Method for producing corrugated paper by utilizing papermaking waste residues and sludge

A papermaking waste residue and production method technology, applied in papermaking, papermaking machines, textiles, papermaking, etc., can solve problems such as environmental pollution and safety hazards, waste of land and forest resources, etc., to avoid pollution, save papermaking raw materials, and save processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

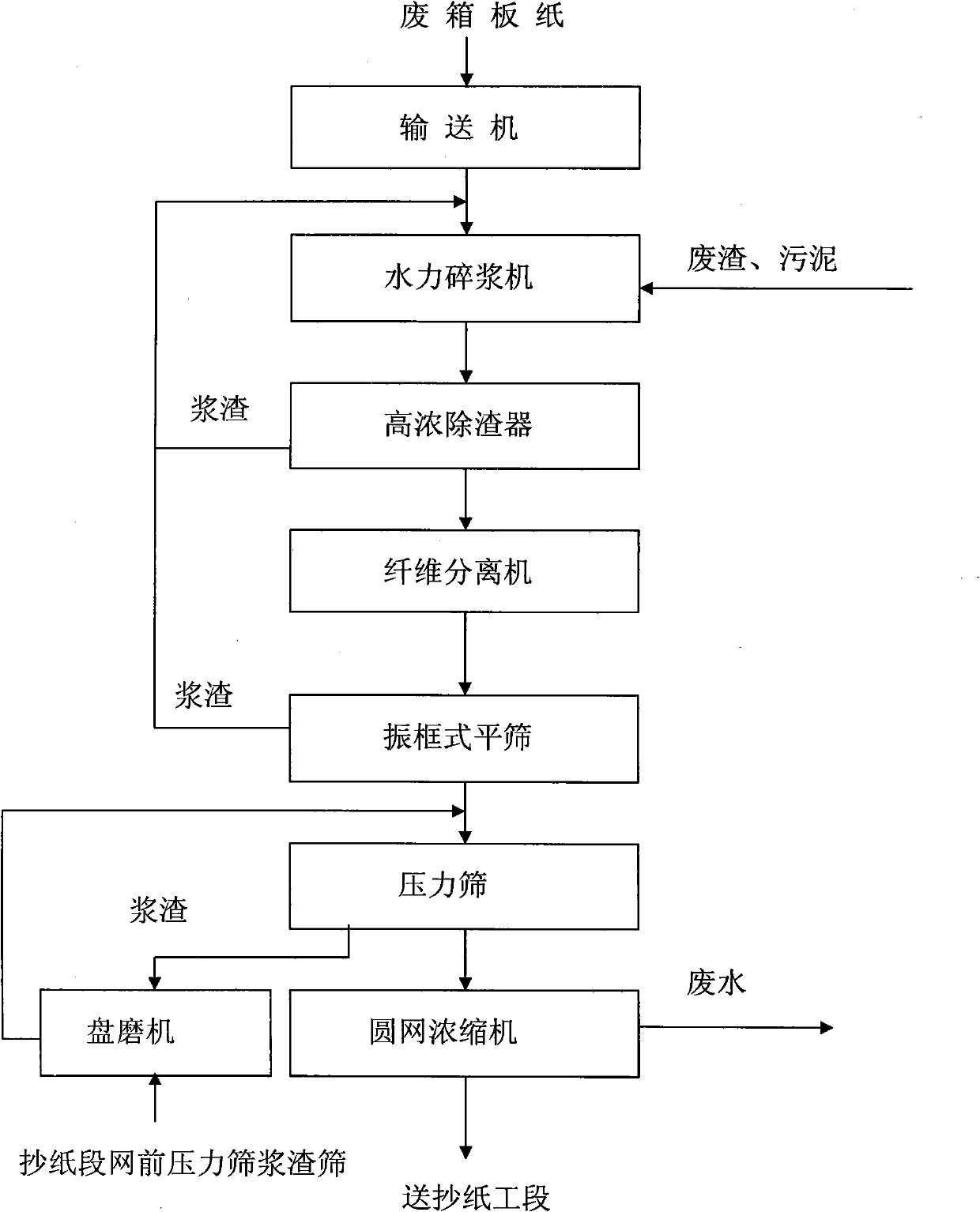

[0017] 1. Pulping:

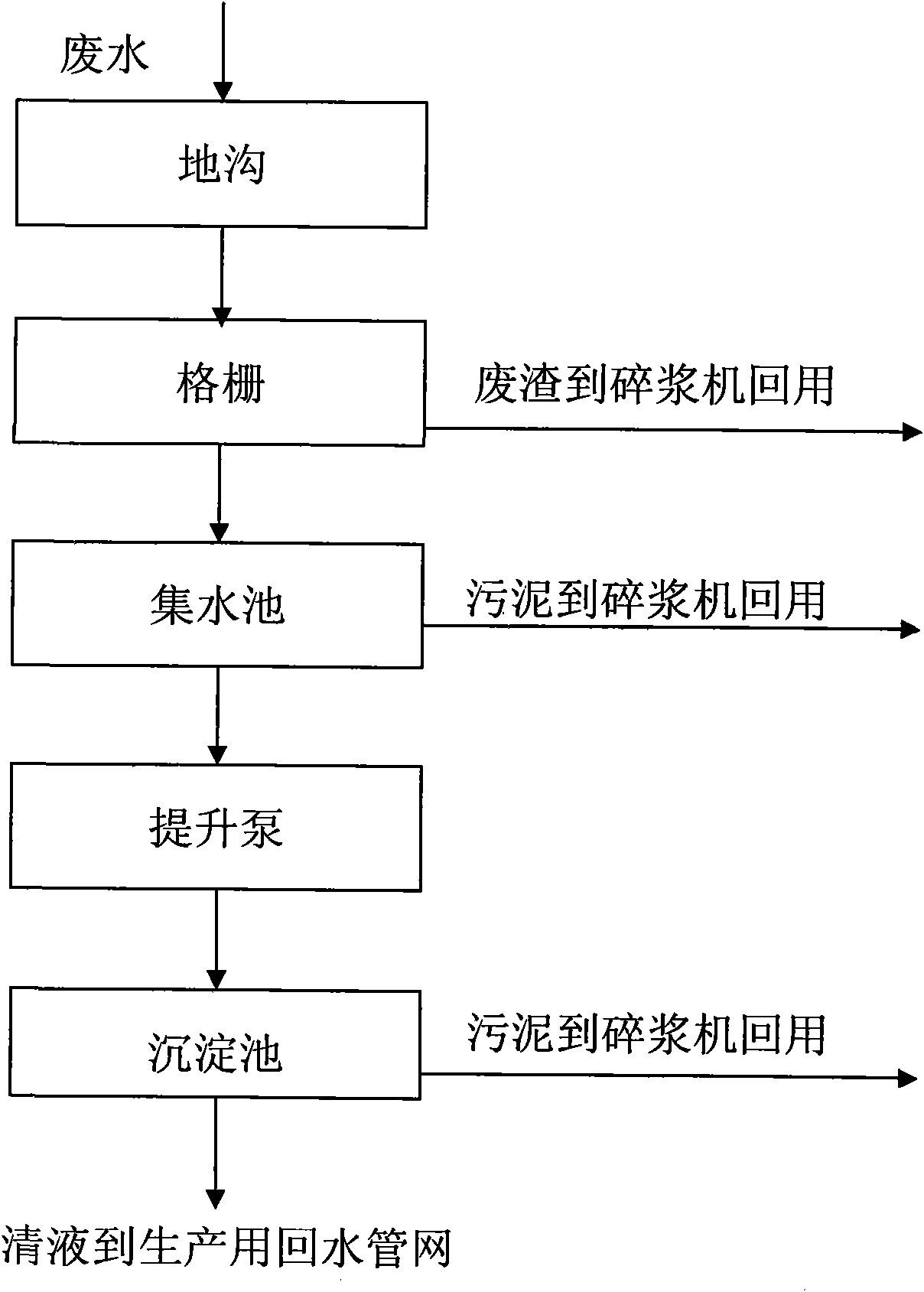

[0018] 1) The waste containerboard is sent to the hydraulic pulper by the chain conveyor to disintegrate the waste paper, and at the same time, the waste residue and sludge are introduced into the hydraulic pulverizer for crushing and mixing at the same time. The moisture content of the papermaking waste residue is 65%, and the moisture content of the sludge is 80%; the weight ratio of the waste container board paper to the papermaking waste residue and the sludge is 10:6:5.

[0019] 2) Send high-concentration slag remover to remove heavy impurities such as stones and iron filings

[0020] The pulp from the hydropulper is pumped into the high-consistency cleaner along the tangential direction from the top of the high-consistency cleaner. With the help of the high-speed rotating impeller close to the pulp inlet, the pulp is made into the cleaner at a high speed. Rotating motion, correspondingly affected by the centrifugal force, the slurry moves downward a...

Embodiment 2

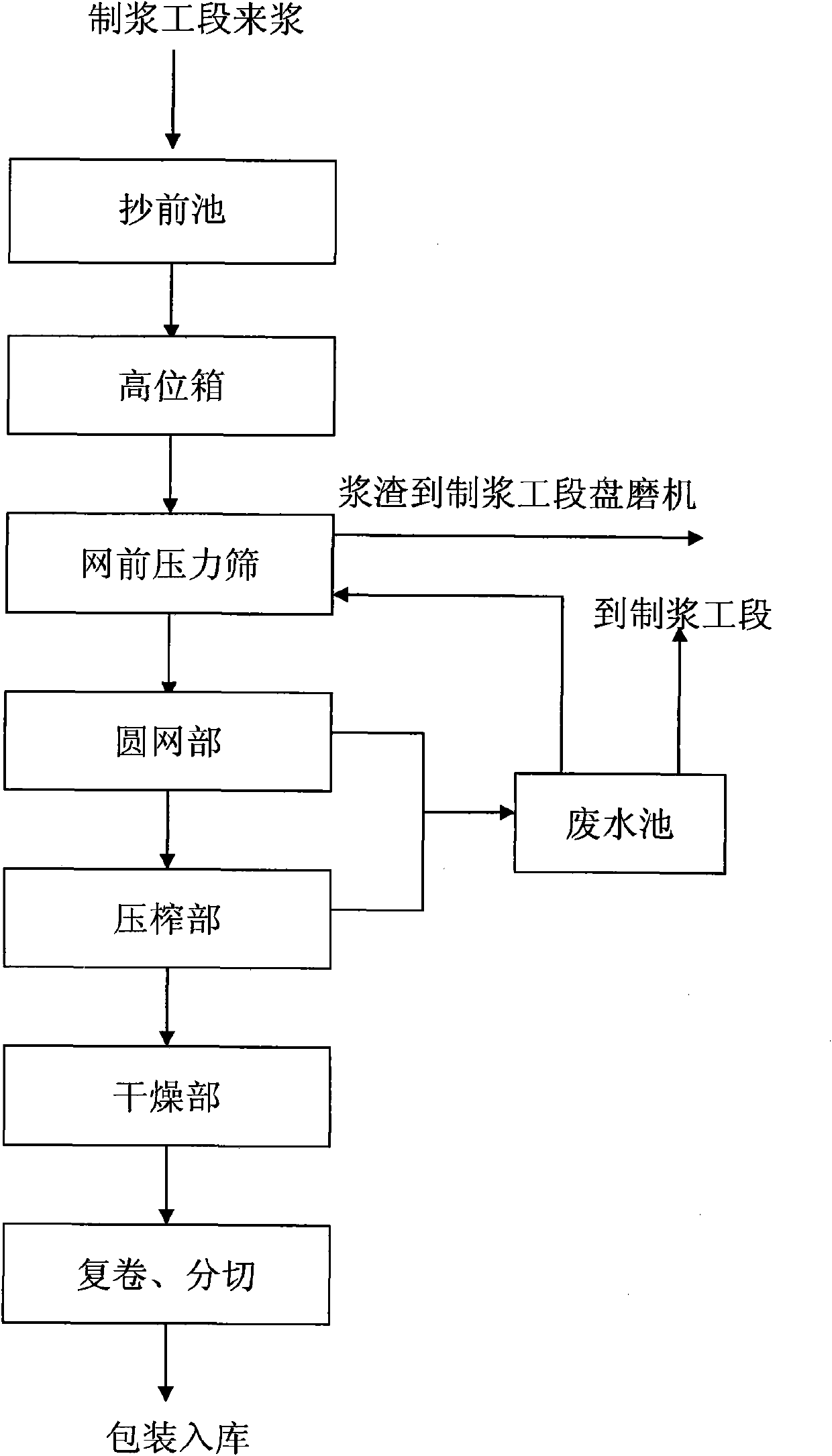

[0033] (1) Pulping: the waste containerboard is sent by the conveyor to the hydraulic pulper for waste paper disintegration, and at the same time, the waste residue and sludge are introduced into the hydraulic pulverizer for crushing and mixing; then sent to the high-concentration slag remover for removal Heavy impurities such as stones and iron filings; after the heavy impurities are removed, the coarse pulp is decompressed and graded by a fiber separator; then the pulp is vibrated and screened by a vibrating frame-type flat screen, and the good pulp is further screened by a pressure screen, and the qualified fibers are sent to the round After being concentrated by the net thickener, it enters the papermaking section; the moisture content of the papermaking waste residue is 70%, and the moisture content of the sludge is 78%; the weight ratio of the waste boxboard to papermaking waste residue and sludge is 10:5: 4.

[0034] (2) Papermaking: The slurry from the self-made pulp s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com