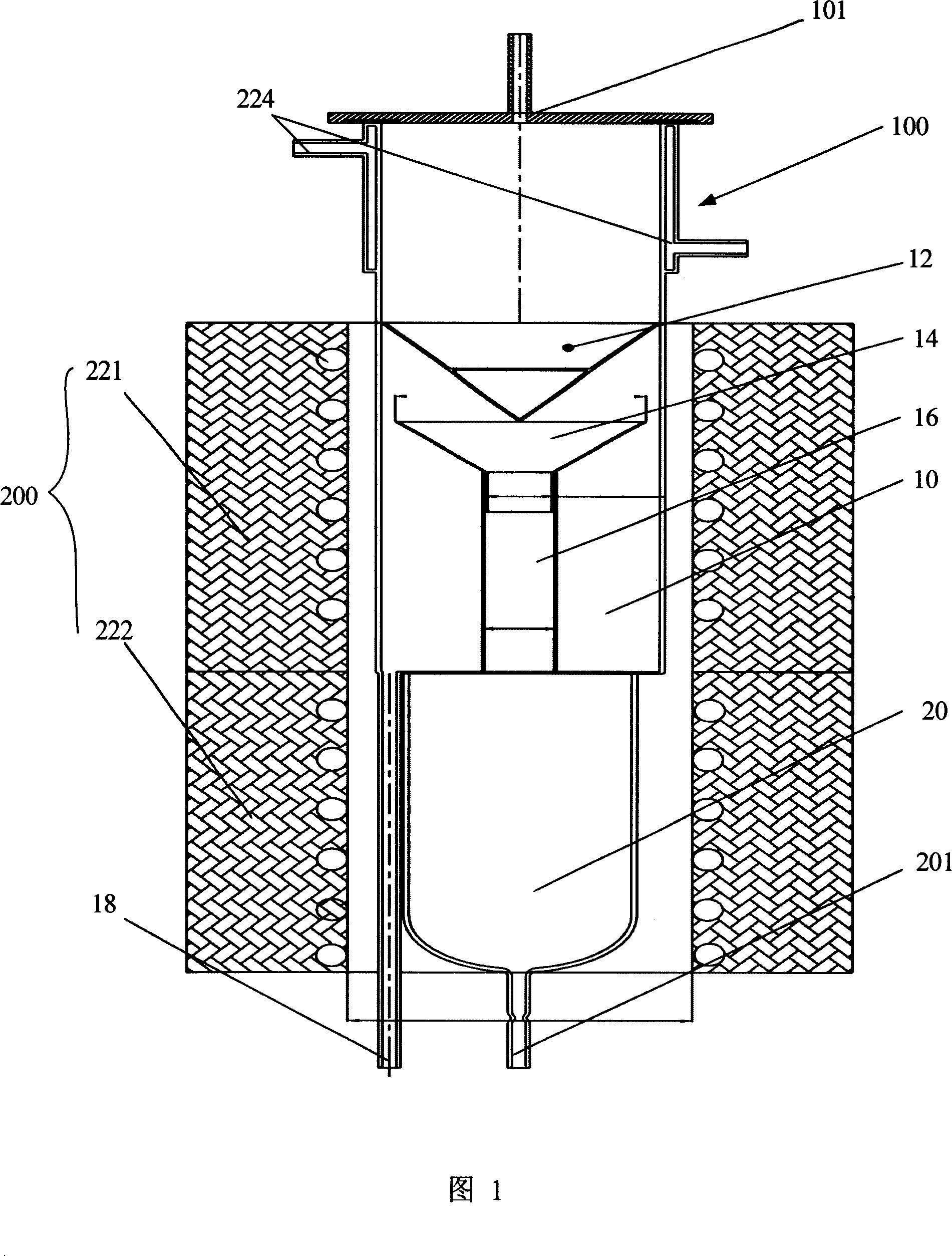

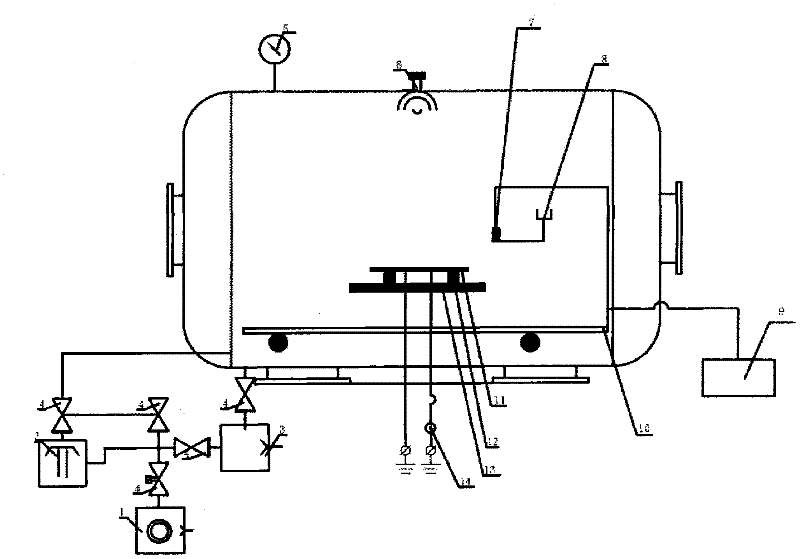

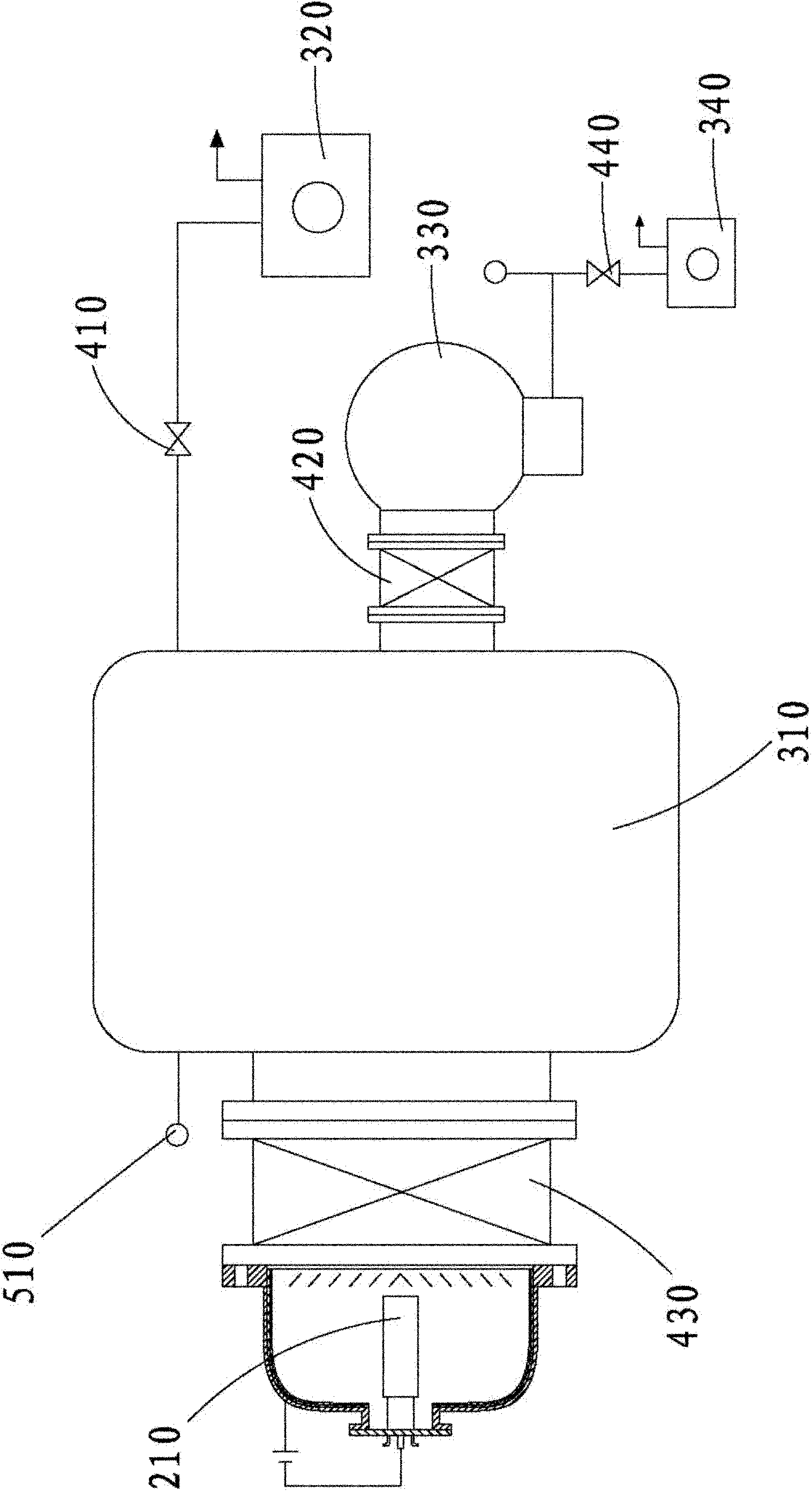

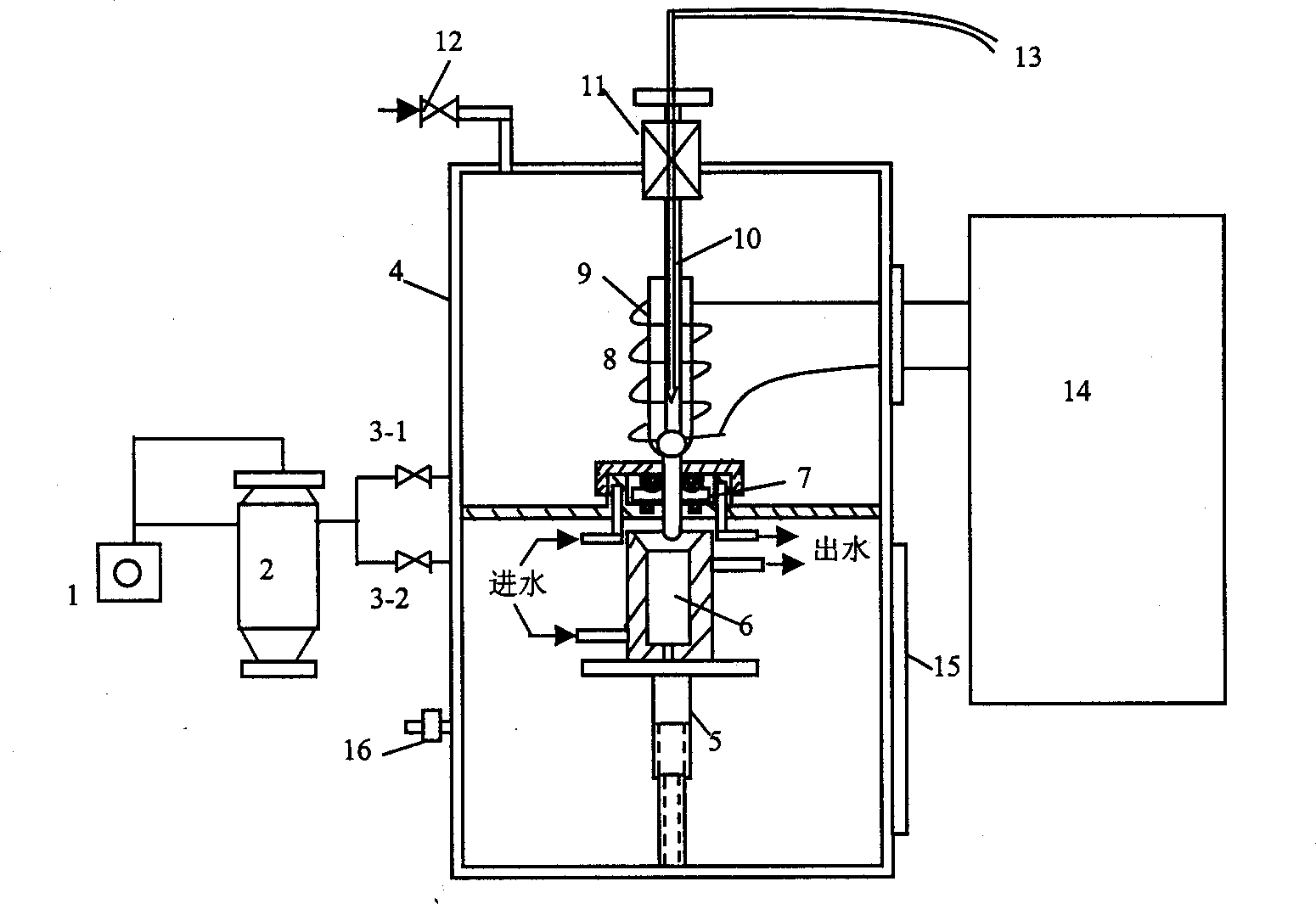

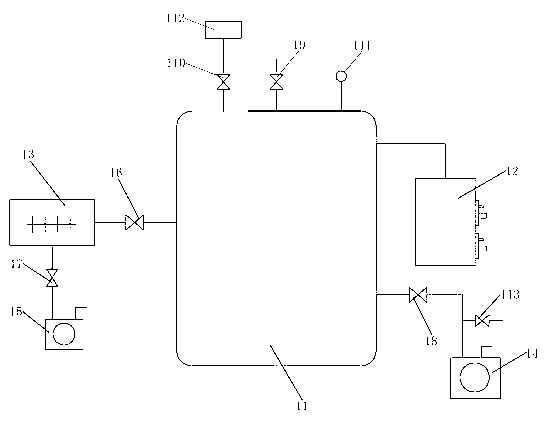

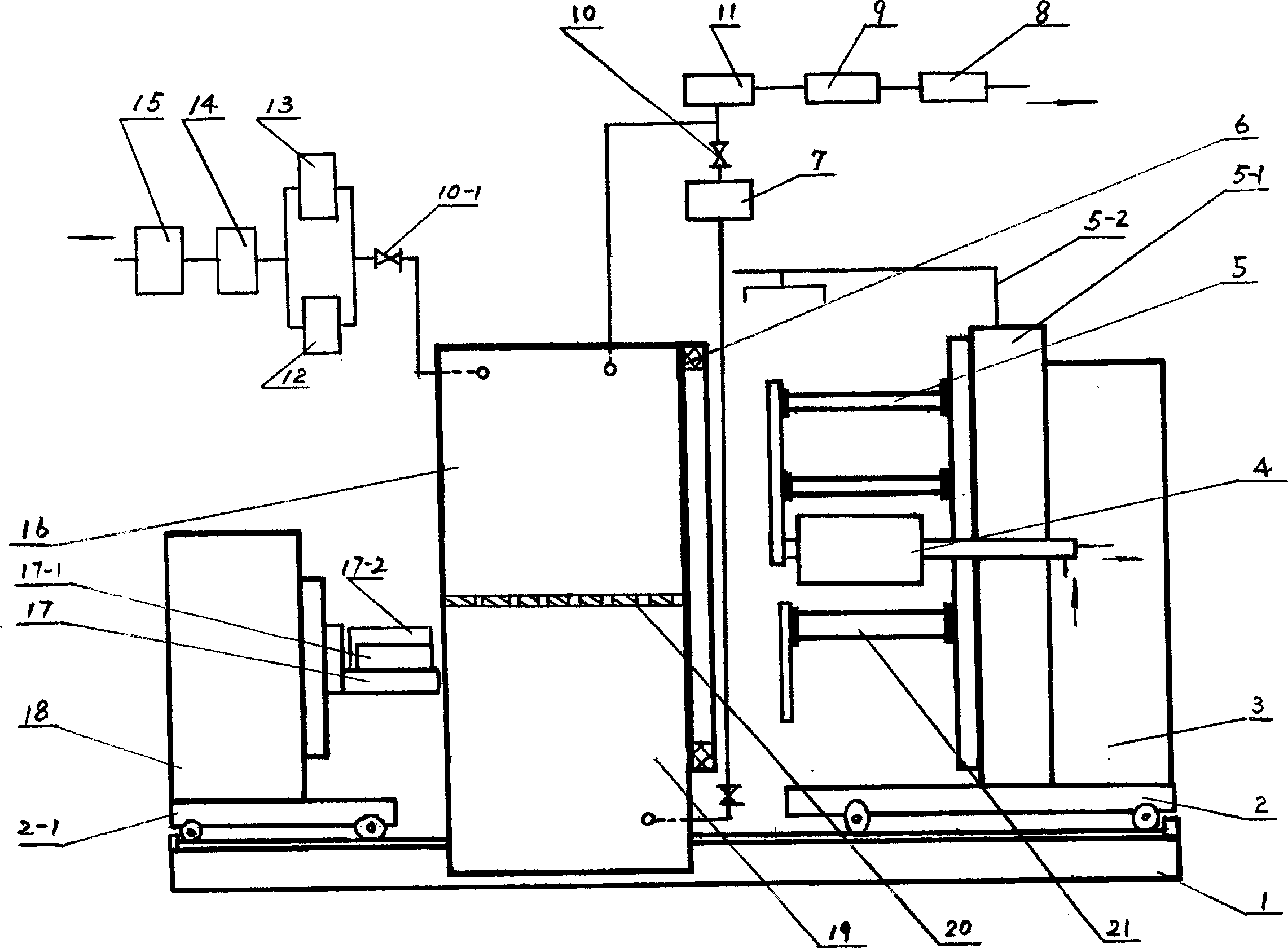

Purification apparatus and method for solar energy level polysilicon

Disclosed are a purification device as well as a purification method of solar-grade polysilicon, relating to a polysilicon, which provides a purification device and a purification method of solar-grade polysilicon characterized by low cost, high purity, simple process, easy operation and suitability for large-scale production. The purification device is equipped with a vacuum system, a melting system and a directional solidification system; wherein the vacuum system is provided with a mechanical rotary vane pump, a lobed element pump and an oil diffusion pump, and the melting system is provided with a vacuum chamber, a secondary feeder, an observation window, a rotary ventilation device which can be raised and lowered, an induction coil and a graphite crucible; and the directional solidification system is disposed at the lower part of the vacuum chamber and is equipped with an electric resistance-wire heating and holding furnace, a graphite mold, a holding furnace frame, a water-cooled copper tray and an elevating lever which can control speed. The metal silicon is treated by induction heating to be molten, the oxidizing gas is fed under conditions of low vacuum and high temperature to remove boron, and then under conditions of high temperature and high vacuum to remove phosphorus, and finally the molten silicon solution is poured into a directional mold to strictly conduct directional solidification to remove metal impurities.

Owner:XIAMEN UNIV

Process and device for removing phosphorus and metal impurities in polycrystalline silicon

InactiveCN101289188AHigh purityImprove efficiencyChemical industrySilicon compoundsMetal impuritiesLow vacuum

The invention relates to a method and a device for removing impurity phosphorus and metal impurities in polycrystalline silicon, which pertains to the technical field of purifying the polycrystalline silicon by a physical metallurgy technology, particularly relates to the method for removing the impurity phosphorus and the metal impurities in the polycrystalline silicon by an electron-beam fusion technology. Cooperative ways of electron-beam fusion and induction heating are used for completing the fusion and solidification process of the polycrystalline silicon. Silicon powder with high purity is used for spreading in a hollow-out space at a water cooled copper base which is filled with quartz crucibles; polycrystalline silicon material is put into the quartz crucibles and the cover of a vacuum device is closed; in the process of vacuumization, a mechanical pump and a lodz pump are firstly used for vacuumizing a vacuum room to low vacuum and then a diffusion pump is used for vacuumizing to high vacuum; the device used is provided with a vacuum device cover and a vacuum drum which are formed into the outer shell of the device; the inner cavity of the vacuum drum is the vacuum room, in which a fusion system is arranged. The method and the device of the invention effectively improve the purity of the polycrystalline silicon, which have the advantages of high efficiency, simple device and saving energy.

Owner:QINGDAO NEW ENERGY SOLUTIONS

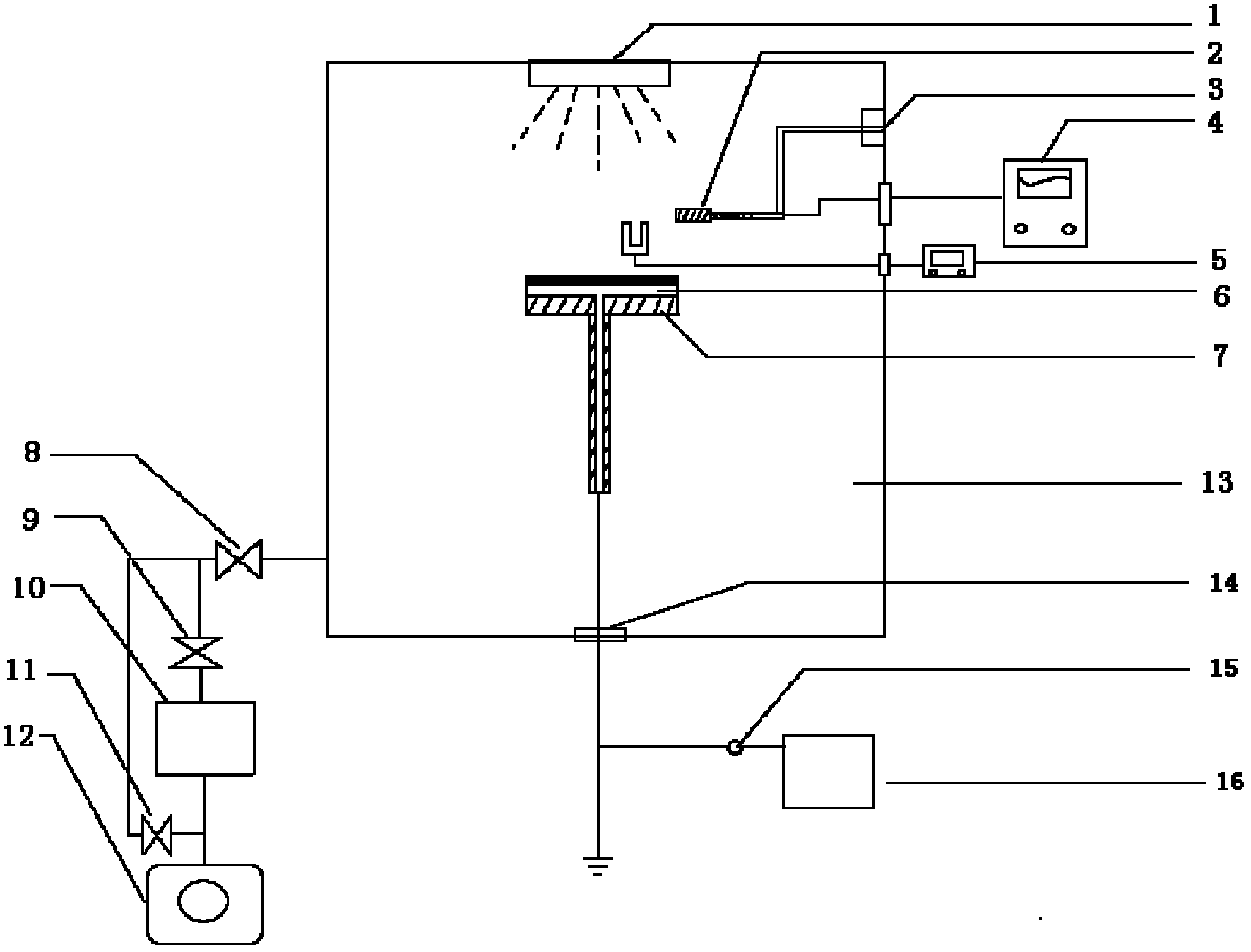

Device and method for on-orbit monitoring of charging of satellite material surface

ActiveCN102507717ASimple physical structureEasy to carry in spaceMaterial analysis by electric/magnetic meansSurface chargesElectron

The invention relates to a device and a method for on-orbit monitoring of charging of a satellite material surface, belonging to the technical field of space application. The device comprises an electron gun, a non-contact potentiometer probe, a three-dimensional transmission mechanism, a non-contact surface potentiometer, an electron beam current density measuring system, a monitoring electrode,a supporting structure, a first electromagnetic valve, a second electromagnetic valve, a diffusion pump, a third electromagnetic valve, a vacuum box, a mechanical pump, a vacuum penetrating wall, a measurement circuit interface and a measurement circuit. The test method comprises the steps as follows: sending an electron to a sample for monitoring the electrode surface under a vacuum condition, adjusting the position of the non-contact potentiometer probe through the three-dimensional transmission mechanism, recording charging potential Vsurface on the sample surface, measuring leakage current I through the measurement circuit, and finally obtaining a proportional relation coefficient K by known sample resistance rho according to the formula that Vsurface is proportional to KrhoI. According to the invention, the on-orbit surface charging condition of the satellite material is inverted by monitoring the leakage current of the sample in a space environment, and the device and the methodhas the advantage of simple physical structure and is easy to carry in space.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

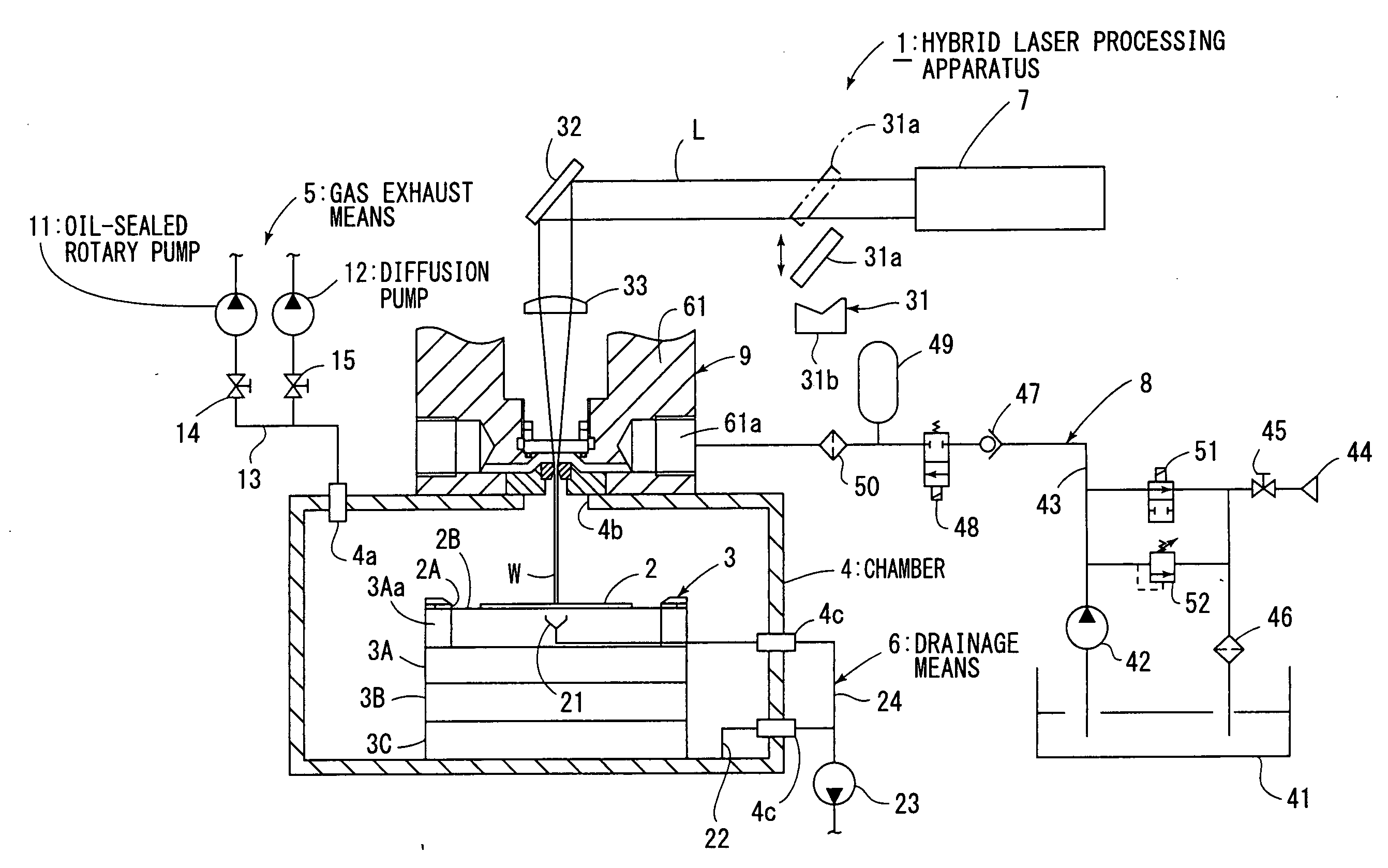

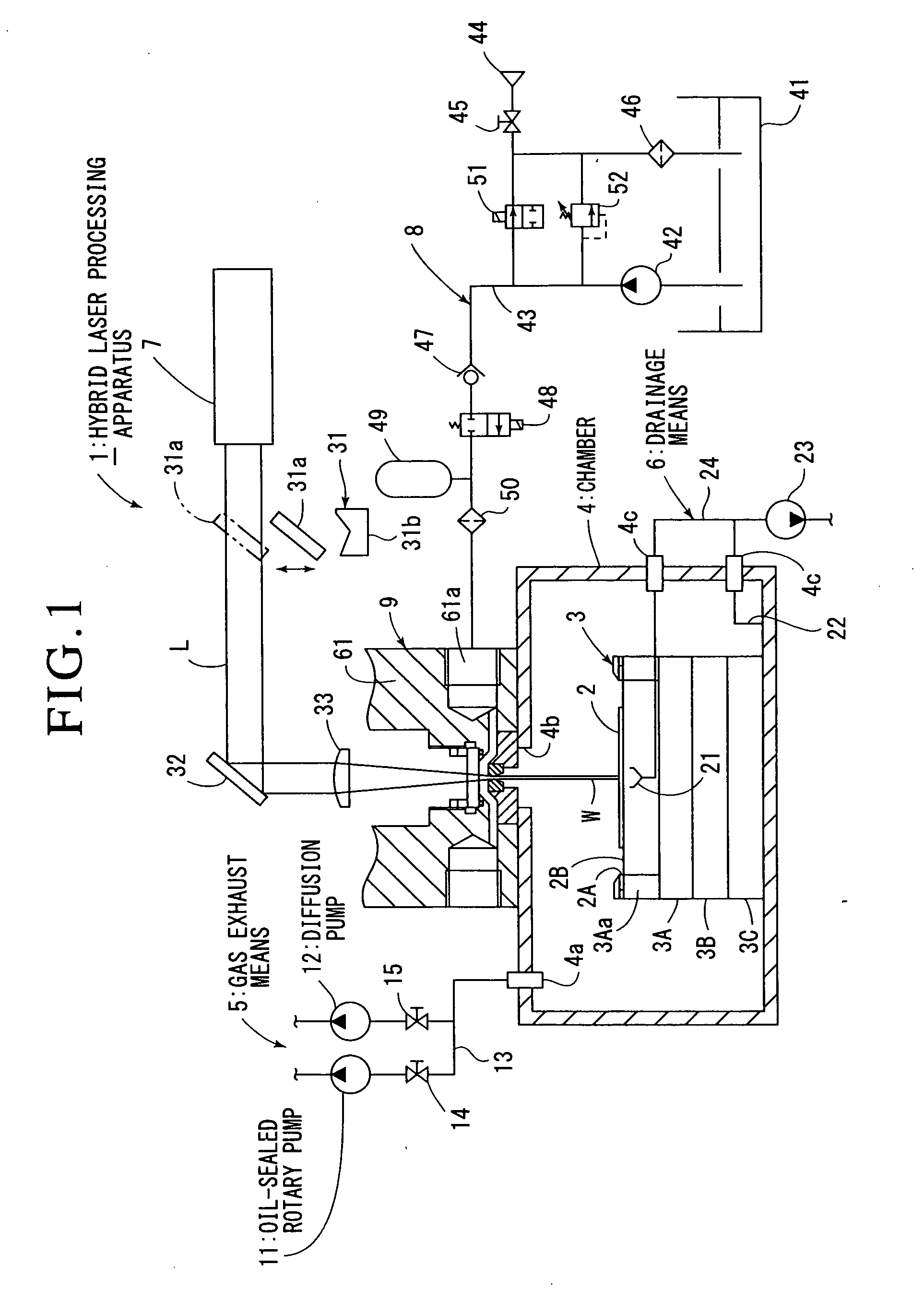

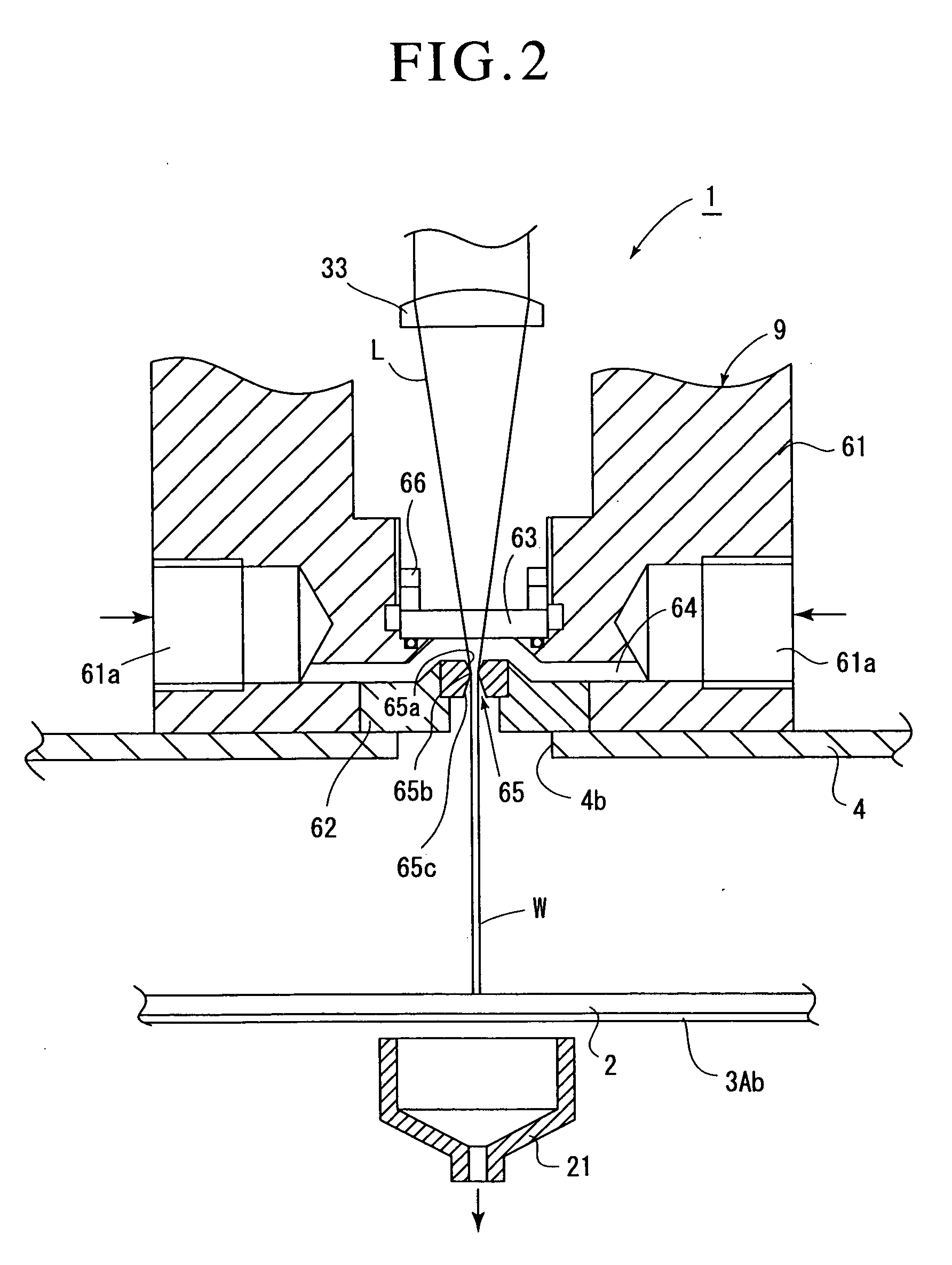

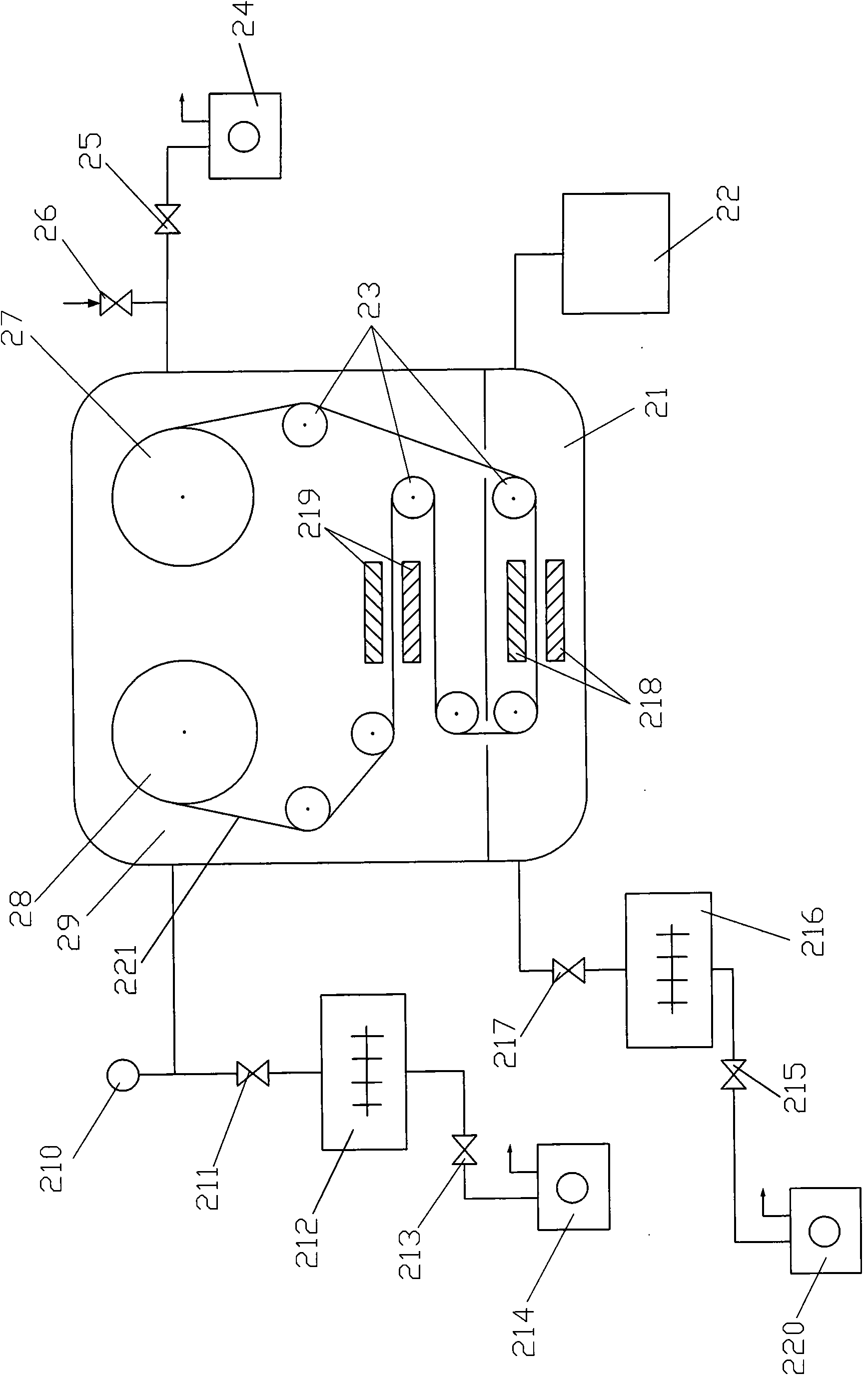

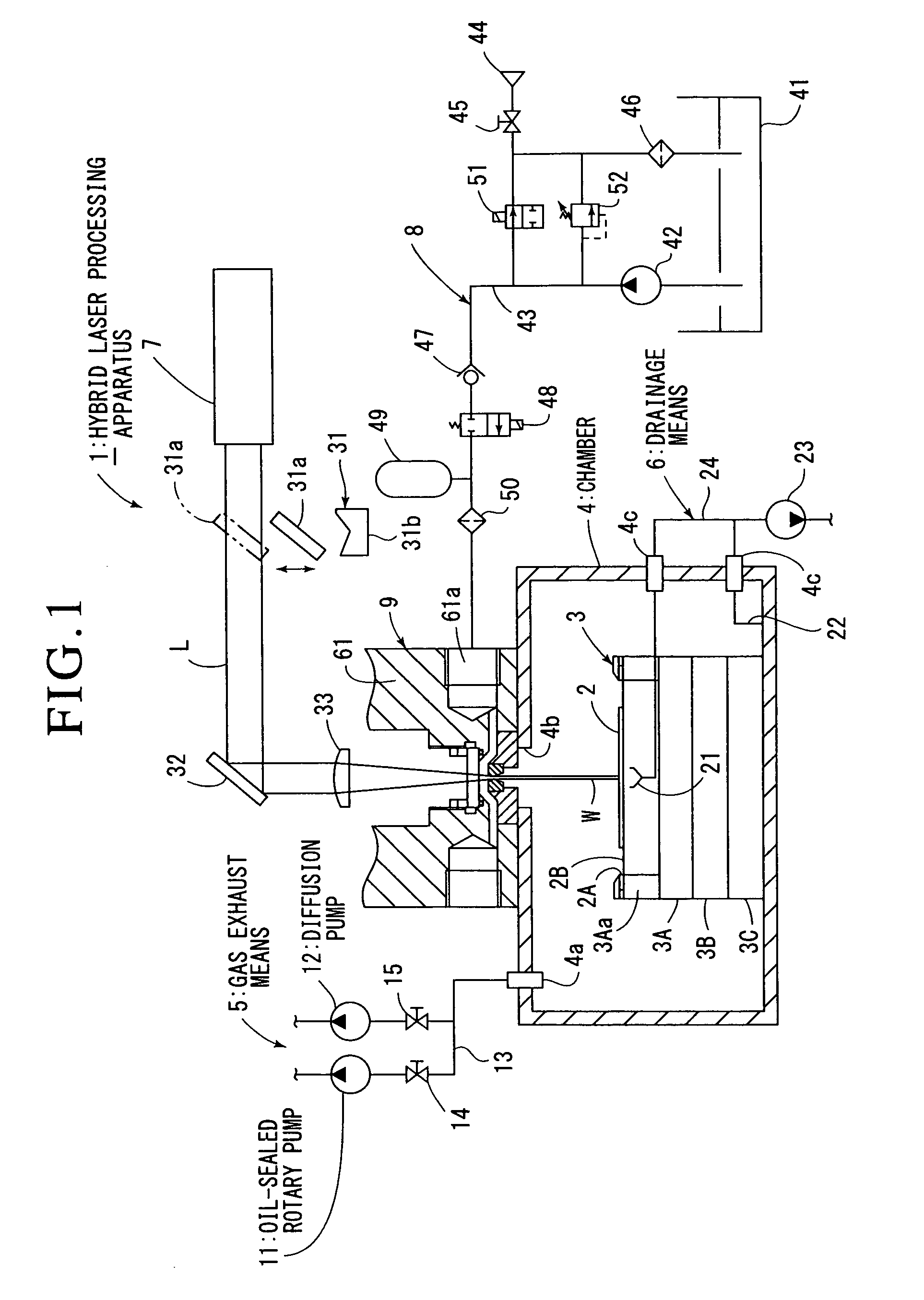

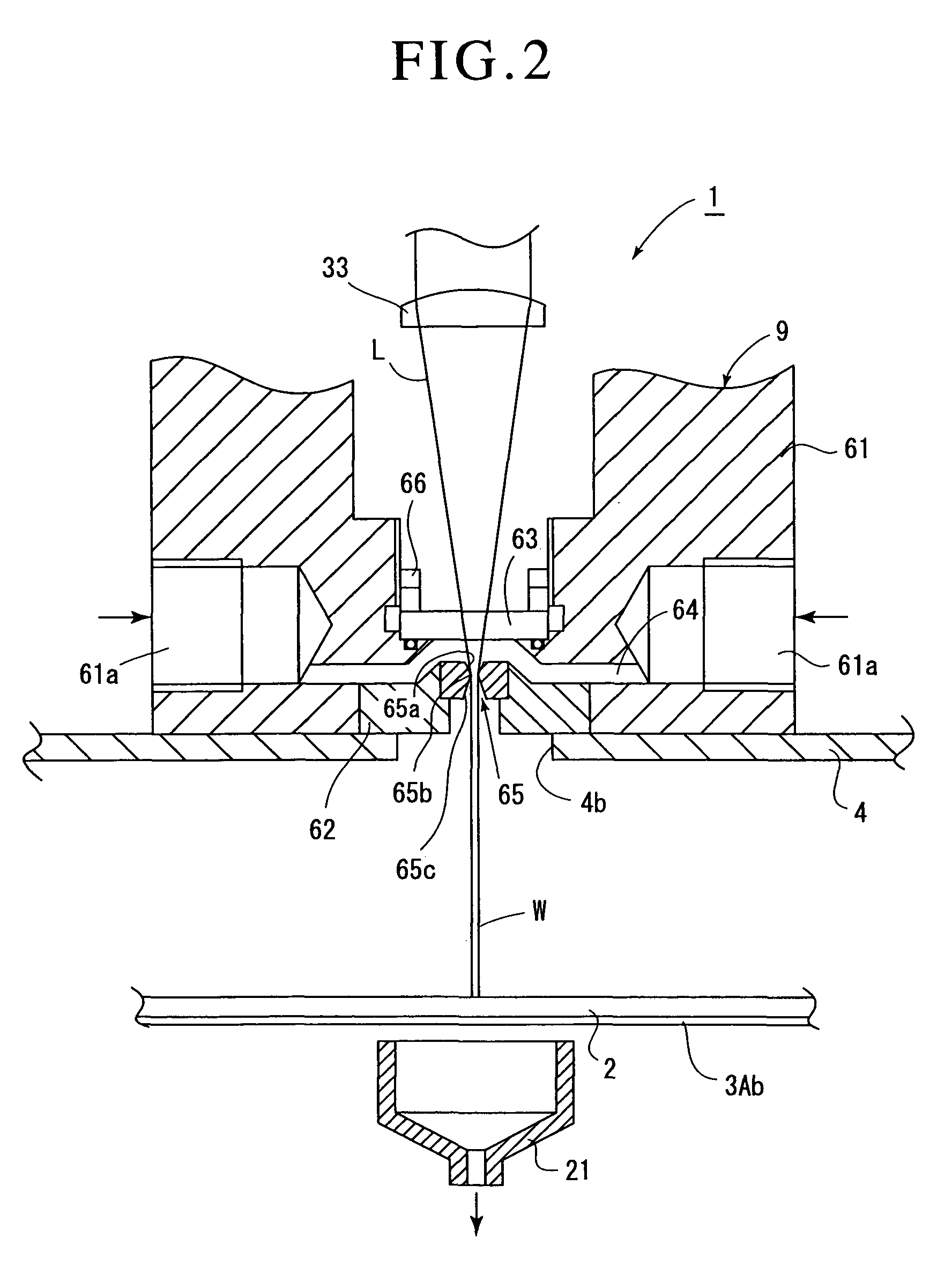

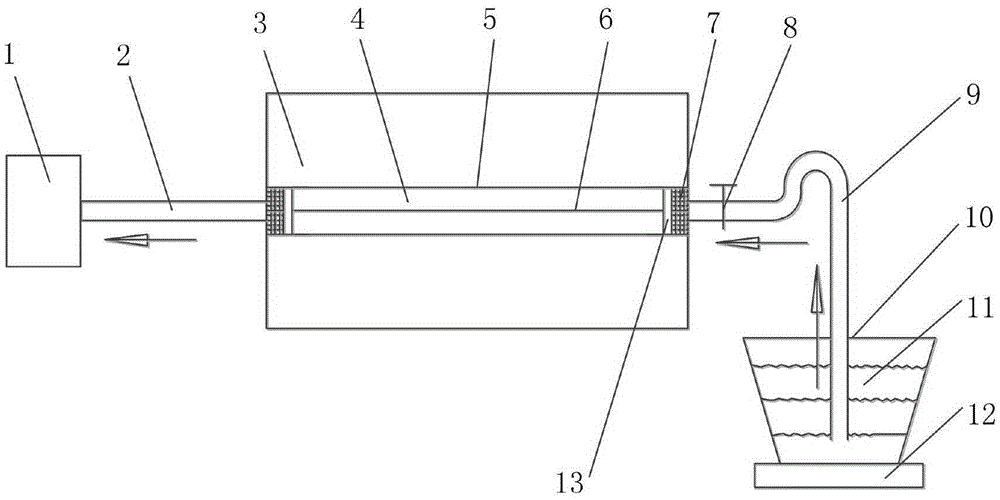

Hybrid laser processing apparatus

InactiveUS20100108648A1LengthReduce diffuseElectrostatic cleaningCleaning using liquidsStable stateLaser processing

A processing table 3 holding a workpiece 2 is accommodated in a chamber 4 with a gas-tight condition kept, and a liquid column W is jetted to an upper surface of this chamber 4, and a processing head 9 that guides laser beam L to the liquid column W is secured to the upper surface of this chamber 4. Gas exhaust means 5 in which an oil-sealed rotary pump 11 and a diffusion pump 12 are provided in parallel is connected to the chamber 4, and the diffusion pump 12 is actuated after the actuation of the oil-sealed rotary pump 11, brining the inside of the chamber 4 into a vacuum state.Bringing the inside of the chamber 4 into a vacuum state, no gas current is generated around the liquid column W jetted from the processing head 9, making it possible to prevent turbulence of the liquid column W due to turbulence of the gas current.A liquid column having a small diameter can be jetted in a stable state.

Owner:SHIBUYA IND CO LTD

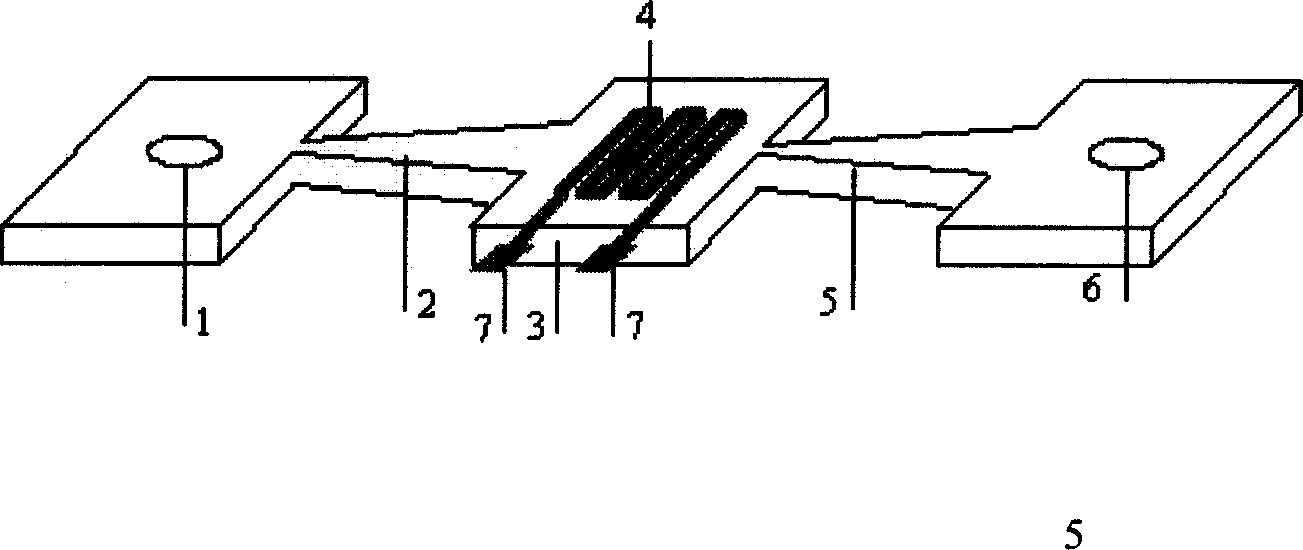

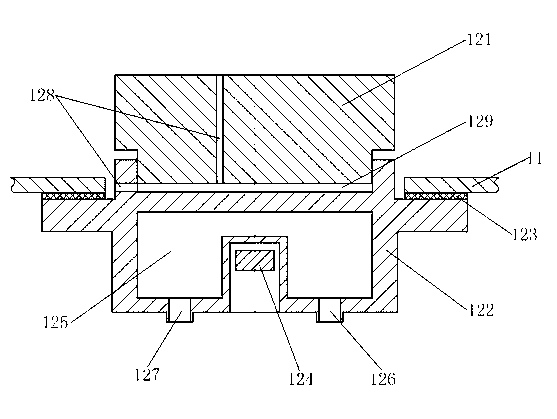

Minisize diffusion pump and preparation method thereof

InactiveCN1844681AReduce processing difficultyNo increase in processing difficultyMachines/enginesDiffusion pumpsMicrofluidicsPump chamber

The invention discloses a micro disperse pump which comprises a pump chamber, a one-way valve, a pump inlet, a pump outlet and a driving device inside the pump chamber; wherein, the one-way valve is between the pump chamber and the pump inlet, and between the pump chamber and the pump outlet; the one-way valve is a wedge disperse tube with different positive and passive fluxes; the fluid of pump chamber can be expanded and contracted to generate pressure difference, and according to the different pressures of positive and passive fluxes in the wedge disperse tube, to generate one-way continuous fluid transmission. The inventive micro disperse pump can drive fluid via adsorbing fluid or directly drive fluid. The production is based on silicon micro-mechanical processing technique and micro-mould technique, with simple process, lower cost, high reliability and the application for integrating other micro-fluid systems. It has wider application in the micro-fluid control analysis chip.

Owner:PEKING UNIV

High and low temperature vacuum lunar soil environment simulator

The invention discloses a high and low temperature vacuum lunar soil environment simulator, which comprises a high and low temperature vacuum environment simulator including a simulant lunar soil containing device and a vacuum tank; a low temperature refrigeration cycle device; a diffusion pump; a mechanical pump and a heating component; the simulant lunar soil containing device is provided with a lunar soil drum for containing simulant lunar soil, and the location of the simulant lunar soil containing device is trimmed by a mobile platform; the simulant lunar soil containing device is arranged in the vacuum tank; the vacuum tank is vacuumized by a vacuum tube through the diffusion pump and the former mechanical pump; the low temperature refrigeration cycle device can refrigerate the lunar soil by a purple copper pipe which is designed on the wall of the lunar soil drum and is internally provided with a freezing medium; the surface of the simulant lunar soil is heated by an iodine-tungsten lamp arranged above the lunar soil drum. The high and low temperature vacuum lunar soil environment simulator has the advantages that daytime high temperature or night low temperature environment of surface-layer lunar soil and low temperature environment of deep-layer lunar soil under vacuum conditions can be simulated, and the high compactness of 1.9g / cm3 and moisture content less than 0.1% of the simulant lunar soil can be ensured.

Owner:BEIHANG UNIV

Producing device of high-purity selenium and producing process

ActiveCN1927701AEasy to collectHelp to separateElemental selenium/telluriumTemperature controlBoiling point

High purity selenium producing apparatus and process are disclosed. The producing apparatus includes one rectifying unit coated with heat insulating layer, one temperature controlling system and one vacuum system comprising one mechanical pump and one diffusion pump. The rectifying unit with vacuum gland in the upper part is divided into one material layer and one product layer communicated mutually. The material layer includes one conical condenser, one umbrella shaped material accepter and one connecting pipe vertically distributed successively; and the product layer is provided with one product kettle connected through the connecting pipe to the material accepter. The rectifying unit in inside multilayer structure is favorable to the separation of selenium from other impurity elements, and has high yield and high product purity.

Owner:广东先导稀贵金属材料有限公司

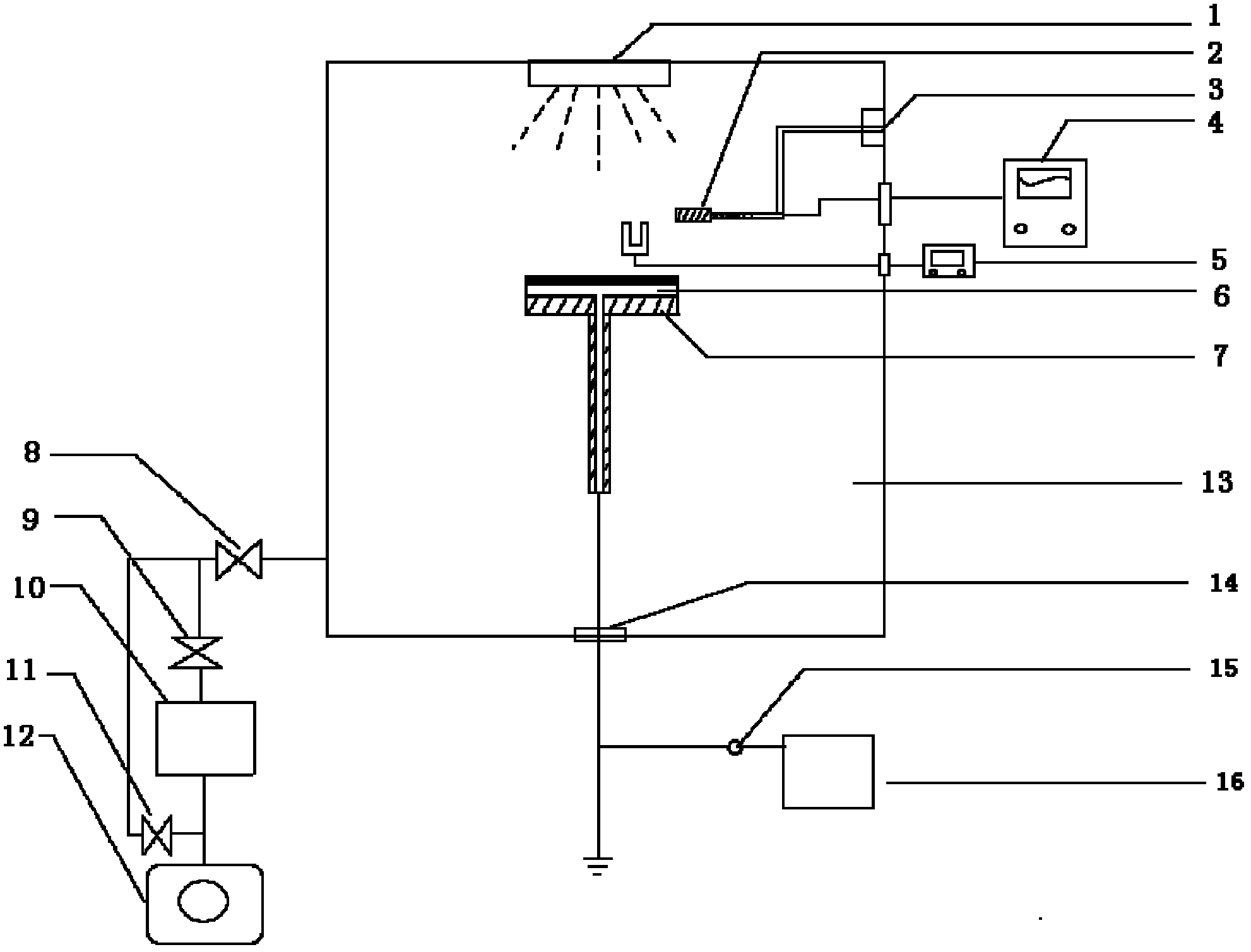

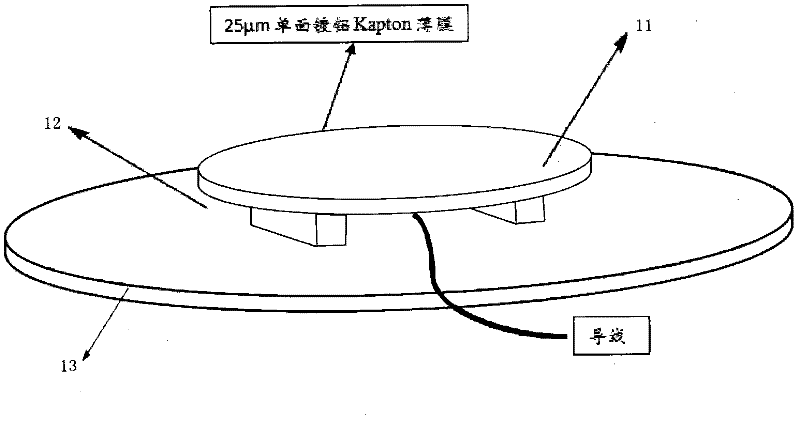

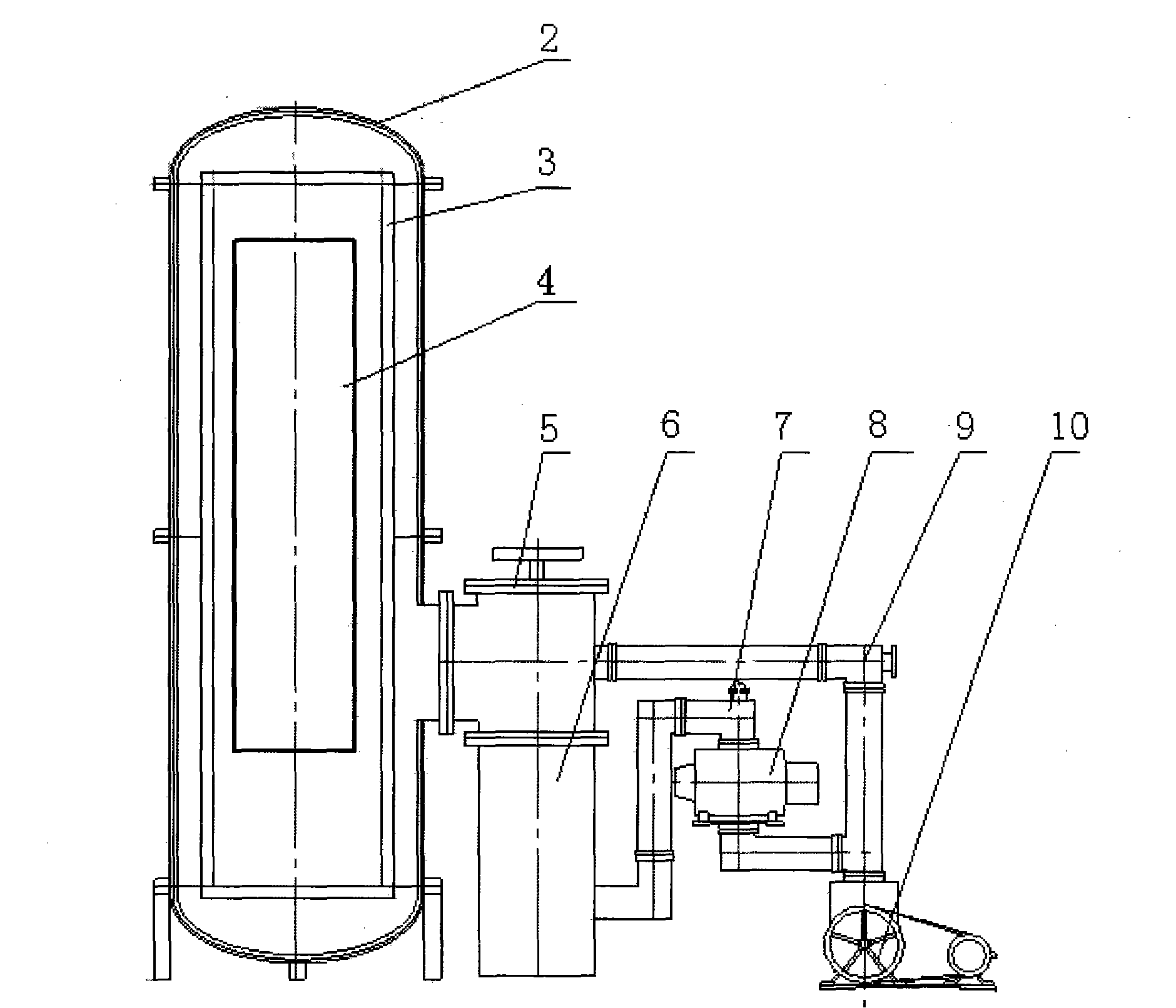

Charge-discharge test equipment for medium material

ActiveCN102162825AFacilitated releaseImprove test automationResistance/reactance/impedenceUltrasound attenuationCurrent meter

The invention discloses charge-discharge test equipment for a medium material. The charge-discharge test equipment comprises a vacuum system, a charge-discharge system and a potential test system, wherein the vacuum system comprises a vacuum tank, a mechanical pump (3), a diffusion pump (2), a multistage rotary vane pump (1), a valve, a sealing pipeline and a workbench; the charge-discharge system comprises an electronic gun (6) and a sample (11) mounting system; the potential test system comprises a potentiometer (9) and a micro current meter (14); a vacuum valve (4) and a vacuum gauge (5) are arranged in the vacuum tank; in addition, a baffle valve A (15), a baffle valve B (16) and a copper plate (13) are further provided; in conclusion, the equipment measures the attenuation relation of surface potential with time by using a surface potential probe, and the conductivity of the sample can be calculated according to the measured sample surface attenuation potentials at different moments. The conductivity test equipment provided by the invention is suitable for estimating deep charging hazard, and can supply valuable engineering data to protection of deep charging and discharging effect.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Large high-vacuum air pumping set

InactiveCN101776063AEliminate pollutionQuality improvementPump installationsPositive-displacement liquid enginesRoughing pumpVacuum extractor

The invention relates to a novel air pumping set which is applicable to the evacuating field. The novel air pumping set comprises a traction molecular pump, an arc titanium pump, a roughing pump and a fore pump, complements each other's advantages, and achieves the purpose of replacing the traditional air pumping set comprising a diffusion pump, a Roots pump and a roughing pump. Compared with the traditional air pumping set, the invention can save the air-pumping energy by 60-90%, eliminate the oil steam pollution in a vacuum chamber, and obviously improve the quality of vacuum products. The cost performance of the air pumping set is approximately 2-3 times better than that of the traditional high-vacuum air pumping set. Besides, the transpiration rate of the titanium materials of the air pumping set can be accurately controlled, and the titanium materials have a high use ratio and can be recycled. The roughing pump of the invention works in a very short time, and one roughing pump can be shared by multiple high-vacuum air pumping sets, thereby saving the device cost and the occupied space.

Owner:SHENZHEN MOL VACUUM TECH CO LTD

Carbon and hydrogen isotope analysis pre-treating device for gas and liquid inclusion in mineral

ActiveCN103091137AVacuum degree reaches the standard quicklyImprove sample preparation efficiencyPreparing sample for investigationMeasurement deviceCopper oxide

The present invention relates to a carbon and hydrogen isotope analysis pre-treating device for gas and liquid inclusion in minerals. The analysis pre-treating device comprises a high-temperature bursting system, an oxidization system, a separating purifying system, a carbon dioxide collecting pipe, a reduction system, a hydrogen collecting pipe and a vacuum system which are in sealing connection in turn, wherein the high-temperature bursting system comprises a quartz pyrolysis tube and a first vacuometer; a copper oxide furnace is used as the oxidization system; the separating purifying system comprises a fifth cold trap, a second vacuometer and a first cold trap which are in sealing connection in turn; the reduction system comprises a second cold trap, a first vacuum measurement device, a zinc furnace, a second vacuum measurement device and a third cold trap; and the vacuum system comprises a mechanical pump and a diffusion pump. The first vacuometer of the analysis pre-treating device provided is utilized to monitor the bursting degree of a sample, so as to determine the bursting temperature and the bursting time of various samples. Due to the design of the first vacuum measurement device and the second vacuum measurement device, the analysis pre-treating device can be used for monitoring the reduction degree of water.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

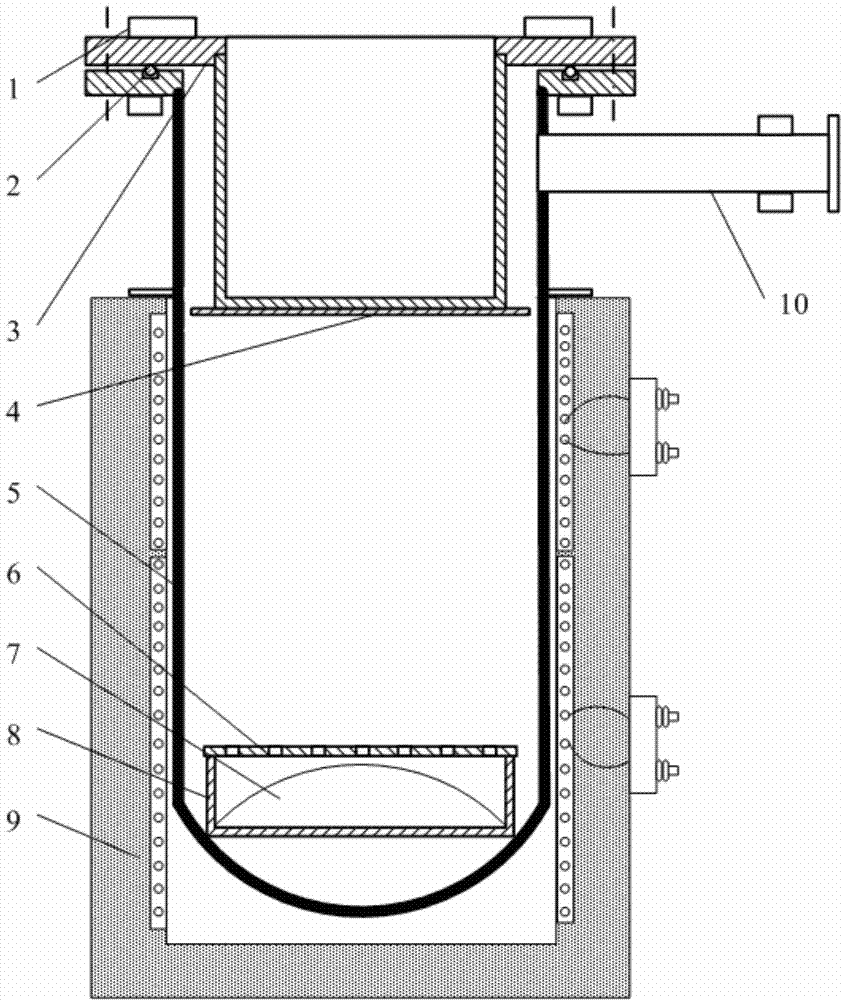

Blue-jewel-crystal multi-crucible melt growth technolgoy

ActiveCN101024898AThe structure of the temperature field is stableAdjustable temperature gradientPolycrystalline material growthFrom frozen solutionsFurnace temperatureHearth

The invention provides a multi-pot melt growth technique for growing sapphire crystals, comprising: (1) pretreating aluminum oxide raw material; (2) placing the pretreated aluminum oxide blocks and the oriented seed crystals into pots and moving into high temperature descending furnace, sealing the whole system and power-on to raise temperature, starting mechanical pump and diffusion pump in turn, vacuumizing to 10-3-10-4Pa, and when the furnace temperature up to 1500-1800deg.C, charging inert gas and continuing raising temperature to the set temperature (2100-2250deg.C); (3) when the furnace temperature up to the set temperature, preserving heat for 4-8 hours, regulating hearth temperature and pot positions to smelt raw material and seed crystal top to implement inoculation growth and setting solid-liquid interface temperature gradient at 10-50deg.C / cm and controlling pot descending rate at 0.1-3.0mm / h; and (4) after the crystal growth ends, making in-situ annealing treatment. And the process has features of raw material pretreatment, special temperature field design, multi-pot technique, in-situ annealing treatment, etc, and advantages of stable temperature field, adjustable temperature gradient, operating convenience, low average energy consumption, high yielding by one furnace, and beneficial to industrialized production.

Owner:苏州晶生新材料有限公司

Annular region smelting furnace

InactiveCN101469940AAvoid heatingReduce pollutionBy zone-melting liquidsCharge supportsShielding gasZone melting

The invention relates to an annular region melting furnace comprising an annular zone melting boat, a furnace body, a heating system, a vacuum pumping system, a protective gas input device, a temperature measuring and controlling system and a rotating drive system; the annular zone melting boat is positioned inside of the furnace body and arranged above the steel ring; a high-frequency electric source is positioned outside of the furnace body, the heating coil is surrounded on the annular zone melting boat; the vacuum pumping system comprises a mechanical pump, a diffusion pump and a vacuum valve connected with the pipe; the protective gas input device is connected with the furnace body by the gas conveying pipe; the temperature measuring and controlling system comprises a thermo-electric couple and a temperature display apparatus electrically connected with the thermo-electric couple, the thermo-electric couple is extended into the furnace by a thermo-electric couple connection interface on the upper cover of the furnace body.

Owner:有研资源环境技术研究院(北京)有限公司

Method for generating silicon carbide coating on surface of carbon fiber

The invention discloses a method for generating a silicon carbide coating on the surface of a carbon fiber. The method is used to synthesize the SiC coating on the surface of a polyacrylonitrile carbon fiber. The method comprises the following steps: placing silicon powder or fragments of silicon briquets into the bottom of a graphite crucible, and placing the carbon fiber horizontally on the top of the crucible; inversely placing a crucible with the same size on the crucible in which the carbon fiber is placed in order to increase the contact between the carbon fiber and silicon vapor as much as possible and fix the carbon fiber, and always keeping a distance between the fragments of the silicone briquets and the carbon fiber; placing the device into a high temperature vacuum sintering furnace, carrying out forvacuum pumping to 1 to 5 Pa by a mechanical pump, then charging shielding gas argon, carrying out vacuum pumping again to 10 to 10 Pa by the mechanical pump and a diffusion pump, then charging the shielding gas argon again, and turning off an argon source; and then raising the temperature above the melting point of silicon, holding the temperature for 1 to 9 hours, turning off power supply, and taking out the fiber after cooling down to find the silicone carbide coating generated on the surface of the fiber. The method has a series of advantages of simple device, no precursor gas such as chlorosilane or polycarbosilane needed, no hydrogen needed, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

High-purity calcium vacuum distillation purification device and method

InactiveCN104762486AHigh calcium activitySimple structureProcess efficiency improvementCrucibleHeating furnace

The invention discloses a high-purity calcium vacuum distillation purification device and a method. The high-purity calcium vacuum distillation purification device comprises a heating furnace; a distillation reaction pot arranged in the heating furnace; and a crucible and a crucible cover which are arranged on the bottom of the distillation reaction pot, wherein the crucible cover is provided with holes; coarse calcium is placed in the crucible; the upper end of the distillation reaction pot is provided with a vacuum pipeline and a reaction pot furnace cover, wherein the vacuum pipeline is used for connecting with a vacuum system, and the cross section of the reaction pot furnace cover shapes like T; the top of the reaction pot furnace cover is provided with a water cooled jacket; the lower T-shaped part of the reaction pot furnace cover is provided with a condensation plate; and the external edge of the condensation plate not covered by the lower end of the lower T-shaped part of the reaction pot furnace cover is provided with a plurality of small holes uniformly. A combination of a rotary vane mechanical pump with an oil diffusion pump is adopted by a vacuum system of the high-purity calcium vacuum distillation purification device; the high-purity calcium vacuum distillation purification device is simple in structure, and high in separation effect, and is convenient for maintenance; compared with the prior art, distillation rate is stable, product purity is high, batch quality is stable, and obtained calcium metal is high in activity.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Large vacuum coating equipment

InactiveCN101560645AReduce energy consumption of pumpingReduce pollutionVacuum evaporation coatingSputtering coatingBiochemical engineeringWater vapor

The invention relates to a large vacuum coating equipment. A combined unit of a large pumping speed molecular drag pump and a water vapor pump is adopted to replace a diffusion pump and a lobed element pump of the traditional large vacuum coating equipment. The large vacuum coating equipment can save the air exhaust energy consumption by 80 percent, shortens rough pumping time, greatly reduces oil vapor pollution of a coating chamber and obviously improves the quality of coating products; a set of rough pumping system can be shared by a plurality of coating equipment, thus saving equipment cost and occupied space.

Owner:SHENZHEN UNIV

Electric arc titanium pump and vacuum air pump group comprising same

InactiveCN101936278AIncreases chances of adsorbing gasOvercome the disadvantage of uneven thicknessPumpsPositive-displacement liquid enginesRoughing pumpHigh energy

The invention is applies to the technical field of vacuum acquisition and discloses an electric arc titanium pump and a vacuum air pumping group comprising the same. The electric arc titanium pump comprises a pump shell, a trapping plate, a cathode arc source member and a power supply, wherein the trapping plate is arranged on the inside wall of the pump shell, the cathode arc source member is fixedly arranged in the pump shell, and the pump shell and the cathode arc source member are in cylindrical shapes and are coaxially arranged; and the vacuum air pumping group comprises a vacuum chamber, wherein a molecular pump, a prepump, a roughing pump and the electric arc titanium pump are connected to the vacuum chamber. The electric arc titanium pump can be used for leading atoms steamed by the cathode arc source member to form an active film with even thickness and increasing the utilization rate of the cathode arc source member, thereby increasing pumping speed and air-pumping flow rate and reducing energy consumption and operation cost. The vacuum air pumping group can be used for replacing the current large-size diffusion pump with high energy consumption and high oil-vapor pollution and a Lobed pump air-pumping group in order to clean vacuum, save pumping energy consumption and reduce operation cost.

Owner:储继国

Method and equipment of preparing massive great-specific weight Zr-W-base amorphous alloy

The massive amorphous alloy has the components (in atomicity percentage): Zr 40-60, Cu 5-25, Ni 5-20, Al 2-10, W 5-15 and B2-10. The suspension smelting and double chamber casting equipment for producing the alloy consists of mechanical pump, diffusion pump, air valve, vacuum chamber, elevator, water cooled copper mold, upper and lower connection and sealing structure, suspension coil, quartz glass crucible, thermocouple, power supply and other parts. The amorphous alloy of the present invention has specific weight of 7.5-8.0 g / cu cm, 15-20 % greater than that of traditional Zr-base massive amorphous alloy. The suspension smelting can purify and homogenize melt and the double chamber casting can raise melt filling speed, simplify mold design and manufacture and lower manufacture cost.

Owner:UNIV OF SCI & TECH BEIJING

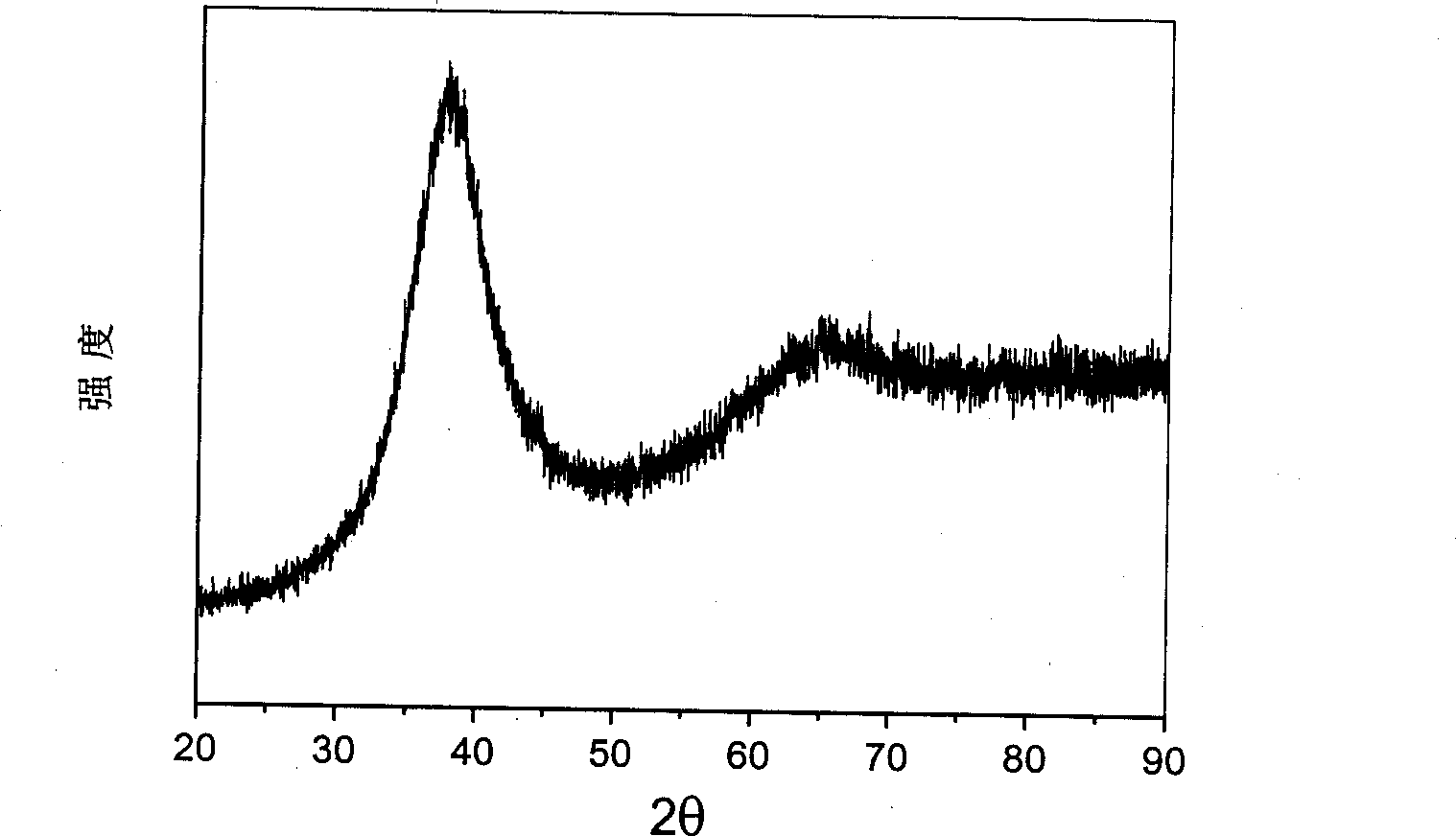

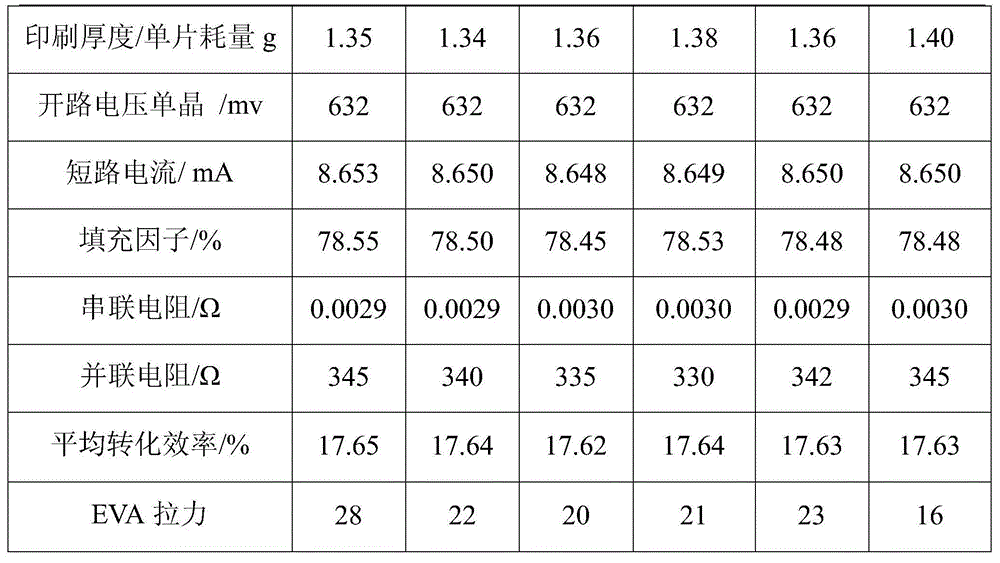

Crystal silicon solar cell high adhesive force back surface field aluminum electrocondution slurry and preparation method

InactiveCN104575685AImprove conversion efficiencyGuaranteed reliabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon alloyBack surface field

The invention discloses crystal silicon solar cell high adhesive force back surface field aluminum electrocondution slurry which comprises 68%-80% of aluminite powder, 1%-6% of glass powder, 16%-25% of organic bond and 1%-3% of auxiliaries. The auxiliaries are composed of 60% of wetting dispersant and 40% of diffusion pump oil. The aluminum electrocondution slurry is printed on the back surface of a crystal silicon solar cell piece. Aluminium-silicon alloy reaction is performed on aluminum and substrate silicon through infrared quick calcining technology. A preparation method for the aluminum electrocondution slurry comprises the following steps that the aluminite powder, the glass powder, the organic bond and the auxiliaries are put in a vacuum mixer to be mixed, and dispersed by a three-high mill to obtain aluminum electrocondution slurry with less than or equal to 15Mum of precision and 20-40 Pa.s viscosity. The aluminum electrocondution slurry is good in property, and suitable for the use of a crystal silicon solar cell back surface field. A calcined aluminum film and a silicon substrate have good adhesive force and water resistence, aluminium pills and aluminium blisters do not exist, the calcined cell piece is small in bending, and the conversion efficiency is higher.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

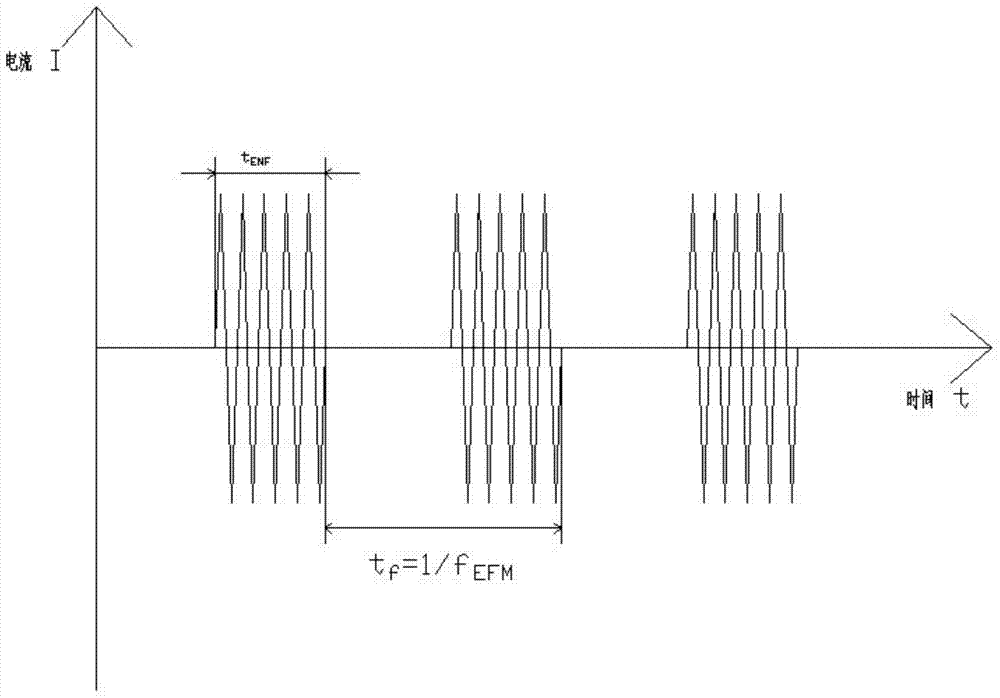

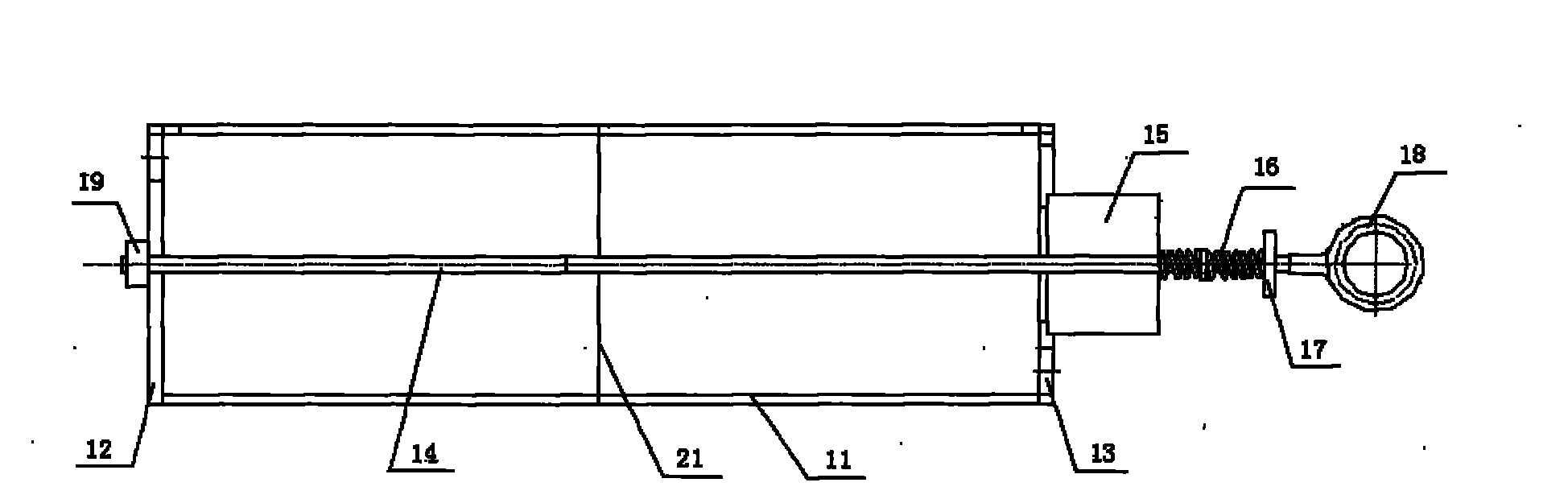

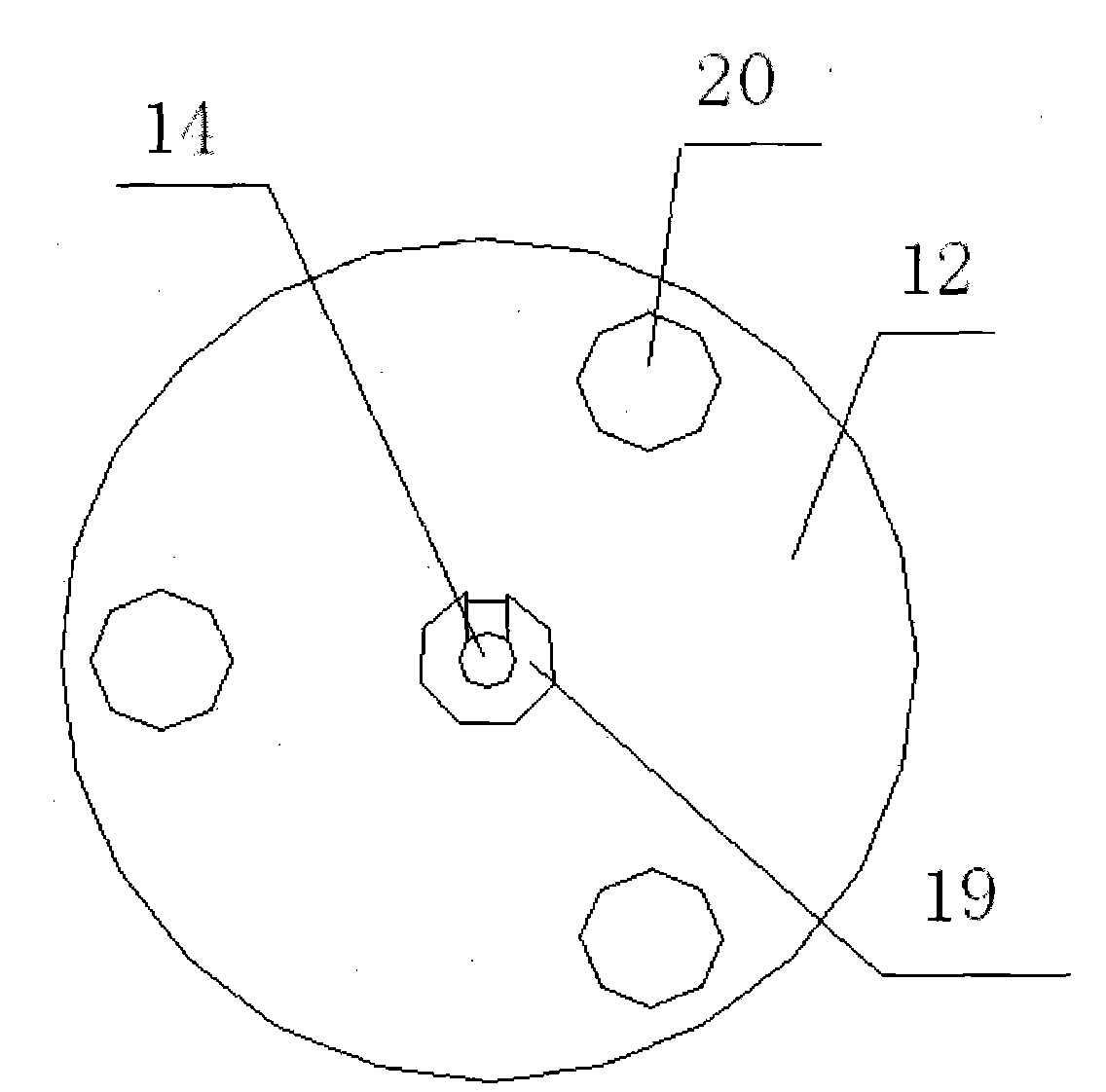

Device and method for manufacturing uniform spherical micro-particles

The invention discloses a device and a method for manufacturing uniform spherical micro-particles. The device comprises a crucible, an induction heater, an induction coil, a concentrator, a mechanical pump, a diffusion pump, a cavity, a high-speed camera and a collector. The device and the method have the advantages that capillary jet flow is cut by the aid of electromagnetic force to manufacture the uniform spherical micro-particle, metal materials molten in the crucible are ejected from small holes in the bottom of the crucible under the effect of pressures to form the capillary jet flow, the electromagnetic force is generated by the induction coil and acts on the capillary jet flow via the concentrator, sausage-shaped liquid droplet strings are gradually formed by the capillary jet flow under the disturbance effects of surface tension and the electromagnetic force and can be ultimately dispersed to form liquid droplets with consistent sizes and equal distances, and metal particles can be formed by the liquid droplets in containerless solidification procedures; the metal particles manufactured by the aid of the method are uniform in particle size (the relative deviation of the particle sizes is smaller than 1.8%) and are high in sphericity, and manufacturing materials can be prevented from being polluted by the crucible in the solidification procedures.

Owner:DALIAN UNIV OF TECH

Brazing process of ceramic vacuum pipe with diameter greater than 300mm and device

ActiveCN101767236AEnsuring natural capillarityEvenly distributedSoldering apparatusTubular articlesShielding gasNitrogen gas

The invention provides a brazing process of a ceramic vacuum pipe with diameter greater than 300mm and a device, comprising the following steps: firstly, cleaning the ceramic pipe and a titanium ring, then putting them into a vacuum furnace, conducting temperature-rising weld under vacuum condition, providing shielding gas after welding, taking the ceramic pipe out from the furnace, and completing the butt-weld of two ceramic vacuum pipes. The device provided by the invention comprises a first-class mechanical rotary vane pump, a second-class Roots pump, and a third-class oil diffusion pump; the pumps are arranged in serial, meanwhile, the device is provided with a pipeline for transmitting high-purity inert gas (such as nitrogen and argon) into the furnace. The advantages of the invention are as follows: the brazing process of the ceramic vacuum pipe with diameter greater than 300mm and the device is provided, the vacuum leak rate at welded joint of the welded ceramic pipes is less than 5 * 10-12Pa. M3 / s, and no crack exists on the ceramic pipe.

Owner:上海克林技术开发有限公司

Plasma coating equipment and air extraction process thereof

InactiveCN103290388AQuick extractionQuality improvementVacuum evaporation coatingSputtering coatingPlasma coatingTitanium

The invention discloses plasma coating equipment and an air extraction process thereof. An arc titanium pump, a molecular drag pump and a fore pump unit which are connected in series to extract air are adopted to substitute a turbo molecular pump (or diffusion pump) and a roots pump unit which are connected in series to extract air in the prior art. The arc titanium pump and the molecular drag pump are both pumps with low energy consumption, the arc titanium pump only needs to operate at a fine extraction stage, the operation time does not reach 1 / 3 of the whole air extraction time, the air extraction capability of the molecular drag pump at a coating stage is greatly higher than that of the turbo molecular pump (or diffusion pump), and the extraction speed of the molecular drag pump at the coating stage cannot be changed remarkably along with the change of pressure intensity, so that the air extraction energy consumption is greatly reduced, and the stability of a coating process and the quality of a coating product are improved; and in addition, the arc titanium pump, the molecular drag pump and the fore pump unit are free of oil vapor pollution, so that the oil vapor pollution caused by the traditional air extraction unit is also eliminated, and the quality of the coating product is further ensured.

Owner:苏州摩星真空科技有限公司

Hybrid laser processing apparatus

InactiveUS7910856B2LengthStable stateElectrostatic cleaningCleaning using liquidsStable stateRotary pump

A processing table 3 holding a workpiece 2 is accommodated in a chamber 4 with a gas-tight condition kept, and a liquid column W is jetted to an upper surface of this chamber 4, and a processing head 9 that guides laser beam L to the liquid column W is secured to the upper surface of this chamber 4. An oil-sealed rotary pump 11 and a diffusion pump 12 provided in parallel are connected to the chamber 4, and the diffusion pump 12 is actuated after the actuation of the oil-sealed rotary pump 11, bringing the inside of the chamber 4 into a vacuum state.No gas currents are generated around the liquid column W jetted from the processing head 9, making it possible to prevent turbulence of the liquid column W due to turbulence of the gas currents and enabling a liquid column having a small diameter to be jetted in a stable state.

Owner:SHIBUYA IND CO LTD

Large medium/high vacuum gas-bleeding unit and pumping process thereof

InactiveCN103758733ALow pumping efficiencyThe actual pumping efficiency is excellentVacuum evaporation coatingSputtering coatingVacuum extractorWater vapor

The invention provides a large medium / high vacuum gas-bleeding unit and a gas-bleeding process of the large medium / high vacuum gas-bleeding unit. The mode that a cryogenic water vapor pump, a traction molecular pump and a chemical adsorption pump unit are connected in parallel for gas bleeding replaces a traditional mode that a diffusion pump and a Roots pump unit are connected in series for gas bleeding. The traction molecular pump is used for gas bleeding and removing gas with pressure ranging from several Pa to hundreds of Pa. The cryogenic water vapor pump is connected with the traction molecular pump in parallel for gas bleeding and removing gas with pressure ranging from several Pa to 10<-2> Pa. The traction molecular pump, the cryogenic water vapor pump and the chemical adsorption pump unit are connected in parallel for gas bleeding and removing gas with pressure smaller than or equal to 10<-2> Pa. In this way, the gas-bleeding capacity of medium / high vacuum transition sections is improved, gas-bleeding energy consumption and operating cost are reduced, oil vapor pollution is eliminated, and the quality of vacuum products is improved.

Owner:储继国

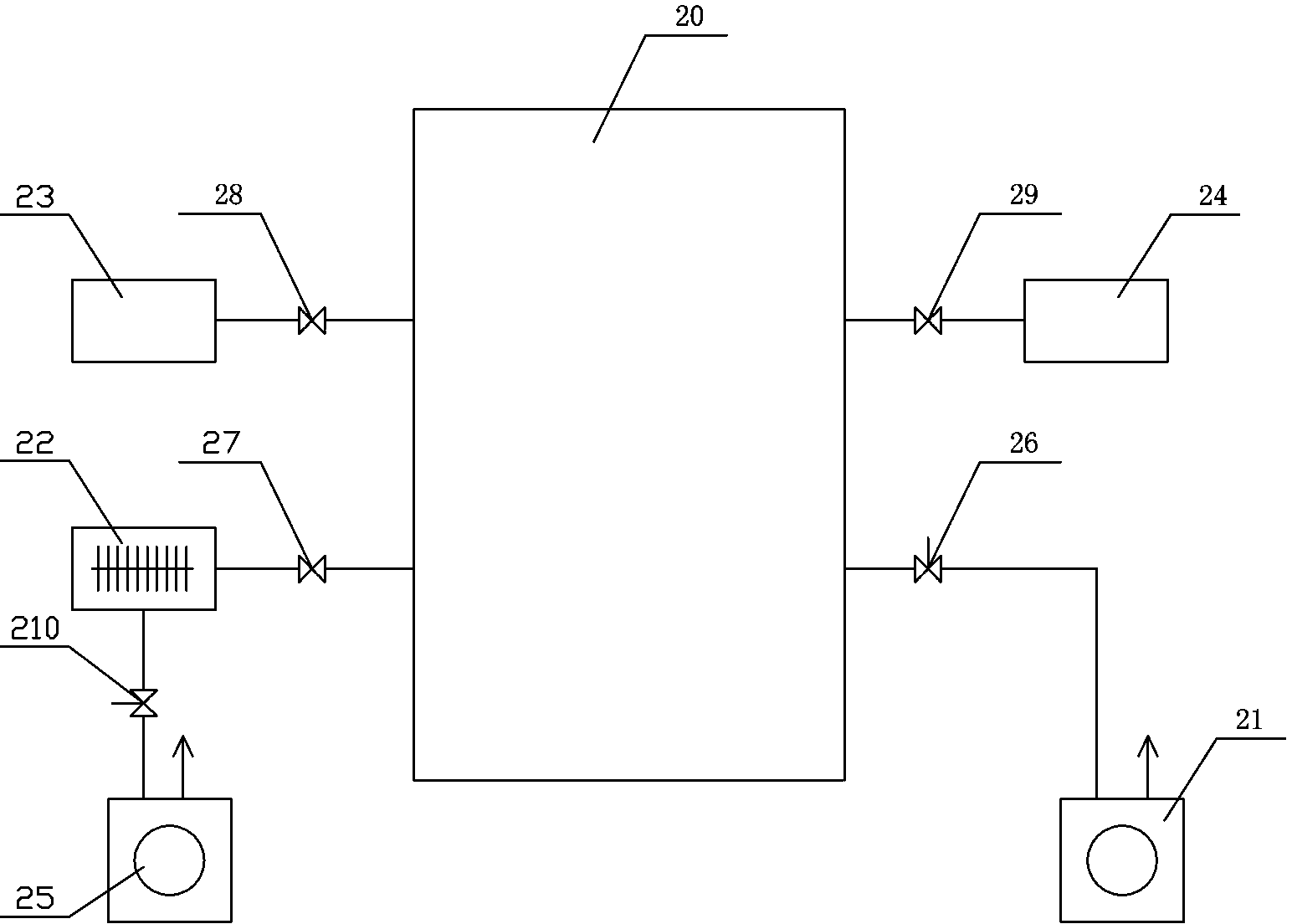

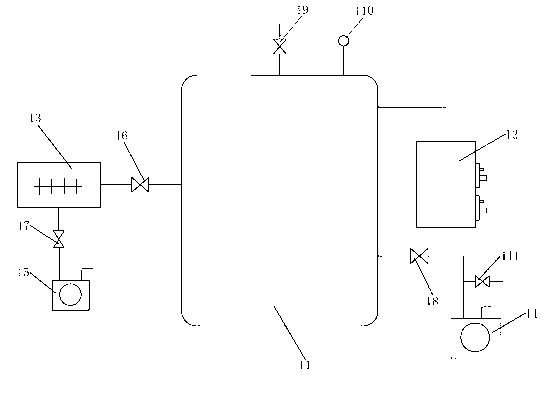

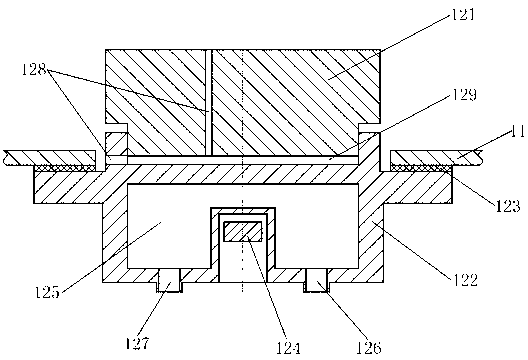

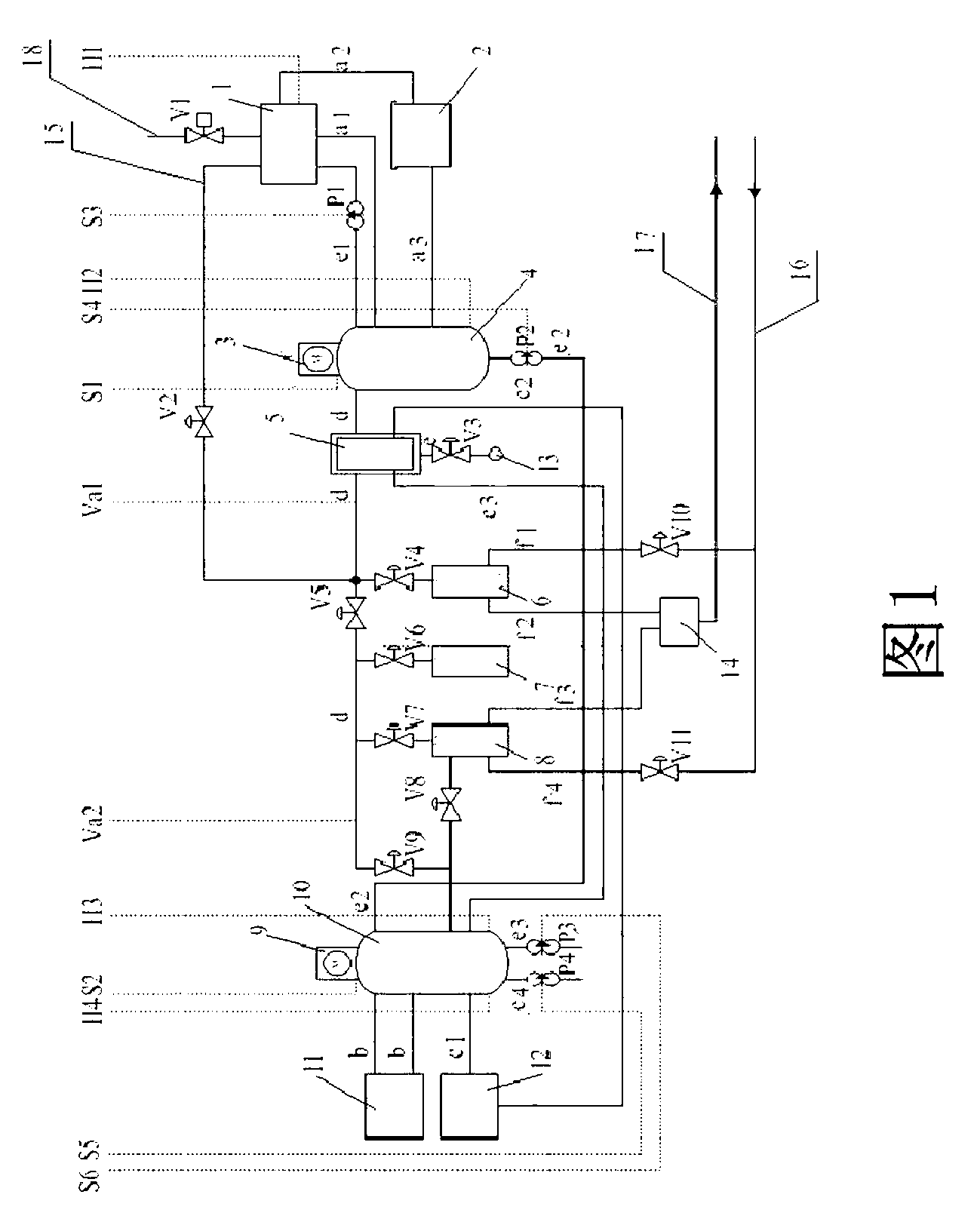

Circulating cooling water system of diffusion pump of vacuum coater

InactiveCN101831609AAvoid wastingGo heat uninterruptedVacuum evaporation coatingSputtering coatingDraining tubeWater flow

Owner:XIDIAN UNIV

Vacuum furnace air-pumping system and air-pumping technology thereof

InactiveCN103291586AQuick extractionReduce energy consumption of pumpingPump installationsPositive-displacement liquid enginesRoughing pumpAir pump

The invention discloses a vacuum furnace air-pumping system and an air-pumping technology of the vacuum furnace air-pumping system. An electric arc titanium pump, traction molecular pump and backing pump unit conducting air-pumping and arranged in parallel connection is adopted, so that a high-vacuum diffusion pump, medium-vacuum roots pump machine and roughing pump unit conducting air-pumping and arranged in parallel connection in the prior art is replaced. An electric arc titanium pump is used for rapidly pumping high-vacuum active gases and a traction molecular pump and a backing pump are used for rapidly pumping medium-vacuum gases and high-vacuum inert gases. Due to the fact that the electric arc titanium pump and the traction molecular pump are both low-energy pumps, the electric arc titanium pump mainly operates at an accurate pumping stage, and the operation time usually occupies about 70% of the whole air-pumping time, the air-pumping energy consumption can be obviously reduced, In addition, the electric arc titanium pump, traction molecular pump and backing pump unit is free of oil vapor contamination, so that the oil vapor contamination of a traditional vacuum furnace air-pumping system is eliminated.

Owner:苏州摩星真空科技有限公司

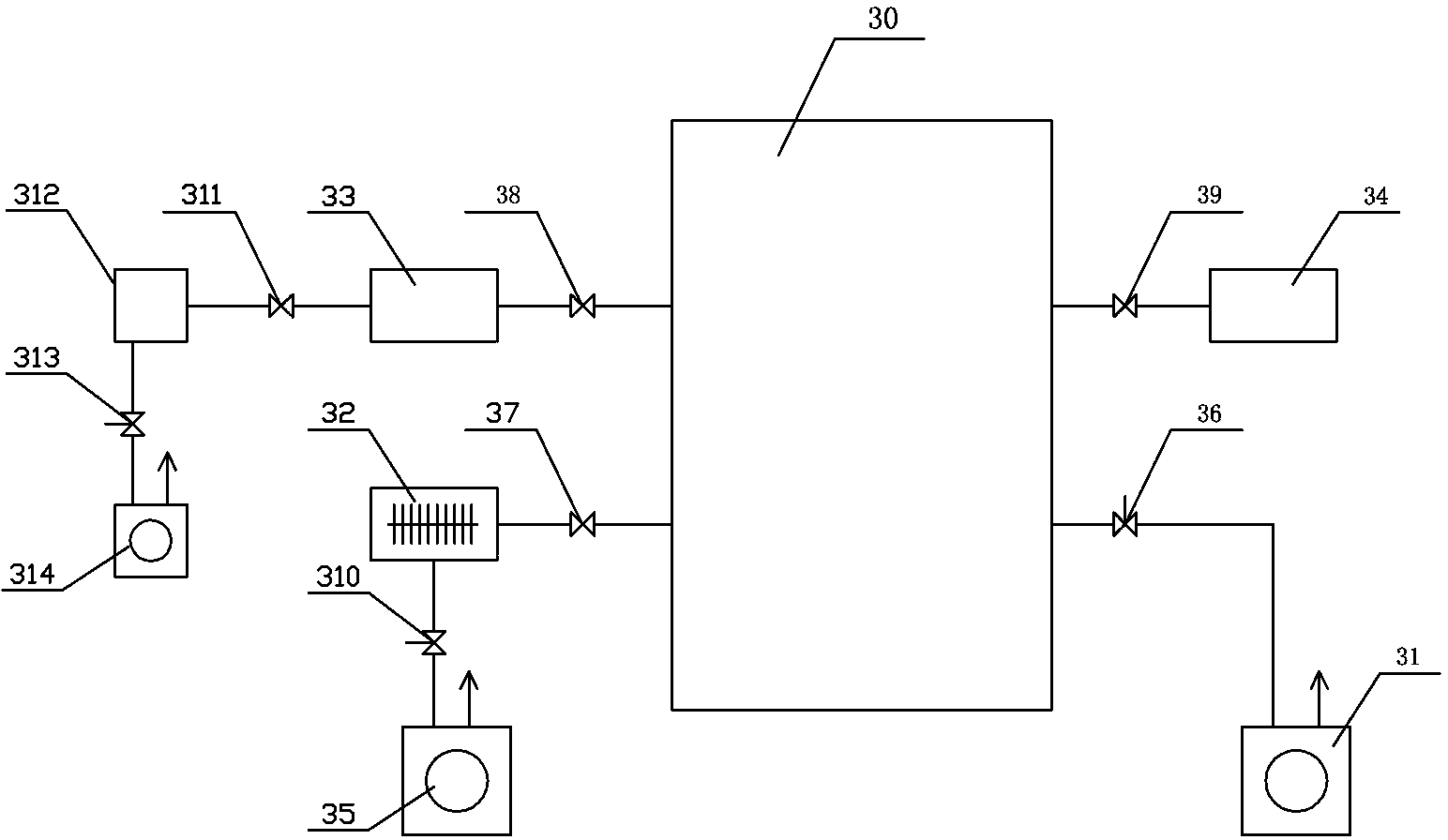

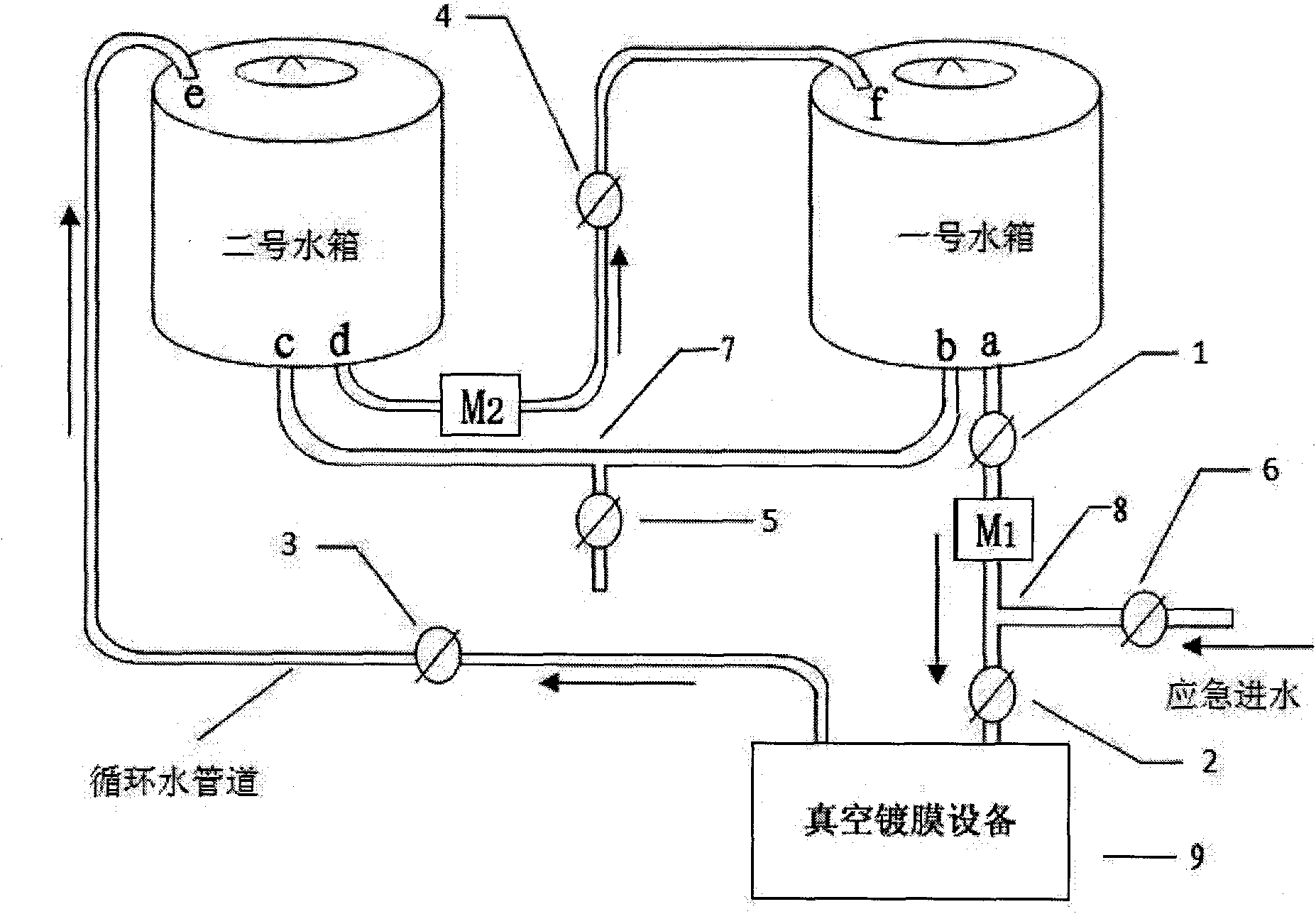

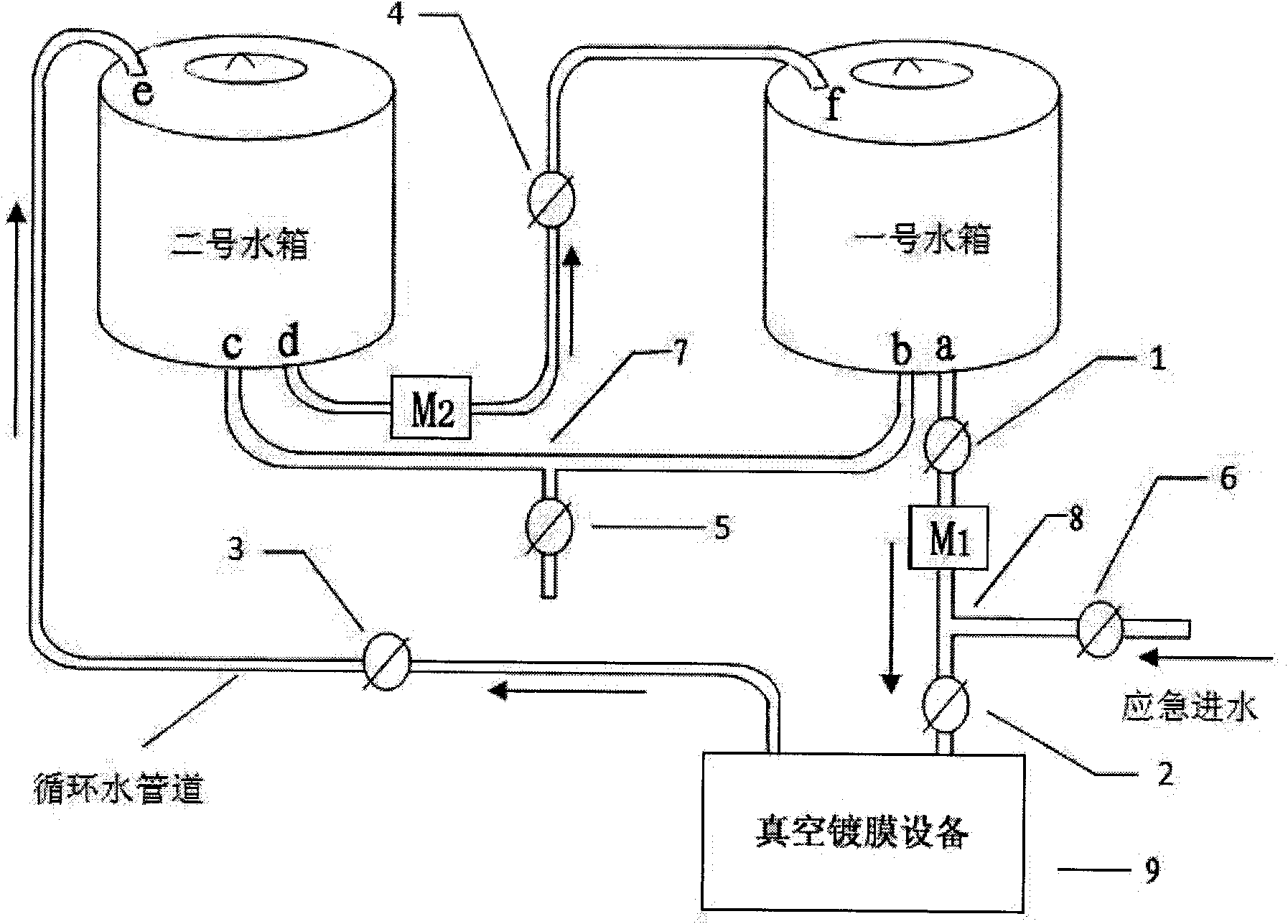

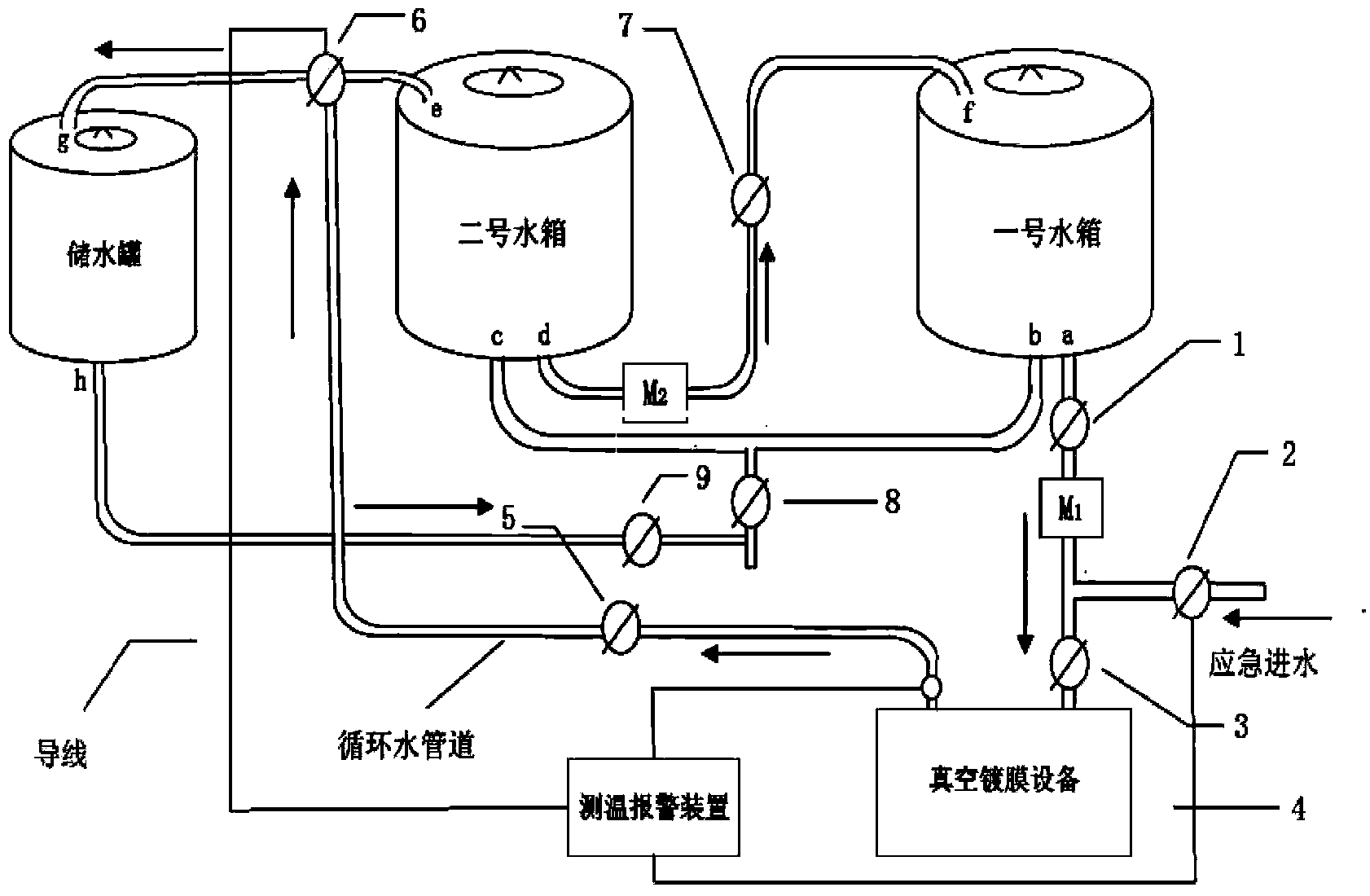

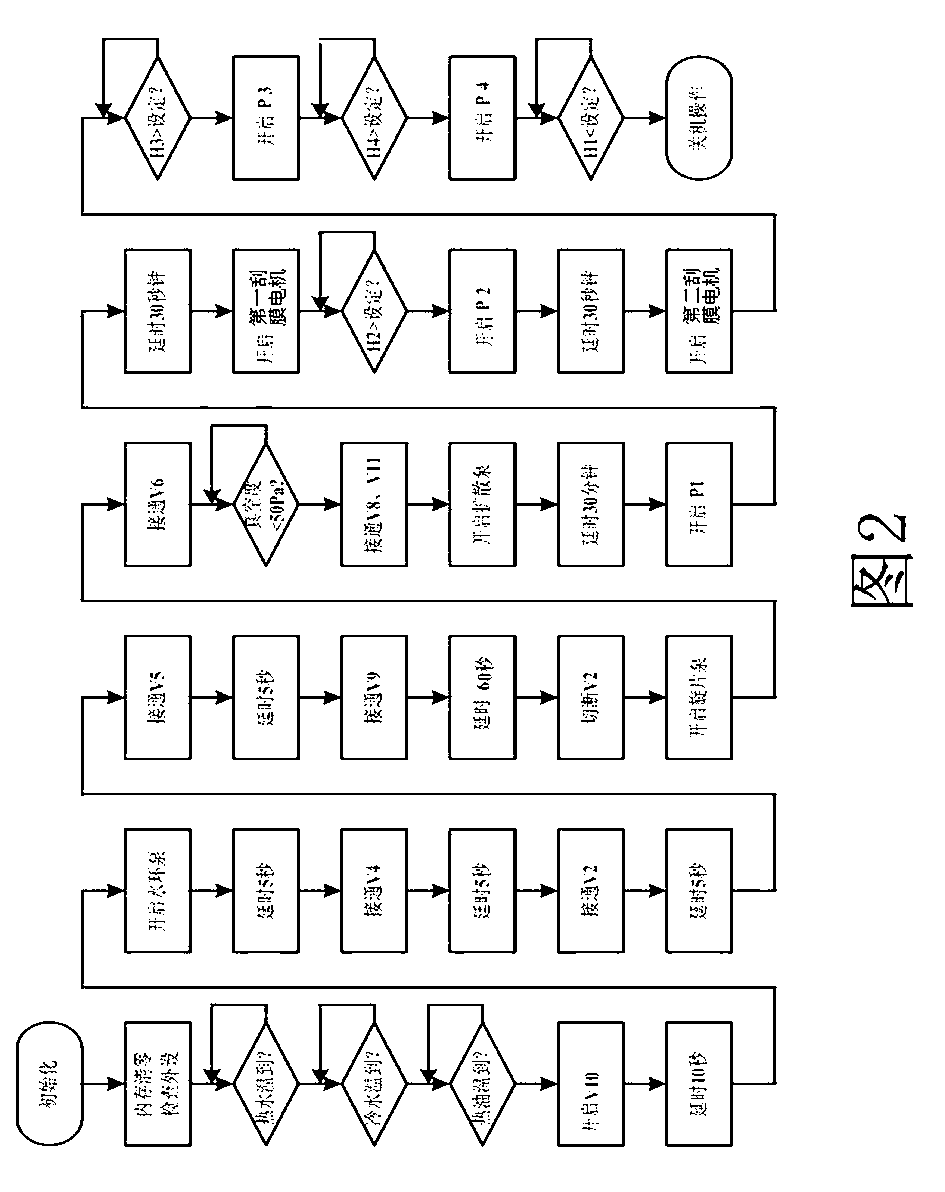

Water temperature control circulating cooling system for diffusion pump of vacuum coating machine

ActiveCN103911588AAvoid damageEnsure safetyVacuum evaporation coatingSputtering coatingAutomatic controlWater storage tank

The invention discloses a water temperature control circulating cooling system for a diffusion pump of a vacuum coating machine, which mainly aims at solving the problems that when the temperature of cooling water is higher than the safety threshold value in the normal work of vacuum coating equipment in the prior art, the vacuum coating equipment is damaged and the emergency water entering the vacuum coating equipment is wasted in vain. The water temperature control circulating cooling system comprises two water boxes, a water storage tank, a water pump, the vacuum coating equipment, a control water valve, a manual solenoid valve and a temperature measuring alarm device. The water storage tank is connected with the water boxes by the manual solenoid valve; the vacuum coating equipment is provided with the temperature measuring alarm device and is connected with the solenoid valve so as to automatically control the whole circulating cooling system. The automatic control on the circulating water cooling system and the effective protection on the vacuum coating machine are achieved. The water temperature control circulating cooling system can be used for a vacuum coating experiment in a laboratory.

Owner:西安点云生物科技有限公司

Interlayer vacuum coating method during blank manufacturing process of hot rolling composite plate

ActiveCN105251971AEliminate the surface nickel plating processImprove composite qualitySiphonComposite plate

Disclosed is an interlayer vacuum coating method during a blank manufacturing process of a hot rolling composite plate. A vacuum coating device mainly comprises an electrolytic furnace, an electromagnetic oscillator, a siphon pipe, a siphon valve, a vacuum pipe and a mechanical pump and diffusion pump assembly. Symmetrically combined stainless steel composite blank materials comprise two groups which each include a low alloy steel base layer and a stainless steel cladding layer, and a nickel plating interlay is generated between each low alloy steel base layer and the corresponding stainless steel cladding layer. When the stainless steel cladding layers of the two groups of blank materials are opposite, the space between the two stainless steel cladding layers is coated with a separant layer. According to the specific operation method, the lateral surfaces of the stainless steel composite blank materials are drilled, then the vacuum pipe, the siphon pipe and the composite plate are welded together, the periphery of the symmetrically combined stainless steel composite blank materials is sealed and vacuumized, and the vacuum pipe is sealed; the siphon valve is opened, molten nickel in the electrolytic furnace is made to enter the space between the layers of the stainless steel composite blank materials, and after the nickel is condensed, multiple times of rolling is carried out. The interlayer vacuum coating method during the blank manufacturing process of the hot rolling composite plate is simple in process, good in product quality, high in yield and low in cost.

Owner:YANSHAN UNIV

Zinc-aluminium vacuum evaporation coating machine

InactiveCN1455015ARealize localizationVacuum evaporation coatingSputtering coatingVacuum pumpingEngineering

The zinc-aluminium vacuum evaporation coating machine comprises vacuum chamber formed from coiling chamber, film-coating chamber and network plate, first vacuum-pumping system formed from diffusion pump, Roots pump, slide valve pump and valve, cold trap type second vacuum-pumping system and evaporation source. Said second vacuum-pumping system adopts non-condensaing trapping pump which is formed from slide valve pump, Roots pump, one booster pump or two booster pumps and valve which are successively series-connected, or two booster pumps are mutually parallel-connected, then series-connected with said other elements. Said second vacuum-pumping system is substituted for cold trap, so that it can simplify technological process, reduce cost and raise working efficiency.

Owner:上海奥移电器有限公司

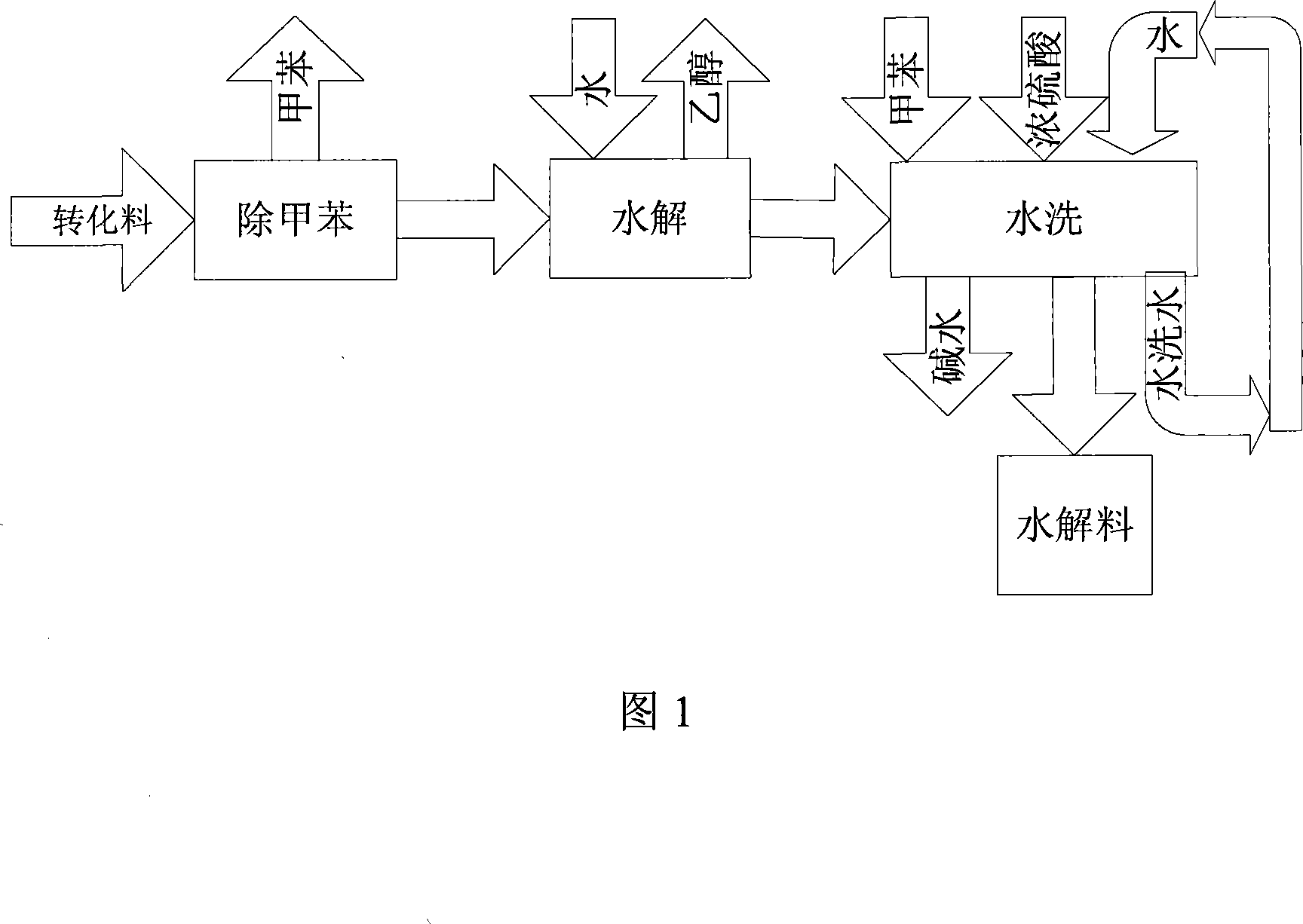

Method for hydrolyzing methyl phenyl siloxane

ActiveCN101182329AReduce lossesReduce sewageGroup 4/14 element organic compoundsChlorobenzeneTriethoxysilane

The present invention provides a method of hydrolyzing methyl phenyl siloxane, comprising the steps that methyl triethoxysilane, chlorobenzene and sodium are processed for the condensation reaction in toluene to obtain a transformation material containing the methyl phenyl siloxane, the toluene of which is removed, water is dripped directly, the temperature is increased to 95 DEG C to 115 DEG C, and the hydrolysis reaction is processed. The method of the present invention considers NaOH produced from the reaction as catalyst. Compared with the traditional method, the method of the present invention can reduce the material loss during the washing process of the transformation material and as well as can shorten the working procedures; the pollution discharge quantity towards the environment is reduced greatly, which is protective to the environment; the quality of hydrolyzing material is improved, which obviously improves the quality of diffusion pump oil produced by the method of the present invention.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Molecular-distillation purification method of celery seed oil and purification device thereof

InactiveCN103215127ALow costHigh degree of automation controlFatty-oils/fats refiningPurification methodsDistillation

The invention discloses a molecular-distillation purification method of celery seed oil and a purification device thereof. The purification device consists of a hot oil machine, a cold water machine, a material tank, a thermostatic bath, a grade-I evaporator, a grade-II evaporator, a cold well, a water ring pump, a rotary vane pump, a diffusion pump and a controller, wherein the hot oil machine is communicated with the grade-II evaporator through a hot oil pipe; one end of the cold water machine is communicated with the grade-II evaporator through a first cooling water pipeline; the other end of the cold water machine is communicated with the cold well through a second cooling water pipeline; and the grade-I evaporator is communicated with the grade-II evaporator through a vacuum cavity pipeline and a second material conveying pipeline. The molecular-distillation purification method comprises the steps of: first, preparation work; second, the process of distillation separation; and third, shutdown. The method and the device have the beneficial effects of greatly enhancing the production efficiency, lowering the cost of purifying the celery seed oil, improving the working environment of workers, truly raising the automation control degree in purification of the celery seed oil, and being high in reliability and remarkable in practical effect.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com