Zinc-aluminium vacuum evaporation coating machine

A technology of vacuum evaporation and coating machine, which is used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

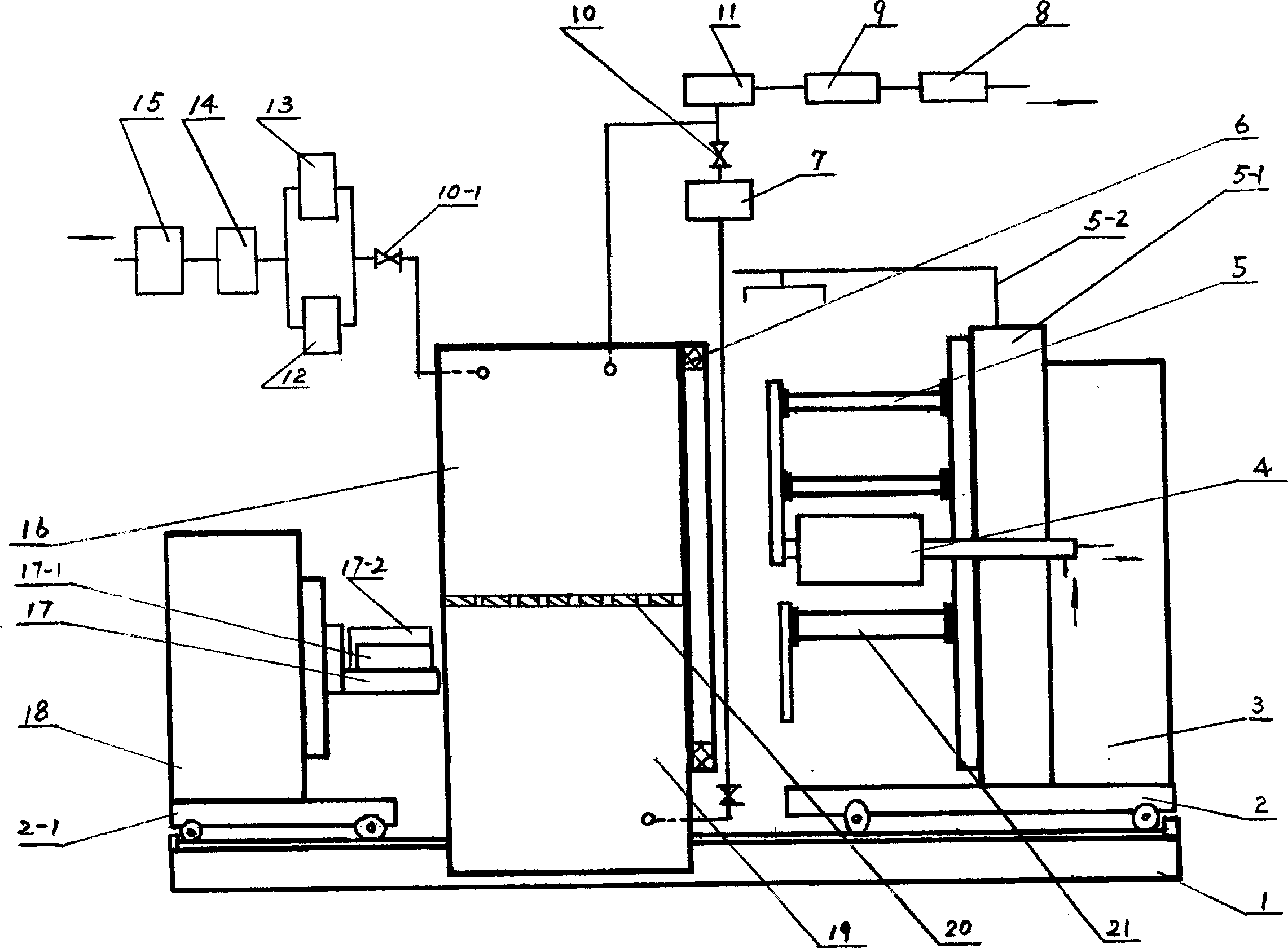

[0008] See accompanying drawing 1, the complete machine that implements computer control is seated on the chassis 1, is provided with track on the chassis 1, can be seated on the freezer 3 on the main frame 2 by the roller of the main frame 2, and the freezer 3. The film transfer frame box 5-1 connected in parallel and the film transfer frame box 5-1 are provided with the main shaft 4, the film transfer frame 5, and the shielding bracket 21 to move along the track. The vacuum chamber 6 includes the grid plate 20 and communicates with each other. The two parts of the winding chamber 16 and the coating chamber 19 are fixed on the chassis 1. The opening of the winding chamber 16 of the vacuum chamber 6 faces the main shaft 4 and the film transfer frame 5, and the opening of the coating chamber 19 faces the evaporation source 17. Zinc and aluminum crucibles 17-1 and 17-2 are arranged successively on the source 17, and the evaporation boat 17 is fixed on the side wall of the heating...

Embodiment 2

[0012] See accompanying drawing 1, the second vacuum system is a booster pump 12, is communicated with the coiling chamber 16 of vacuum chamber 6 by pipeline, valve 10-1, and the other end is connected Roots pump 14, slide valve pump 15 by pipeline, slide valve The other end of valve pump 15 communicates with atmosphere, and all the other are identical with embodiment 1, do not repeat narration again;

Embodiment 3

[0014] See accompanying drawing 1, the zinc pot 17-1 that carries on the evaporating boat 17 does not work, according to the aluminum pot 17-2 temperature is constant at 1500 ℃ ± 10, aluminum is plated on the plastic film, all the other are the same as embodiment 1, no longer make Repeat the narrative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com