Platemaking method and platemaking apparatus

A printing plate and modulator technology, which is applied in the field of plate making of printing plates and plate making devices of printing plates, can solve the problems of high power and long time of printing plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

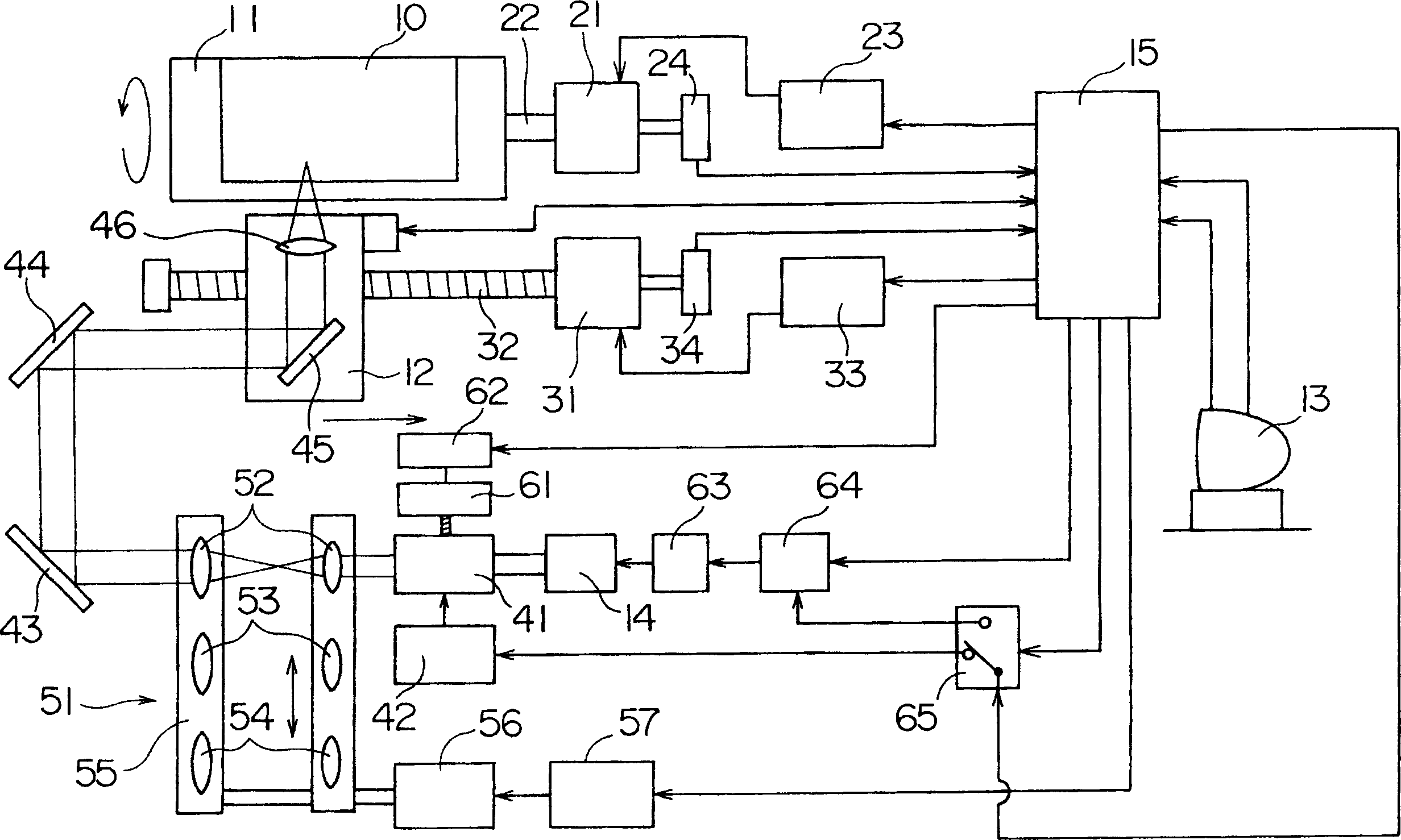

[0032] Embodiments of the present invention will be described below based on the drawings.

[0033] In the following description, first, the fine engraving process of engraving up to the maximum depth dp by irradiating the flexible photosensitive material 10 with the fine engraving beam L1 at the fine engraving pixel pitch pp, and the coarse engraving beam L2 at the coarse engraving pixel pitch pc irradiates the flexible photosensitive material 10 to engrave until the rough engraving step of the embossed depth d. The first feature of the present invention, which shortens the plate making time by performing engraving in two steps, will be described. The second feature of the present invention, which shortens the plate-making time while maintaining high plate-making accuracy, will be described.

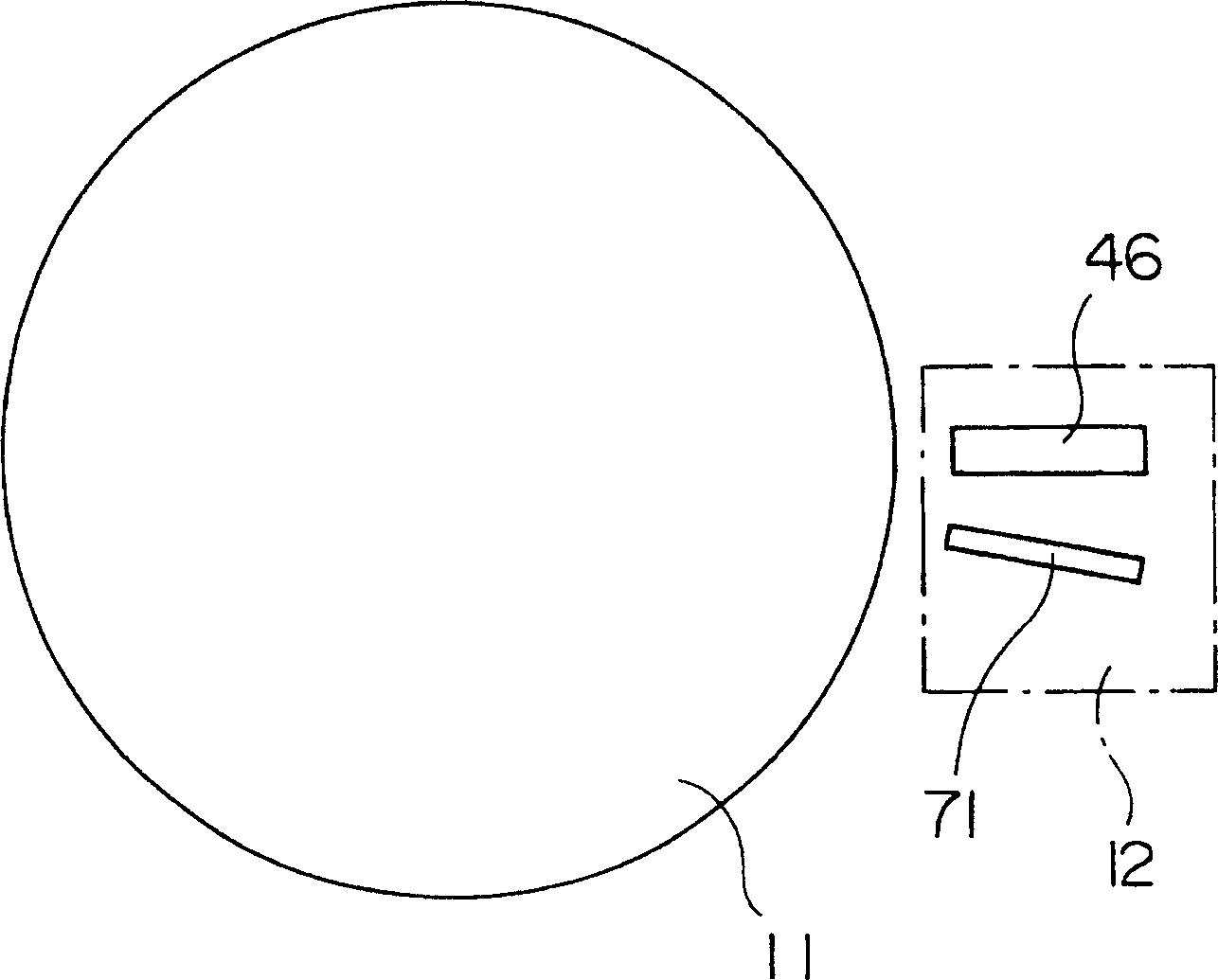

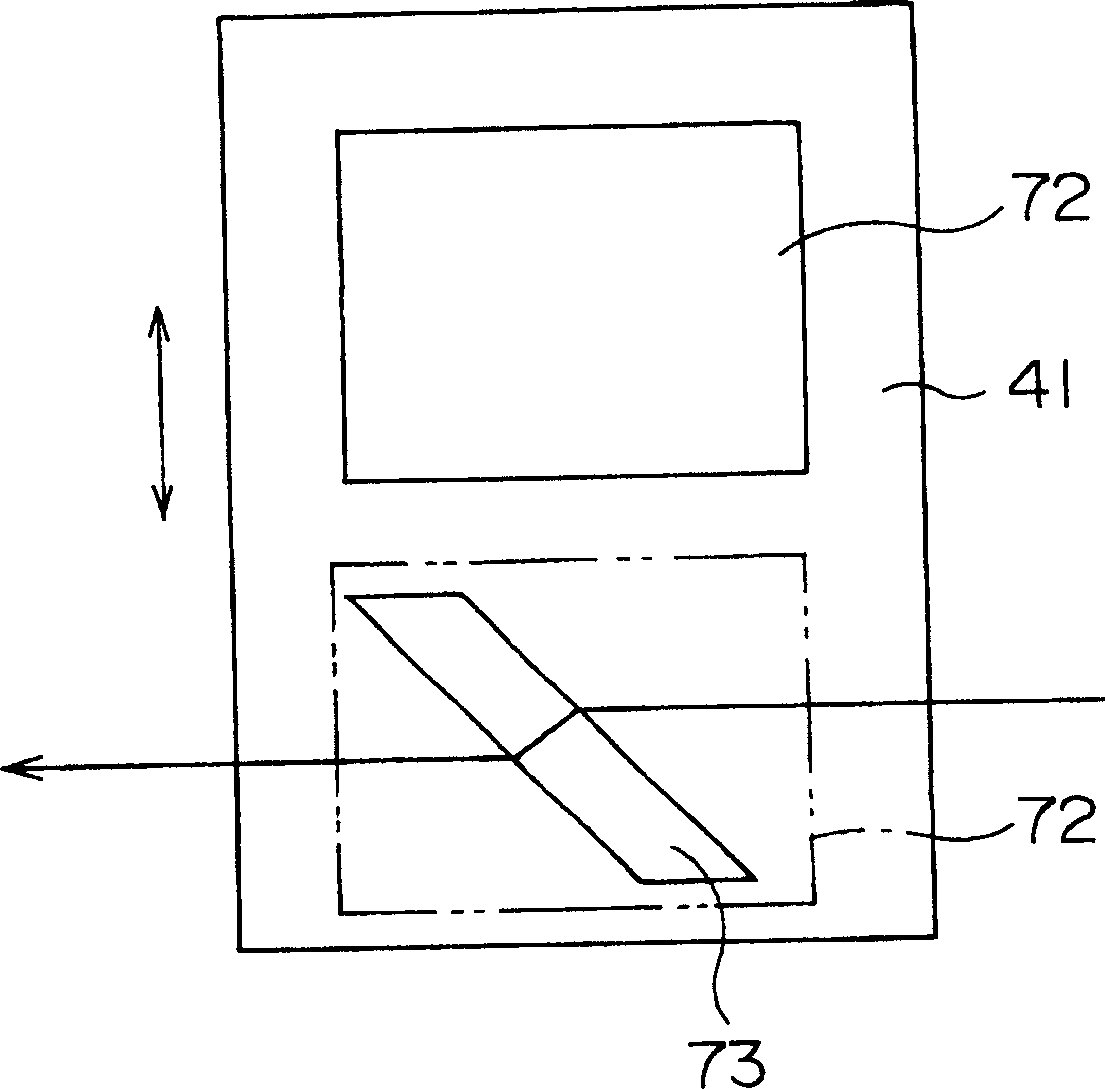

[0034] figure 1 It is a block diagram showing the outline of a laser engraving machine as a plate making device of a relief printing plate according to the present invention.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com