Interlayer vacuum coating method during blank manufacturing process of hot rolling composite plate

A composite plate and process layer technology, which is applied in the field of metal composite billet making, can solve the problems of low compactness, pits, pinholes, particulates, and carbon steel matrix in the thermal spraying technology coating, so as to improve the composite Quality and yield, avoidance of uneven thickness, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

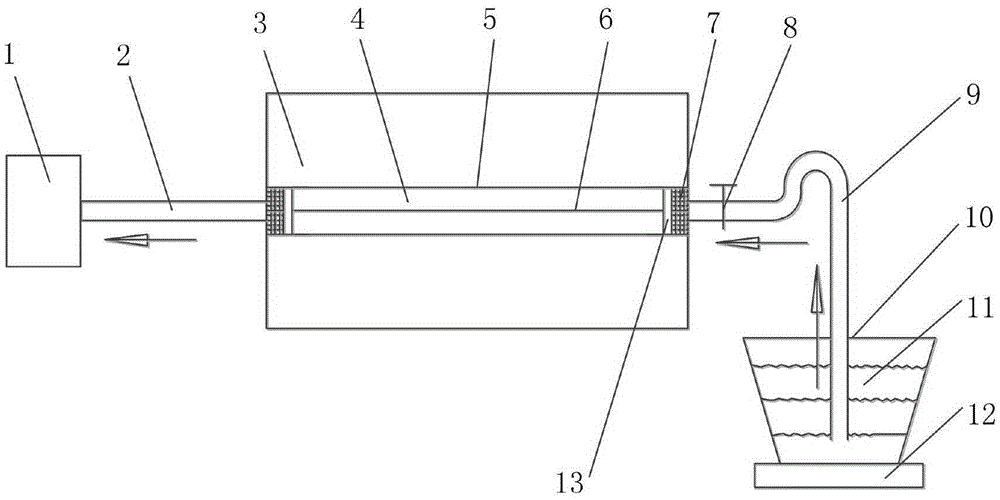

[0021] exist figure 1 In the schematic diagram of the front view of the working state of the interlayer vacuum coating device in the hot-rolled composite slab making process, an electromagnetic oscillator 12 is provided at the bottom of the electrolytic melting furnace 10. One end of the siphon tube 9 of the electrolytic melting furnace is located in the nickel water 11, and the A siphon valve 8 is provided on the siphon tube outside the electrolysis furnace. The end of the siphon tube located outside the electrolysis furnace is connected to a symmetrical composite stainless steel billet. There is also a mechanical pump and a diffusion pump assembly 1, which is connected to one end of the vacuum tube 2. The other end of the vacuum tube is It is connected with a symmetrical combination of stainless steel composite blanks. The stainless steel composite blanks of the symmetrical combination are two groups with the same length and width, and they all include Q345R low-alloy steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com