Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

227results about How to "Improve composite quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

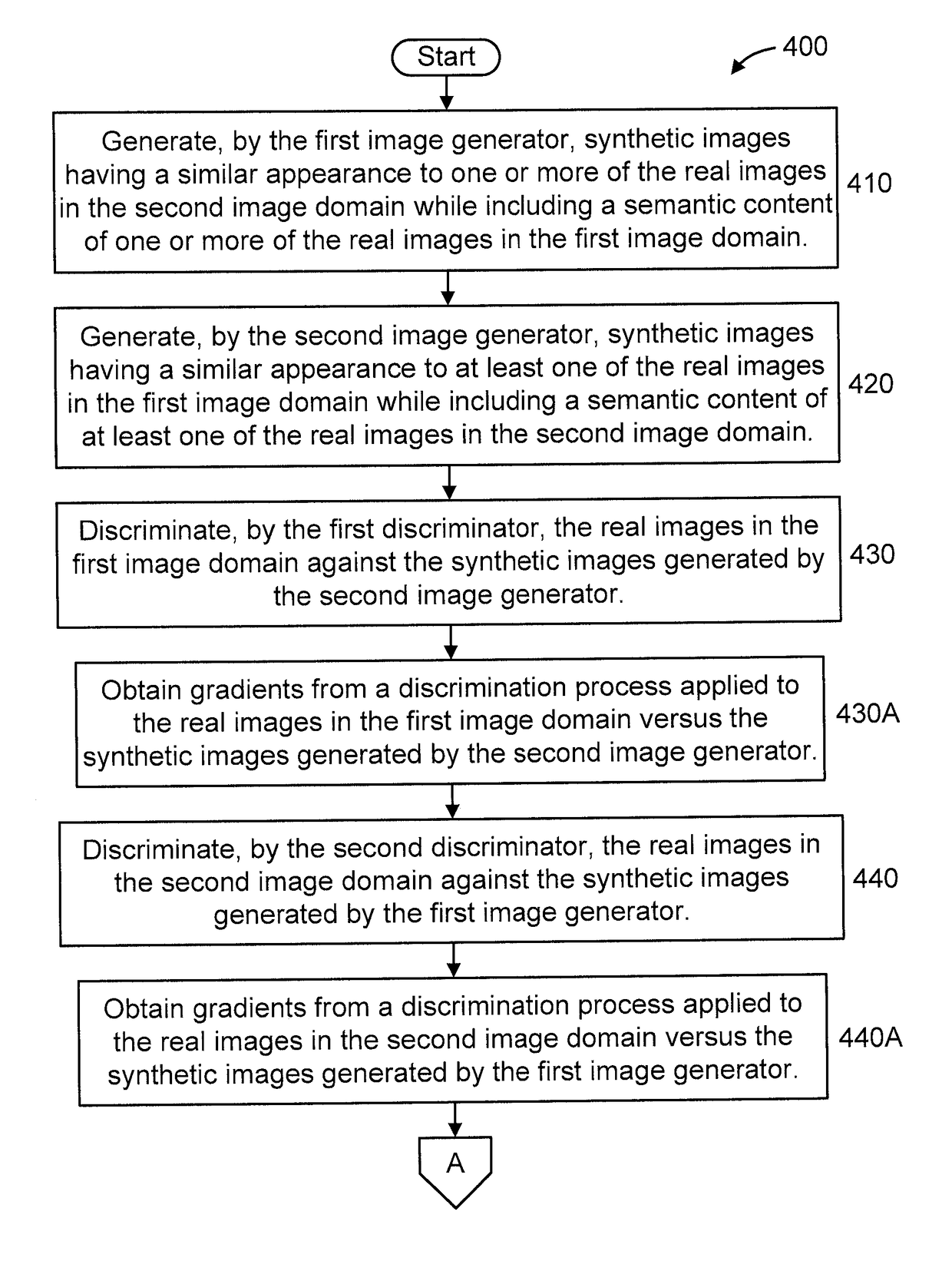

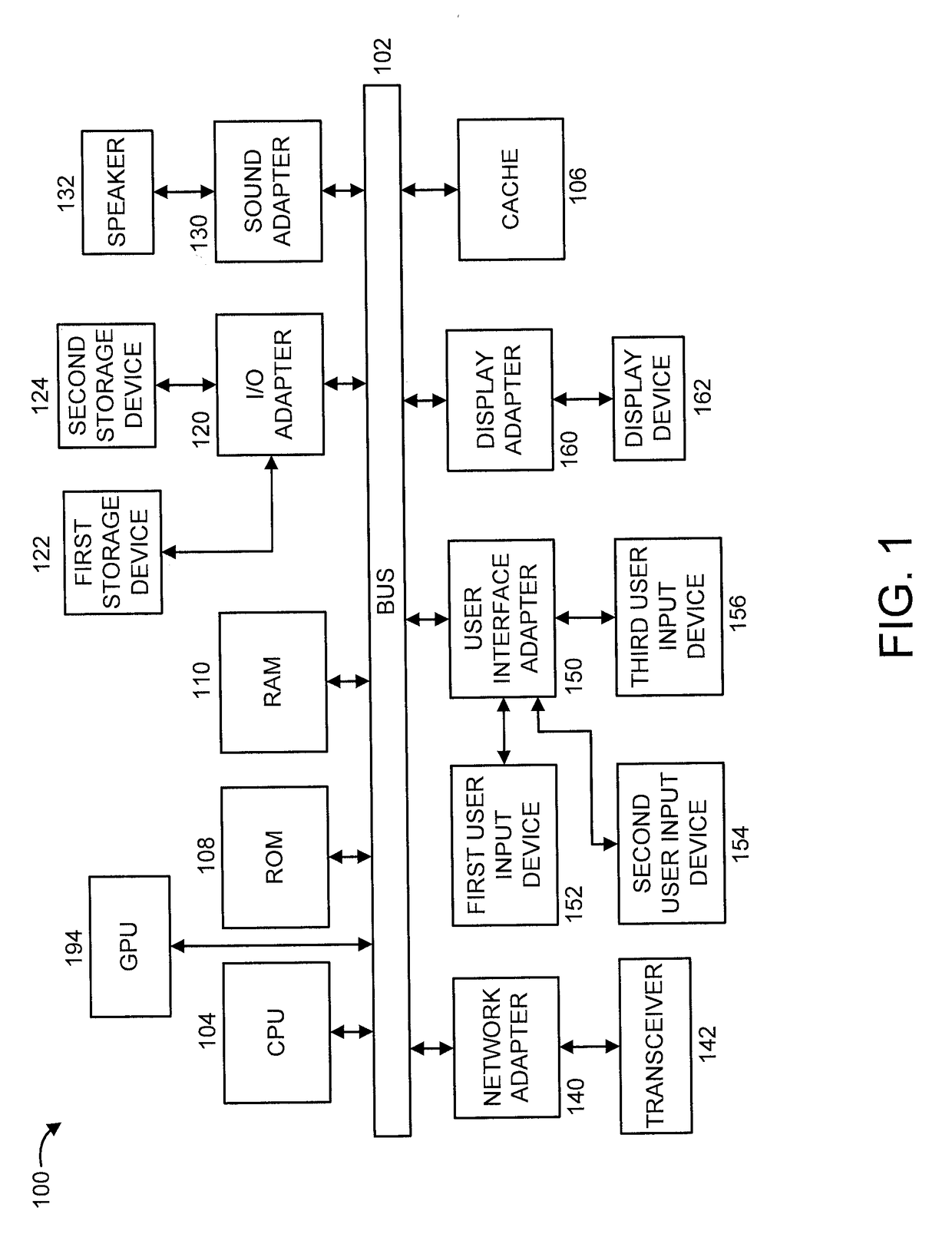

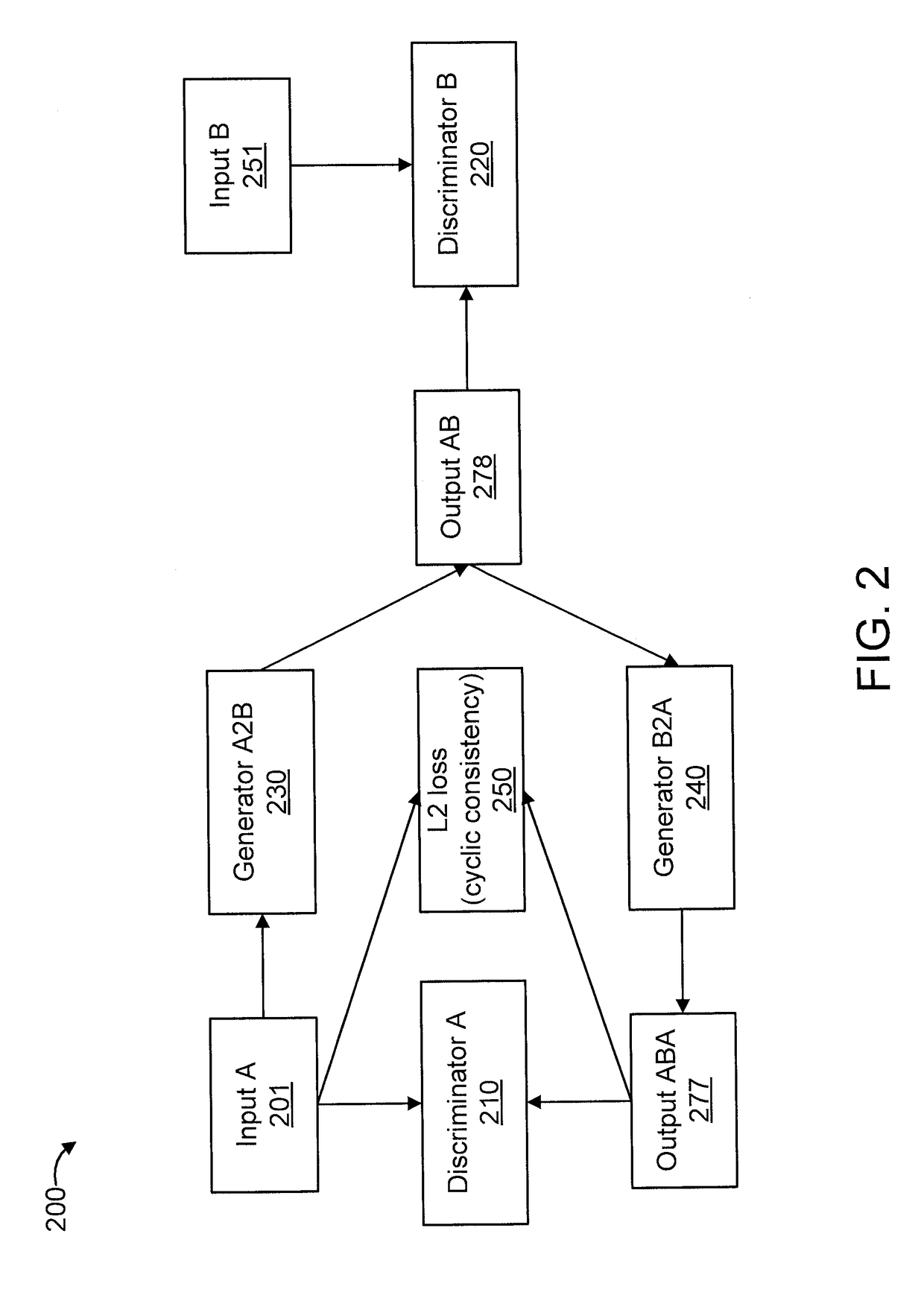

Cyclic generative adversarial network for unsupervised cross-domain image generation

ActiveUS20180307947A1Error rate of discriminativeQuality improvementTexturing/coloringCharacter and pattern recognitionGenerative adversarial networkAdversarial network

A system is provided for unsupervised cross-domain image generation relative to a first and second image domain that each include real images. A first generator generates synthetic images similar to real images in the second domain while including a semantic content of real images in the first domain. A second generator generates synthetic images similar to real images in the first domain while including a semantic content of real images in the second domain. A first discriminator discriminates real images in the first domain against synthetic images generated by the second generator. A second discriminator discriminates real images in the second domain against synthetic images generated by the first generator. The discriminators and generators are deep neural networks and respectively form a generative network and a discriminative network in a cyclic GAN framework configured to increase an error rate of the discriminative network to improve synthetic image quality.

Owner:NEC CORP

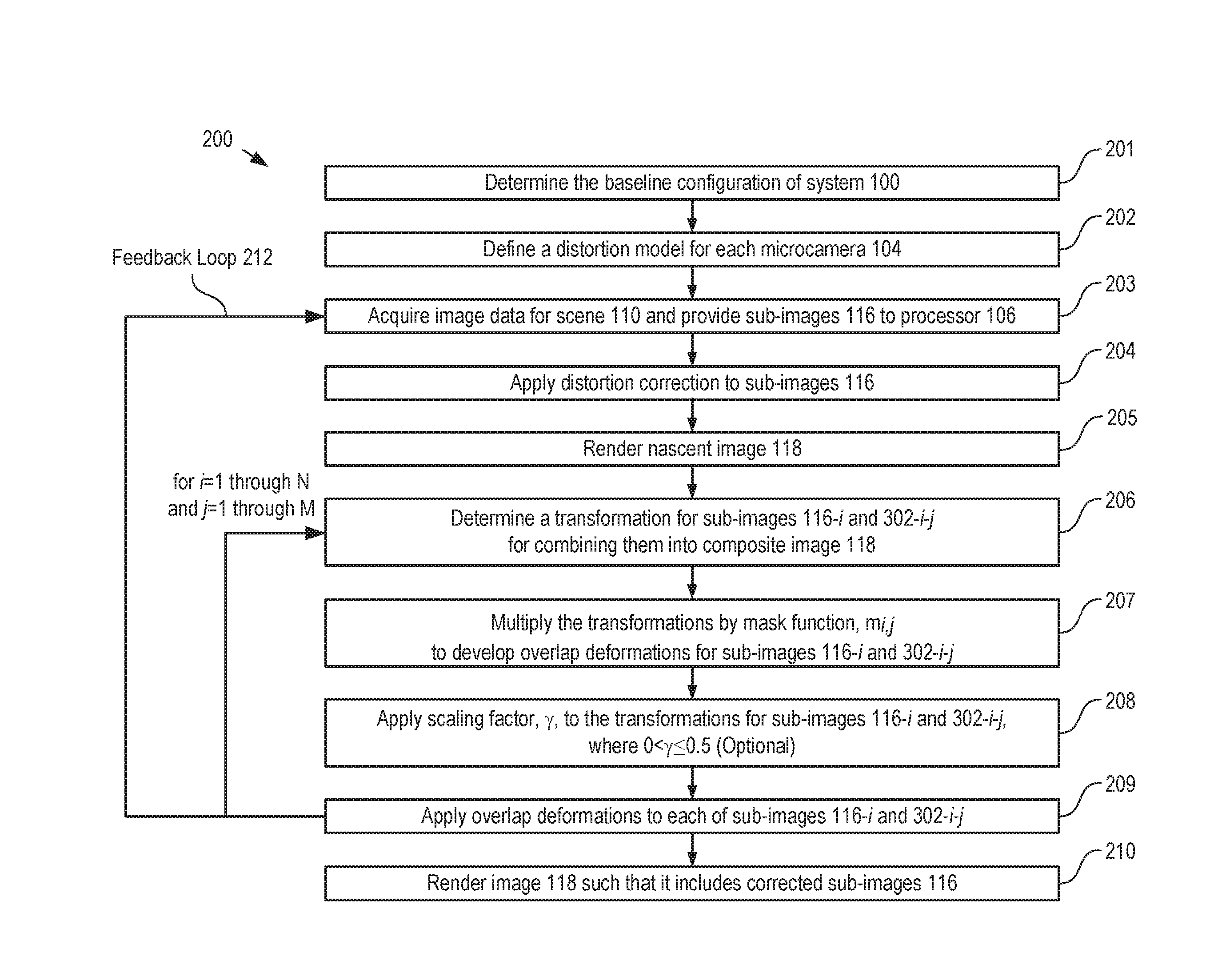

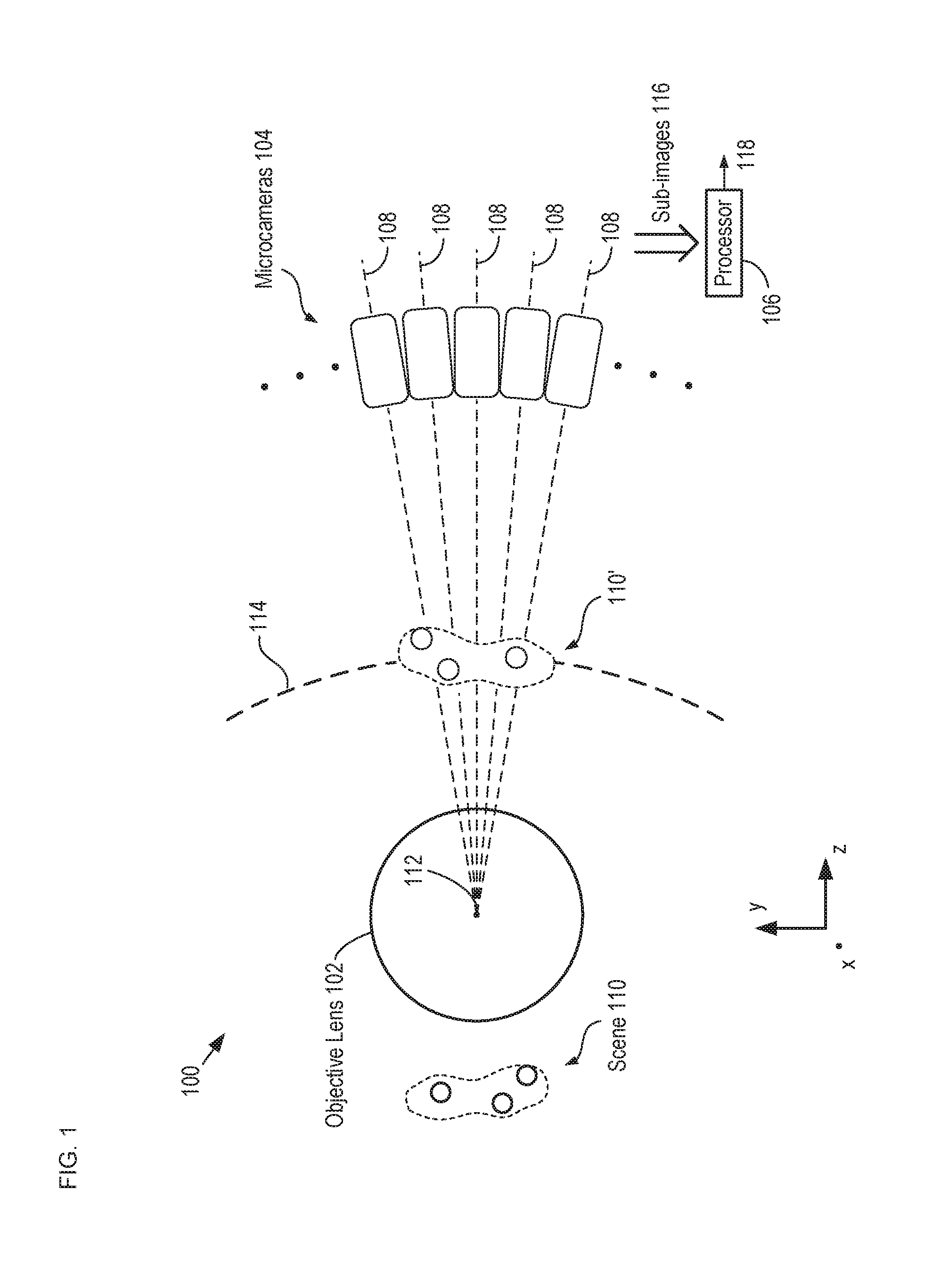

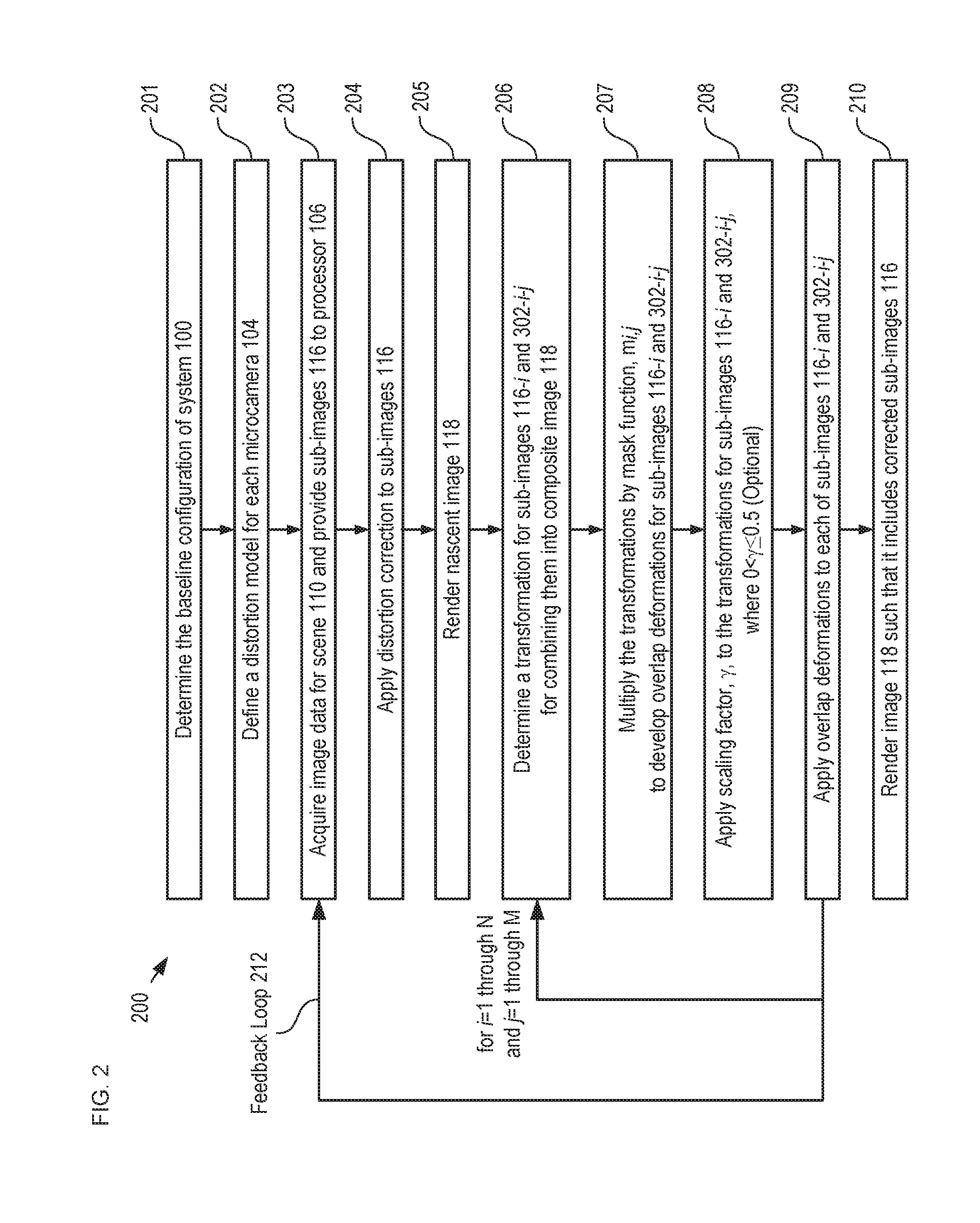

Method for combining multiple image fields

ActiveUS20160286137A1Improve fluencyReduce impactImage enhancementTelevision system detailsPattern recognitionComputer graphics (images)

Methods for stitching multiple sub-images together to form a substantially seamless composite image are disclosed. Overlap regions formed by each pair of neighboring sub-images are periodically examined and key features common to the overlap regions in each sub-image of the pair are identified. A transformation is determined for each sub-image pair based on the positions of these key features. The transformation is split between the sub-images and applied to distort the overlap regions in each sub-image pair such that they are substantially aligned. Applying the transformations to each overlap region in the overall image enables creation of a substantially seamless composite image. In some embodiments, the process wherein the transformations are determined is run as a feedback loop to enable continuing refinement of the transformations.

Owner:DUKE UNIV

Method and apparatus for improving quality of composite video signal and method and apparatus for decoding composite video signal

InactiveUS20060274210A1Improve picture qualityImprove composite qualityTelevision system detailsColor signal processing circuitsComputer graphics (images)Image quality

A method and apparatus for improving the quality of a composite video signal and a method and apparatus for decoding the composite video signal. The method for improving the quality of the composite video signal respectively detects edges from a luminance information signal and a chrominance information signal separated from the composite video signal, detects an artifact region using the detected edges, and filters the detected artifact region. Accordingly, an artifact can be effectively removed while preserving edge information and detail information of an image to improve picture quality.

Owner:SAMSUNG ELECTRONICS CO LTD

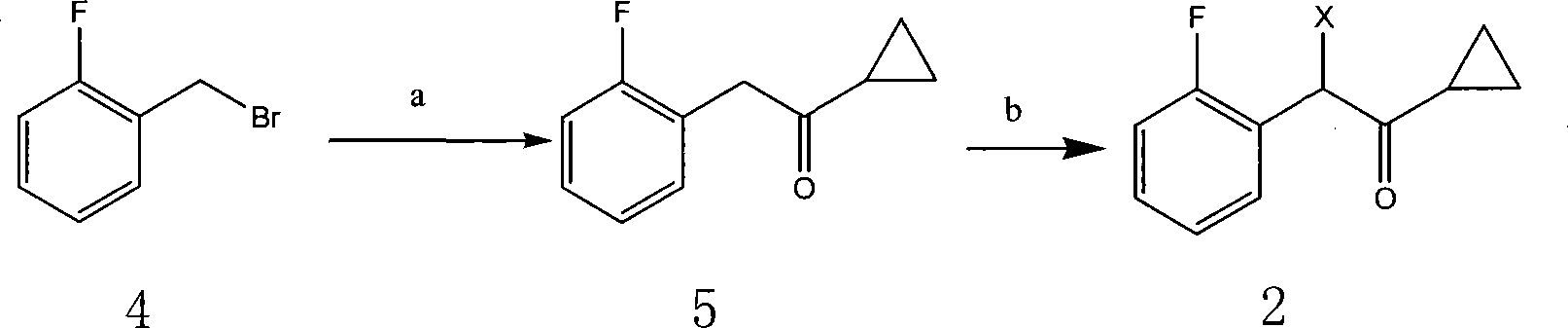

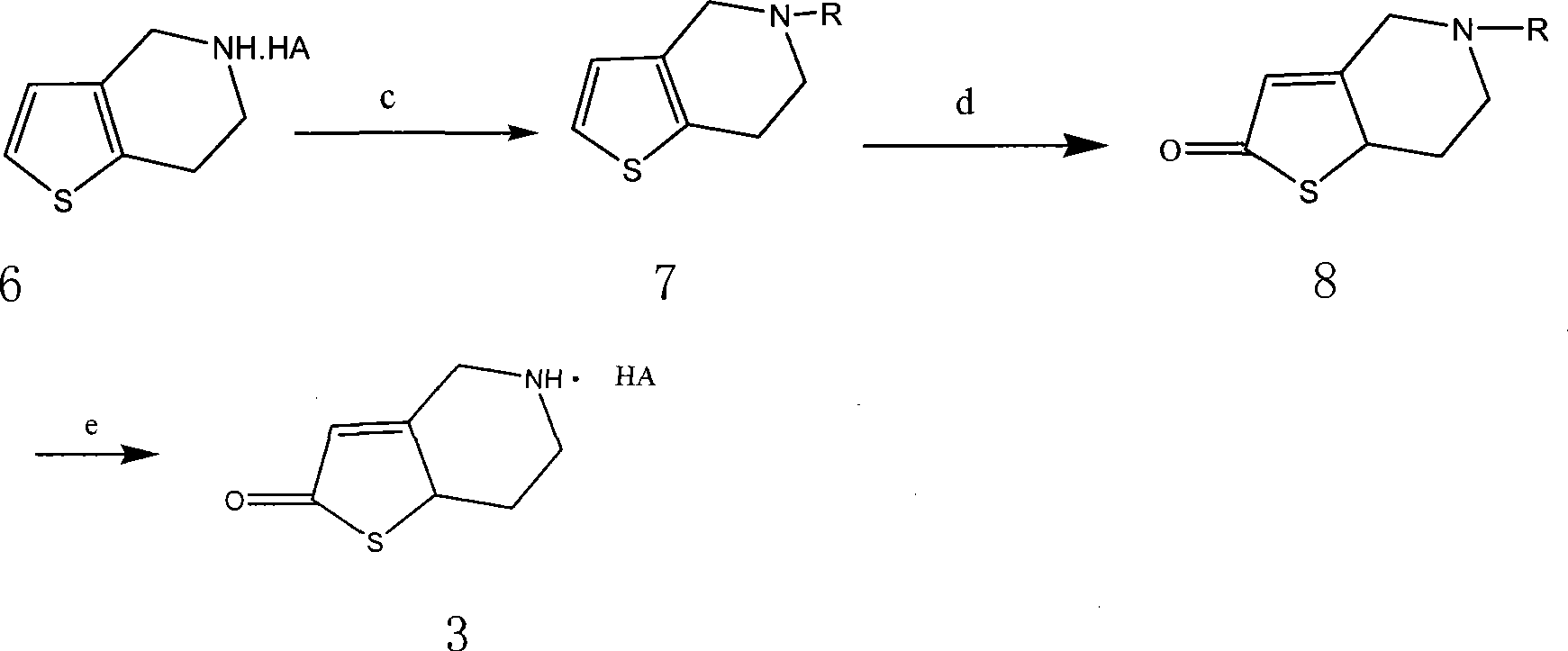

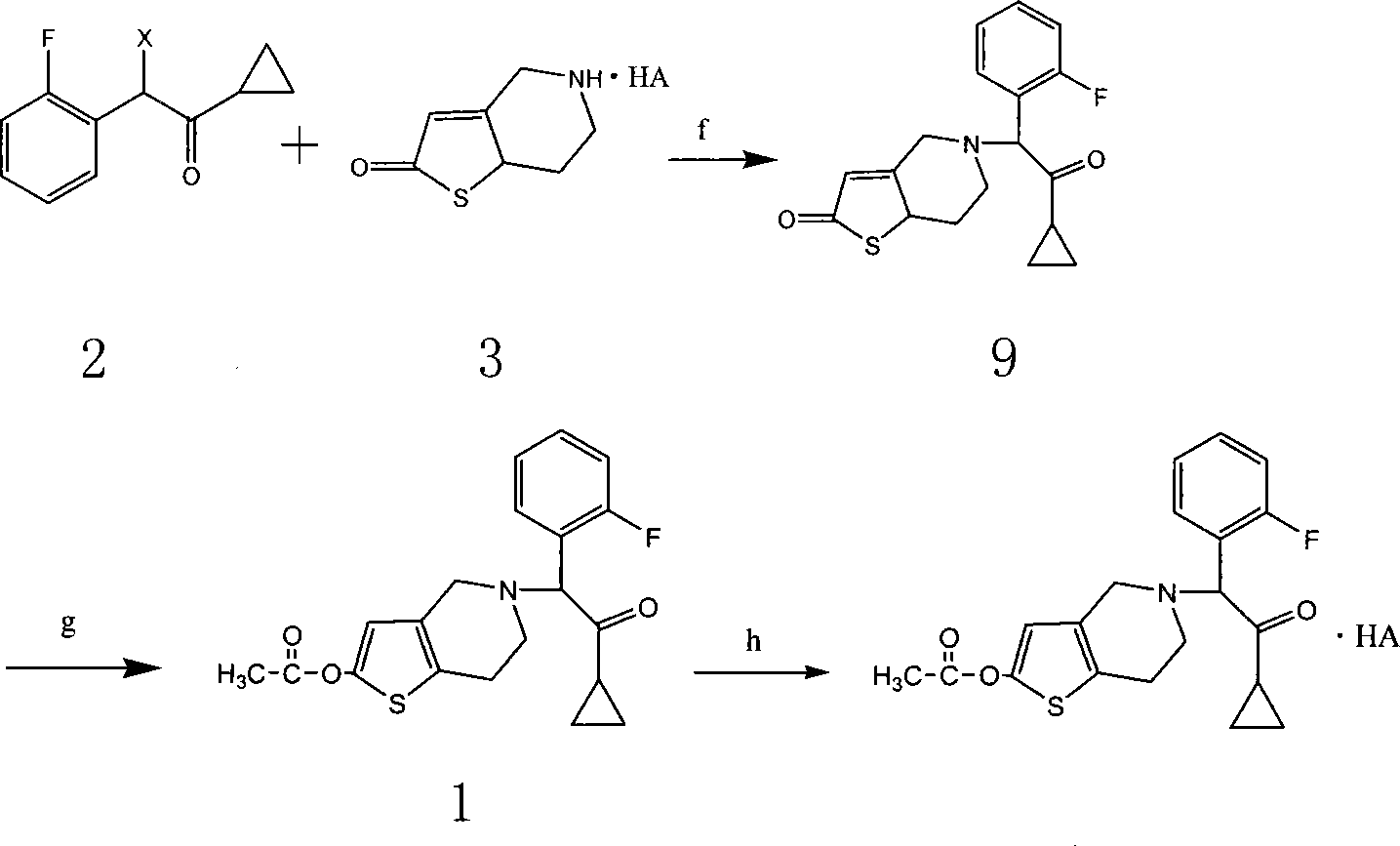

Hydrogenated pyridine derivative and method for preparing salt thereof

InactiveCN101177430AMild reaction conditionsEasy to scale up productionOrganic active ingredientsOrganic chemistryPyridiniumHalogen

The invention relates to the hydropyridine derivatives of 2-acetoxy-5- (Alpha-cyclopropyl carbonyl-2-fluorobenzyl) -4, 5, 6, 7-tetrahydrothiophene plus [3, 2-C] pyridine and salts of the hydropyridine derivative as well as the preparation method. The invention comprises following steps: preparing two main intermediates: Alpha-cyclopropyl carbonyl-2 fluorobenzyl halogen 2 (wherein, X=F, CL, Br, I) and 2-oxygen-2, 4, 5, 6, 7, 7 Alpha-hexahydrothiophene plus [3, 2-C] pyridinium salt 3 (wherein, HA=HCL, H2SO4, HBr, HI); esterifying the product obtained through condension of the two main intermediates using acetic anhydride to get target product. The target product and the needed acid are combined to be salts via addition reaction; during the process of crystallization, necessary crystal seed is added to achieve single-morphic crystals.

Owner:LUNAN PHARMA GROUP CORPORATION

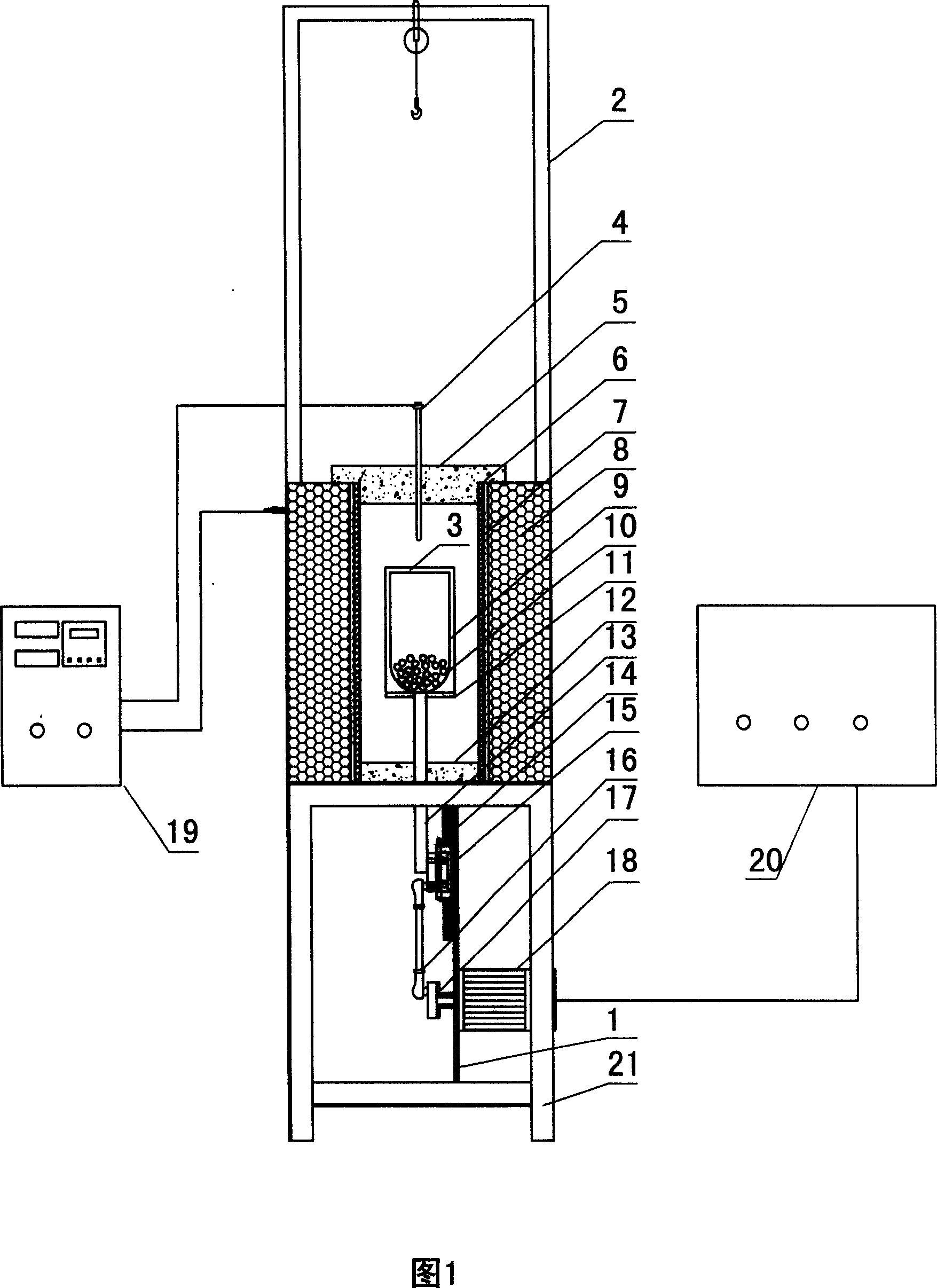

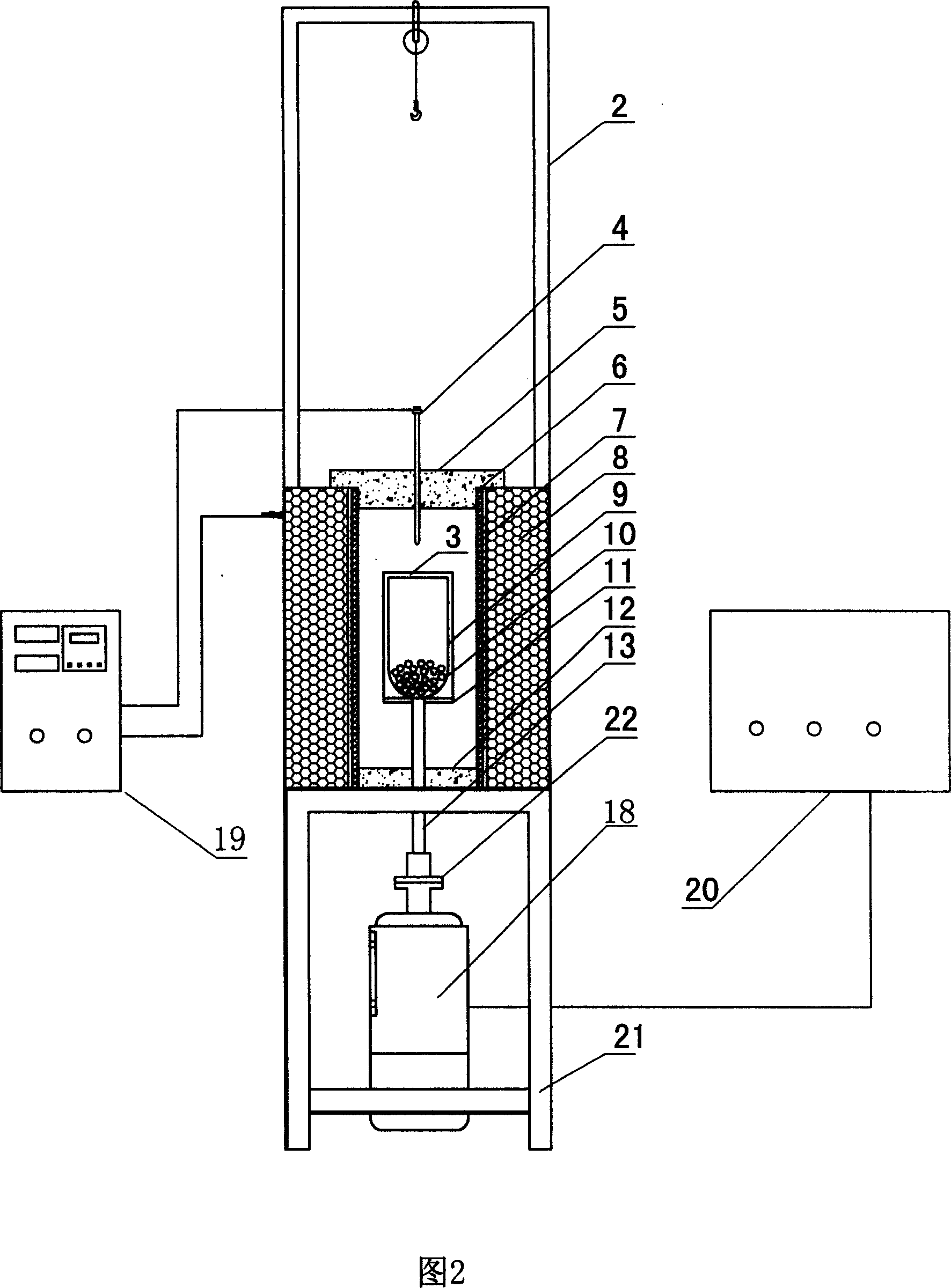

High temperature energy ball grinder

InactiveCN101003024AContinuously adjustable temperatureStrong ability to workGrain treatmentsVertical furnacesTemperature controlEngineering

A high-temp and-energy ball grinder for alloying ceramics is composed of motor, high-temp furnace, ball grinding pot in said high-temp furnace, temp controller with electrothermal couple, speed regulator, supporting frame, and drive mechanism.

Owner:NORTHEASTERN UNIV

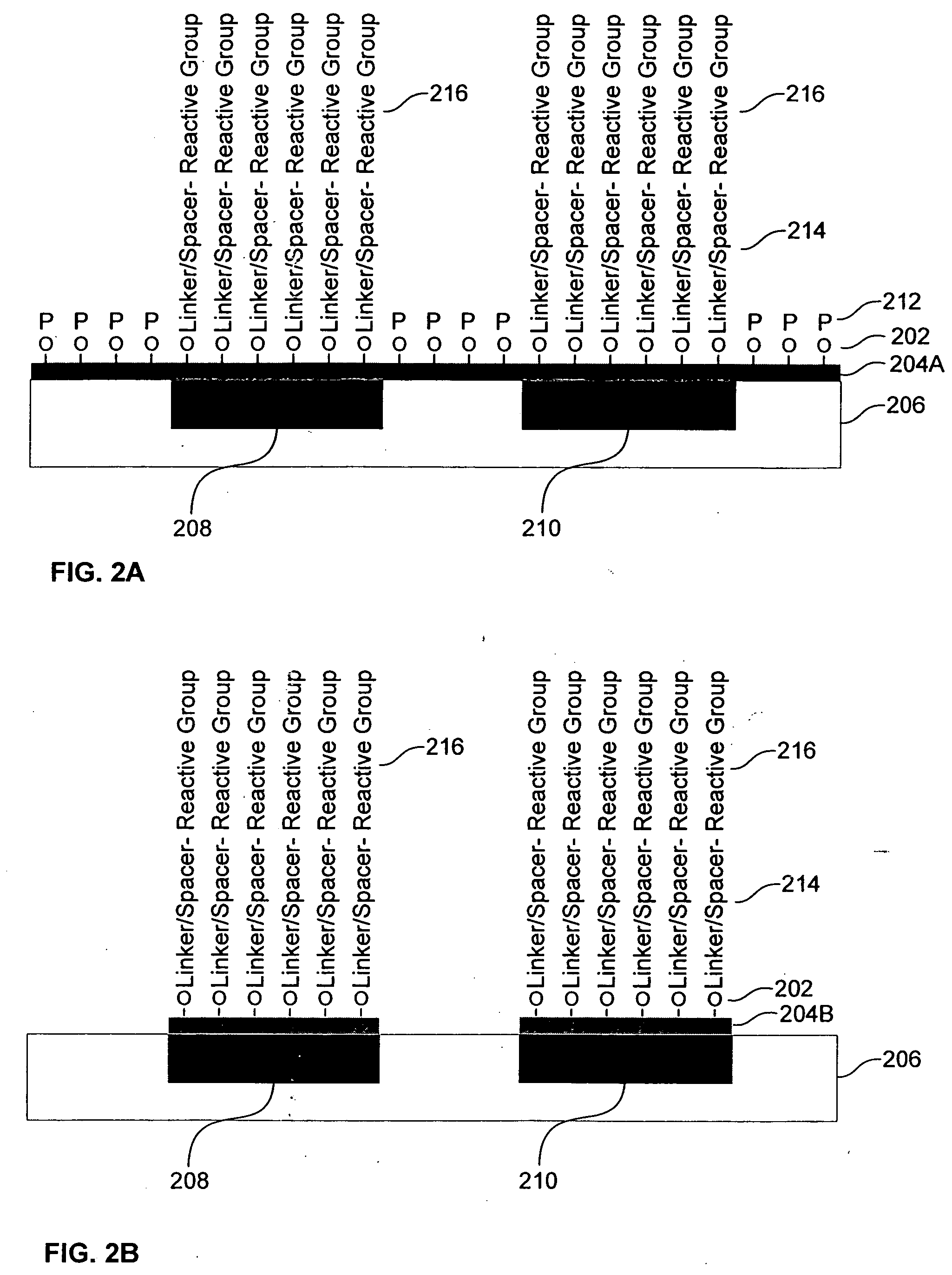

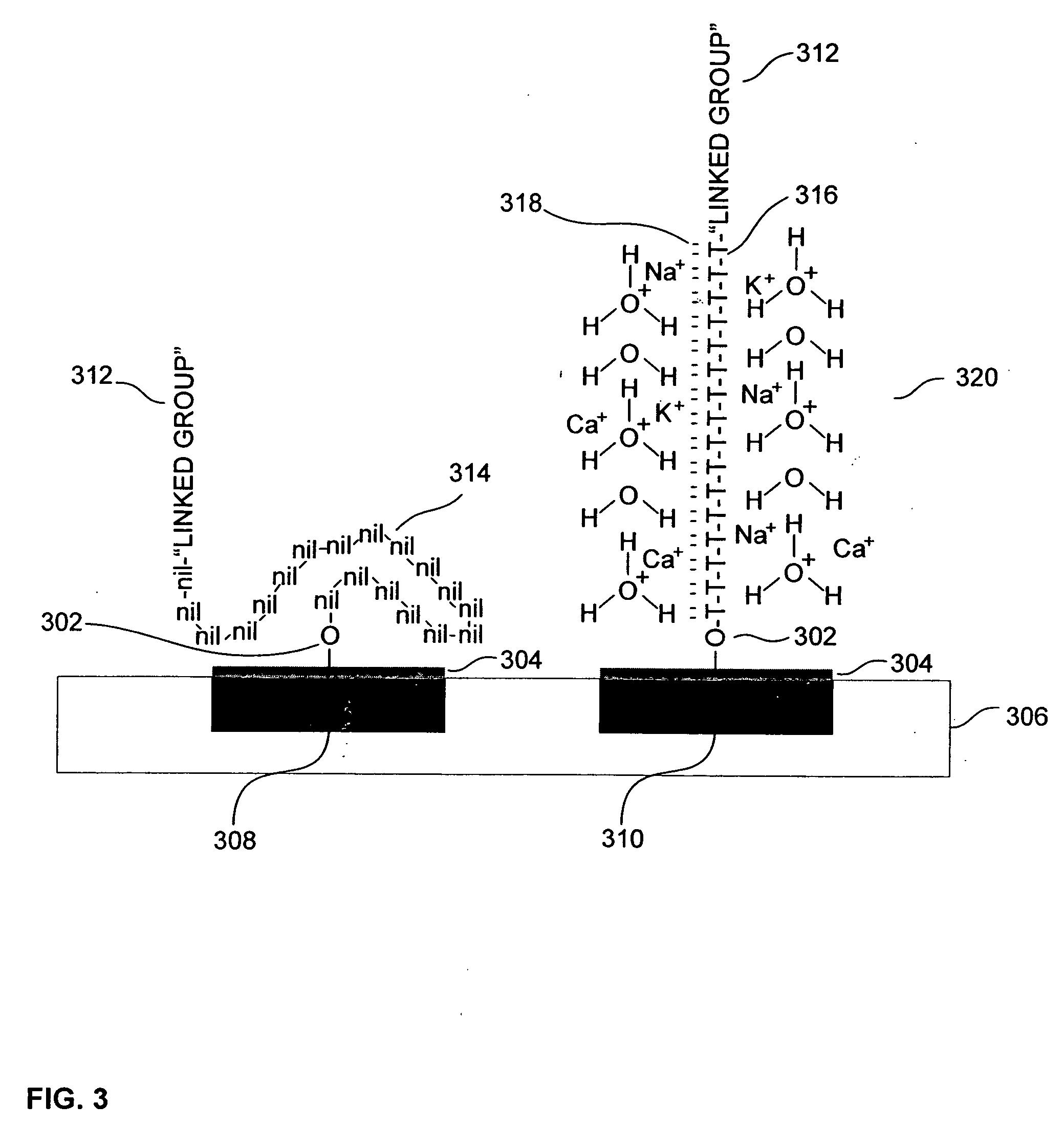

Electrode array device having an adsorbed porous reaction layer having a linker moiety

InactiveUS20060105355A1Improve composite qualityQuality improvementMaterial nanotechnologySequential/parallel process reactionsReaction layerComputer control system

There is disclosed an electrode array device having an adsorbed porous reaction layer having a linker attacher thereto for improved synthesis quality. The array comprises a plurality of electrodes on a substrate, wherein the electrodes are electronically connected to a computer control system. The array has an adsorbed porous reaction layer having a linker attached thereto on the plurality of electrodes, wherein the adsorbed porous reaction layer comprises a chemical species having at least one hydroxyl group. In the preferred embodiment, the reaction layer is sucrose having an ionic linker comprised of DNA. In another preferred embodiment, the reaction layer is sucrose, fructose, and glucose having an ionic linker comprised of DNA.

Owner:CUSTOMARRAY

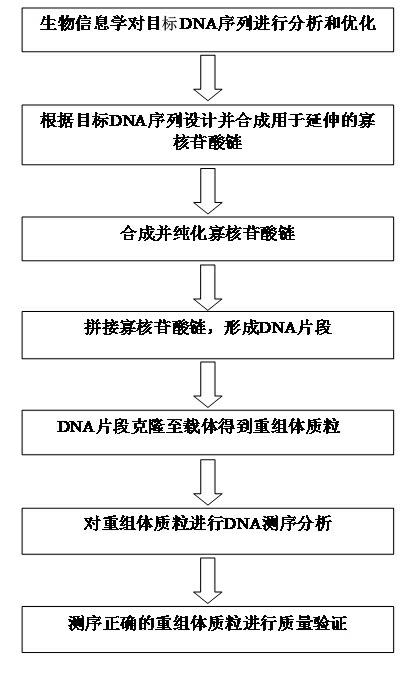

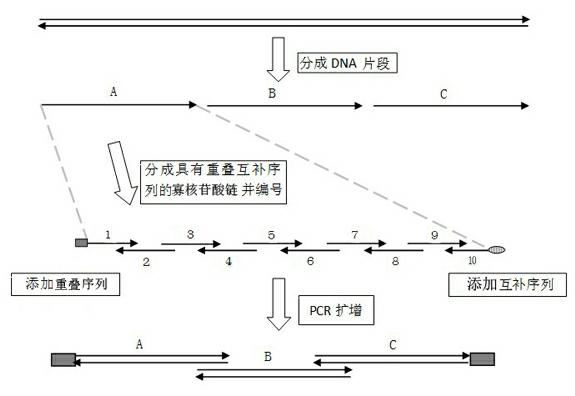

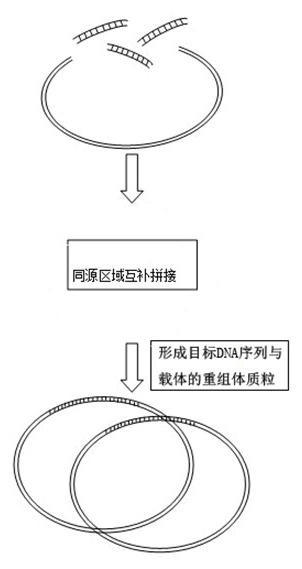

Industrialized gene synthesis method

The invention discloses an industrialized gene synthesis method. The industrialized gene synthesis method comprises the following steps of (1) analyzing and optimizing a DNA sequence for synthesis to obtain a target DNA sequence; (2) designing an oligodeoxynucleotide chain for extension according to the target DNA sequence; (3) synthesizing and purifying the oligodeoxynucleotide chain; (4) splicing the oligodeoxynucleotide chain to form a DNA fragment; (5) cloning the DNA fragment to a vector to obtain a recombinant plasmid; (6) carrying out sequencing analysis of the recombinant plasmid; and(7) carrying out a quality validation process on the recombinant plasmid with a correct sequence. The industrialized gene synthesis method has the characteristics of high success rate, high throughput, high speed, low cost, simple design, wide application scope and standardized operation. Therefore, the industrialized gene synthesis method has feasibility of industrial scale popularization, and is beneficial for reduction of costs, shortening of a synthesis cycle and improvement of synthesis quality.

Owner:GENEWIZ INC SZ

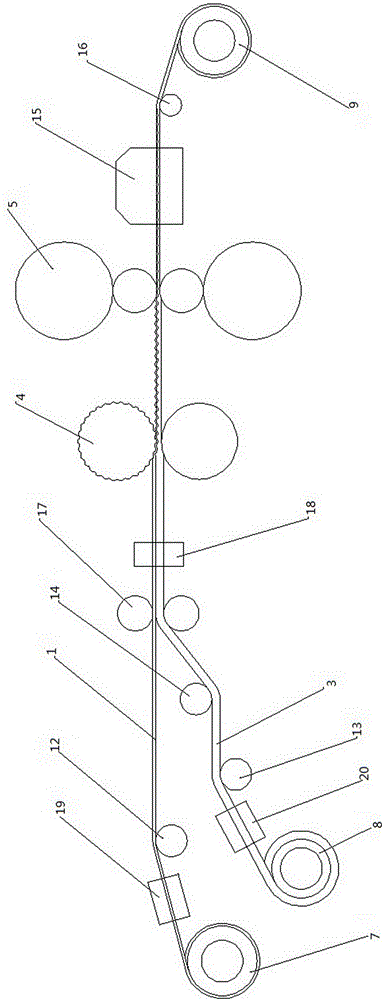

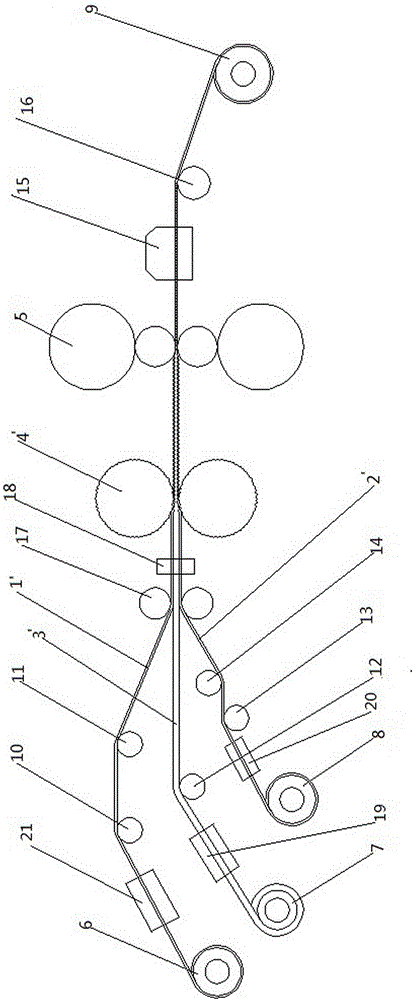

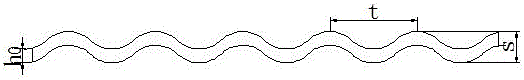

Device and method for producing metal composite sheet strips through corrugated-flat continuous rolling

ActiveCN105057386AHigh bonding strengthUniform deformationMetal rolling arrangementsCrazingContinuous annealing

The invention discloses a device and method for producing metal composite sheet strips through corrugated-flat continuous rolling. The method is characterized in that a base material steel coil and a composite material steel coil are uncoiled through uncoilers, cleaned through a cleaning device to remove oxide layers and then rolled into a composite sheet strip through a corrugated-flat cold continuous rolling unit, and the composite sheet strip is annealed through a continuous annealing device and then coiled to obtain a composite sheet coil. The corrugated-flat cold continuous rolling unit is composed of a double-roller corrugated rolling mill and a four-roller flat rolling unit. When double-layer sheet strips need to be produced, a roller system of the double-roller corrugated rolling mill comprises a corrugated roller and a flat roller, and the corrugated roller always makes contact with a large-deformation-resistance metal layer; when three-layer sheets need to be produced, the roller system of the double-roller corrugated rolling mill comprises two corrugated rollers, and the two corrugated rollers make contact with a large-deformation-resistance composite layer. In corrugation section dimensions, the corrugation depth is s, and the corrugation width is t; the thickness of the large-deformation-resistance metal layer is h0, i.e., s / h0=(0.1-10), and t=(10-20)s. By using the corrugated-flat cold continuous rolling unit, the problem that composite sheet strips buckle, crack and have large residual stress due to the difference of deformation resistances of dissimilar metals is solved, and the composite ratio is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

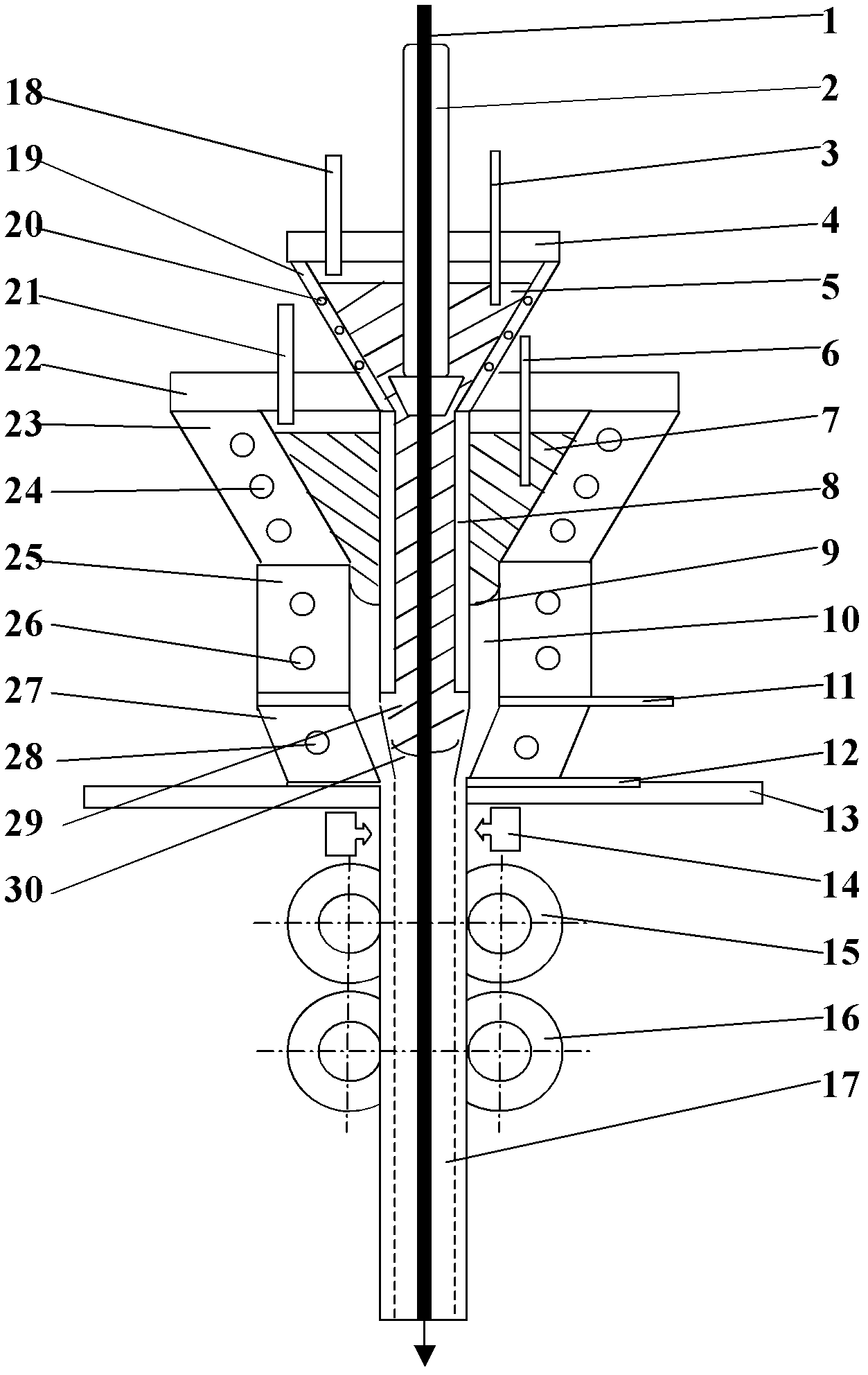

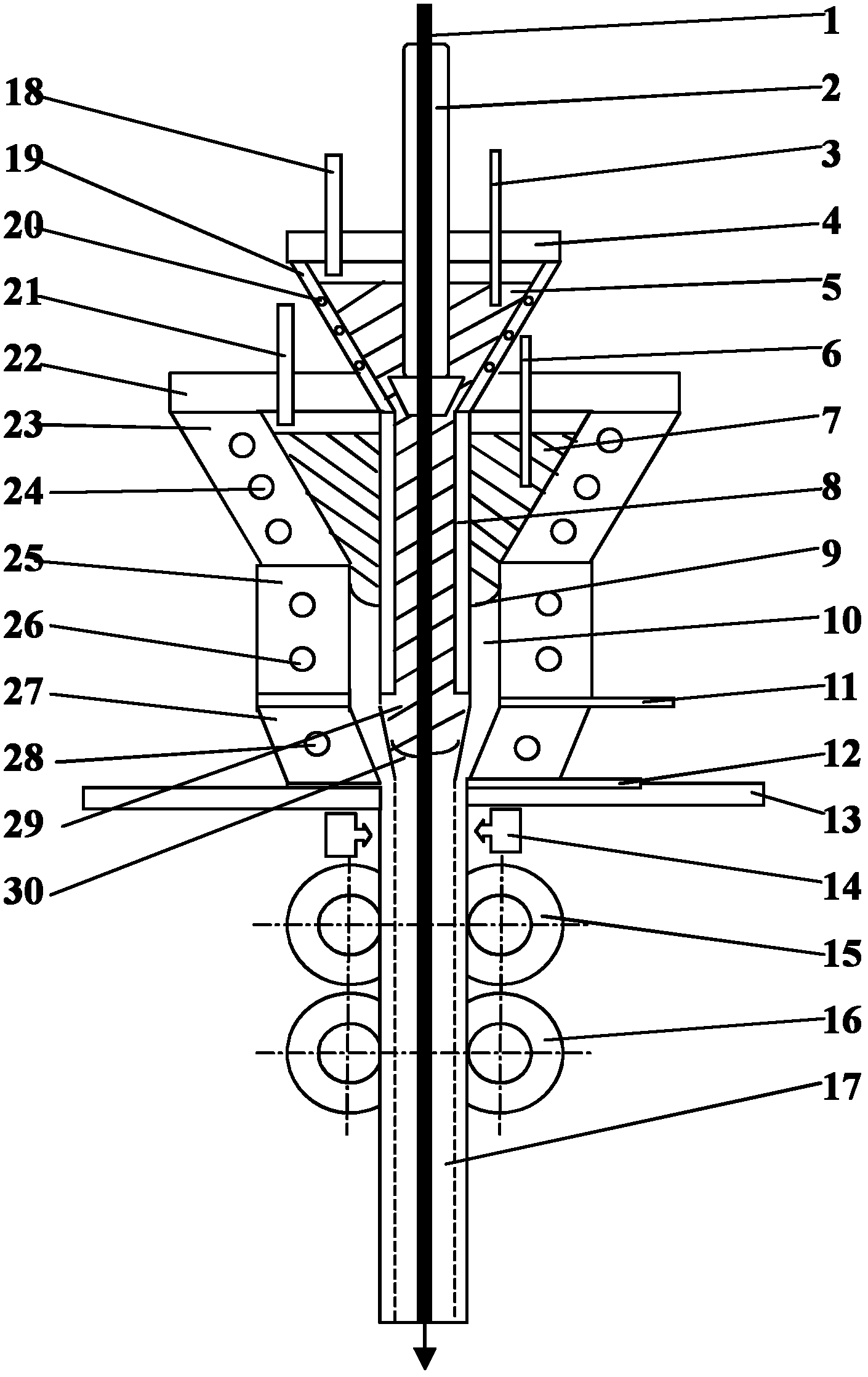

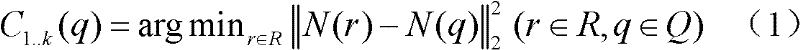

Pressure core-filling continuous casting equipment and process for double-metal-bag long carbon fiber composite material

The invention provides pressure core-filling continuous casting equipment and a process for a double-metal-bag long carbon fiber composite material. The continuous casting equipment is composed of an inner-layer metal plug rod, a carbon fiber guide pipe, an inner-layer metal thermodetector, an inner-layer metal pressurizing cover, an outer-layer metal thermodetector, a core filling pipe, an outer-layer metal pipe thermodetector, a composite interface pressurizing device, a heat-insulating and water-stopping plate, a secondary cooling device, a drawing roller, a finishing roller, an inner-layer metal liquid pressurizing pipe, an inner-layer metal temperature control furnace, an outer-layer metal liquid pressurizing pipe, an outer-layer metal pressurizing cover, an outer-layer metal liquid temperature control furnace, an outer-layer metal liquid temperature control crystallizer, a composite interface pressurizing device, a heating element and a temperature control element. Inner-layer metal is smelted and insulated in the inner-layer metal temperature control furnace and is filled into a condensed outer-layer metal pipe inner hole and one bundle of long carbon fibers through the core filling pipe, so as to be fused and condensed with the inner-layer metal and the carbon fibers to form a composite material. The speed of core-filling and continuous casting is controlled by the drawing roller and an outer-layer metal pipe casting blank is pressurized to be ejected out from the outer-layer metal liquid temperature control crystallizer.

Owner:UNIV OF SCI & TECH BEIJING

Method for rolling copper-aluminum double-layer composite plate

ActiveCN104959382AReduce residual stressIncrease the amount of plastic deformationAuxillary arrangementsMetal rolling arrangementsComposite plateCopper

The invention discloses a method for manufacturing a copper-aluminum double-layer medium-thick composite plate through a cold rolling manner. The method comprises following steps: 1) cleaning an aluminum plate and a copper plate in an immersion manner, removing oil of the plates, drying the plates, and cleaning the composite surfaces of the plates; 2) stacking and compressing the copper plate and the aluminum plate, and riveting the plates at a rolling bite end; 3) rolling the copper-aluminum composite plate blank through a two-roller roughing mill; 4) rolling the copper-aluminum composite plate through a three-roller intermediate mill; 5) rolling the copper-aluminum composite plate through a four-roller finishing mill; 6) rolling the copper-aluminum composite plate through a six-roller finishing mill to reach the required thickness; and 7) annealing the copper-aluminum composite plate. According to the invention, rolling is carried out through the rolling mills provided with working rolls having different roll diameters, so that the plastic deformation is increased, the composite ratio is improved, and a plate shape problem of the copper-aluminum double-layer medium-thick composite plate is solved as the working rolls are different in linear speed.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing extra thick composite board through dissymmetrical composite rolling

ActiveCN102649123AImprove deformationImprove the degree of recrystallizationMetal rolling arrangementsSurface cleaningComposite plate

A method for producing extra thick composite board through dissymmetrical composite rolling comprises the following steps: a), board preparation: three slabs including a first slab, a second slab and a third slab are prepared, and the combined surfaces of the three slabs are subjected to surface cleaning, the thicknesses H1, H2 and H3 of the first slab, the second slab and the third slab meet the following requirement: the total thickness H: H1+H2+H3 is larger than 600 mm, 1 / 5 <H1 / H <1 / 2, 1 / 5 <H3 / H ,1 / 2; b), vacuum welding: the peripheries of the combined surfaces of the three slabs are welded under the vacuum environment, and the peripheries of the combined surfaces are sealed; c), heating: the heating temperature is 1100 DEG C to 1250 DEG C, and the temperature holding time is larger than 4 hours; and d), rolling: the bloom rolling temperature is 1000 DEG C to 1200 DEG C, the finishing rolling temperature is within recrystallization temperature, and the reduction in pass is 5 to 60 mm. According to the invention, the combined interfaces are placed at the positions of a half to one fifth of thicknesses of the slabs, the combined surfaces of the slabs are deformed greatly, and recrystallization is performed near the combined surfaces to a greater degree, so that composite quality of good combination is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

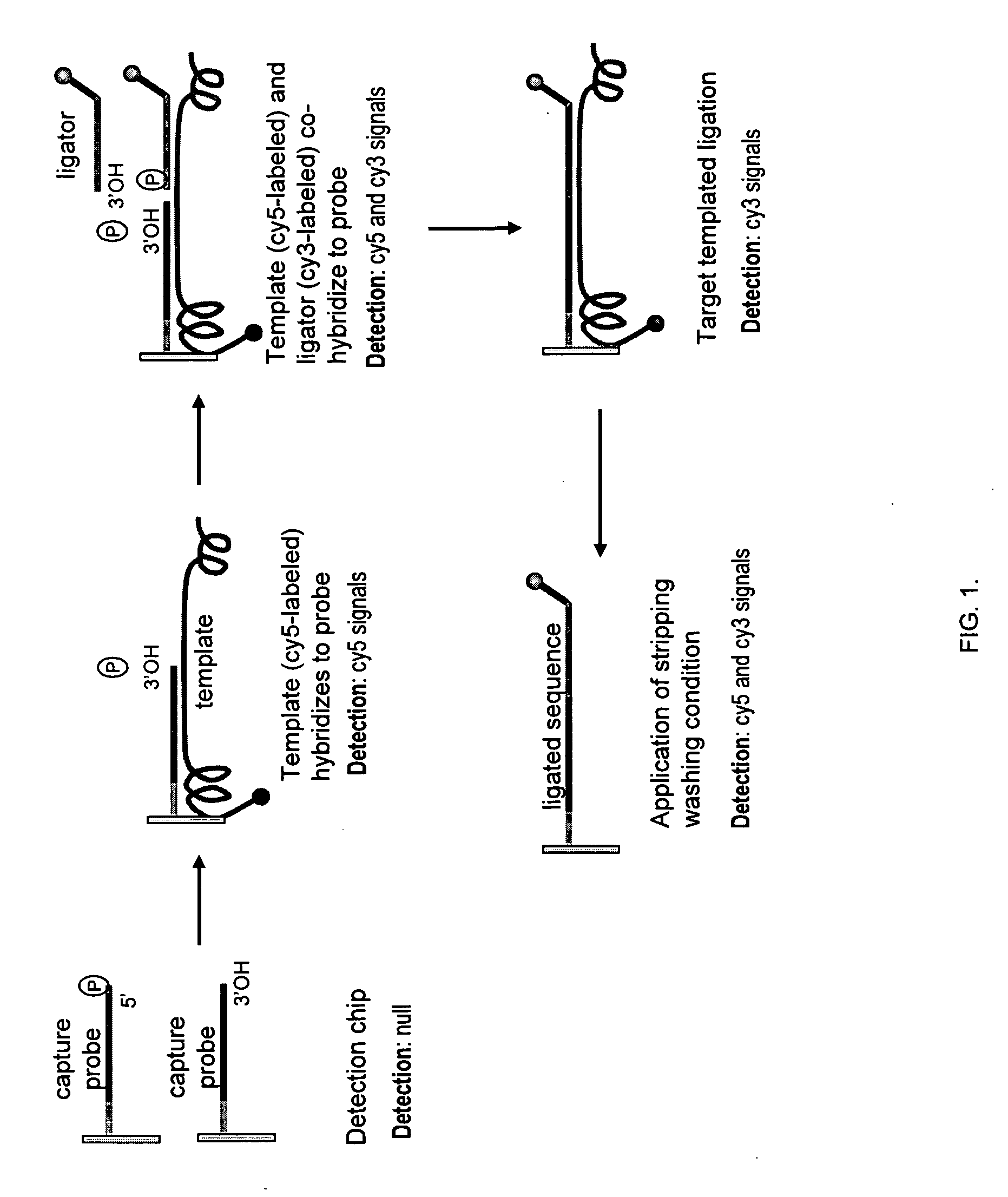

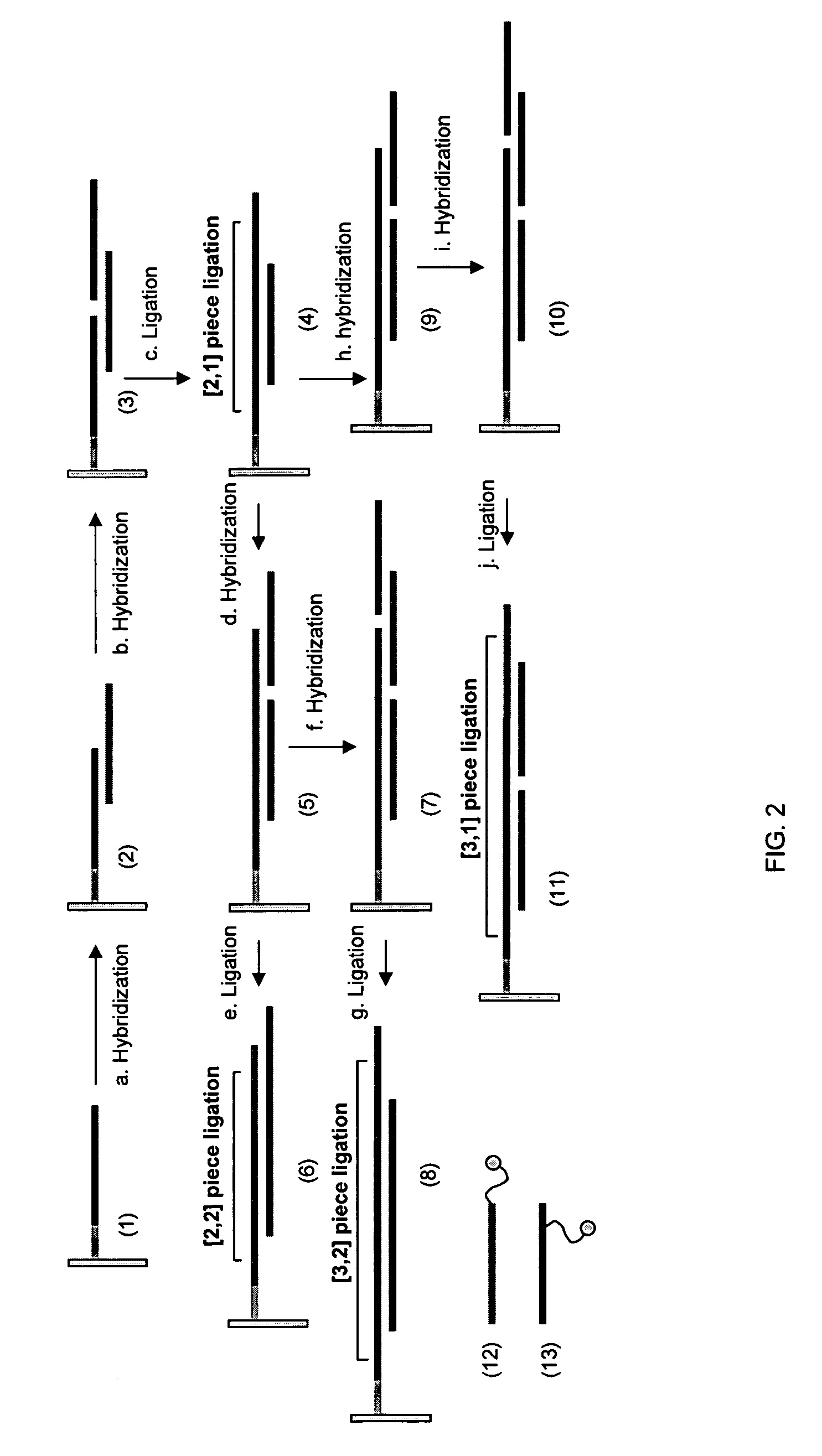

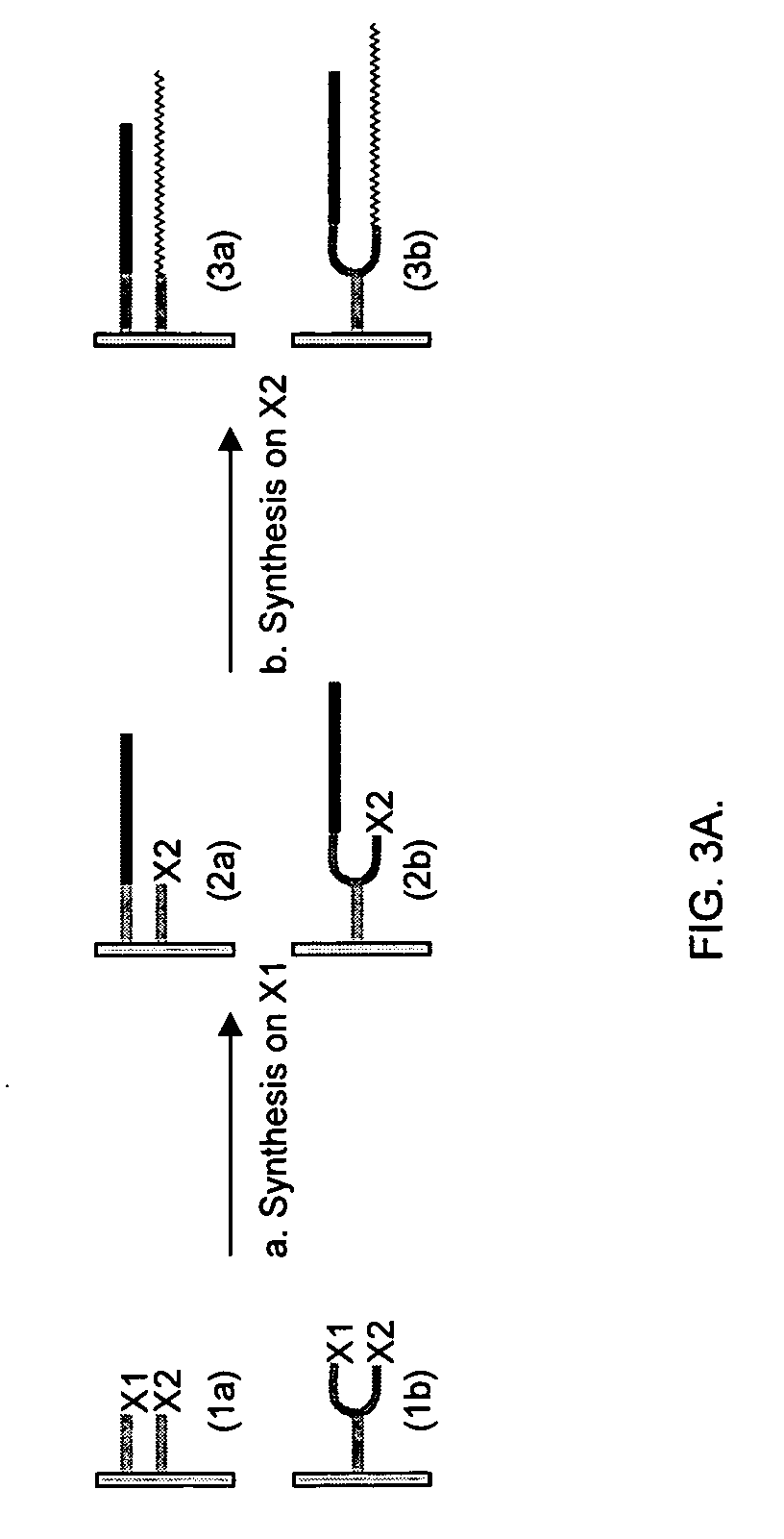

Making nucleic acid sequences in parallel and use

ActiveUS20070031942A1Strong hybridization specificityImprove fidelitySugar derivativesMicrobiological testing/measurementGenomicsSynthetic biology

The present invention relates generally to the fields of genomics, synthetic biology and genetic engineering. More particularly, the present invention concerns the methods that enable parallel multiplex ligation and amplification on surface for making assemblies of nucleic acids of various biological applications and for analysis of biological samples such as DNA, RNA, and proteins.

Owner:LC SCI LC

Method and apparatus for improving quality of composite video signal and method and apparatus for decoding composite video signal

InactiveUS7969511B2Improve picture qualityImprove composite qualityTelevision system detailsColor signal processing circuitsComputer graphics (images)Lightness

A method and apparatus for improving the quality of a composite video signal and a method and apparatus for decoding the composite video signal. The method for improving the quality of the composite video signal respectively detects edges from a luminance information signal and a chrominance information signal separated from the composite video signal, detects an artifact region using the detected edges, and filters the detected artifact region. Accordingly, an artifact can be effectively removed while preserving edge information and detail information of an image to improve picture quality.

Owner:SAMSUNG ELECTRONICS CO LTD

Manganese-doped inorganic halogen perovskite quantum dot, and preparation method and application thereof

ActiveCN108504356AReduce manufacturing costImprove production efficiencyInksNanotechnologyHalogenPhysical chemistry

The invention discloses a manganese-doped inorganic halogen perovskite quantum dot, and a preparation method and an application thereof. The preparation method comprises the following steps: dissolving lead salt and manganese chloride, and carrying out heating at 80 DEG C to 110 DEG C so as to obtain a halogen precursor; dissolving caesium salt so as to obtain a caesium precursor; adding the caesium precursor into the halogen precursor, and carrying out heating at 80 DEG C to 110 DEG C so as to obtain a quantum dot solution; and purifying the quantum dot solution so as to obtain the manganese-doped inorganic halogen perovskite quantum dot. The invention provides a method for high-yield preparation of the manganese-doped inorganic halogen perovskite quantum dot without the need of protection of inert gas at a low temperature. The method provided by the invention reduces preparation cost, improves preparation efficiency, and can be used for large-scale production. The quantum dot is applied to invisible ink which has good effect, is convenient to write and has stable invisible effect; meanwhile, after manganese is doped, the quantum dot has greatly-improved thermal stability and greatly-reduced toxicity.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for hydrogenated pyridine derivant and its salt

ActiveCN101343278AMild reaction conditionsEasy to scale up productionOrganic active ingredientsOrganic chemistryHalogenAcetic anhydride

The invention relates to hydrogenated pyridine derivates of 2-acetoxy-5-(Alpha-cyclopropyl carbonyl-2-fluorobenzyl)-4, 5, 6, 7-tetrahydrothiophene-[3, 2-C] pyridine as well as a preparation method of salt thereof. The method is to prepare two key intermediates of an Alpha-cyclopropyl carbonyl-2-fluorobenzyl halogen 2 (wherein, X=F, CL, Br and I) and a 2-oxygen-2, 4, 5, 6, 7, 7 Alpha-hexahydrothiophene-[3, 2-C] pyridine salt 3 (wherein, HA=HCL, H2SO4, HBr, HI, etc.), and to obtain the target product by esterifying products acquired through condensing the two key intermediates with acetic anhydride. The target product and the required acid addition salt are added with the needed crystal seed for obtaining crystals with a single crystal form in the process of crystallization.

Owner:LUNAN PHARMA GROUP CORPORATION

Virtual viewpoint synthesis method based on GPU acceleration

InactiveCN104822059AQuality improvementIncrease compositing speedSteroscopic systemsGraphicsViewpoints

The invention discloses a virtual viewpoint synthesis method based on GPU acceleration, and a high-quality virtual viewpoint image is synthesized in an accelerating manner by utilizing a depth image based rendering (DIBR) technology and a GPU multithreading parallel characteristic. The method comprises the following steps: firstly, performing smoothing processing on depth images of a left reference viewpoint and a right reference viewpoint; secondly, restoring two-dimensional plane coordinates of various pixel points in the depth images, after the smoothing processing, of the left reference viewpoint and the right reference viewpoint to a three-dimensional space through 3D mapping; then projecting coordinates in the three-dimensional space to a virtual viewpoint imaging plane by using graphics API rendering so as to obtain a synthetic virtual viewpoint image; and, finally, performing hole filling of the synthetic virtual viewpoint image. The method can utilize a powerful parallel computing ability of a GPU, accelerate a traditional virtual viewpoint synthesis algorithm, effectively reduce rendering time, and provide a great reference for real-time virtual viewpoint synthesis.

Owner:SOUTHEAST UNIV

Alkali resistant ceramic coating material and preparation method thereof

The invention relates to an alkali resistant ceramic coating material and a preparation method thereof which are mainly applied in lithium battery production. The alkali resistant ceramic coating material is characterized by being formed by mixing the raw materials including composite powder, a binding agent and an additive, and the raw materials comprise, by mass, 50 parts of the composite powder, 10-40 parts of the binding agent and 15-40 parts of the additive. The alkali resistant ceramic coating material has the advantages that the coating is good in alkali resistance, capable of being fired in a wide temperature range and low in preparation cost.

Owner:WUHAN UNIV OF TECH

Process for rolling inner-corrugated combined surface metal composite tube

The invention provides a process for rolling an inner-corrugated composite surface metal composite tube. The process for rolling the inner-corrugated composite surface metal composite tube comprises the steps: selecting a metal parent tube and a metal coated tube, and manufacturing a tube blank by combining the coated tube outside and the parent tube inside, wherein the deformation resistance of the coated tube is smaller than the deformation resistance of the parent tube; rolling the manufactured composite tube blank in a composite roughing mill, in which a spiral corrugated mandril is mounted, thereby obtaining a composite tubular billet, the inner surface and the composite surface of which have a spiral corrugated shape, wherein the spiral corrugated shape can be circular arc, ellipse, sine wave, triangle, trapezoid or rectangle, the corrugated height is (0.1-10) times of the thickness of the coated tube, and the width of the corrugated is (3-20) times of the height of the corrugated; putting the composite tubular billet in a composite finishing mill, in which a smooth circular hole is formed, to roll the corrugated shape of the inner surface to be level and round till the required tube wall thickness is obtained, thereby obtaining a composite tube. According to the process for rolling the inner-corrugated composite surface metal composite tube, by utilizing corrugated composite surfaces of the roughly rolled coated tube and parent tube, the difference of metal plastic deformation caused by dissimilar metal deformation resistance difference is solved, the composite strength and force of metal layers are increased, and the composite rate is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

New manufacture technique of duplex metal composite lining board

InactiveCN101332558AImprove composite qualityImprove wear resistanceGearingCylindersWear resistantHeight difference

The invention discloses a new manufacturing process of a bimetal compound scaleboard, which comprises molding and pouring and includes the following steps: (1) a thin steel plate (C) welded with a steel shore (D) is put into a mold cavity, the thin steel plate (C) divides the mold cavity into a wear resistant layer (A) and an ordinary steel layer (B); (2) when pouring, the wear resistant layer (A) is poured first, when the height of the molten steel reaches 1cm, the ordinary steel layer (B) is poured, the height difference between the liquid in the two mold cavities is constantly kept at 2cm; 3) the temperature is increased to 980 DEG C, the heat preservation time is calculated according to the thickness of the liner by 0.5h / cm, after the heat preservation, the hardness of the scaleboard reaches 61-62HRC by quenching and the shock value reaches 8-10J / cm<2>. The new production process of the bimetal compound scaleboard simplifies the pouring process, improves the compounding quality of the scaleboard, improves the wear resistant property of the scaleboard, can prevent the scaleboard from fracture, and reduces the maintenance cost.

Owner:张剑鑫

A video data synthesis method and a device

ActiveCN109040641AImprove composite qualityInhibit synthesisTelevision system detailsColor television detailsPattern recognitionSynthesis methods

The invention provides a video data synthesis method and a device, which relate to the technical field of video processing. The method comprises the following steps: acquiring an original audio signaland an original image signal; separating the original audio signal into a plurality of sub-audio signals; identifying mouth shape characteristic information of a target object from the original imagesignal; determining a target sub-audio signal matching the mouth shape characteristic information from the plurality of sub-audio signals; synthesizing the target sub-audio signal and the original image signal into video data. According to the mouth shape characteristic information of the target object in the original image signal, the sound of the target object is accurately determined, and thetarget sub-audio signal and the original image signal are synthesized into video data, thereby avoiding synthesizing the ambient sound signal, recording only the sound of the target object in the synthesized video, avoiding the influence of the ambient sound on the sound of the target object, and improving the synthesizing quality of the video data.

Owner:VIVO MOBILE COMM CO LTD

Quick microwave synthesizing-sintering preparation method of ZrNiSn bulk thermoelectric material

The invention discloses a quick microwave synthesizing-sintering preparation method of a ZrNiSn bulk thermoelectric material and belongs to the technical field of thermoelectric material preparation methods. The quick microwave synthesizing-sintering preparation method of the ZrNiSn bulk thermoelectric material comprises the following steps: preparation and cold-pressing forming of raw materials, microwave synthesis, crushing, ball milling and secondary cold-pressing forming of ZrNiSn thermoelectric alloy, and microwave sintering. According to the method, microwave synthesis and microwave sintering are combined, and various processing parameters in the synthesizing and sintering processes are controlled, so that in-situ nano-crystals precipitation from tissues of the ZrNiSn thermoelectric material is realized, accordingly, the thermal conductivity of the ZrNiSn thermoelectric material is remarkably reduced, and the single-phase ZrNiSn bulk thermoelectric material with superior thermoelectric property and uniform tissue and performance distribution is obtained.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

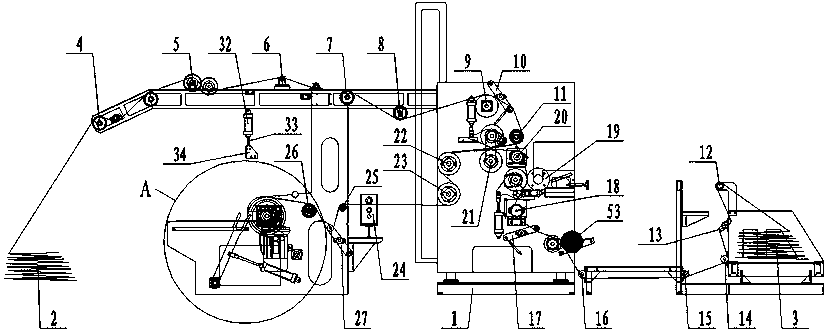

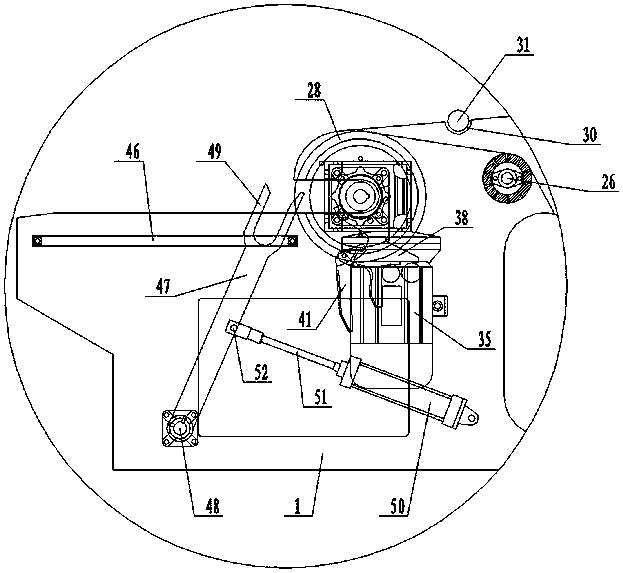

Full-automatic hot melt adhesive composite machine

ActiveCN107934619ACompact structureImprove composite qualityArticle deliveryWebs handlingAgricultural engineeringHot-melt adhesive

The invention discloses a full-automatic hot melt adhesive composite machine. The full-automatic hot melt adhesive composite machine comprises a machine frame, a front feeding device and a rear feeding device wherein the front feeding device is arranged at the front end of the machine frame, and the rear feeding device is arranged at the rear end of the machine frame; a cloth pulling rubber rolleris arranged on the position, at the rear end of the front feeding device, of the machine frame; a separating spreading roller is arranged on the position, at the rear end of the cloth pulling rubberroller, of the machine frame; a deviation correcting device is arranged on the position, at the rear end of the separating spreading roller, of the machine frame; a first supporting roller is arrangedon the the position, at the rear end of the deviation correcting device, of the machine frame; a first full-width roller is arranged on the position, at the rear end of the first supporting roller, of the machine frame; a cloth feeding rubber roller is arranged on the position, at the rear end of the first full-width roller, of the machine frame; a first tension controller is arranged on the position, at the rear end of the cloth feeding rubber roller, of the machine frame; an aluminum full-width roller is arranged on the position, at the lower end of the first controller, of the machine frame; and a first traction roller, a cloth expander and a second traction roller are arranged on the position, at the front end of the rear feeding device, of the machine frame from top to bottom.

Owner:JIANGSU JINFENG LIGHT IND EQUIP CO LTD

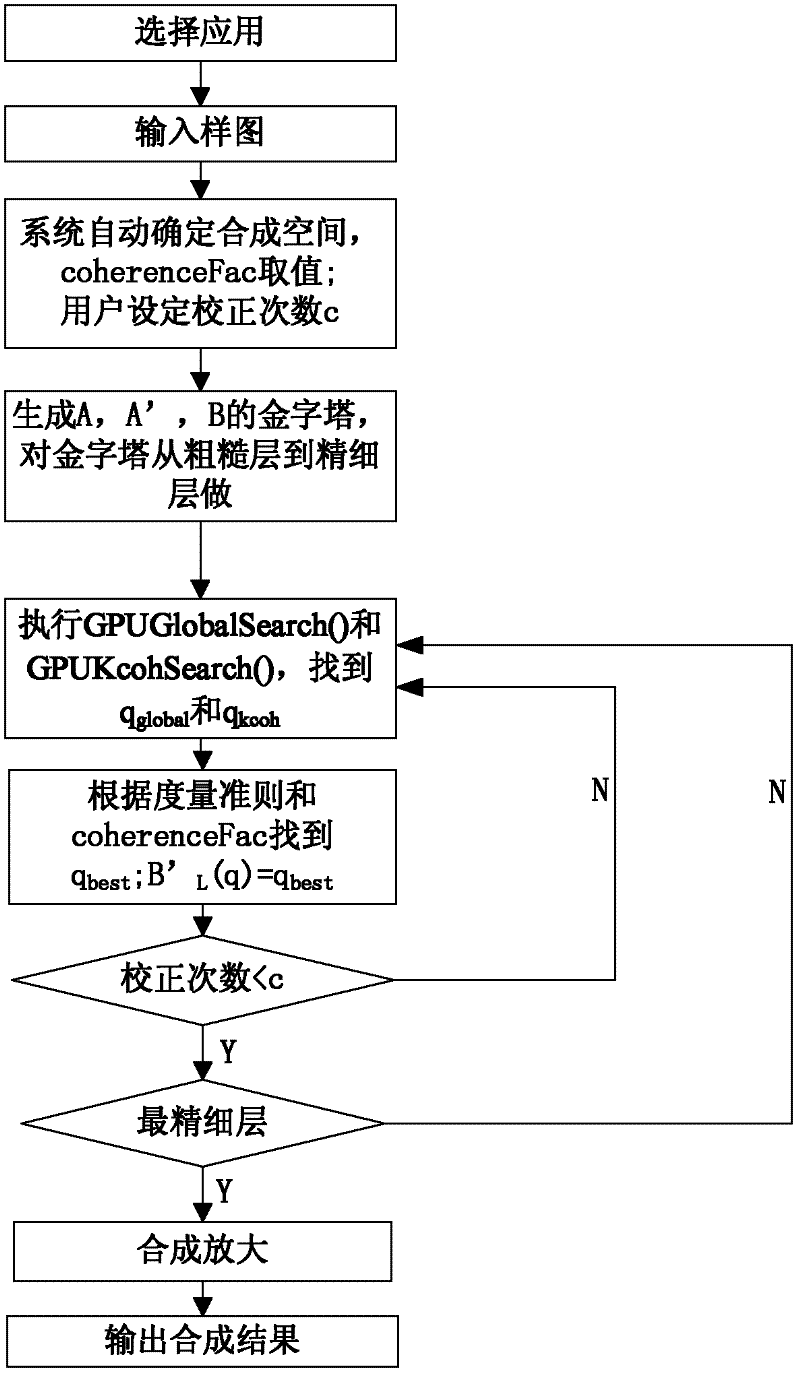

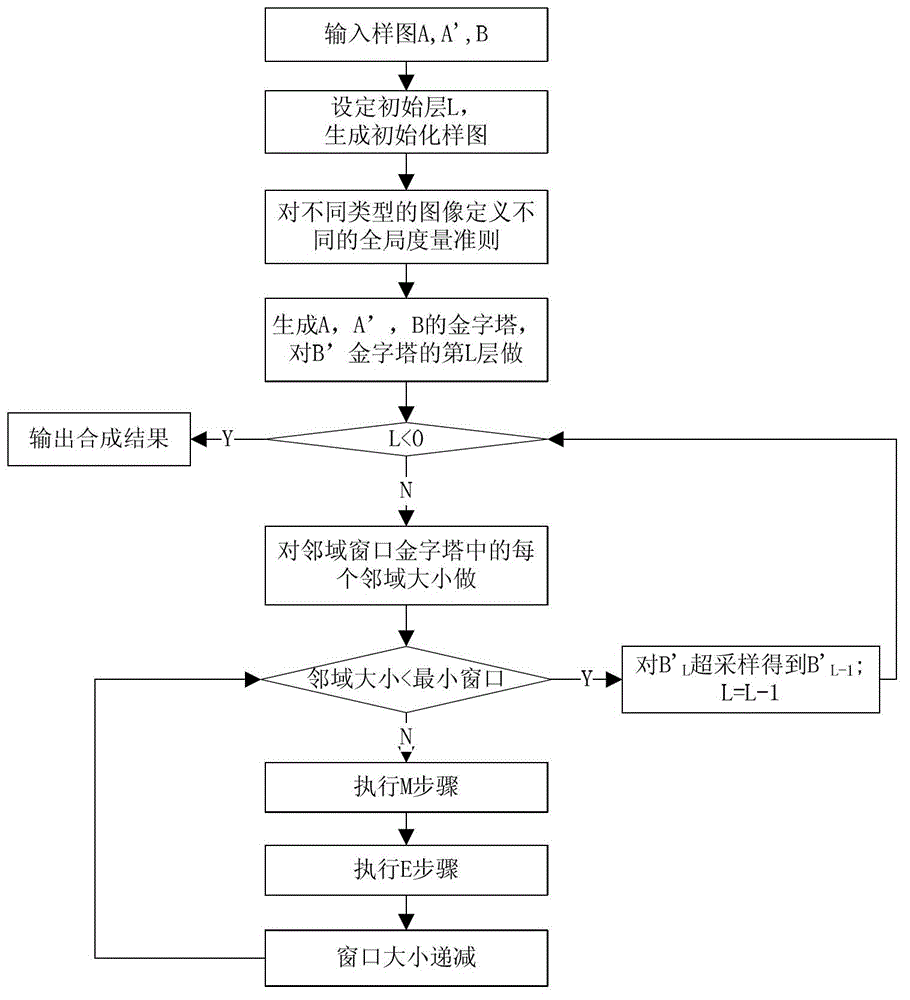

Fast image analogy analysis method based on compute unified device architecture (CUDA)

ActiveCN102646271AInnovative ideasBreak the time limitImage enhancementSynthesis methodsSource image

The invention provides a fast image analogy analysis method based on a compute unified device architecture (CUDA). The method comprises the following steps that: 1) a source image A, a filtered image A' and a Gaussian pyramid of a source image B are generated; 2) an L-th layer is synthesized at present, and the following processes are executed for the pyramid from a coarse layer to the fine layer: 2.1) carrying out super sampling on B'L+1 to obtain B'L; 2.2) adopting a global search strategy eglobal based on a graphics processing unit (GPU) for each pixel point q in the B'L; 2.3) for each pixel point q in the B'L, adopting a k-coherence search strategy based on the GPU for finding consistency search optimal solution qkcoh; 2.4) giving aglobal as the value to qBest if the results obtained through the global search are better, otherwise, giving qkcoh as the value to the qBest, and storing the corresponding coordinates of the qBest in the A'L into the B'L(q); and 2.5) cyclically executing the steps 2.2) to 2.4) for setting the times; and 3) the B' is subjected to synthesis amplification to obtain high-resolution EHB'. The method has the advantages that the synthesis speed is accelerated, and the synthesis quality is improved.

Owner:ZHEJIANG UNIV OF TECH

Zone melting and directional solidifying method used for volatile element alloy

InactiveCN103343238AAxial components are evenly distributedEvenly distributedBy zone-melting liquidsIncreasing energy efficiencyCrucibleZone melting

The invention discloses a zone melting and directional solidifying method used for a volatile element alloy. The method comprises the following steps of: selecting raw metals according to alloy components; matching the raw metals selected; smelting into an initial alloy bar; transferring into a directional solidifying crucible; fully filling slag forming constituents into a clearance between the initial alloy bar and the directional solidifying crucible; transferring the directional solidifying crucible into a directional solidifying device; and heating through an induction coil to realize zone melting of the initial alloy bar and the slag forming constituents, wherein volatile components of the alloy are prevented from volatilizing through the molten slag forming constituents, and the slag forming constituents react with impurities in the alloy to generate molten slag; the directional solidifying device downwards moves relative to the induction coil to accomplish the zone melting and directional solidifying of the whole initial alloy bar; the molten slag is continuously generated and floats upwards, and then stops on the top of the alloy and finally is removed. By adopting such directional solidifying method, the consumption in volatilizing of the volatile element of the alloy can be greatly reduced during solidifying, the impurities and air pores are removed at the same time, and the alloy with components approaching to design components and having a uniform distribution an axial direction can be obtained.

Owner:SHANGHAI JIAO TONG UNIV

Compounding device for inner liners

The invention discloses a compounding device for inner liners, which is used for tyre production. The compounding device comprises a second conveying belt, and a press roll device, wherein the press roll device comprises a support and a second press roll; the second press roll is arranged on the support by means of being capable of moving up and down, and located just above the second conveying belt; and the axis of the second press roll is vertical to the rotating direction of the second conveying belt. During the use of the compounding device, the jointed inner liners are placed on the second conveying belt, and then the second press roll capable of moving up and down is moved to a proper height, and used for performing press fit on the inner liners on the second conveying belt; and simultaneously, the second conveying belt is rotated, so that the inner liners are subjected to press fit sequentially via the second press roll until press fit for all the inner liners is finished. Compared with the operation for press fit carried out by an operator using a manual press wheel, the compounding device for inner liners provided by the invention has the advantage that multilayer glue components in the inner liners are uniformly compacted section by section, so as to realize no air bubbles and no wrinkles; and therefore, the quality of compounding the inner liners can be greatly improved.

Owner:SHANDONG JINYU INDUSTRIAL CO LTD

Device and method for casting large-sized compound steel ingot by using graphite electrode ring for preheating electroslag

The invention provides a device and method for casting a large-sized compound steel ingot by using a graphite electrode ring for preheating electroslag. The device comprises a T-shaped electric conduction crystallizer, supporting arms and a lined electroslag furnace, wherein two transverse arms on a support are respectively used for lifting and dropping the graphite electrode ring and a self-consuming electrode ring; the lined electroslag furnace is used for slagging and pouring premelting slag into the T-shaped electric conduction crystallizer; and an annular bottom water tank is arranged onan ingot introducing plate. The method comprises the following steps of: (1) putting a core rod in the T-shaped electric conduction crystallizer, slagging the premelting slag in the lined electroslagfurnace, and forming a slag tank by pouring; (2) lowering the graphite electrode ring, and causing the graphite electrode ring, the slag tank, the upper crystallizer, a casting power source and the traverse arms to form an electric conduction loop, and heating the surface of the core rod and the slag tank by electrifying; and (3) when a preset temperature reaches, moving away the graphite electrode ring, inserting the self-consuming electrode ring into the slag tank, and carrying out electroslag casting. The method has high utilization rate of heat, can prevent interlayer slag from being generated on the compound interface of the steel ingot, facilitates the improvement of the quality of the steel ingot and simplifies the production equipment.

Owner:NORTHEASTERN UNIV LIAONING

Solvent-free adhesive for high-wettability flexible packaging compounding and preparation method thereof

ActiveCN105969289AAvoid insecurityAvoid Spots and BubblesPolyureas/polyurethane adhesivesPrepolymerSolvent free

The invention belongs to the technical field of high-polymer adhesives, and discloses a solvent-free adhesive for high-wettability flexible packaging compounding and a preparation method thereof. The adhesive is prepared by mixing an isocyanate-terminated prepolymer component and a hydroxy polyester polymer component according to the weight ratio of 100:50 at 45-55 DEG C. The mass percent of the isocyanic acid group in the isocyanate-terminated prepolymer component is 12.5-15%, and the viscosity at 25 DEG C is 3500-5500m Pa.s. The hydroxy polyester polymer component is formed by mixing a polyhydroxy polyester polymer and a high-efficiency leveling and wetting component polymer according to the weight ratio of (70-80):(20-30), the hydroxyl value is 150-200mg KOH / g, the functionality is 2.1-2.5, and the viscosity at 25 DEG C is 1500-3000m Pa.s. The adhesive prepared by the method enhances the bonding power with the composite substrate, and avoids spots and bubbles; the surface tension of the adhesive is lowered, so the adhesive has favorable wetting and leveling properties; and the adhesive reduces the generation of carcinogen aromatic amines, and thus, is environment-friendly and sanitary.

Owner:杨川

Texture optimization-based non-homogeneous image synthesis method

The invention discloses a texture optimization-based non-homogeneous image synthesis method. The image synthesis method comprises the following steps of: 1) generating a tag image A, a color image A', and a Gaussian pyramid of a new tag image B, wherein AL, A'L, BL, and B'L indicate the Lth layer of the pyramid; 2) setting an initial layer L, and generating an initial master drawing; 3) defining different global measurement rules for different types of images; and 4) starting from the roughest layer L and performing the following steps on the pyramid from a rough layer to a fine layer circularly: 4.1) performing the steps on each neighbourhood in a neighbourhood window pyramid winSizePyr of the layer: 4.1.1) executing the step M according to the AL, the A'L, the BL and the B'L to obtain Match L; and 4.1.2) executing the step E according to the AL, the A'L, the BL, the B'L and the Match L to obtain optimized new B'L; and 4.2) performing super-sampling on the B'L to obtain B'L-1. The texture optimization-based non-homogeneous image synthesis method is high in synthesis speed, high in synthesis quality and high in synthesis efficiency.

Owner:ZHEJIANG UNIV OF TECH

Method for reducing impurity content of CVD (chemical vapor deposition) synthetic diamond

ActiveCN109355702AAvoid introducingImprove composite qualityPolycrystalline material growthFrom chemically reactive gasesPolycrystalline diamondThermal conductivity

The invention provides a method for reducing the impurity content of CVD (chemical vapor deposition) synthetic diamond. A polycrystalline diamond coating is arranged on a substrate, and the diamond isused for covering the substrate to prevent substrate etching from leading to introduction of impurity atoms. The method has the advantages that a polycrystalline diamond film is deposited on the surface of the substrate, contact between diamond seed crystals and the foreign substrate is blocked, the impurity atoms of the substrate are effectively isolated, and the synthesis quality of the monocrystal diamond is improved; the substrate is coated with the polycrystalline diamond coating, and the surface roughness of the substrate is enhanced, so that the remarkable effect on position fixation of the diamond seed crystals is achieved, limited space can be utilized maximally, the monocrystal diamond can be synthesized as much as possible, and the cost can be reduced; the thermal conductivityof the polycrystalline diamond coating is high, the temperature uniformity of the diamond seed crystals is enhanced, and stable growth of the monocrystal diamond for a long time is benefited; the method is applied to the field of diamond synthesis.

Owner:航天科工(长沙)新材料研究院有限公司

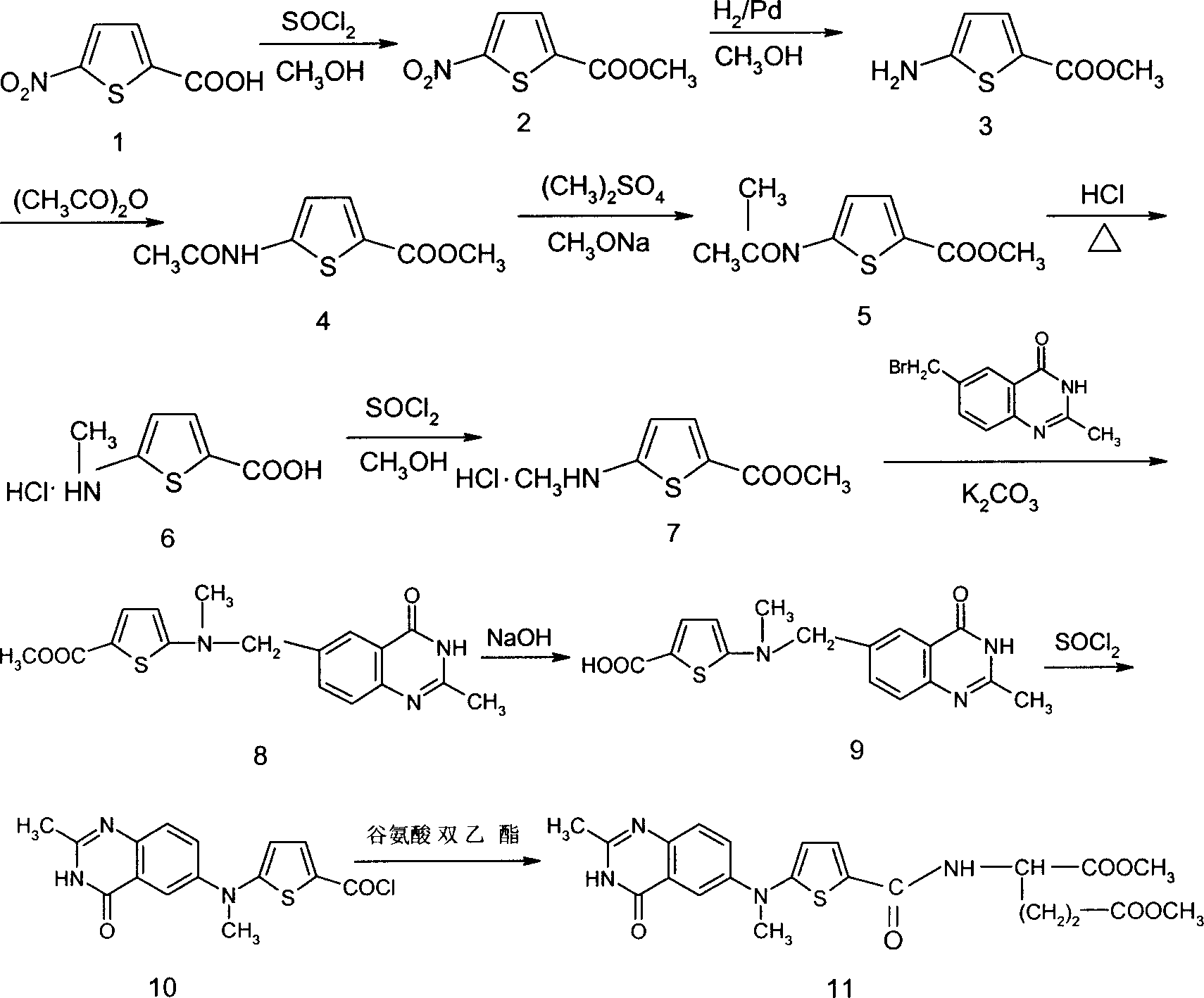

Preparation of Leiliqusai

A process for preparing Leitiqusai from 5-nitro-thiophene-2-formate through esterifying, nitro reduction, acetylation, methylation, hydrolysis, esterification nucleophilic substitution, hydrolysis, acylation, amide nucleophilic substitution, hydrolysis and acidification. Its advantages are high output rate and low cost.

Owner:LUNAN PHARMA GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com