An intelligent screen-set plate-making process

A technology of nesting system and screen plate, which is applied in the field of intelligent screen plate making technology, can solve the problems of high repeated waste rate, high cost, and film pollution, so as to reduce the waste of manpower and material resources, improve work efficiency, Correction of high precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

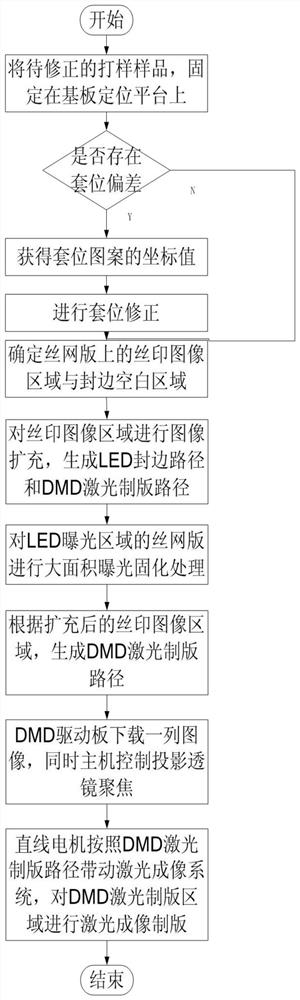

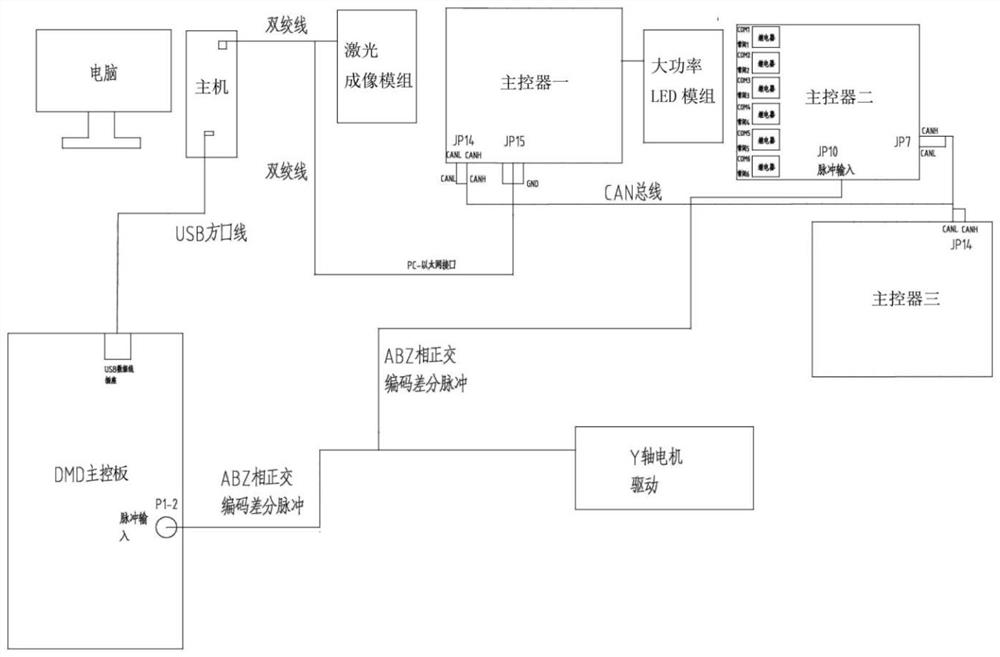

[0070] Embodiment 1 of the present invention discloses an intelligent silk screen register plate making process, which not only has high correction accuracy, but also greatly reduces the waste of manpower and material resources, abandons the traditional film plate making technology, adopts the laser direct plate making method, and improves the plate making efficiency At the same time, high-precision matching of laser imaging and silk screen plate making can be achieved.

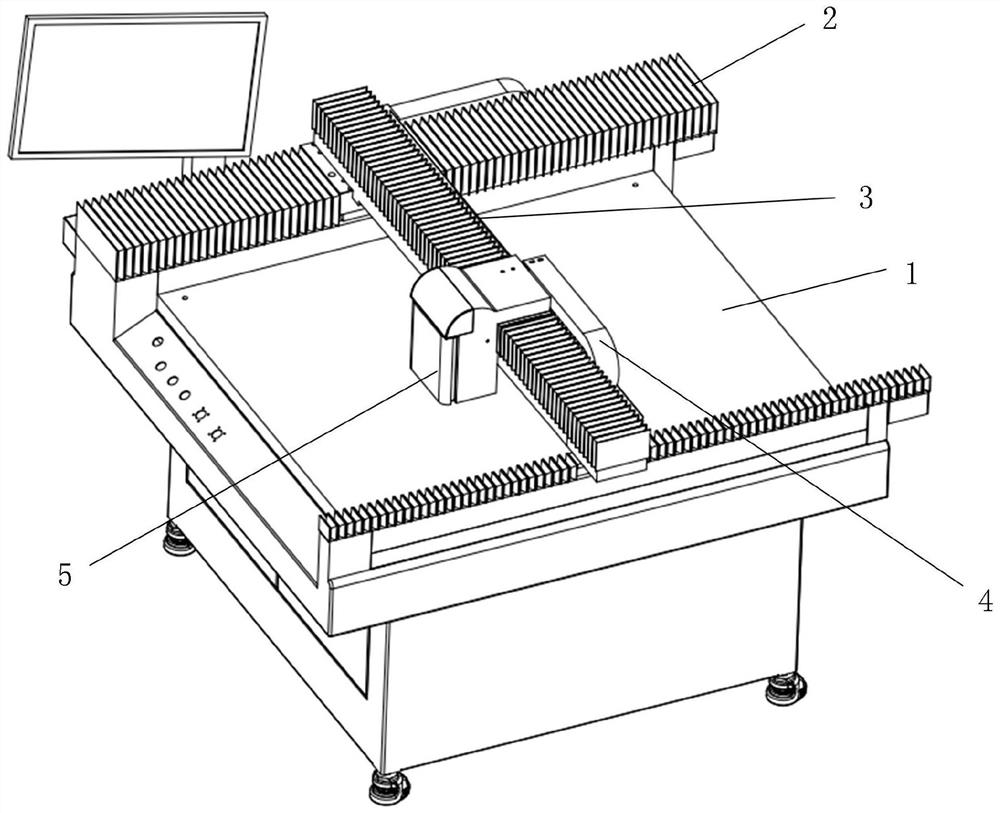

[0071] Attached Figure 1-5 , The present invention discloses an intelligent silk screen nesting plate making process, in which an intelligent positioning scanner includes: a substrate positioning platform 1, scanning X-axis guide rail 2, scanning Y-axis guide rail 3, scanning linear motor 4, camera 5 and Scanning control system;

[0072] Among them, the scanning X-axis guide rail 2 is fixed on both sides of the substrate positioning platform 1; the scanning linear motor 4 is installed on the scanning X-axis guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com