Method for extracting black fungus polysaccharide

A black fungus polysaccharide and extraction method technology are applied in the extraction field of black fungus polysaccharide, which can solve the problems of reducing bioavailability, easily destroying polysaccharide structure, etc., and achieve the effects of stable and fast ultrafiltration rate, shortening process time and low crushing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1 Materials and reagents

[0027]Black fungus (provided by Zhejiang Fulaisen Green Industry Group Co., Ltd.); absolute ethanol, concentrated sulfuric acid, glucose, and phenol, all of analytical grade.

[0028] 2 experimental equipment

[0029] UV-2000 ultraviolet spectrophotometer; HMB-701 ultrafine pulverizer; HELDS / BF laser particle size analyzer; RE-52A rotary evaporator; WVD-01 microwave vacuum drying oven.

[0030] 3 Experimental methods

[0031] 3.1 Black fungus crushing process

[0032] Get the black fungus of 200g, after ordinary mechanical coarse pulverization, sieve with 40 mesh standard sieves earlier, then adopt superfine pulverizer to pulverize under-sieve material, regulate and control superfine pulverizer fan speed to be 16000r / min, obtain black fungus Fungus superfine powder.

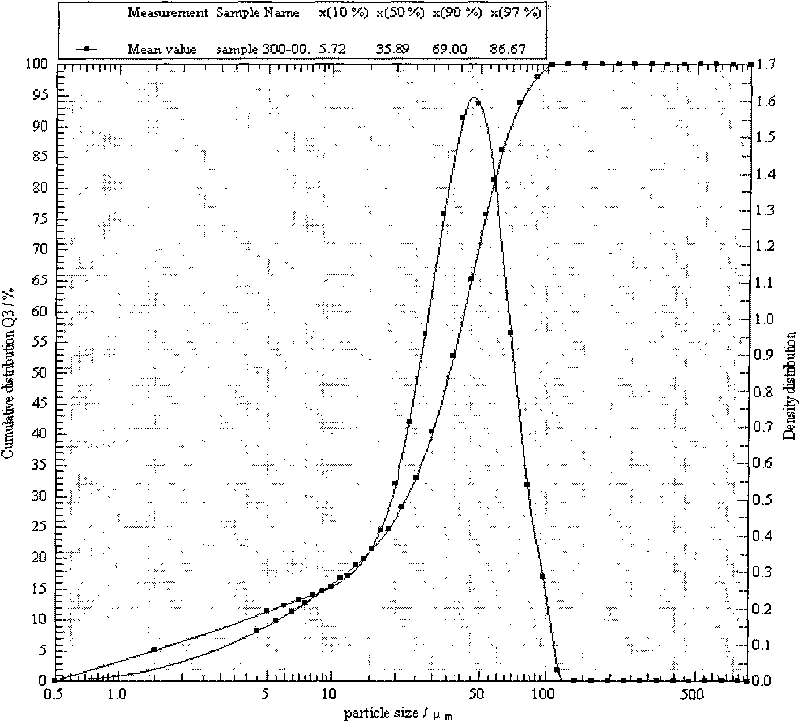

[0033] 3.2 Determination of particle size of dry powder obtained by superfine grinding of black fungus

[0034] Use the HELDS / BF laser particle size analyzer, adopt the VIBR...

Embodiment 2

[0051] The experimental operation is the same as that in Example 1, except that 20 g of black fungus ultrafine powder is added, 2000 g of water is added, and the temperature is 80 ° C. It is extracted with 18 KHz ultrasonic waves for 30 min, extracted twice, centrifuged, and combined to obtain the above two extractions. The supernatant liquid obtained was 1890ml of combined supernatant, and other operations and conditions were the same as in Example 1 to obtain 2.95g of black fungus polysaccharide, with a polysaccharide content of 43.18%, and the dissolution rate of black fungus polysaccharide was 14.75%.

Embodiment 3

[0053] The experimental operation is the same as that in Example 1, except that 20 g of black fungus superfine powder is added, 600 g of water is added, and the temperature is 40 ° C. It is extracted with 22 KHz ultrasonic waves for 50 min, extracted twice, centrifuged, and combined to obtain the above two extractions. Supernatant liquid obtained 530ml of combined supernatant, and other operations and conditions were the same as in Example 1 to obtain 2.59g of black fungus polysaccharide, with a polysaccharide content of 42.18%, and the dissolution rate of black fungus polysaccharide was 11.96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface area mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com