Method and equipment of preparing massive great-specific weight Zr-W-base amorphous alloy

An amorphous alloy, high specific gravity technology, applied in the field of vacuum suction casting preparation, can solve the problems of complex copper mold manufacturing, and achieve the effects of improving the filling speed, reducing manufacturing costs and facilitating mold replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

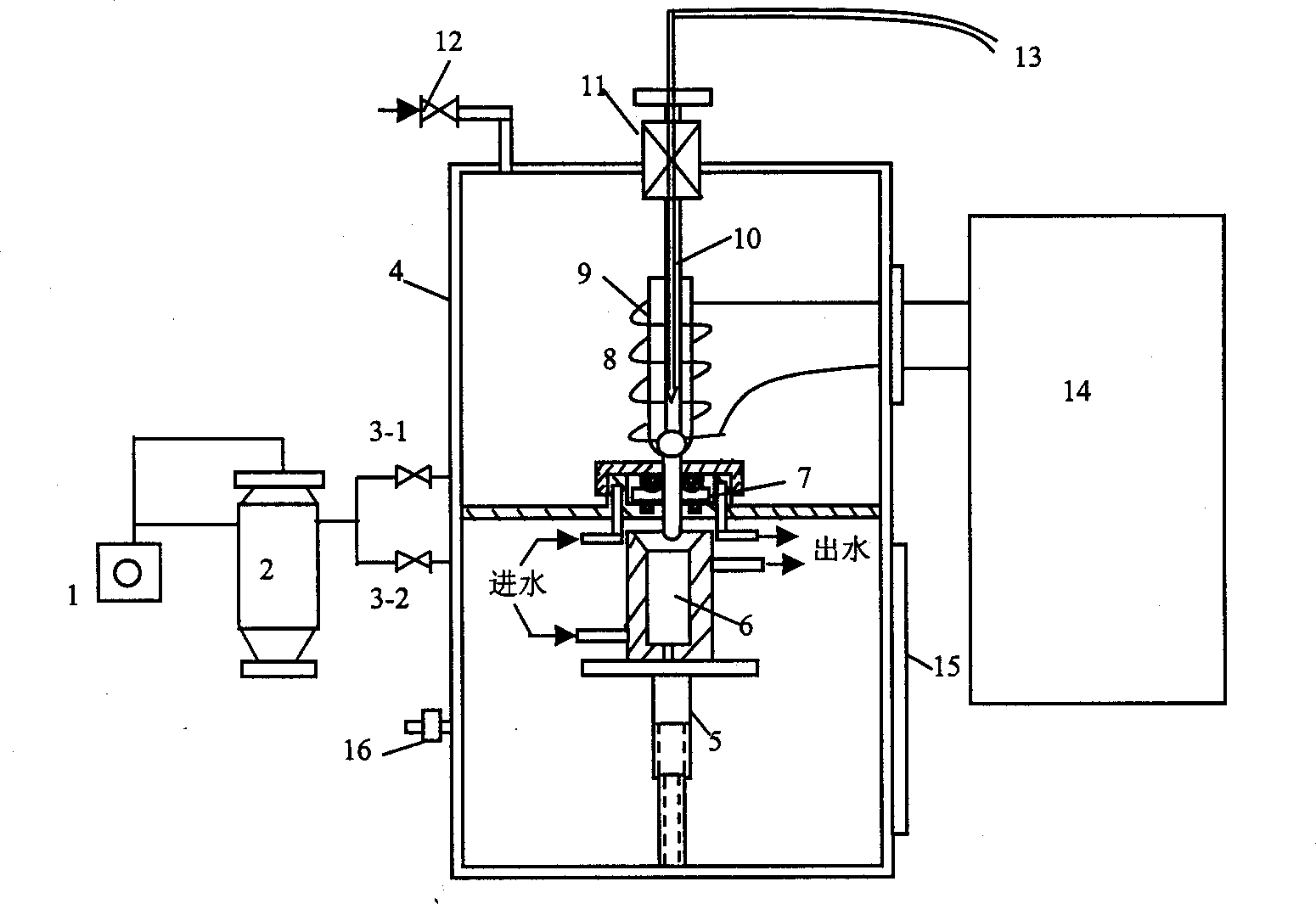

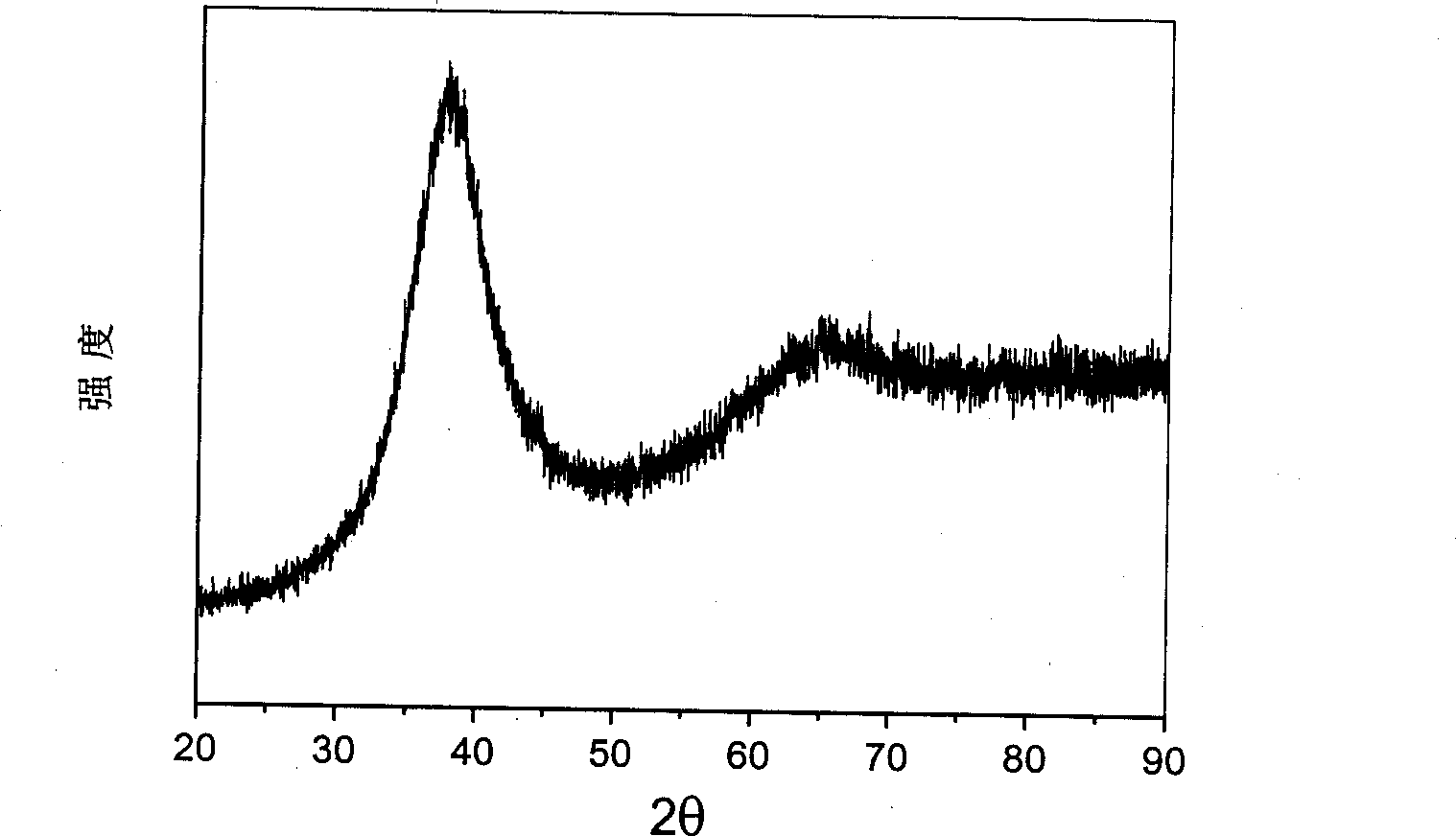

[0021] Select high-purity 6 pure metals, namely Zr (99.9999wt%), Ni (99.999wt%), Cu (99.99wt%), Al (99.999wt%), W (99.99wt%), B (99.9999wt%) ). The atomic percentage is: Zr is 55.2, Cu is 14.8, Ni is 8.5, Al is 6.4, W is 10, and B is 5. Under the protection of high-purity argon, the purification technology of liquid master alloy is applied, and the electric arc is used to The master alloy is obtained by melting. In order to ensure the homogeneity of each component in the master alloy, the master alloy was remelted three times. The surface of the master alloy ingot is mechanically ground and polished to remove surface oxide scale, then crushed into small pieces and the surface is cleaned with alcohol. These master alloy nuggets are put into the quartz tube, utilize the device as shown in accompanying drawing 1, according to the working principle as mentioned above, prepare Zr as shown in accompanying drawing 2 55.2 Cu 14.8 Ni 8.5 Al 6.4 W 10 B 5 Rod, the specific gravit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com