A vacuum pumping system for a wind tunnel body

A vacuum pumping system and cavity technology, applied in aerodynamic tests, measuring devices, instruments, etc., can solve problems such as pump and motor load rise, and achieve the effects of small airflow resistance, simple structure, and good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

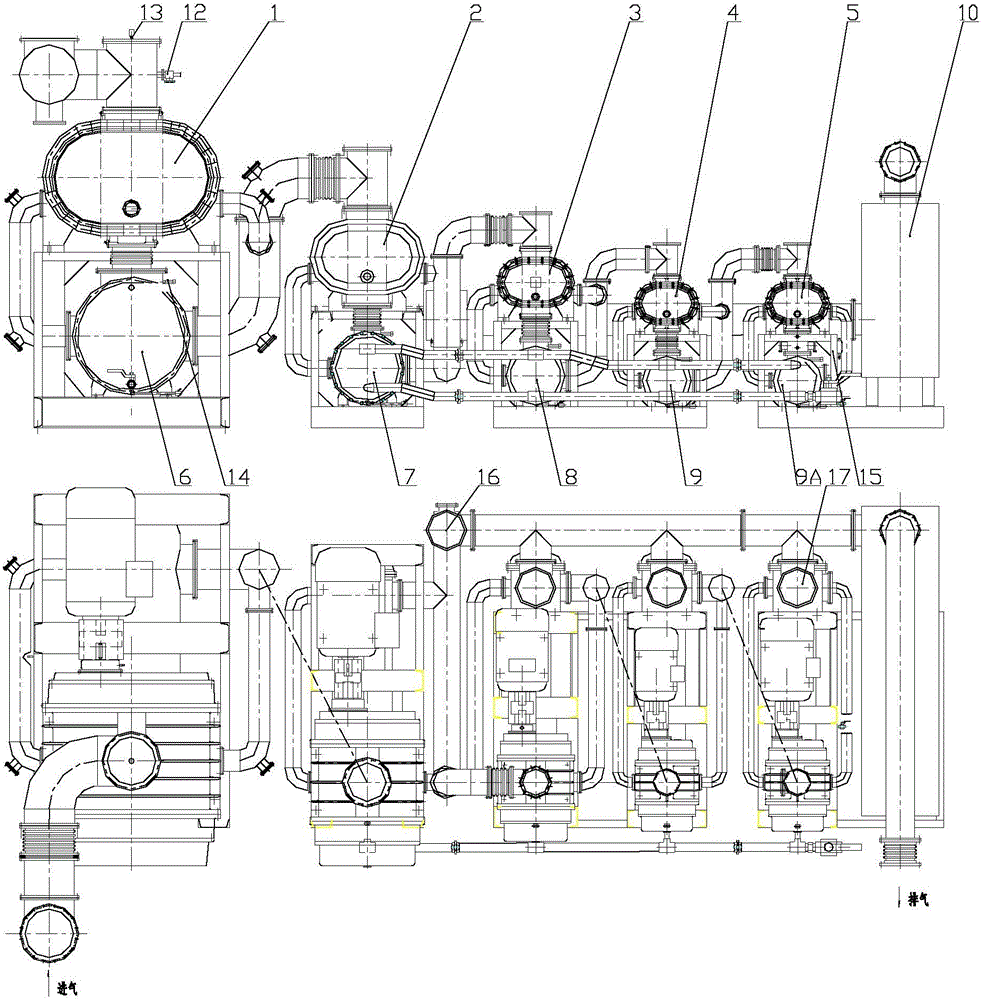

[0026] The wind tunnel body vacuum pumping system of the present invention is composed of a first-stage Roots pump 1, a second-stage Roots pump 2, a third-stage Roots pump 3, a fourth-stage Roots pump 4, a Five-stage Roots pump 5 connected in series to form a vacuum pumping unit. According to the needs, the system is also equipped with a first-stage heat exchanger 6, a second-stage heat exchanger 7, a third-stage heat exchanger 8, a fourth-stage heat exchanger 9, and a fifth-stage heat exchanger 9A , A muffler 10 forms.

[0027] The working principle of the present invention is as follows: the pumped gas passes through the first-stage Roots pump 1, the second-stage Roots pump 2 to the third-stage Roots pump 3, when the pressure at the inlet of the third-stage Roots pump 3 is higher than the exhaust pressure of the unit , then part of the pumped gas is directly discharged into the muffler through the overflow valve 16, and is directly discharged into the atmosphere through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com