Large medium/high vacuum gas-bleeding unit and pumping process thereof

An air extraction unit, high vacuum technology, applied in vacuum evaporation plating, metal material coating process, mechanical equipment, etc., can solve the problems affecting the overall performance of the air extraction unit, long start-up time of the diffusion pump, and restrictions on the popularization and application of the unit , to achieve the effect of eliminating oil vapor pollution, saving equipment and improving the quality of vacuum products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 As shown, a kind of large-scale medium and high vacuum pumping unit provided by Embodiment 1 of the present invention includes a vacuum chamber 10, and the vacuum chamber 10 is connected with a rough pump 11, a traction molecular pump 12, a cryogenic water vapor pump 13 and A chemical adsorption pump 14 is connected, and the exhaust port of the traction molecular pump 12 is connected with a backing pump 15 . Wherein, a first vacuum valve 16 is provided between the vacuum chamber 10 and the rough pump 11, a second vacuum valve 17 is provided between the vacuum chamber 10 and the traction molecular pump 12, and a second vacuum valve 17 is provided between the vacuum chamber 10 and the cryogenic water vapor pump 13. There is a third vacuum valve 18 , a fourth vacuum valve 19 is provided between the vacuum chamber 10 and the chemical adsorption pump 14 , and a fifth vacuum valve 110 is provided between the exhaust port of the traction molecular pump 12 and ...

Embodiment 2

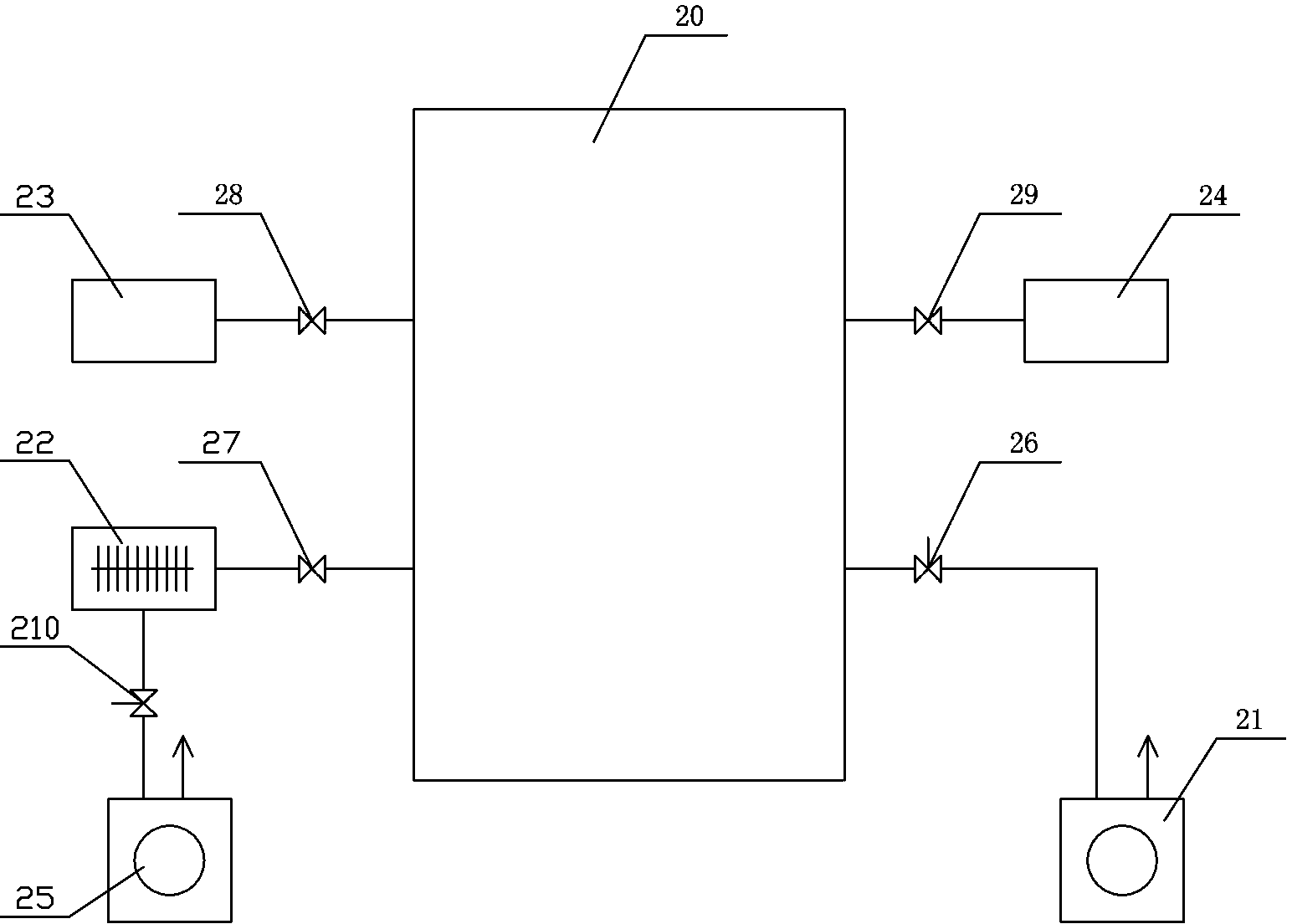

[0062] Such as figure 2 As shown, Embodiment 2 of the present invention provides an evaporation coating device, which adopts the exhaust unit described in Embodiment 1 to extract air.

[0063] The second embodiment is basically the same as the first embodiment, the difference being that the vacuum chamber 10 in the first embodiment is replaced by the coating chamber 20 . Specifically as follows: the second embodiment of the evaporation coating equipment includes a coating chamber 20, and the coating chamber 20 is connected with a rough pump 21, a traction molecular pump 22, a cryogenic water vapor pump 23 and a chemical adsorption pump 24 respectively, and the traction molecular pump 22 The exhaust port of the exhaust port is connected with a backing pump 25.

[0064] Wherein, a first vacuum valve 26 is provided between the coating chamber 20 and the rough pump 21, a second vacuum valve 27 is provided between the coating chamber 20 and the traction molecular pump 22, and a s...

Embodiment 3

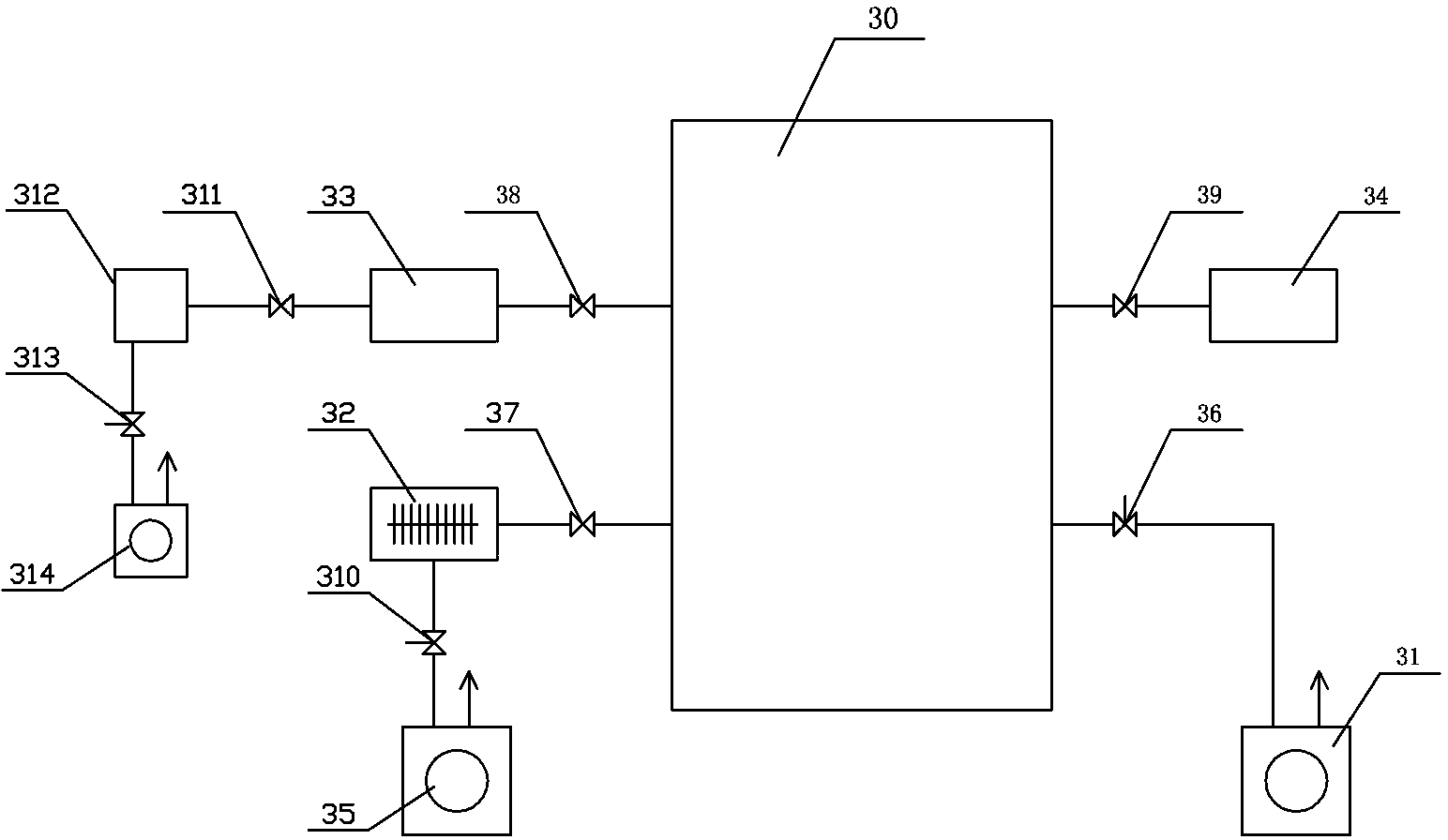

[0097] Such as image 3 As shown, the vacuum furnace provided in the third embodiment of the present invention adopts the exhaust unit described in the first embodiment to extract air.

[0098] The structure of the third embodiment is similar to that of the second embodiment, including a roughing pump 31, a traction molecular pump 32, a cryogenic water vapor pump 33, a chemical adsorption pump 34, a backing pump 35, a first vacuum valve 36, and a second vacuum valve 37 , the third vacuum valve 38, the fourth vacuum valve 39 and the fifth vacuum valve 310, the difference is that the coating chamber 20 in the second embodiment is replaced by the vacuum furnace cavity 30; The clean high vacuum pump (such as traction molecular pump) 312 is connected, and the exhaust port of the small clean high vacuum pump 312 is connected with the small rough pump 314 through the seventh vacuum valve 313, forming a regeneration device dedicated to the cryogenic water vapor pump 33.

[0099] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com