Method for hydrolyzing methyl phenyl siloxane

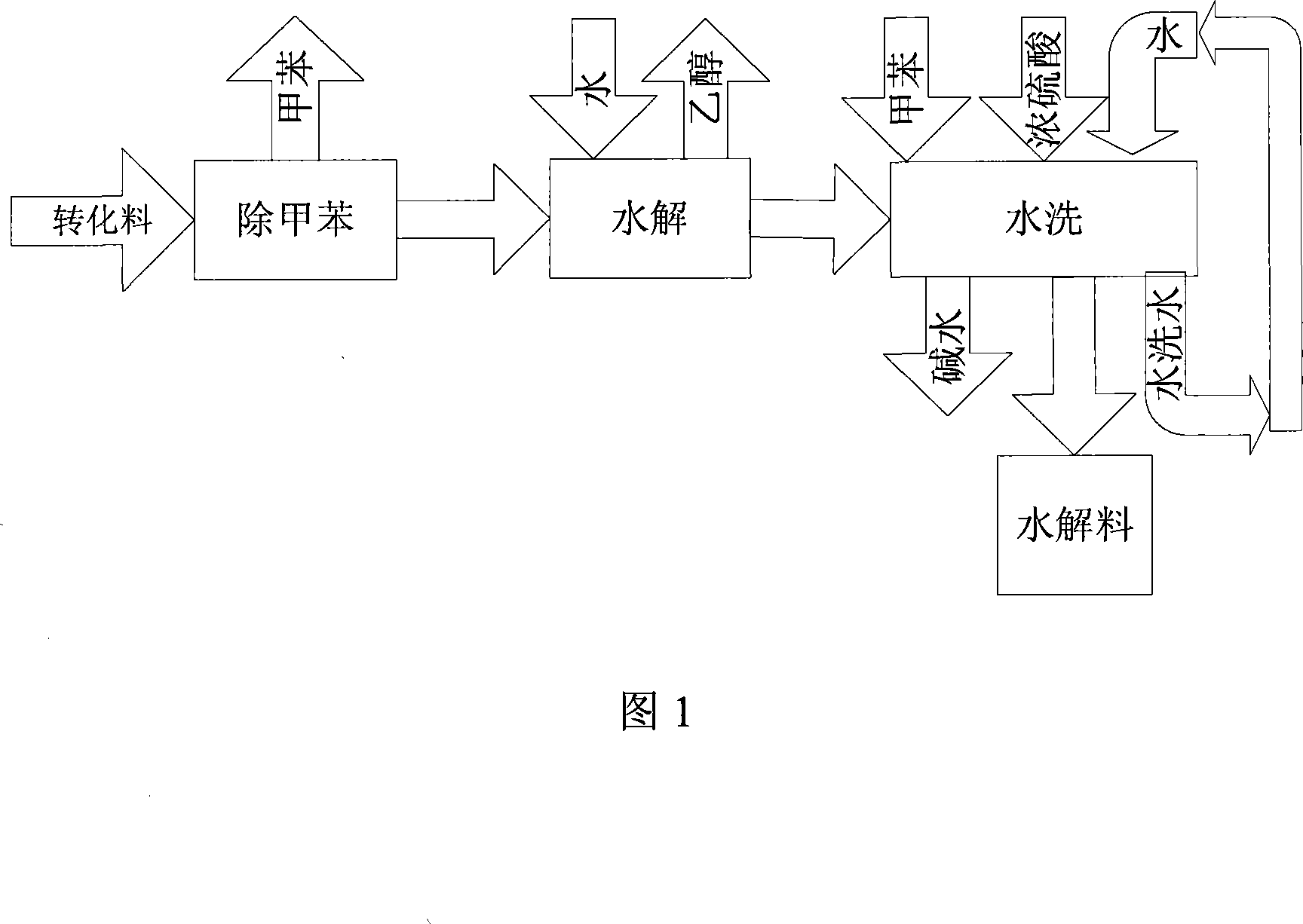

A technology of methyl phenyl siloxane and methyl triethoxy silane is applied in the field of hydrolysis of methyl phenyl siloxane, which can solve problems such as environmental pollution, and achieve the advantages of shortening the process, reducing the amount of sewage and improving the quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The conversion material of tetramethyltetraphenyltrisiloxane is directly hydrolyzed.

[0027] Add 240 kg of monomethyltriethoxysilane and 120 kg of sodium to 800 kg of toluene, heat up to 105 ° C, then drop 300 kg of chlorobenzene to carry out condensation reaction for 16 hours, and then convert 1460 kg of the obtained conversion material (tetramethyltetraphenyltrisilicon dioxane, sodium ethylate and sodium chloride) to the benzene removal kettle, heat up (temperature≤160°C) to remove toluene, cool to 48°C, transfer the converted material after removing toluene to the hydrolysis kettle, add 800kg of water dropwise, heat up and stir, Hydrolyzed for 10 hours, the temperature was controlled at 105°C. The ethanol produced in the hydrolysis process turns into steam and evaporates at 105°C, and is collected after cooling. Frequently measure the specific gravity of the distillate in the later stage of the hydrolysis reaction. When the specific gravity is 0.992, stop the hydro...

Embodiment 2

[0034] The conversion material of trimethylpentaphenyltrisiloxane is directly hydrolyzed.

[0035] Add 280kg of monomethyltriethoxysilane and 120kg of sodium to 800kg of toluene, raise the temperature to 100°C, then add dropwise 300kg of chlorobenzene to carry out condensation reaction for 16h, and then convert the obtained 1460kg of conversion material (trimethylpentaphenyltrisilicon dioxane, sodium ethylate and sodium chloride) to the benzene removal kettle, heat up (temperature≤160°C) to remove toluene, cool to 48°C, transfer the converted material after removing toluene to the hydrolysis kettle, add 800kg of water dropwise, heat up and stir, Hydrolyzed for 12 hours, the temperature was controlled at 95°C. The ethanol produced in the hydrolysis process turns into steam and evaporates at 95°C, and is collected after cooling. Frequently measure the specific gravity of the distillate in the later stage of the hydrolysis reaction. When the specific gravity is 0.995, stop the h...

Embodiment 3

[0040] The conversion material of trimethylpentaphenyltrisiladioxane is directly hydrolyzed.

[0041]Add 240kg of monomethyltriethoxysilane and 120kg of sodium to 800kg of toluene, raise the temperature to 101°C, then add 300kg of chlorobenzene dropwise to carry out condensation reaction for 17h, and then convert 1460kg of the obtained conversion material (trimethylpentaphenyltrisilicon dioxane, sodium ethylate and sodium chloride) to the benzene removal kettle, heat up (temperature≤160°C) to remove toluene, cool to 48°C, transfer the converted material after removing toluene to the hydrolysis kettle, add 800kg of water dropwise, heat up and stir, Hydrolyzed for 8 hours, the temperature was controlled at 115°C. The ethanol produced in the hydrolysis process turns into steam and evaporates at 105°C, and is collected after cooling. Frequently measure the specific gravity of the distillate in the later stage of the hydrolysis reaction. When the specific gravity is 0.990, stop th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com