Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189results about "Waste product addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

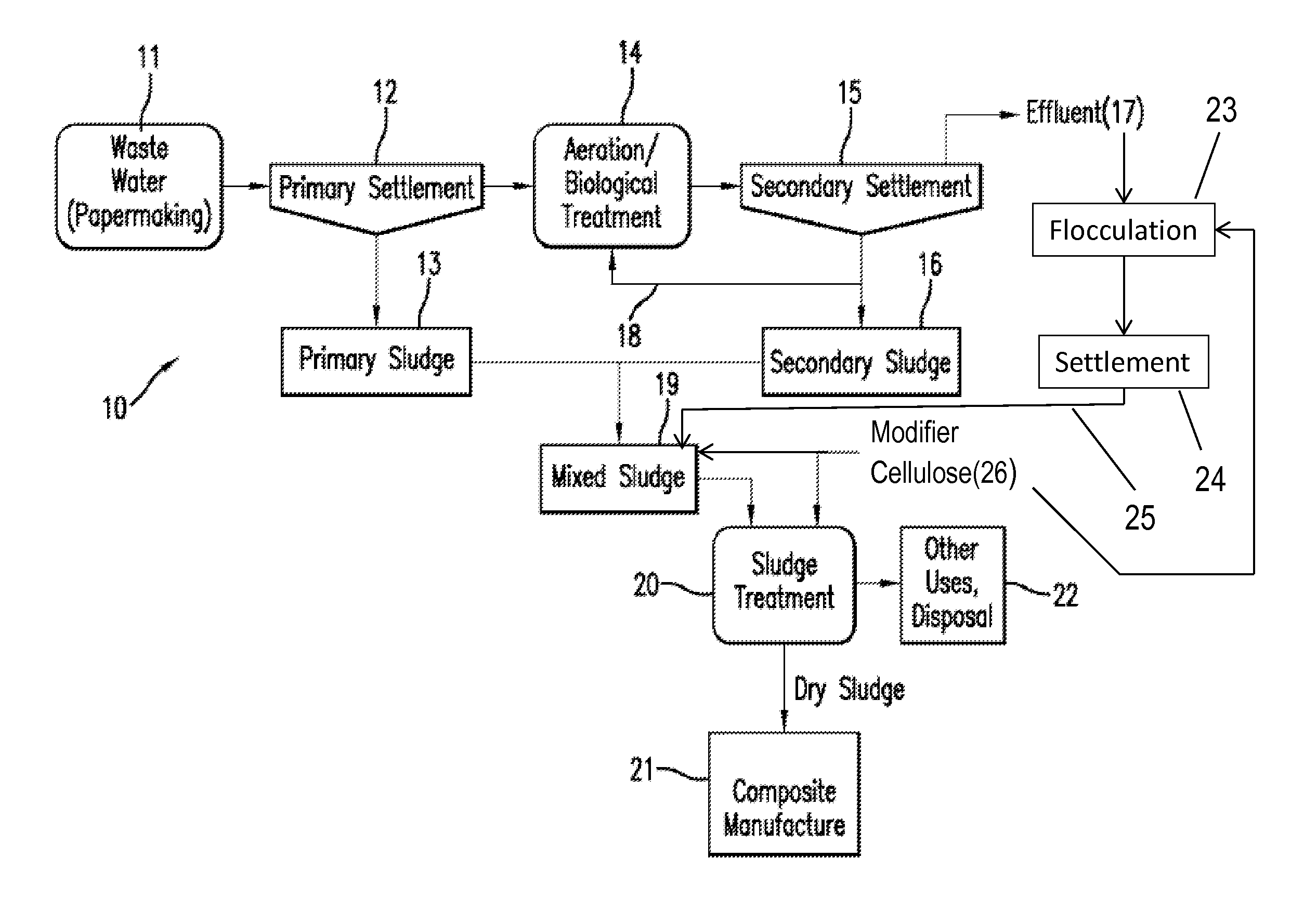

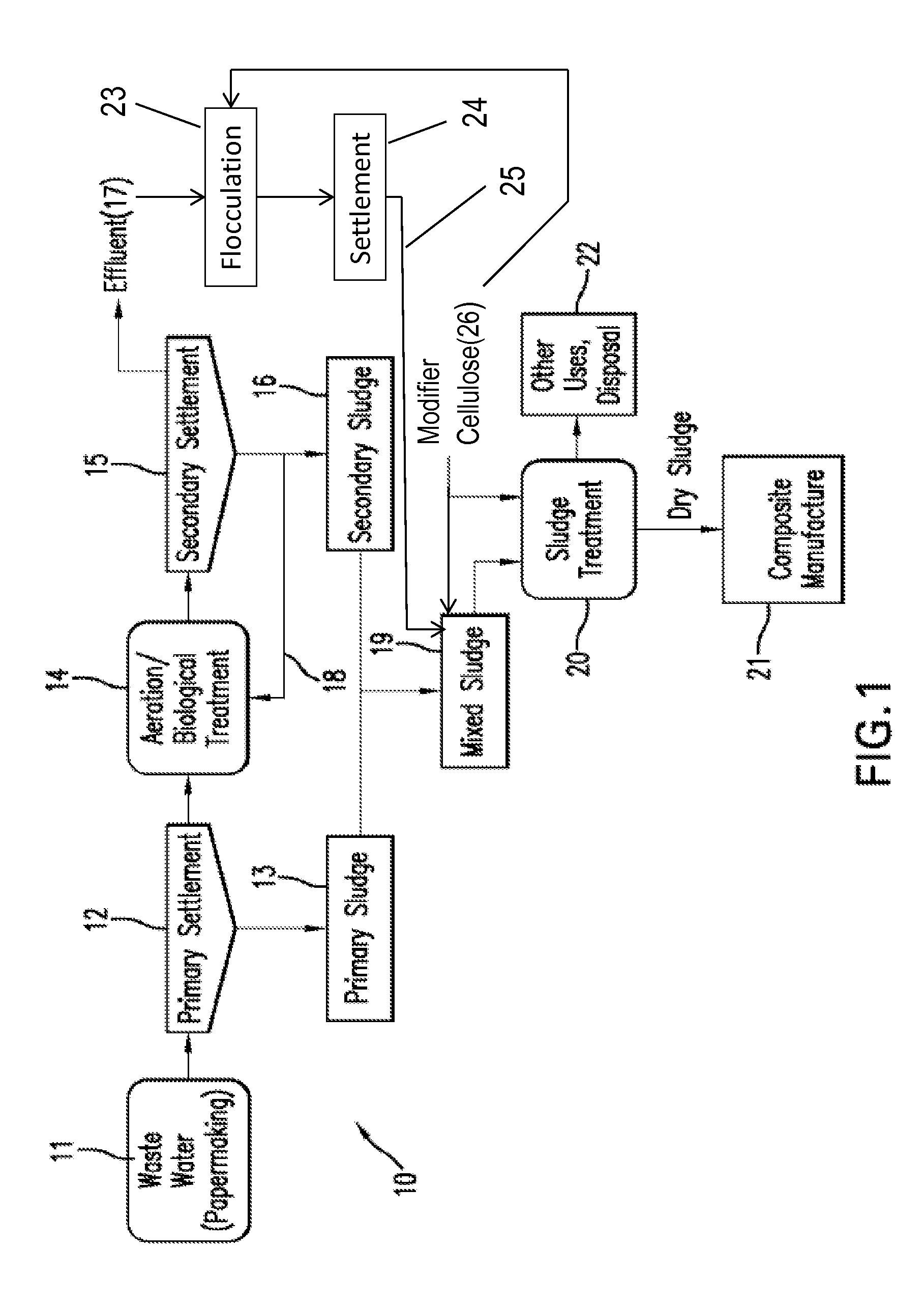

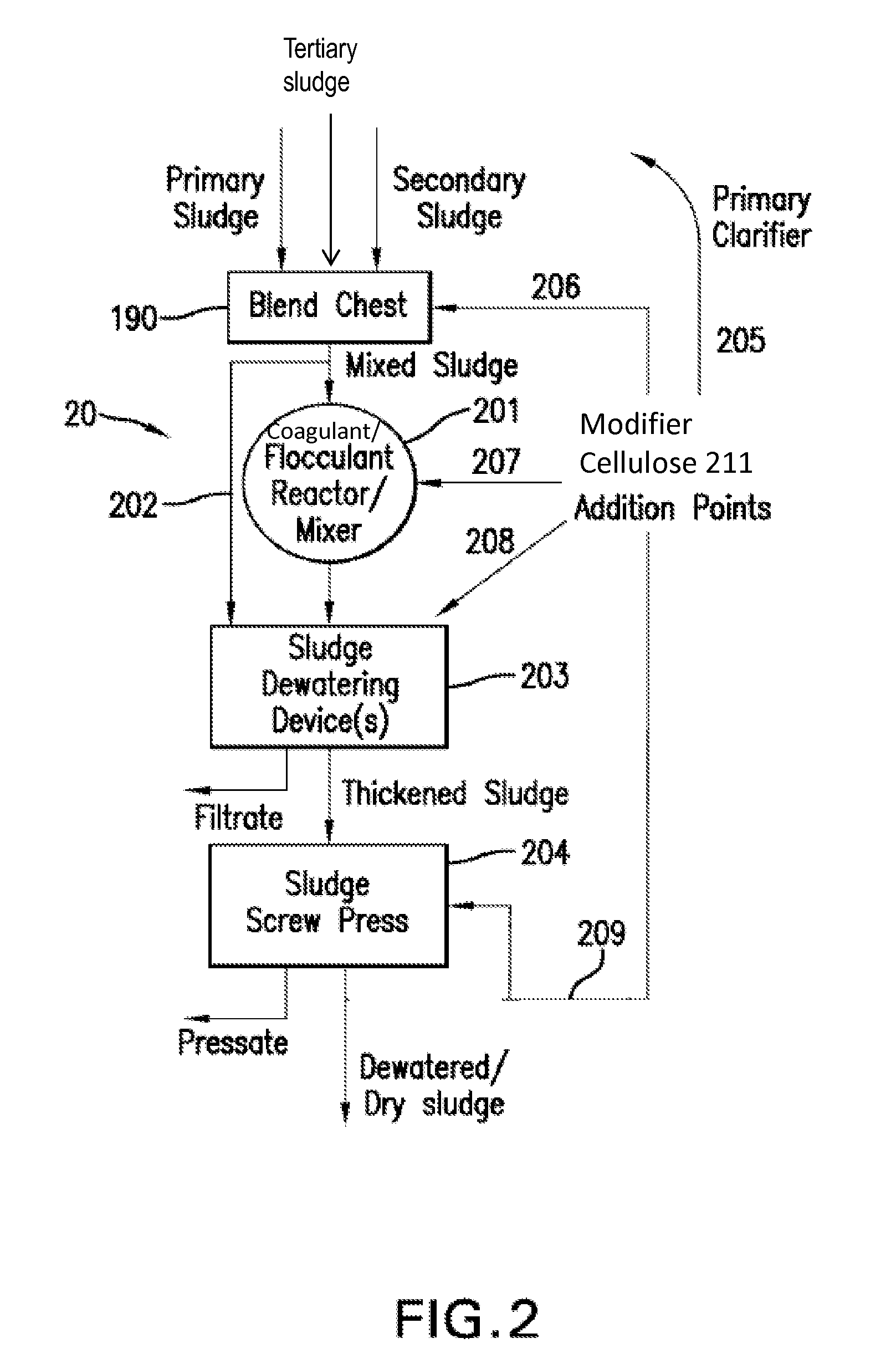

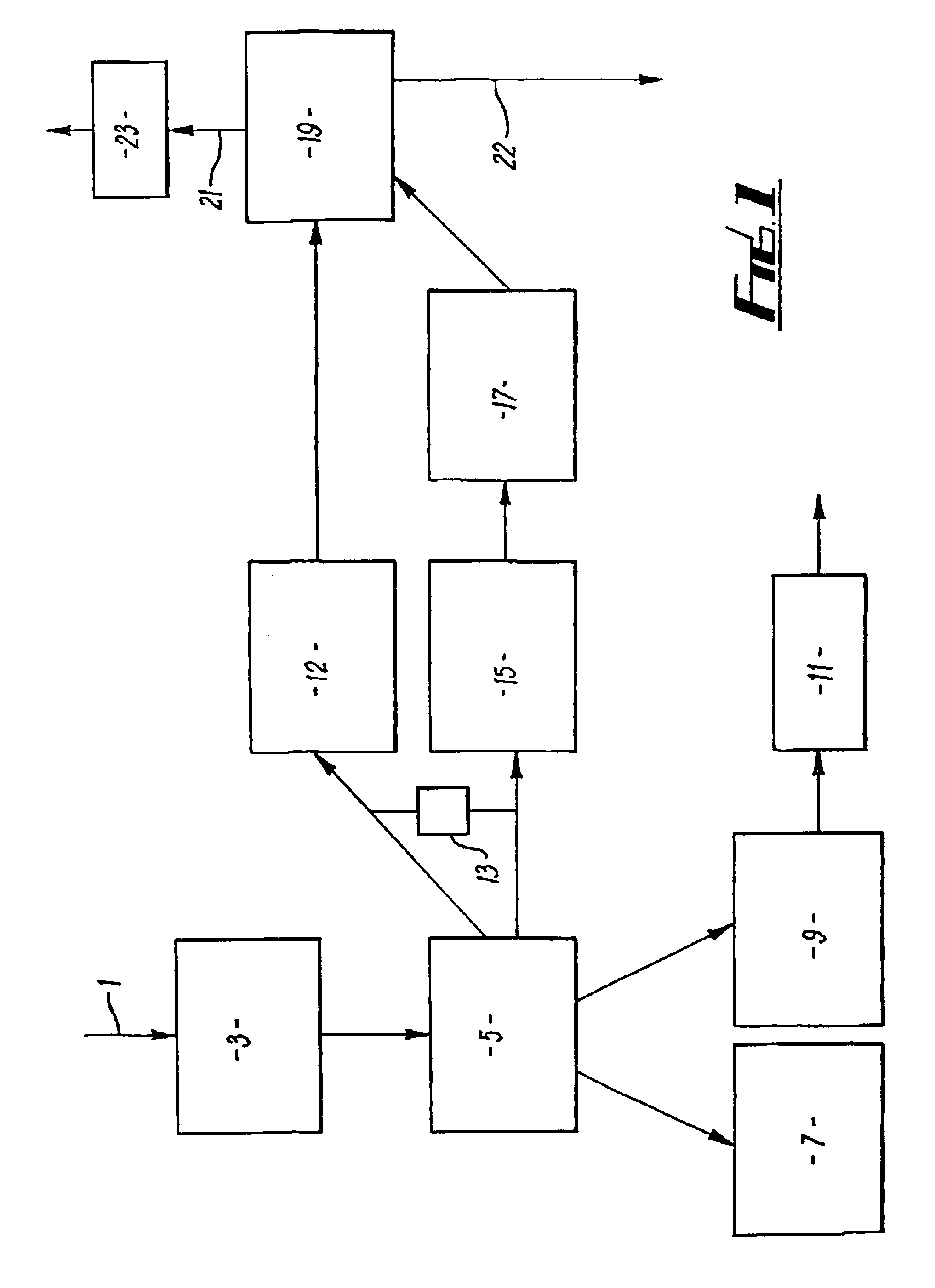

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

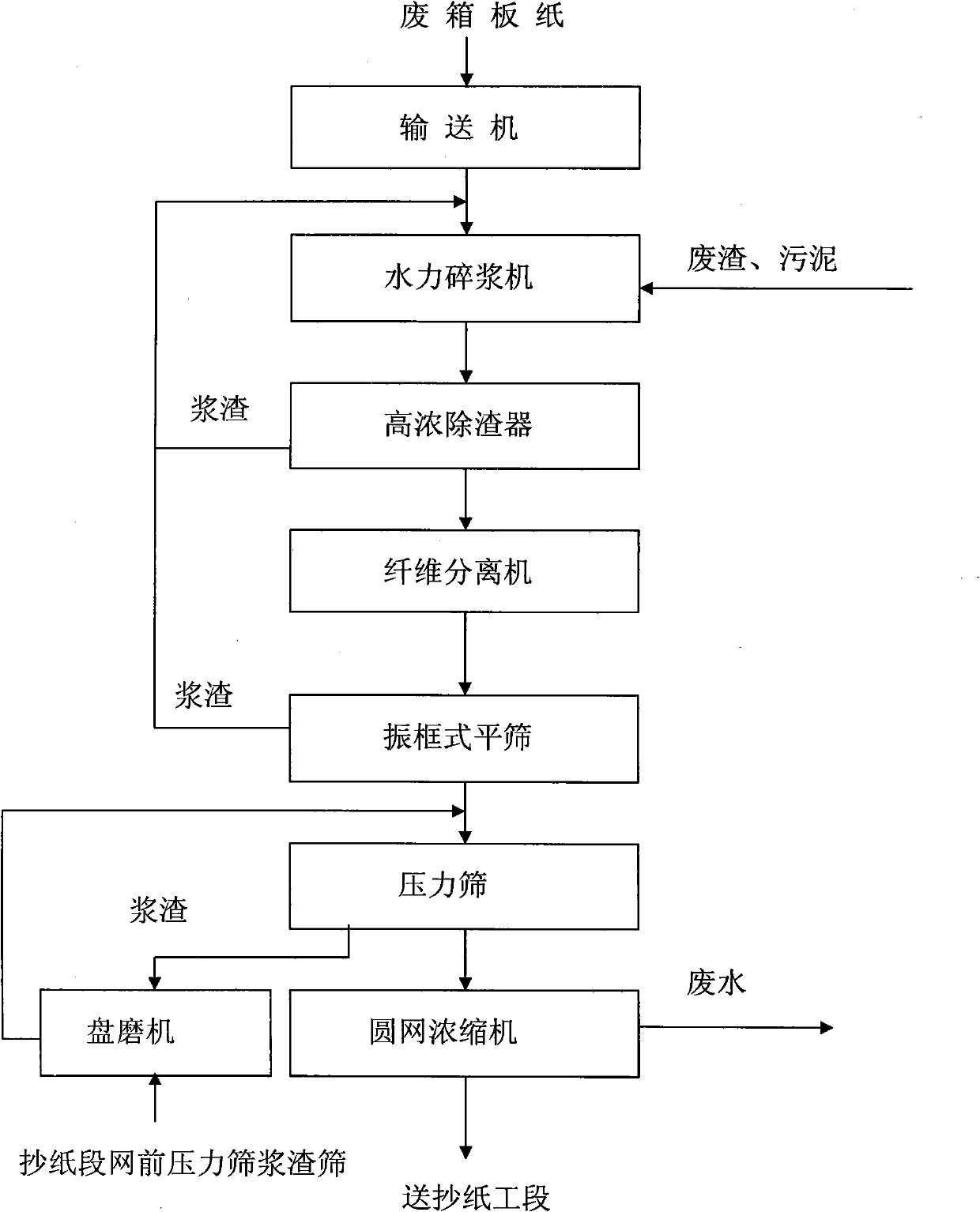

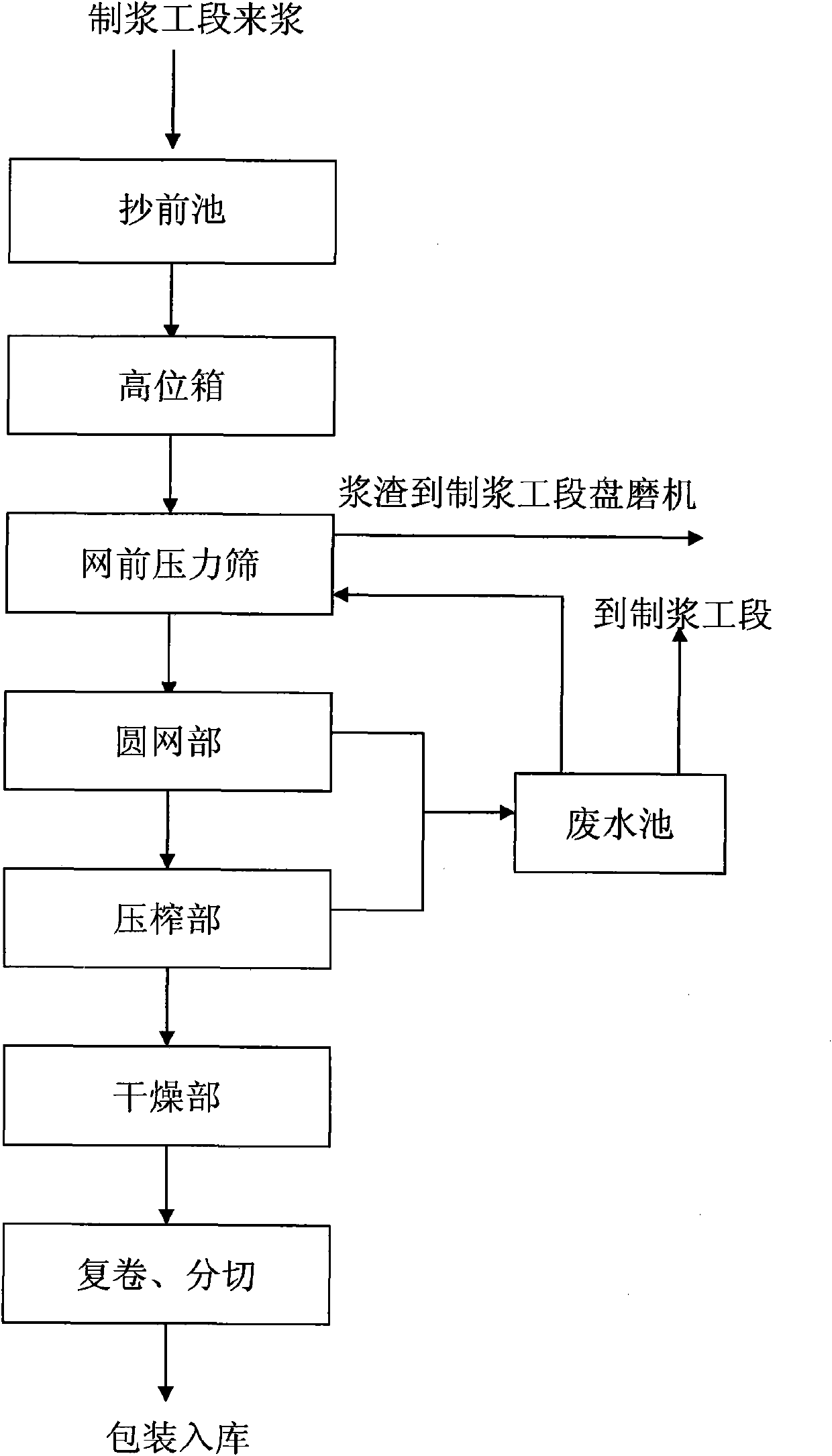

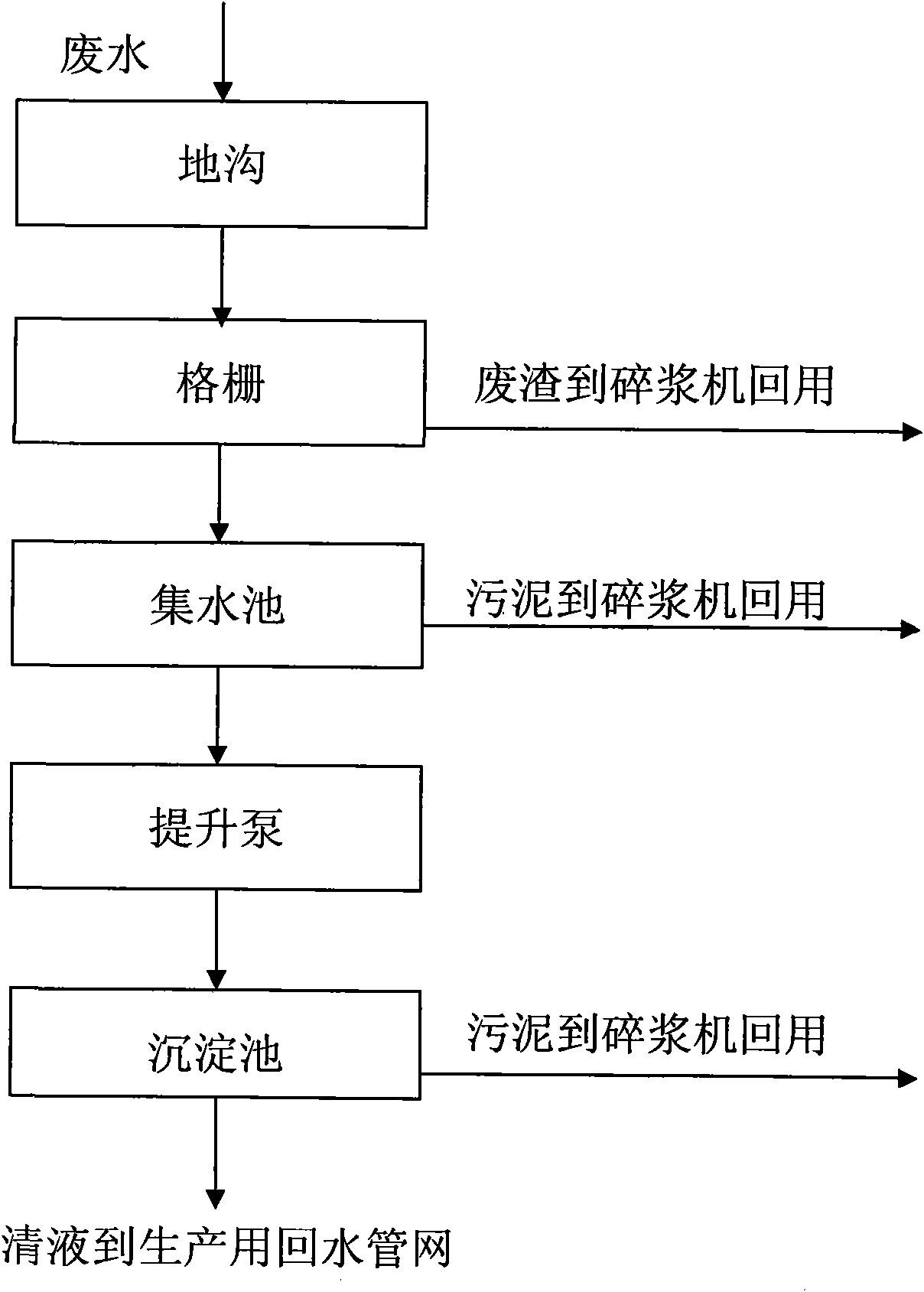

Method for producing corrugated paper by utilizing papermaking waste residues and sludge

InactiveCN102002882AReduce processing costsAvoid emissionsWaste product additionPaper recyclingFiberHigh concentration

The invention discloses a method for producing corrugated paper by utilizing papermaking waste residues and sludge. The production method comprises the following steps of: (1) pulping: breaking waste cardboard paper; meanwhile, introducing the waste residues and sludge into a hydraulic pulverizer and simultaneously pulverizing and mixing; then feeding into a high-concentration residue removing machine and removing heavy impurities; after the heavy impurities are removed from rough slurry, defibering and grading by a defibering machine; vibrating and screening the pulp by a vibration-frame type flat screen; after good pulp is further screened by a pressure screen, feeding qualified fibers into a circular screen concentrator and concentrating and delivering the qualified fibers into a papermaking section; and (2) papermaking: delivering the pulp into a preparing pool; after delivering to a high-level box by a pump, delivering the pulp to a front pressure screen and carrying out fine screening; then delivering to a circular screen part and a squeezing part; and drying in a drying part, then rewinding, cutting and packaging for storage. The method of the invention recycles the waste residues and the sludge generated in the production, saves great papermaking raw materials, prevents the emission of various waste materials and really achieves zero emission.

Owner:SHANDONG TIANDIYUAN IND

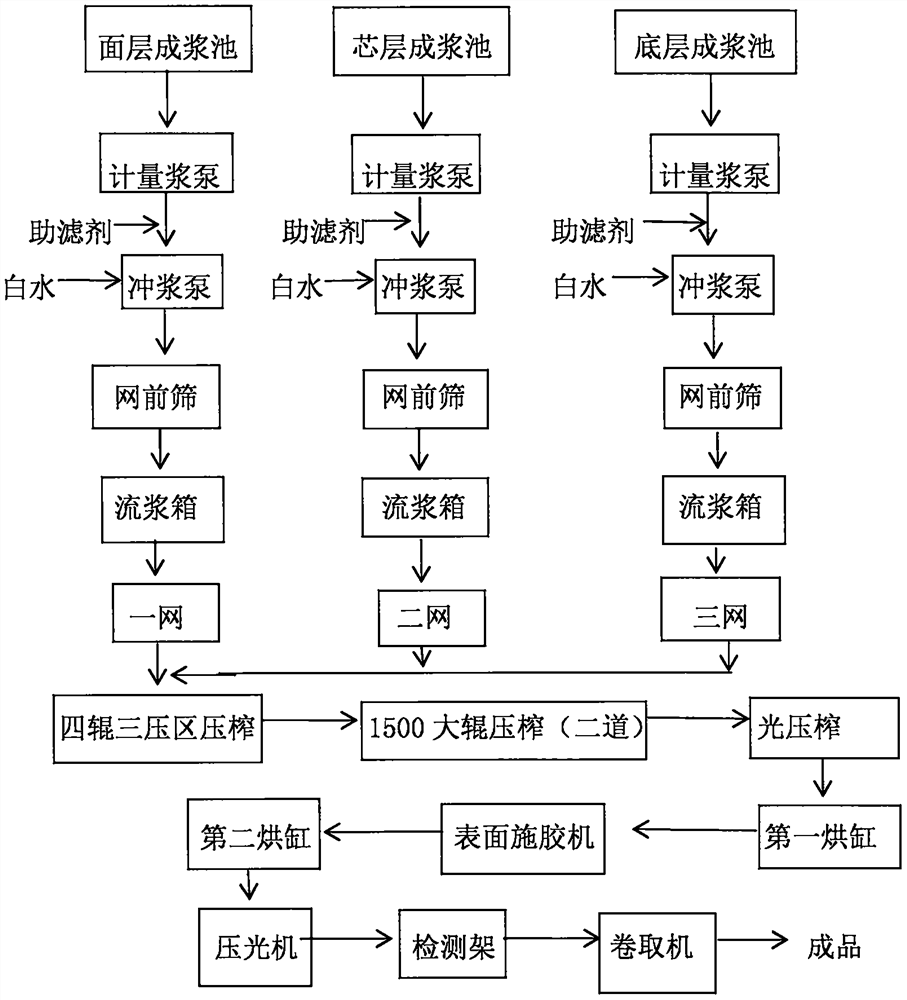

Manufacture process of all waste paper dried noodle cardboard paper

ActiveCN102041750AEfficient use ofLow costSpecial paperWaste product additionHigh concentrationFiber

The invention discloses a manufacture process of all waste paper dried noodle cardboard paper, comprising the following steps: A: conveying the waste paper to a pulper through a scraper chain conveyor, and crushing the waste paper into paper pulp; B: conveying the paper pulp to a high concentration desander, and further removing the heavy impurities; C: screening out the pulp dregs and the impurities containing the heavy impurities from the paper pulp in a rough pulp tower by utilizing a three-section rough screen system; D: carrying out slag removal on the long fiber pulp by utilizing a long fiber three-section low concentration desander system, then feeding the fine pulp after the long fiber three-section low concentration desander into a three-section fine screen system to screen finely, and finally performing the paper making by utilizing a long fiber grinding back pool, a bottom machine chest and a paper remover; and E: carrying out slag removal on the short fiber pulp by utilizing a short fiber three-section low concentration desander system, and finally performing the paper making by utilizing a core machine chest and a paper remover. By utilizing the process provided by the invention, the product having the quality same as that of the dried noodle cardboard paper which is manufactured by the raw material of wood pulp can be produced, thereby greatly reducing the cost and ensuring the effective use of renewable resources.

Owner:东莞理文造纸厂有限公司

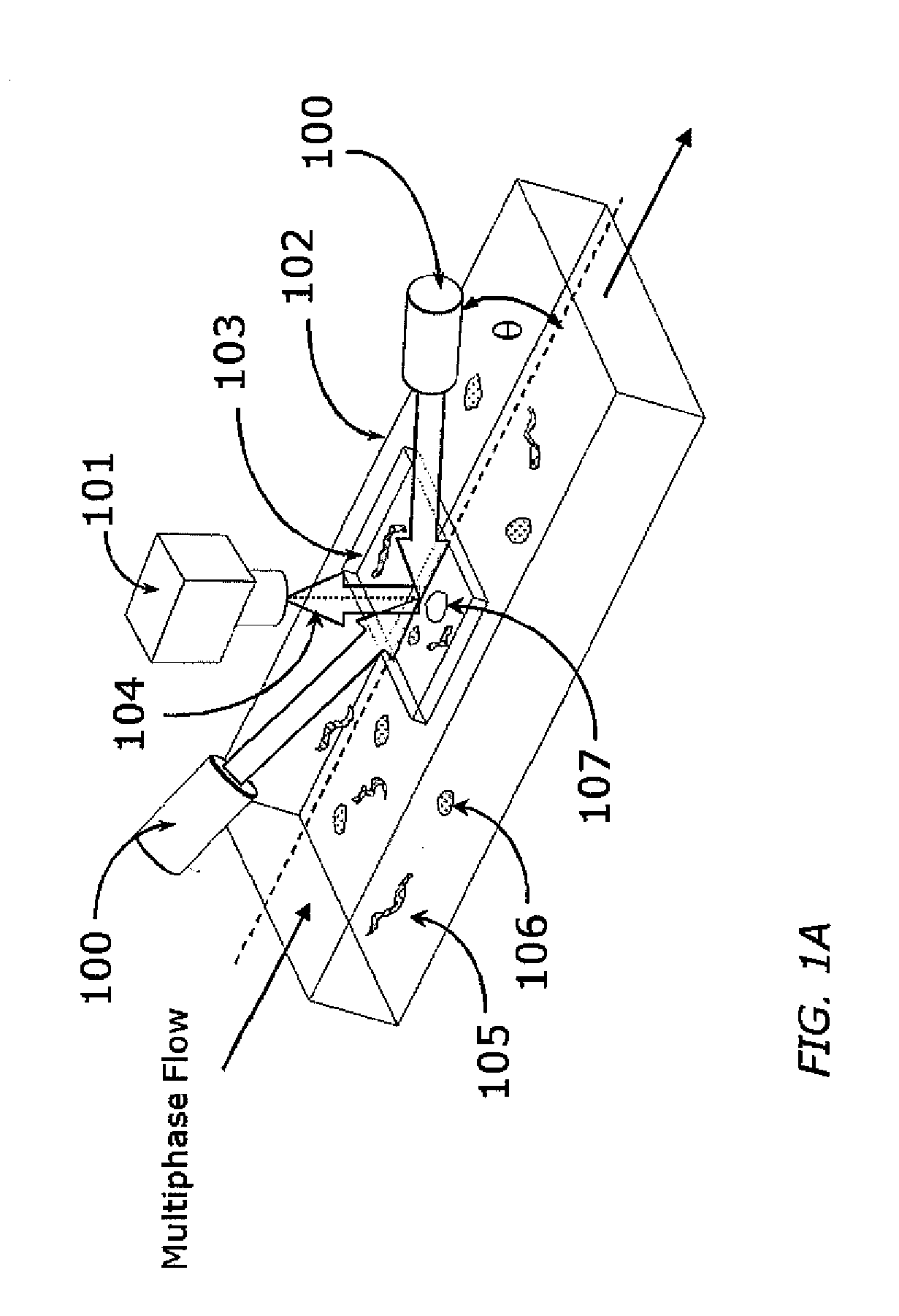

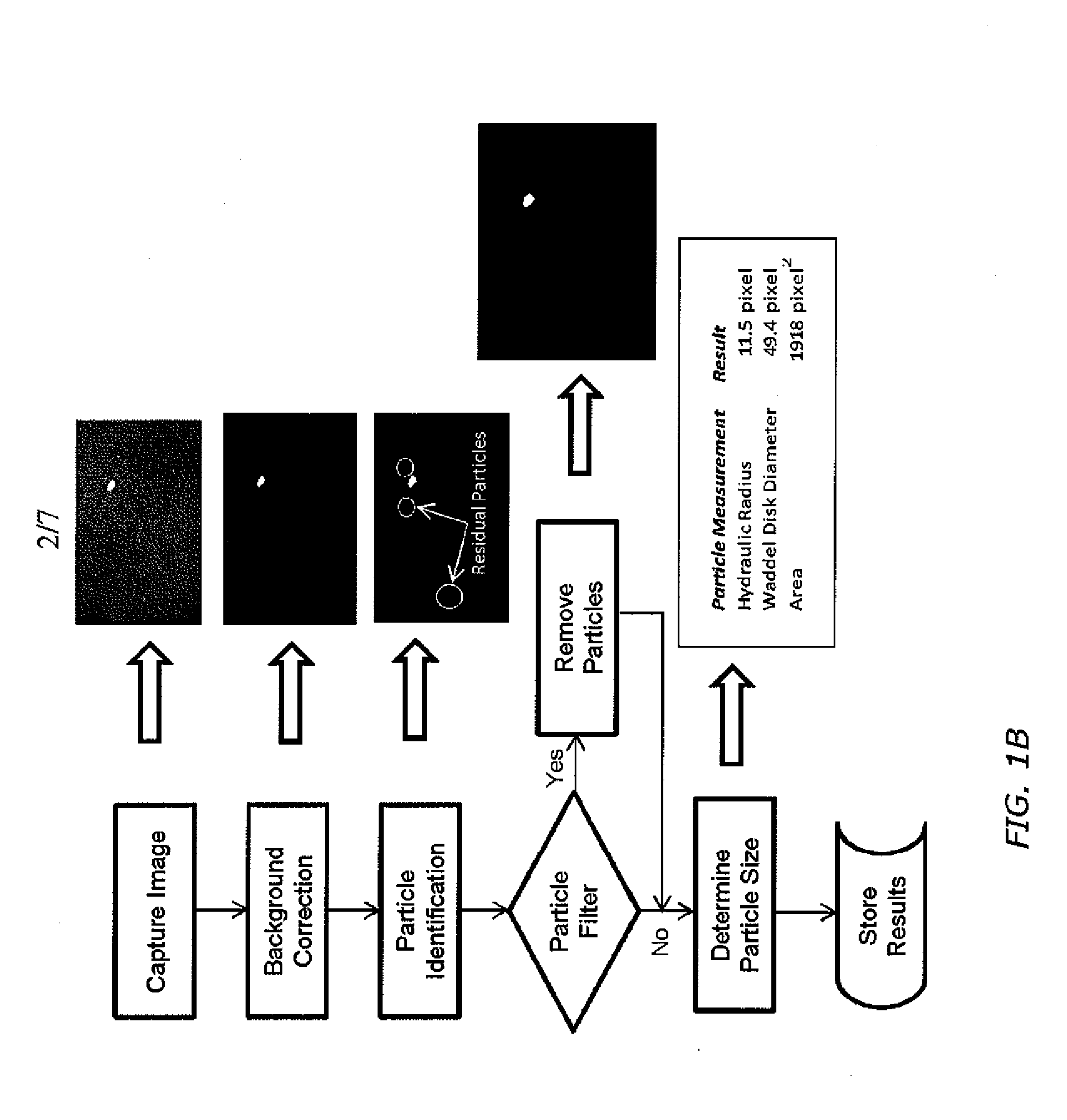

Method of monitoring macrostickies in a recycling and paper or tissue making process involving recycled pulp

ActiveUS20120258547A1Maximize processing efficiencyReduce quality problemsCellulosic pulp after-treatmentWaste product additionImaging analysisFluorescence

A challenge in using recycled material in the papermaking process is the presence of hydrophobic organics with adhesive properties commonly known as “stickies.” Hydrophobic agglomerates can result in spots or defects in the final paper product or deposit on papermaking equipment resulting in poor runnability and downtime. Technologies for monitoring and controlling microstickies exist. However, a need exists for a technique to rapidly determine the size and content of macrostickies (diameter>100 microns) in recycled pulp process streams. The present invention is a device and method to perform real-time macrostickies and / or any visible hydrophobic particle analysis in an aqueous medium. Using the present invention, furnish quality can be monitored and treatment performance can be monitored and controlled. The technique is based on fluorescence image analysis to identify and count sticky particles as well as measure their size.

Owner:ECOLAB USA INC

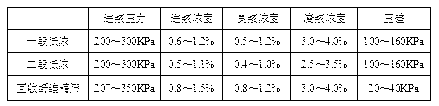

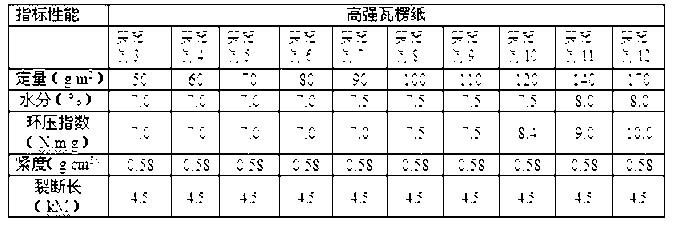

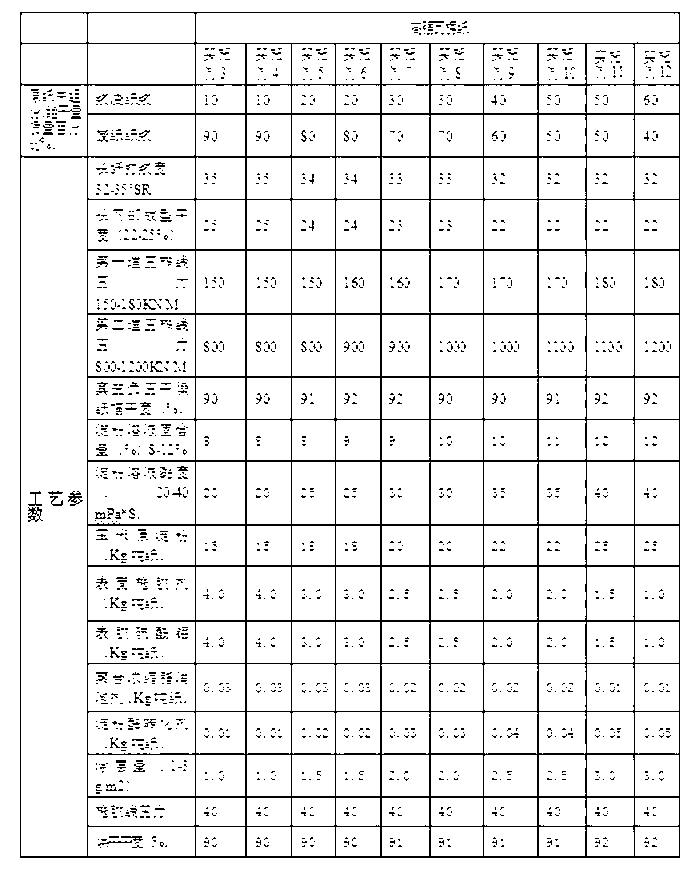

Renewable high-strength corrugated medium and its production method

ActiveCN103321088AReduce paper production costsPromote environmental protectionWaste product additionPaper recyclingPapermakingSizing

The invention relates to a renewable high-strength corrugated medium and its manufacturing method. The raw paper is prepared from 40-90% of old paper stock and 10-60% of dreg paper pulp. The invention also provides a high-strength corrugated paper and its production method. The right side and back side of the corrugated medium are respectively provided with sizing layers. According to the renewable high-strength corrugated medium, waste paper and dregs are used as raw materials. Therefore, the renewable high-strength corrugated medium has good environmental protection property and requires low papermaking cost. According to the renewable high-strength corrugated paper, the raw paper layer is prepared from waste paper and dregs which are used as raw materials. The right side and the back side are both provided with the sizing layers. The production method requires low papermaking cost and is beneficial to environmental protection. Key technical indexes of the production method all reach national standard (GB / T13023-2008) superior product AA grade.

Owner:JIAN GRP

Bobbin paper production technology

ActiveCN104278594AAvoid pollutionSave resourcesWaste product additionSpecial paperHigh concentrationBobbin

The invention discloses a bobbin paper production technology which comprises the following steps: (1) papermaking reclaimed pulp undergoes high-concentration degritting and disk milling and then is placed into a coarse pulp tank; (2) waste paper is crushed by a pulper, and crushed paper pulp undergoes high-concentration degritting and then is placed into the coarse pulp tank; (3) coarse pulp in the coarse pulp tank is separated by a defibrator; (4) medium-concentration degritting is carried out; (5) fine screening and concentration are carried out; (6) the pulp is placed into a concentration tank; (7) the pulp undergoes disk mill and then is placed into a finished product tank; (8) the pulp is delivered to a machine chest, and paper mill sludge is added into the machine chest; (9) drifting is carried out through a drifting system, and a water repellent agent is added; (10) the raw material is conveyed to a net part of a paper machine, a dry strength agent is added into the net part, and starch is sprayed; (11) the raw material is processed by a press part of the paper machine; (12) the raw material is processed by a drying part of the paper machine; and (13) finished paper is reeled. According to the invention, reclaimed pulp and paper mill sludge which are generated during the papermaking process are fully utilized for production of bobbin paper. Thus, resources are saved; cost is reduced; and environmental pollution is also avoided.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

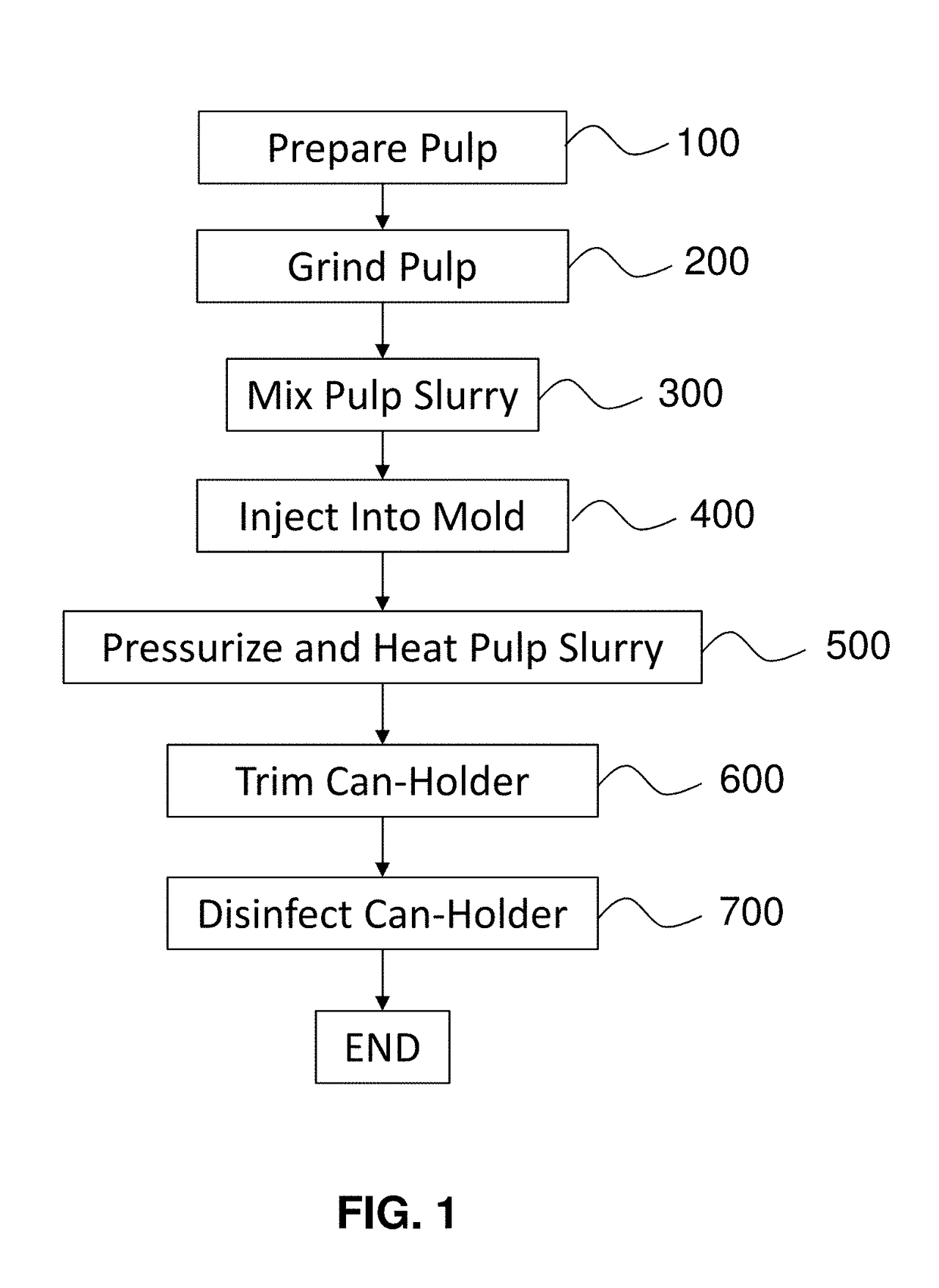

Edible Multi-Ring Can-Holder and Methods for Manufacturing Edible Can-Holders

PendingUS20180016750A1Promote degradationProcess environmental protectionFlexible coversWrappersFiberAdditive ingredient

A method for manufacturing an edible, multi-ring, can holder comprises the steps of dehydrating beer by-product to produce a dried pulp, grinding the dried pulp into a powder, forming a pulp slurry by adding the powder into a mixture comprising plant fibers, an environment-friendly, oil-repellent chemical, an environment-friendly, water-repellent chemical, and water, a water-to-other ingredient ratio being approximately 1000 liters of water to approximately 60 kg of the powder, the plant fibers, the oil-repellent chemical, and the water-repellent chemical, injecting the pulp slurry into a mold having an interior cavity in the shape of at least one six-pack ring, and applying pressure and heat to the mold containing the pulp slurry to produce at least one edible six-pack ring.

Owner:E6PR S A P I DE CV

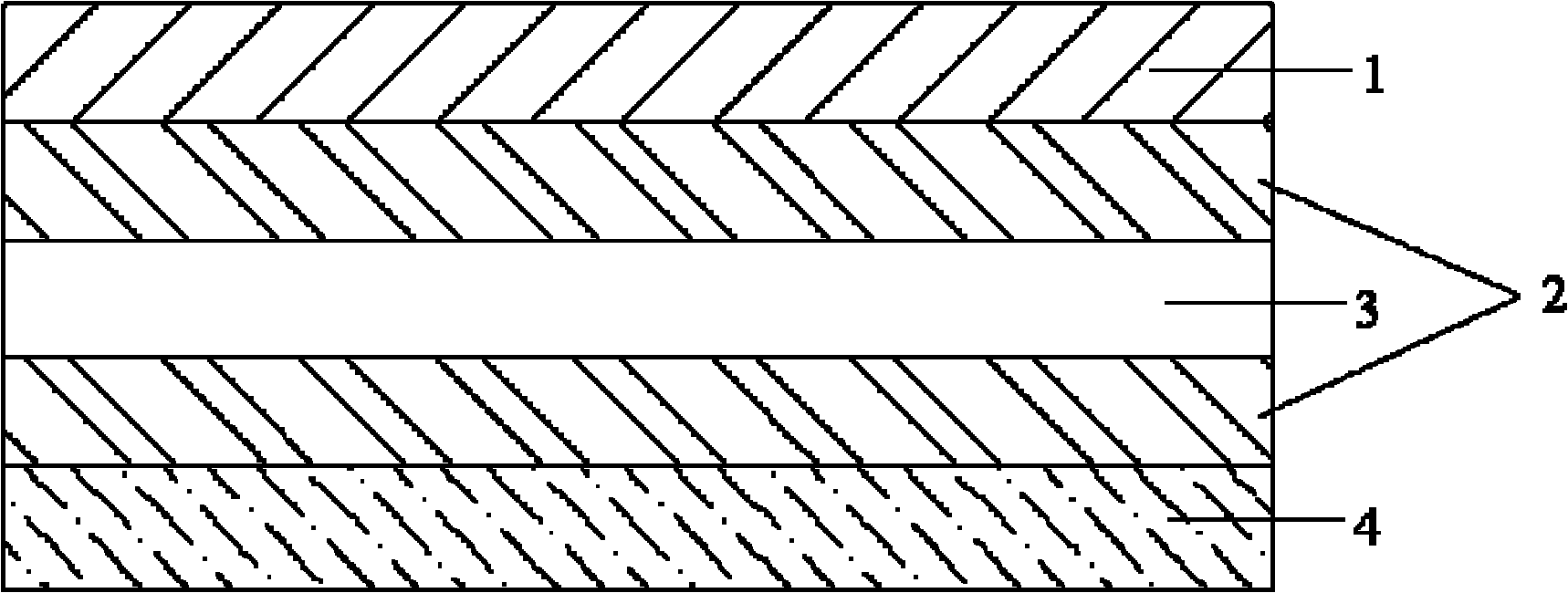

Double-sided composite card paper and preparation method thereof

InactiveCN101818466AFeel thickCrisp paperSpecial paperWaste product additionEconomic benefitsEngineering

The invention provides double-sided composite card paper and a preparation method thereof. A lining pulp layer is covered on one side of a core pulp layer, a bottom pulp layer is covered on the other side of the core pulp layer and a surface pulp layer is covered on the lining pulp layer; or lining pulp layers are covered on two sides of a core pulp layer, a surface pulp layer is covered on the lining pulp layer on one side, and a bottom pulp layer is covered on the lining pulp layer on the other side. Common waste paper pulp (office waste paper, common waste paper boards and the like) is used for replacing wood pulp to serve as core pulp, and waste paper de-inking pulp and waste white paper edge pulp are used for replacing wood pulp to serve as lining pulp so as to save the cost; each layer is specifically quantified; and the obtained double-sided composite card paper has heavy handfeel and crisp paper surface, press molding and embossing processes required for processing and molding have better implementing effects, the expressed levels are richer, the dependency of the product on operating workers is furthest reduced, and effective expansion of the capacity and increment of the economic benefit are furthest realized.

Owner:CHANGSHA TIANTIAN PAPER

Papermaking sludge paperboard and preparation thereof

InactiveCN101949105ASolve the disadvantages caused by the processing methodSolve the disadvantagesWaste product additionSpecial paperFiberCardboard

The invention relates to the field of papermaking, and discloses a sludge paperboard and preparation thereof. The papermaking sludge paperboard is prepared from papermaking sludge and short fibers serving as raw materials. By breaking through sludge papermaking technology and solving the strength problem of the sludge paperboard, 100 percent of papermaking sludge is recycled and the pollution problem of spinning waste, namely the short fibers is partially solved; and the formed sludge paperboard product can replace a thick paperboard and has obvious cost advantage.

Owner:上海洁都纸业有限公司

Production process of advanced grey board paper composite special core paper

ActiveCN110080031AImprove flatnessGood adhesionWaste product additionMechanical/thermomechanical pulpCardboardSludge

The invention relates to the technical field of pulping and papermaking, in particular to a production process of advanced grey board paper composite special core paper. The production process does not use ONP pulp, both surface pulp and bottom pulp adopt 100 percent of OCC pulp, formed paper is good in flatness and is not layered, and the adhesive absorption property and the bonding property of the paper are improved, and the use requirements of the advanced composite grey board paper special core paper are met. Moreover, as core pulp with a larger pulp blending proportion adopts OCC pulp, recovery slag pulp, wood chip pulp and reuse sludge mixed pulp, the quantification, the compactness, the interlayer bonding force, the thickness and the ash content are guaranteed; an ONP pulping line and a paper machine lining section are stopped, so that the pulping power and the installed power of a paper machine are reduced, and the purposes of energy conservation, consumption reduction and product paper improvement are achieved. The produced advanced multi-layer composite special core paper in stead of single grey board paper, has a gram weight range of 280-700 g / m<2> and is used for a corelayer and an inner layer, Through measurement and calculation, the production cost per ton of paper is about 70 yuan; calculated by the annual output of 150,000 tons, the annual production cost can be saved by 10,500,000 yuan.

Owner:LIANSHENG PAPER IND LONGHAI

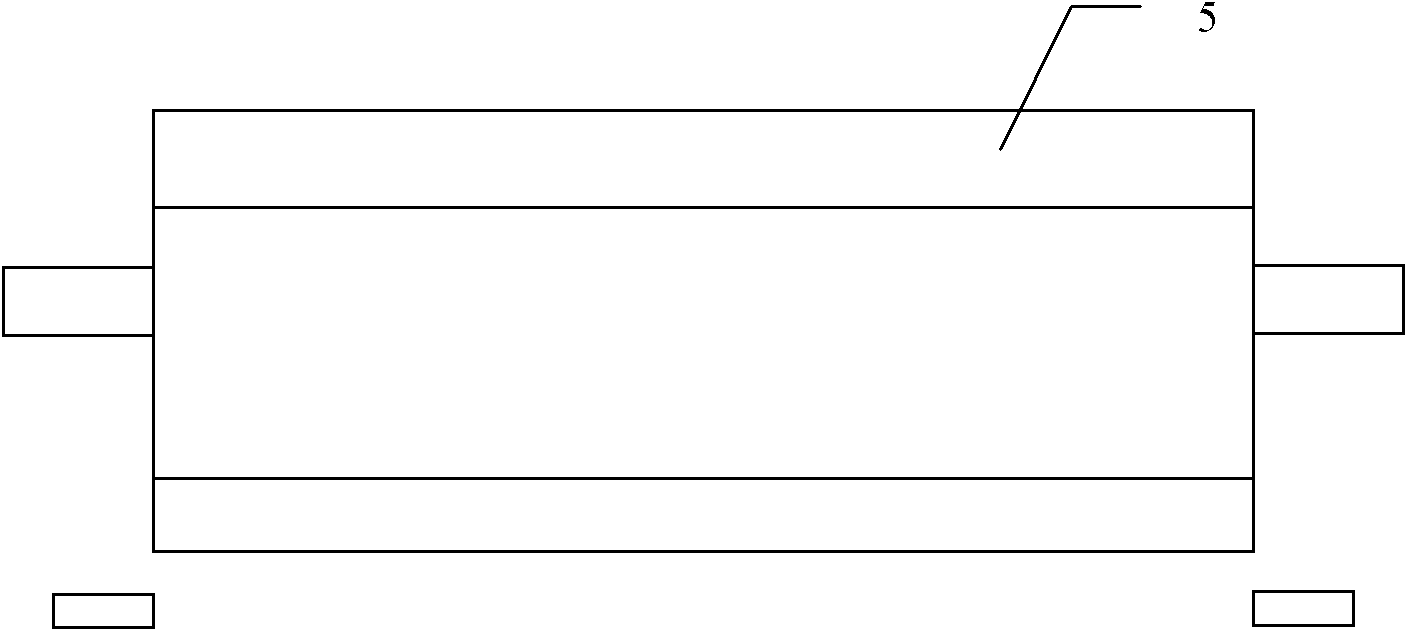

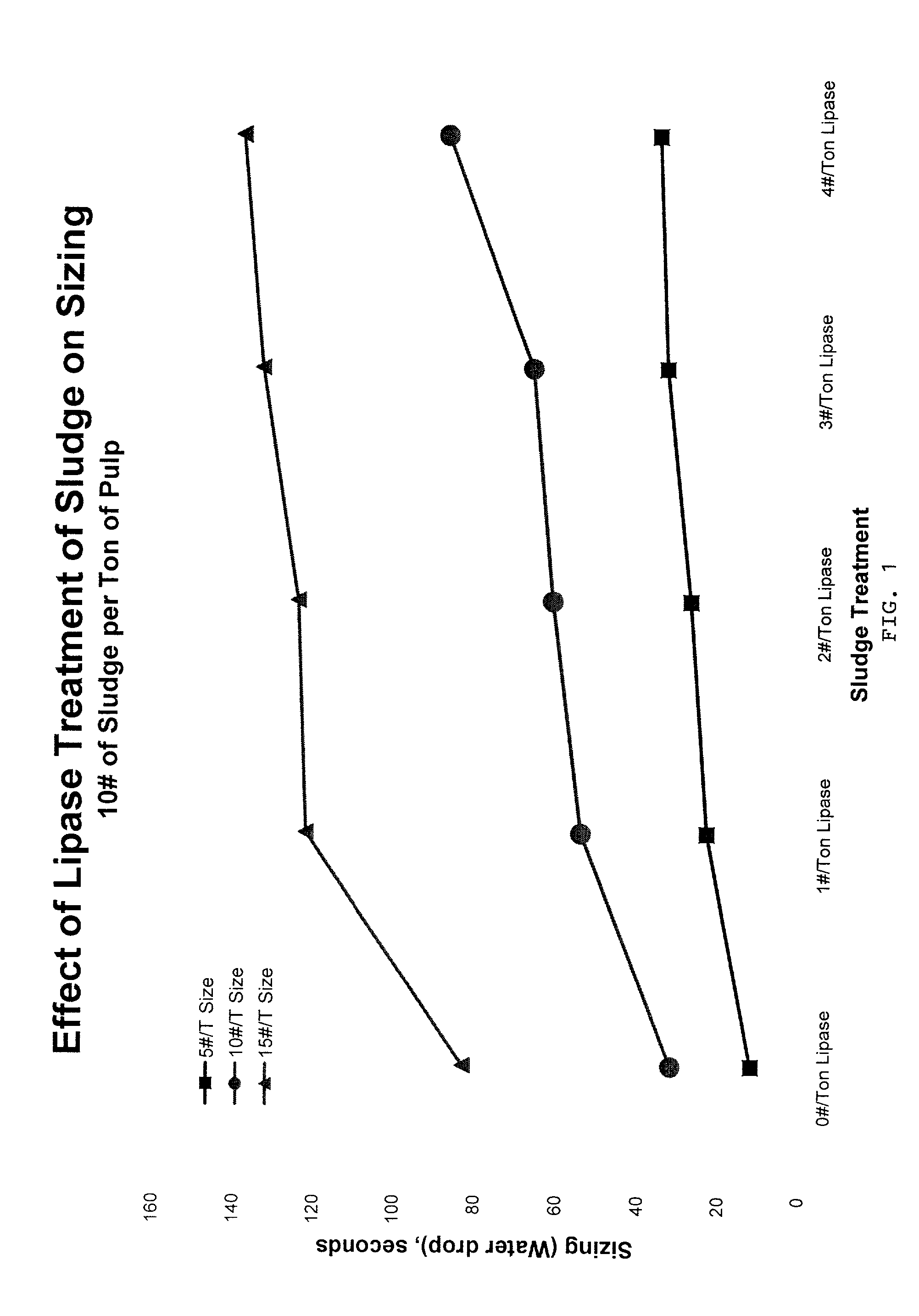

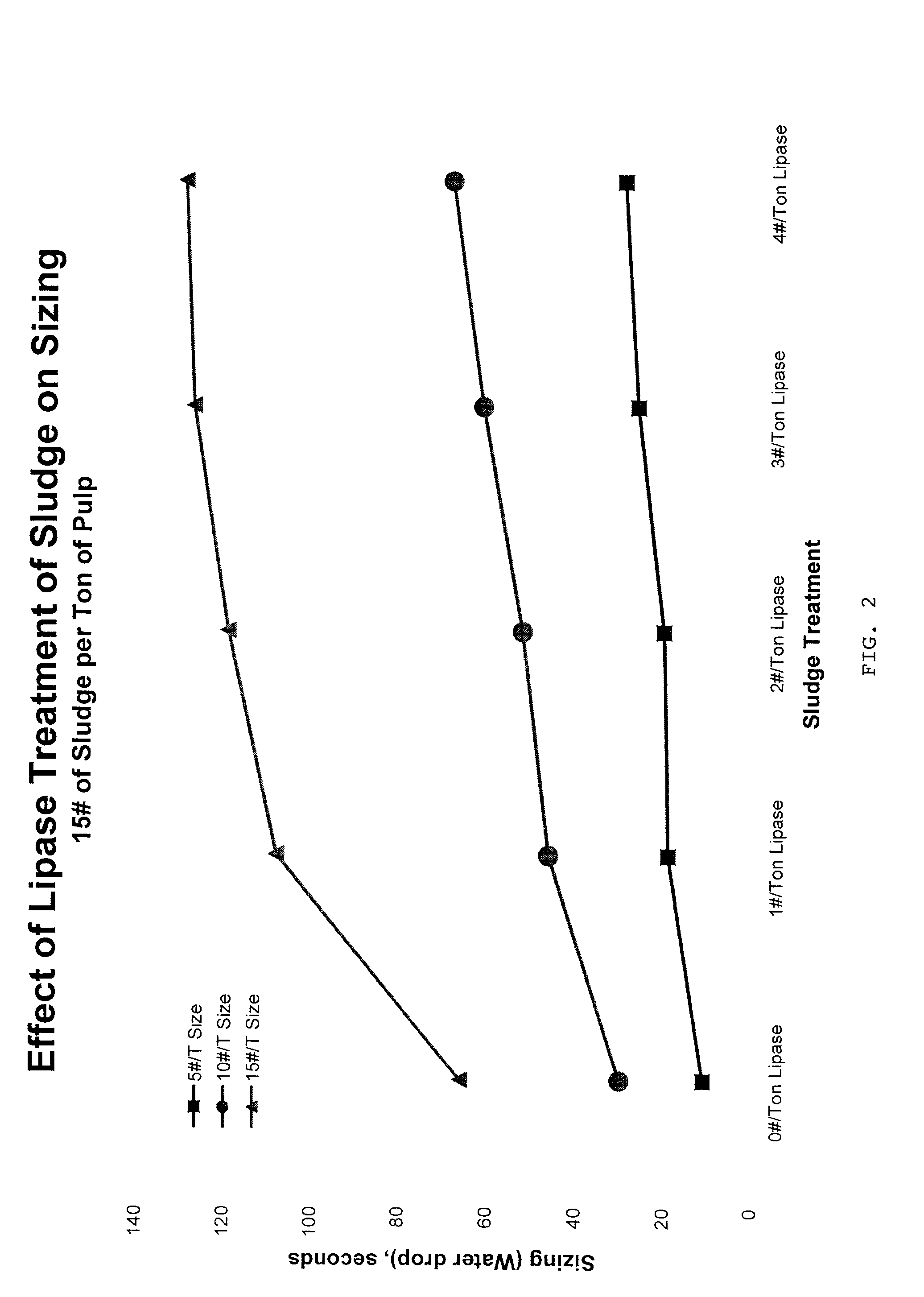

Papermaking process using enzyme-treated sludge, and products

InactiveUS7125471B2Increase in sizeRetention resistanceSpecial paperWater-repelling agents additionSludgePapermaking

Enzyme-treated papermaking sludges are provided, as are methods of making the enzyme-treated sludge. Papermaking processes that incorporate the enzyme-treated papermaking sludges into papermaking pulp are also provided as are paper and paperboard products made from the resultant pulp.

Owner:BUCKMAN LAB INT INC

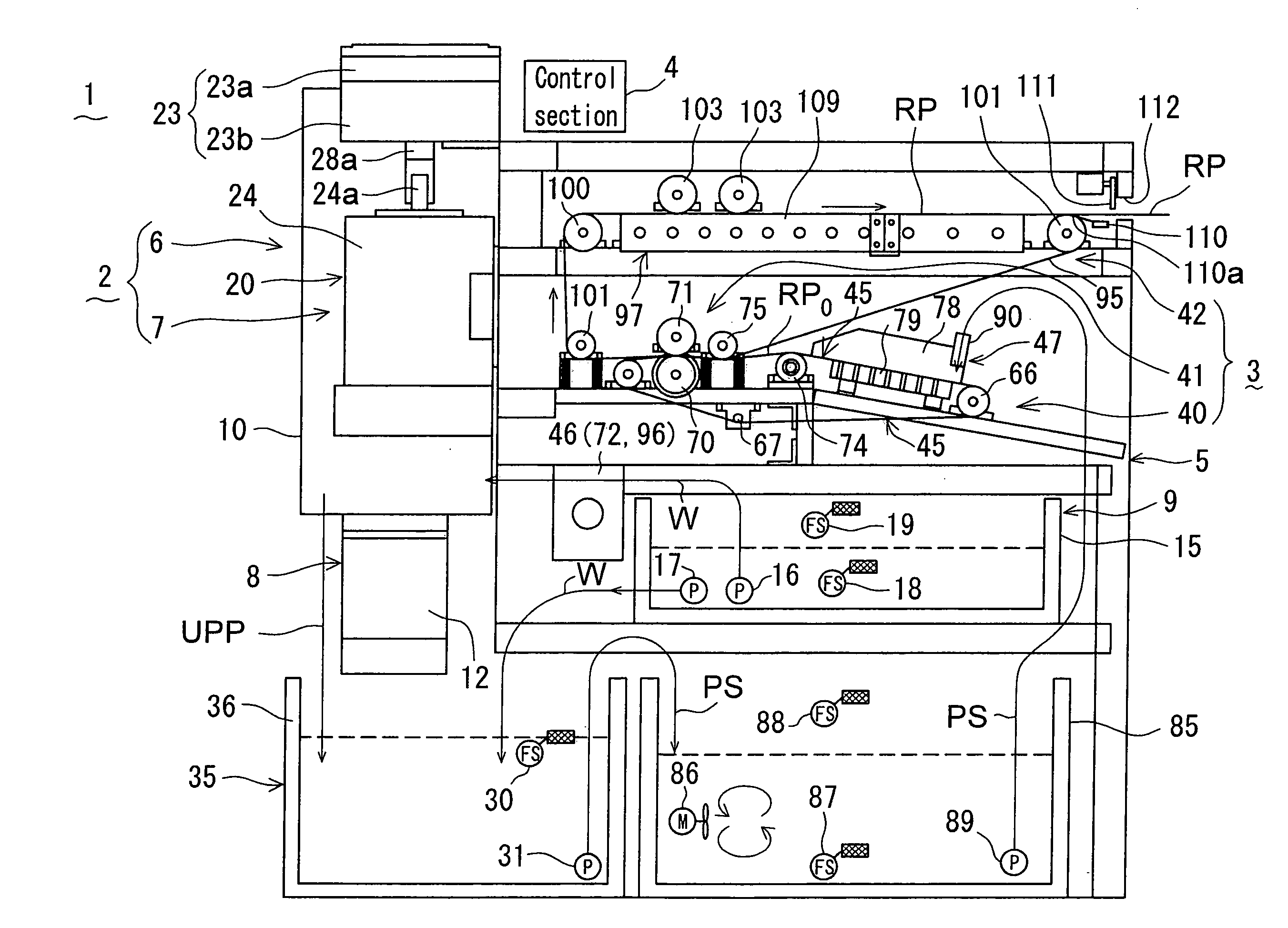

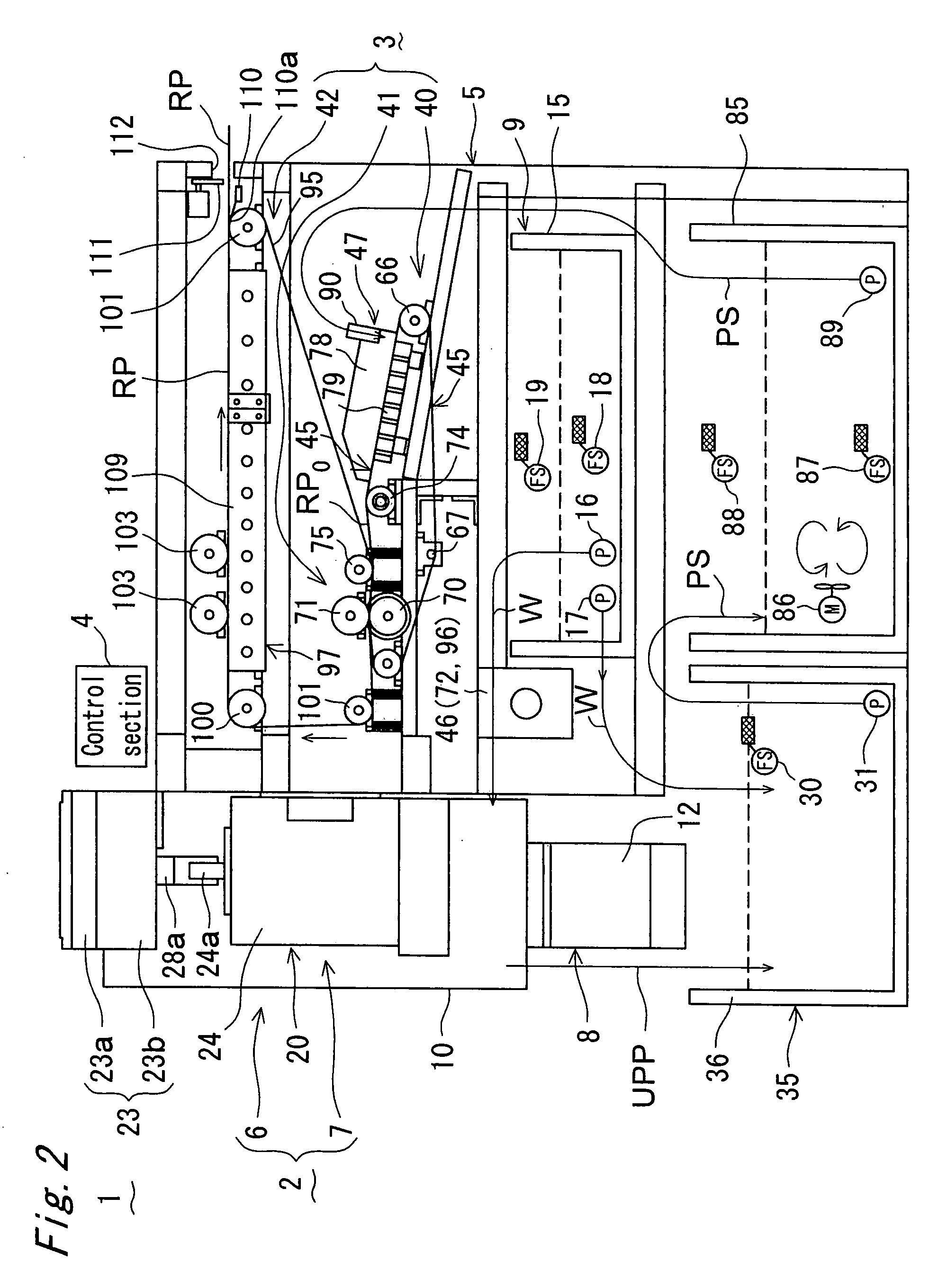

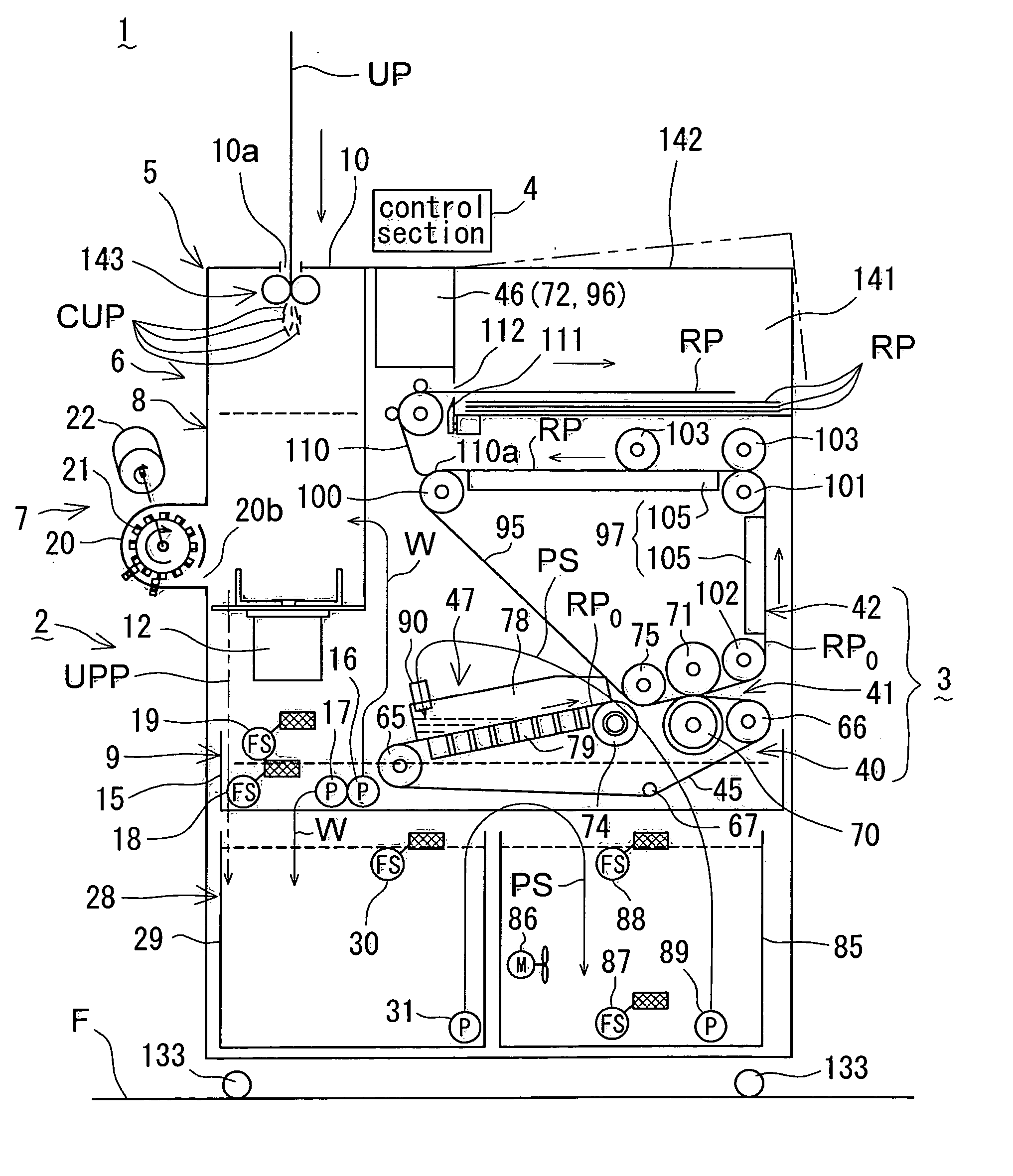

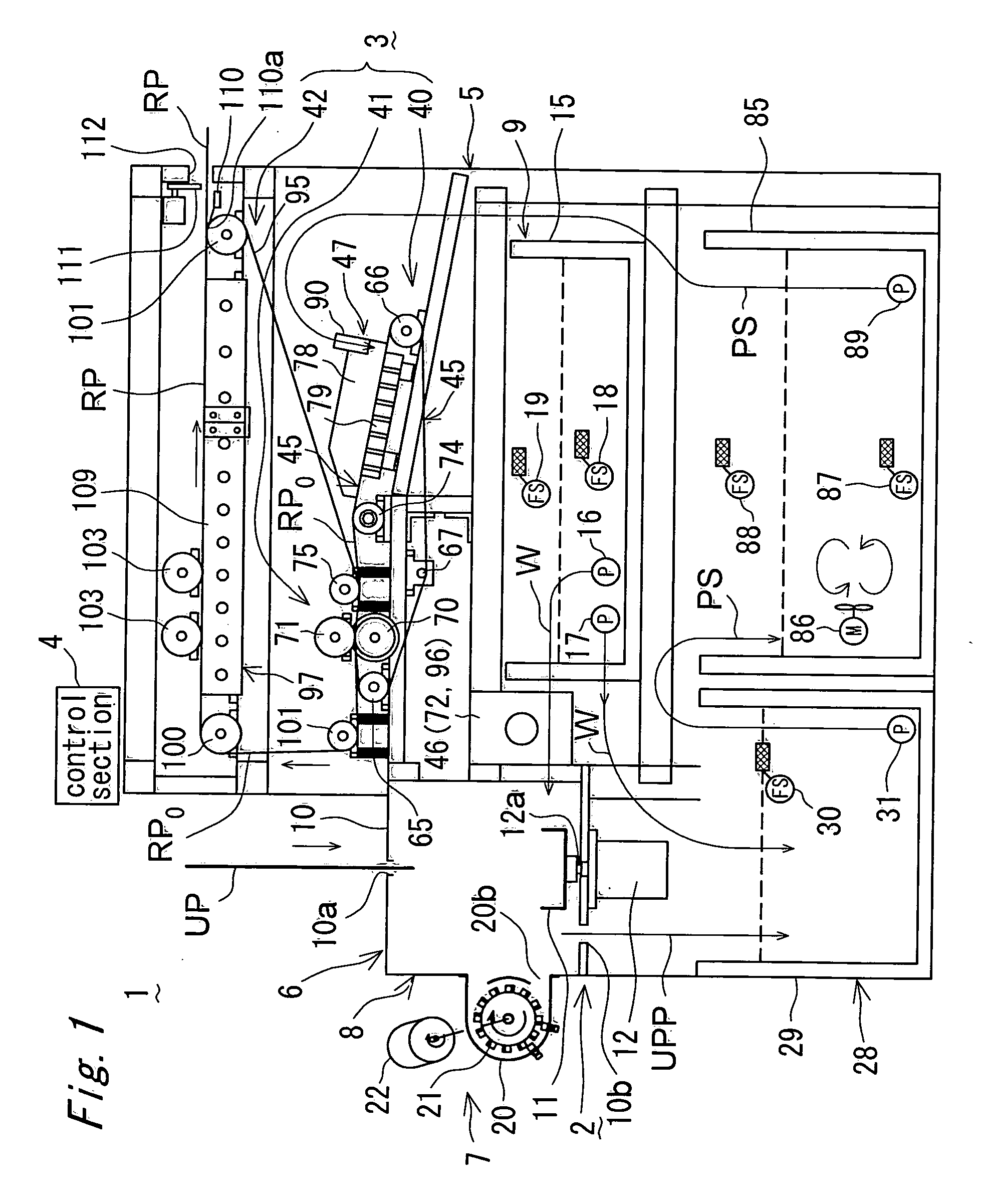

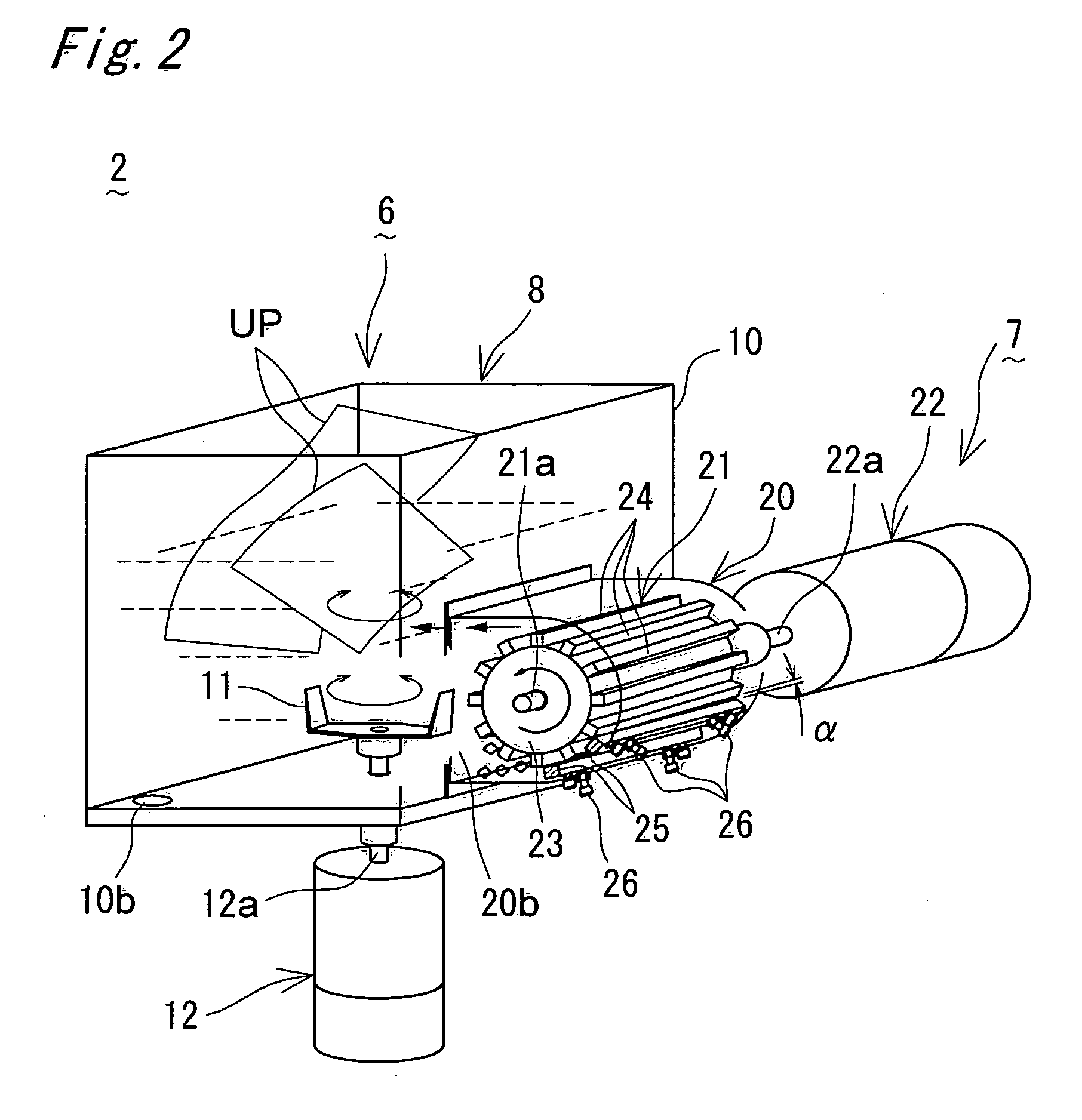

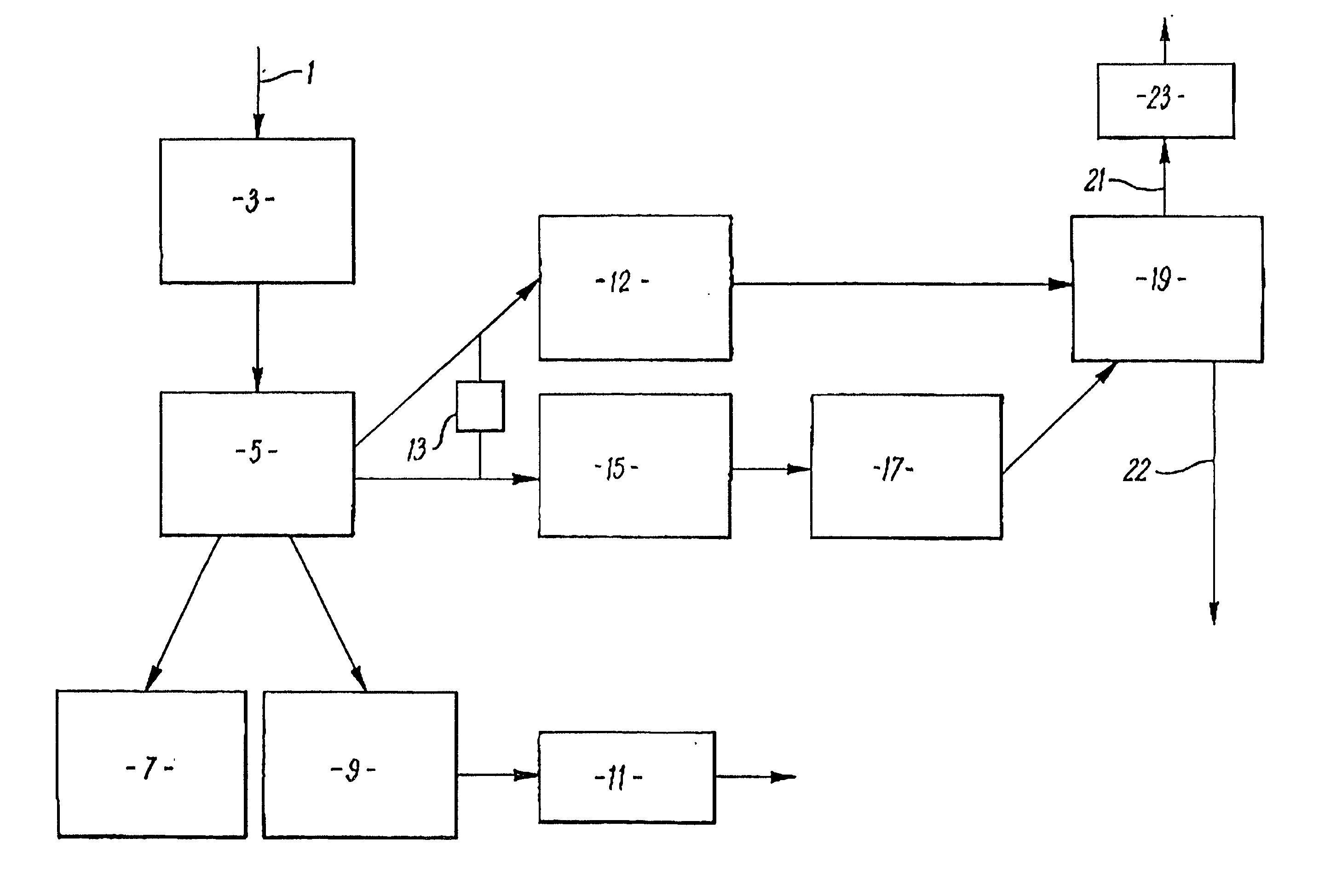

Used paper recycling apparatus and its constitutent devices

InactiveUS20070267163A1Prevent leakage of confidential informationPrevent leakage of private informationWaste product additionPulp de-wateringPaper recyclingPulp and paper industry

A used paper recycling apparatus being installed in a room of a small shop or the like, friendly to the environment, low in running cost, and capable of maintaining a high confidentiality. The apparatus includes, in an apparatus case of furniture size, a pulp making section for manufacturing used paper pulp by macerating and mashing used paper, a paper making section for manufacturing recycled paper by making the used paper pulp manufactured in the pulp making section, and a control section for driving and controlling the pulp making section and paper making section, in which the pulp making section comprises a macerating unit for macerating the used paper by agitating and tearing, and a mashing unit for mashing the used paper macerated in the macerating unit, and the mashing machine of the mashing unit has mashing members rotating relatively being disposed oppositely across a slight mashing clearance, and the opposing faces of these mashing members cooperate to form a mashing action surface, and the used paper passing the mashing clearance is pressurized and mashed by the mashing action surface, and the inks forming characters and patterns on the used paper are pulverized.

Owner:VIEWDLE INC

Method for regenerating corrugated paper by paper mill sludge cracking

InactiveCN108729281AEmission reductionImprove bindingWaste product additionPaper recyclingPapermakingPre treatment

The invention discloses a method for regenerating corrugated paper by paper mill sludge cracking. By means of a papermaking process in which paper mill sludge is subjected to pressurized liquefying, low-temperature cracking, separating and dewatering, filter pressing and the like to be suitable for regenerating corrugated medium paper in a paper mill, the paper mill sludge is better recycled; besides, a low-temperature cracking technology is adopted in the paper mill sludge pretreating process, and no chemical agent is needed; meanwhile, waste gas generated in the paper mill sludge treating process is centralizedly treated, secondary pollution is avoided, and the paper mill sludge treating process further reduces the cost and has higher environmental friendliness.

Owner:DONGGUAN TAICHANG PAPER CO LTD

Pulp Sludge Ash Composition for Producing Building Materials

InactiveUS20080006383A1High strengthImprove water resistanceNatural cellulose pulp/paperSpecial paperSludgeSodium silicate

Disclosed is a pulp sludge ash composition for producing building materials, which comprises pulp sludge ash combined with modified sodium silicate having an acidic group. The pulp sludge ash composition shows excellent water resistance and strength as well as improved physical properties, and thus is useful for various industrial fields as a building material, a civil engineering material, an interior material, a filler for a safe, or the like.

Owner:PARK JONG WON

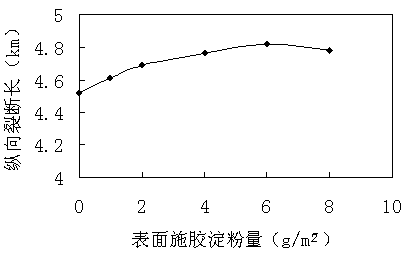

Corrugated medium produced from waste paper papermaking sludge as well as production method of corrugated medium

InactiveCN104674595AOvercome the defect of weak binding forceImprove retentionWaste product additionWater-repelling agents additionFiberSludge

The invention discloses a corrugated medium produced from waste paper papermaking sludge as well as a production method of the corrugated medium. In the process for producing the corrugated medium from waste paper used as a raw material, primary sludge with the paper pulp fiber mass ranging from 0.5% to 2%, biochemical sludge with the paper pulp fiber mass ranging from 0.5% to 1%, cationic starch with the paper pulp fiber mass ranging from 0.1% to 1% and cationic polyacrylamide with the paper pulp fiber mass ranging from 0.01% to 0.08% are added to a paper-making machine pulp tank and evenly mixed, the corrugated medium is produced after net loading, paper-making with pulp, pre-drying, surface sizing with surface sizing starch and after-drying, and the consumption of the surface sizing starch is 0.2-1 time the total amount of the primary sludge and the biochemical sludge. The waste paper papermaking sludge is used for producing the corrugated medium, waste paper raw material consumption can be reduced, the production cost can be reduced, and the economic benefit is better; meanwhile, the yield of solid waste can be greatly decreased, the pollutant end treatment cost can be reduced, and the environmental benefit is significant.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Paper sludge processing for animal bedding

A method for making an animal bedding fiber product, the method includes providing fiber from paper sludge, formulating the fiber in a mixture including a first desiccant agent including ash, so as to form a friable aggregate. Further, a fiber product including at least one short paper fiber from a secondary fiber, one or more inorganic fillers including kaolin clay; and a first desiccant agent including ash. Further still, a heatless process for making a fiber product including providing fiber from paper sludge, formulating the fiber in a non-active heat generating mixture including a first desiccant agent including ash, so as to form a waste fiber product.

Owner:CASELLA WASTE SYSTEMS

Method of monitoring macrostickies in recycling and paper or tissue making process involving recycled pulp

Owner:NALCO CO

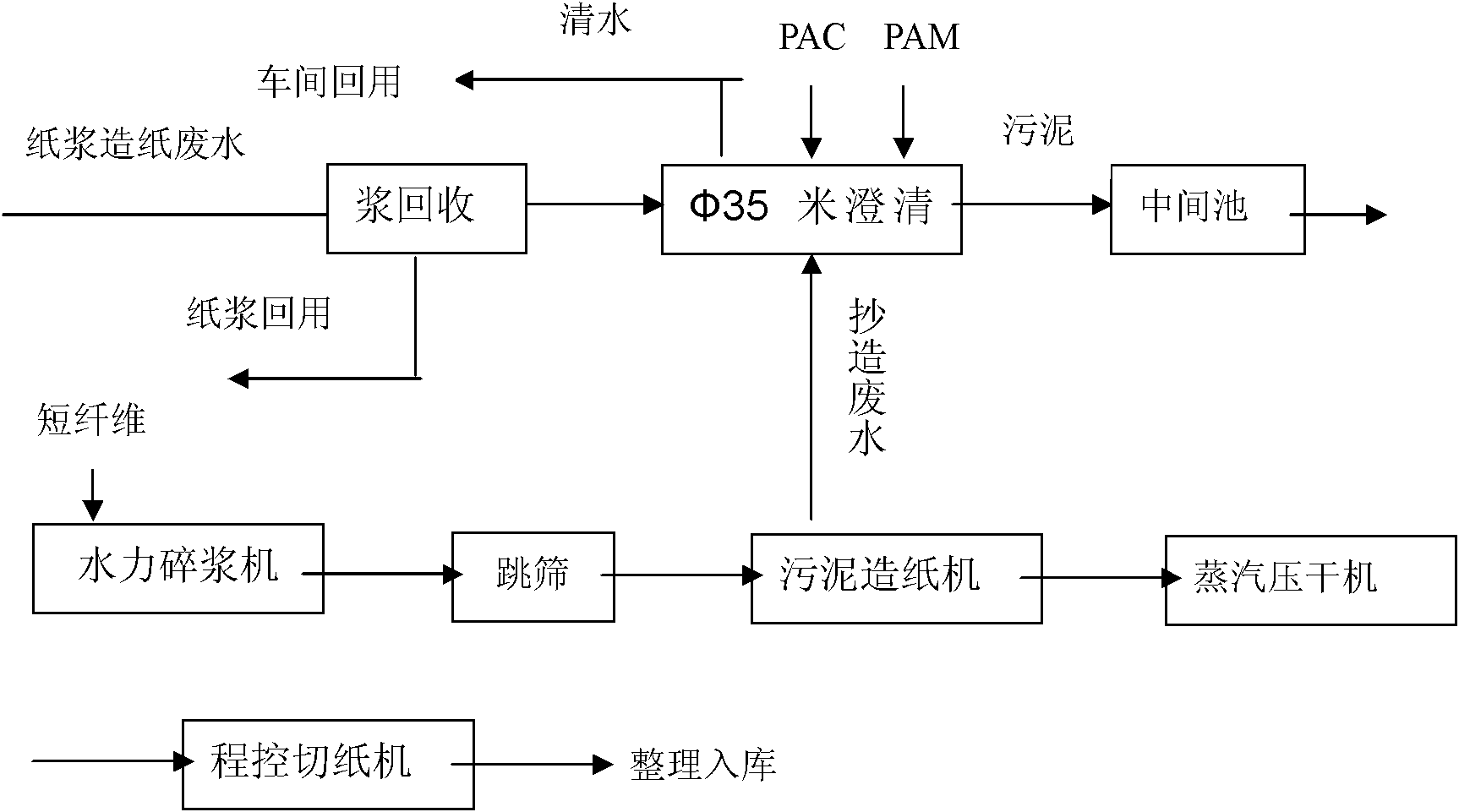

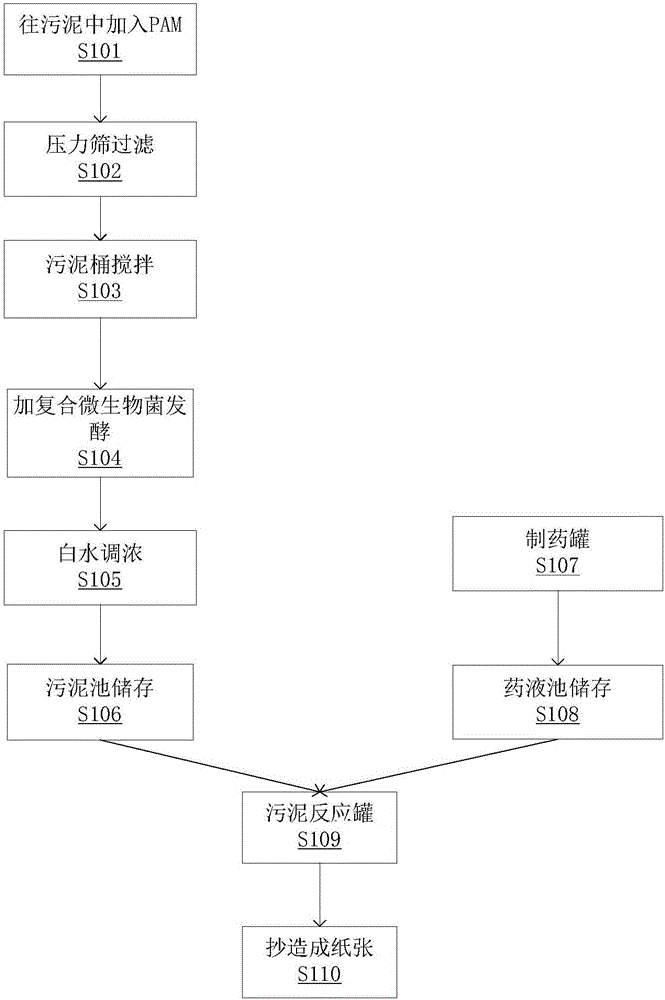

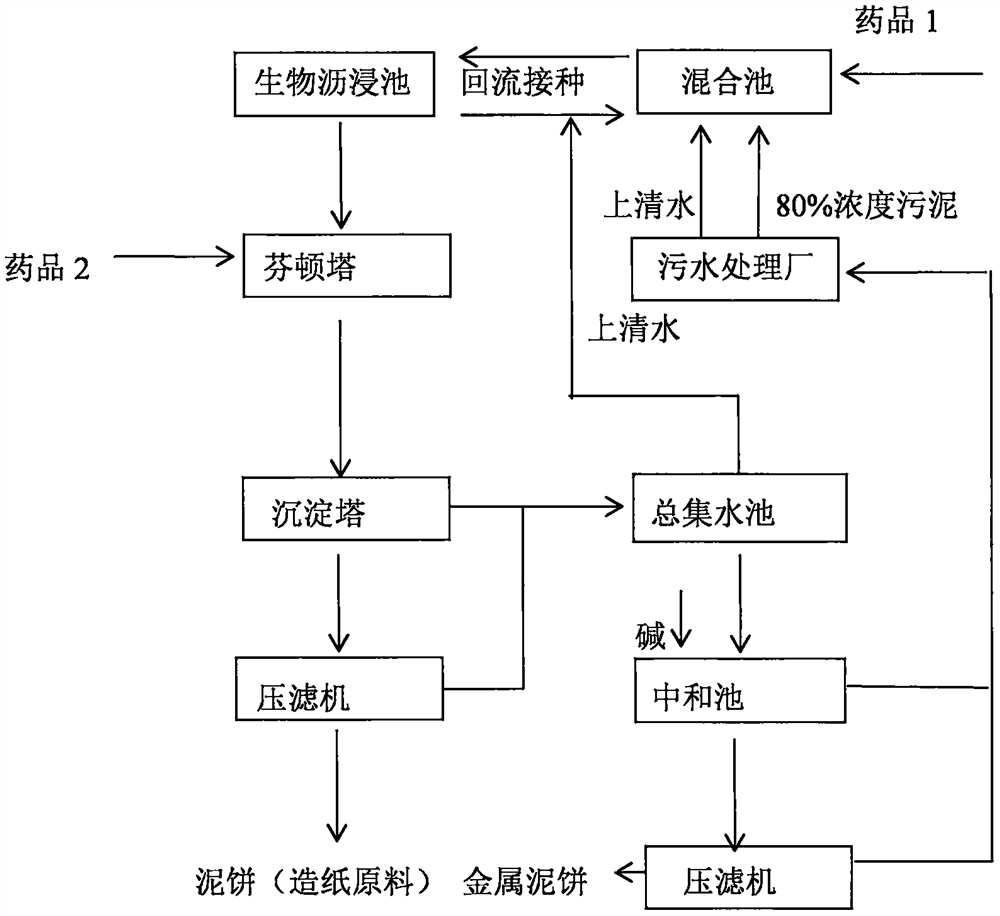

Sludge recovery and paper making method

ActiveCN106007257AReasonable useImprove dehydration efficiencySludge treatmentWaste product additionFiberChemical reaction

The invention discloses a sludge recovery and paper making method, belonging to the field of paper making. The method comprises the following steps: adding PAM (polyacrylamide) into sludge, and dewatering the sludge; filtering the dewatered sludge with a pressurized screen; stirring the sludge at the rotation speed of 1400-1500 r / min; adding composite microbes into the sludge, and carrying out fermentation; after the fermentation, filtering out the water, adding white water into the fermented sludge to regulate the concentration, detecting the sludge concentration by a sludge concentration transducer, and controlling the concentration at 4-6%; after regulating the concentration of the sludge, adding chemical raw materials (PAM, ammonium sulfate and sodium bentonite) into the sludge; after the chemical reaction, dissolving the sludge in water to obtain a suspension; and mixing the sludge with the pulp for paper making, and carrying out paper making. The sludge is activated after being sufficiently treated, and thus, can be better adsorbed to the fibers; and the sludge is added into waste paper pulp to make paper, thereby rationally utilizing the sludge and greatly protecting the environment.

Owner:山鹰华南纸业有限公司

Formula for sludge corrugated base paper, production process and produced corrugated board

ActiveCN102561100AImprove waterproof performanceHigh strengthWaste product additionSpecial paperAdhesiveSludge

The invention discloses a formula for sludge corrugated base paper, which consists of major ingredient and accessory, wherein the major ingredient is papermaking waste water sludge; and the accessory is mixing superfine padding formed by mixing inorganic superfine padding and organic superfine padding. The invention further provides a production process for producing corrugated base paper by the formula for sludge corrugated base paper, as well asprovides sludge corrugated base paper and case board paper prepared by the invention and a corrugated board made of adhesives. The papermaking waste water sludge is directly used as papermaking raw materials to be recycled and manufactured into recycled paper, so that the invention can solve the problem of secondary environment pollution caused by papermaking sludge; the solid wastes of the papermaking waste water sludge can be recycled; and the produced corrugated board has better strength and waterproof property.

Owner:浙江上峰包装新材料有限公司

Treatment of solid containing material derived from effluent

InactiveUS7300539B2Improve propertiesCalcium/strontium/barium carbonatesCellulosic pulp after-treatmentSludgeSolid matter

A method of treating solid containing material derived from effluent or sludge from a plant for deinking paper, the material containing calcium in the form of one or more insoluble calcium compounds, the method including the steps of treating the material with an acid to cause dissolution of the calcium thereby forming a calcium ion-containing solution in which insoluble solids are suspended, separating the solution from the insoluble solids and incinerating the separated solids. The solution containing calcium ions may be treated by adding one or more reagents to form a calcium compound precipitate, eg calcium carbonate. The particulate solids produced following the incineration step and following the precipitate formation may be employed as pigments or fillers in paper making or paper coating.

Owner:IMERYS MINERALS LTD

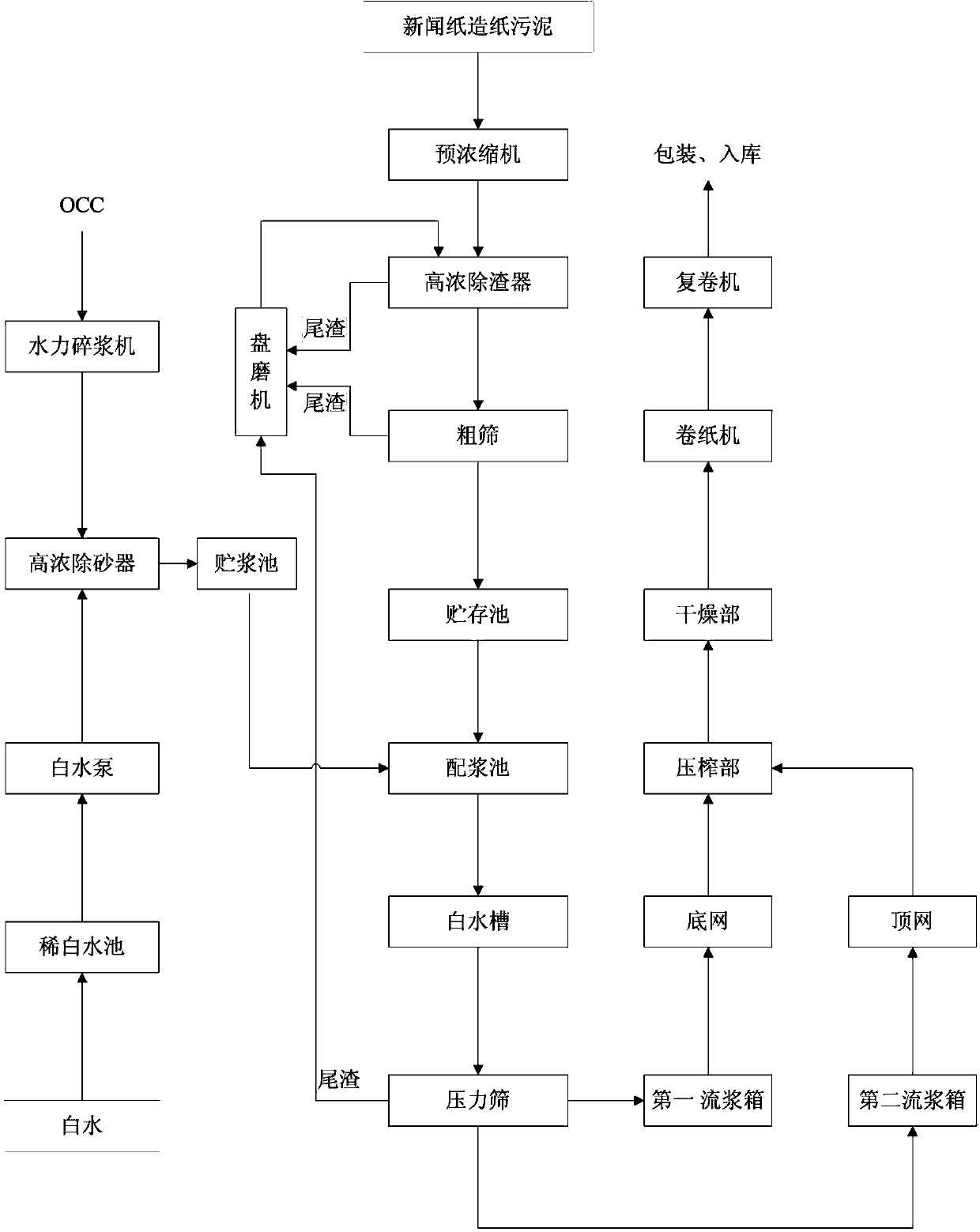

Method for producing environment-friendly regenerated bobbin body paper by using paper mill sludge of newsprint

ActiveCN103437238AAvoid pollutionLow costWaste product additionSecondary cellulose fibresBobbinPapermaking

The invention discloses a method for producing environment-friendly regenerated bobbin body paper by using paper mill sludge of newsprint, relating to the field of recycle of paper mill sludge of newsprint. According to the method provided by the invention, the environment-friendly regenerated bobbin body paper is prepared by the following steps: mixing treated paper mill sludge of newsprint with treated OCC pulp in a certain proportion; and manufacturing paper with pulp by white water in a newsprint papermaking process. According to the method provided by the invention, the environment-friendly regenerated bobbin body paper is produced by using paper mill sludge produced in the production process of newsprint, so that the production cost is lowered, the waste paper resources are saved, the water resources are recycled, and the environmental pollution is avoided.

Owner:GUANGDONG HUATAI PAPER IND

Used paper recycling apparatus and its constituent devices

InactiveUS20070062663A1Prevent leakage of confidential informationLeak of personal informationWaste product additionPaper/cardboard wound articlesPaper recyclingPulp and paper industry

A used paper recycling apparatus capable to be installed in small office or general household, friendly to environment and low in running cost, and assuring high confidentiality. A used paper recycling apparatus comprising a pulp making section for crushing and beating used paper and making into pulp, a paper making section for recycling paper by making used paper pulp from the pulp making section, and a control section for driving and controlling by interlocking the pulp making section and paper making section, which are incorporated in a furniture size apparatus case, in which the pulp making section includes a crushing unit for stirring and grinding the used paper, and a beating unit for beating the crushed used paper from the crushing unit, and the crushing unit and beating unit are circulating the used paper pulp.

Owner:VIEWDLE INC

Method for making paperboards by using paper mill sludge

The invention provides a method for making paperboards by using paper mill sludge. The method comprises the following steps: by using paper mill sludge as auxiliary materials for making the paperboards by adopting an interlayer filling technology, fully mixing the paper mill sludge subjected to impurity removal pretreatment with a reinforcing agent, uniformly applying a mixture between two wet paper sheets, pressing, drying and finishing, thus forming the paperboards similar to sandwich structures. Compared with a conventional technology for making the paperboards through wet-end paper mill sludge addition, the method provided by the invention has the advantages that the added paper mill sludge can be mostly remained in the paperboards so as to form packing layers, thus the retention of the paper mill sludge in the paper boards is increased, and the method is simple in process, strong in operability and convenient to implement through an interlayer spraying method in a conventional papermaking process. The paper mill sludge is added to the paperboard making process so as to make the paperboard products meeting the quality requirements, so that the cost of fiber raw materials is saved for papermaking enterprises, and the purpose of digesting paper mill sludge solid waste in the enterprises is also achieved; the method is an effective approach for the resource utilization of the paper mill sludge.

Owner:SHAANXI UNIV OF SCI & TECH

Application of tea leaf residues in paper making, and making method of paper by using tea leaf residues

InactiveCN103866603ANatural dry brown colorWith tea fragranceWaste product additionFiberPulp and paper industry

The invention provides an application of tea leaf residues in paper making, and a making method of paper by using the tea leaf residues. The making method concretely comprises the following steps: adding an alkaline substance to the tea leaf residues, heating, carrying out pulp grinding, carrying out pulp washing, separating fibers to prepare a pulp, adding a dispersant into the pulp, papermaking, and baking paper to obtain dry paper.

Owner:TIANJIN TASLY GROUP

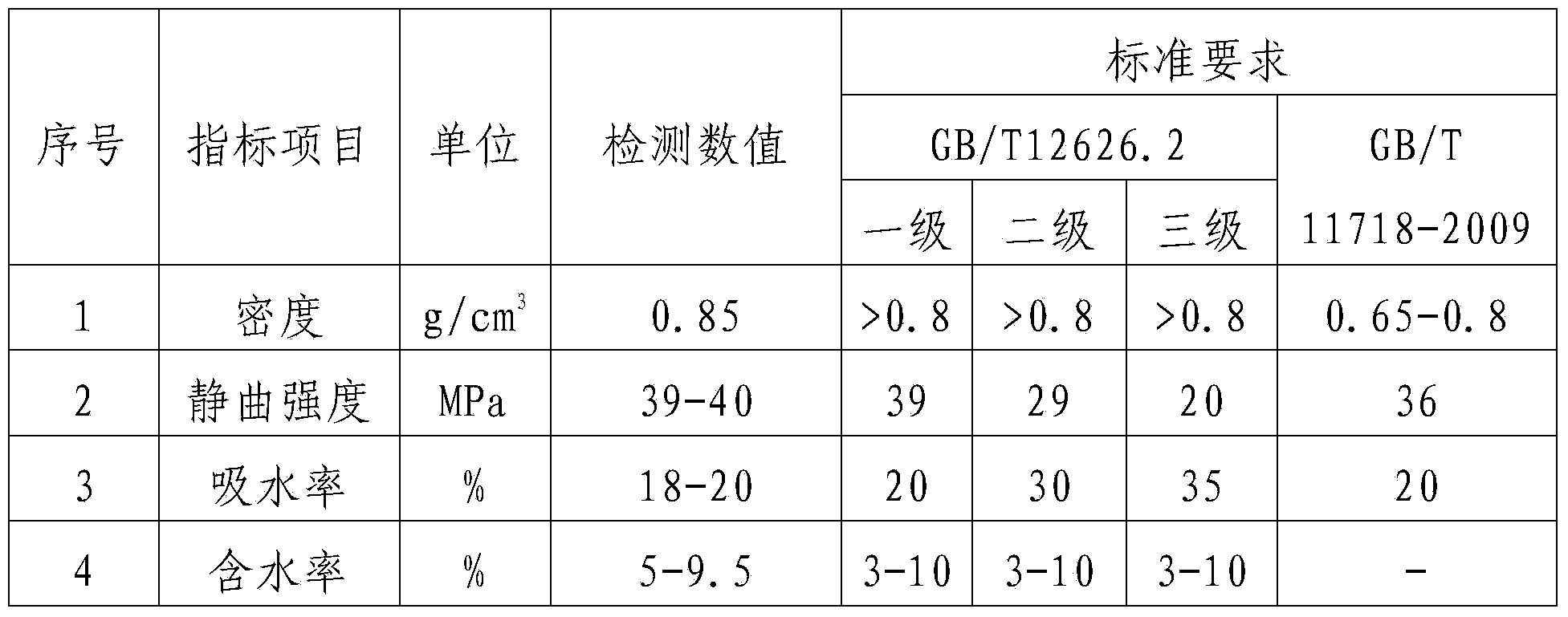

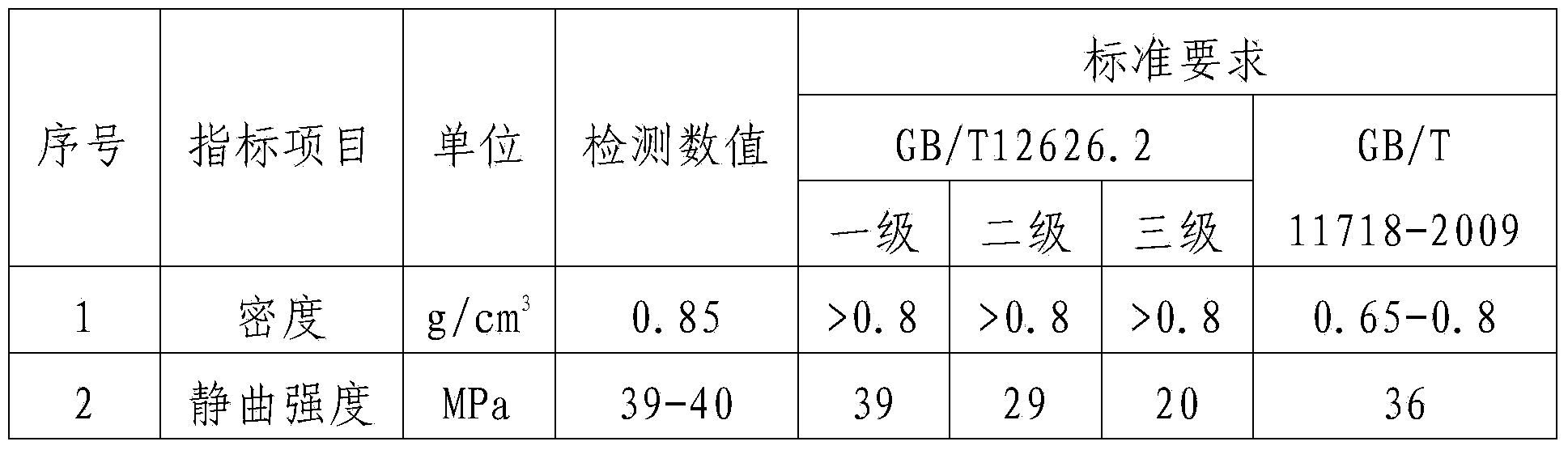

Method for producing hard fiberboard through paper mill sludge

ActiveCN103711041AAct as a cross-linkPlay stabilityFibreboardWaste product additionSludgeNational standard

The invention belongs to paper mill sludge treatment, and particularly relates to a method for producing a hard fiberboard through paper mill sludge. The method comprises the process steps of deodorization, pulp homogenizing, forming, drying and the like. The method solves the problems that in the prior art, the process is complex, cost is high and the environmental protection performance of products is poor. The method has the advantages of being capable of effectively utilizing industrial waste and low in production cost, enabling the products to meet the requirements of national standards, being good in environmental protection performance and low in price and the like.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

Method for preparing edible packing paper by using wheat bran dietary fiber as raw material

The invention relates to a method for preparing edible packing paper by using wheat bran dietary fiber as a raw material, which comprises the following steps of: crushing the wheat bran dietary fiber to the granularity range of 200 to 300 meshes, mixing the crushed wheat bran dietary fiber and water to make the concentration of the solution reach 8 to 15 percent (w / v), performing ultrasonic treatment for 8 to 15 minutes under the condition of 300 to 600W, adding glycerol, oolong tea polyphenol, chitosan and sodium alginate into the solution, rolling, molding, and drying to obtain the edible packing paper using the wheat bran dietary fiber as the raw material. The edible packing paper prepared by the method has exquisite texture, light yellow color and no special odor, and is suitable for inner packages of instant noodle spices and seasonings; and the edible packing paper can be dissolved by soaking into hot soup, so the edible packing paper is convenient and has certain nutritional value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Paper made of textile, industrial and agricultural waste residues and papermaking method

ActiveCN112709092AImprove moisture absorption capacityImprove bindingWaste product additionRadio/micro wave fibre treatmentFiberPapermaking

The invention discloses paper produced by taking textile, industrial and agricultural waste residues as raw materials and a papermaking method, and belongs to the technical field of papermaking. Waste fibers generated in industry and agriculture are subjected to surface modification and blended with papermaking sludge, cottonseed velvet, cotton ash, vinasse, waste mushroom residues, traditional Chinese medicine residues, starch leftovers, potato residues, waste leather, straws, waste veneers, sawdust, waste bamboos, nutshells and other waste residues and corresponding additives for high-speed, medium-speed and low-speed industrial production of paper, 10-1500 g / m<2> paper can be produced, and paper quality reaches national standards. The pollution problem of the industrial and agricultural waste residues is solved from the source, more than 20 million tons of papermaking fibers are found for the papermaking industry, and the problem of domestic waste paper shortage caused by national limit on imported ocean garbage is effectively solved; and meanwhile, 95% of papermaking raw materials are waste residues and garbage, and the raw materials do not need to be purchased, so that the production cost is low, and very high benefits are brought to enterprises.

Owner:夏振明

Method for reproducing heavy-duty package kraft linerboard by utilizing papermaking sludge

ActiveCN108570884ARelieve stressReduce manufacturing costFlexible coversWrappersHigh concentrationFlocculation

A method for reproducing heavy-duty package kraft linerboard by utilizing papermaking sludge is disclosed. The method includes a sludge collection step, a high-concentration slag removal step, a centrifugal dewatering step, a sterilization and drying treatment step, a step of preparing filler slurry, a filler pulp preparing step, a flocculation step, a pulp preparation step, a papermaking step, asurface modification step, and a calendering step. The papermaking sludge is recovered and treated with an ultralow running cost and is used for producing the heavy-duty package kraft linerboard, andtherefore, pressure on sludge treatment of a papermaking enterprise is reduced, the benefit of recycling the papermaking sludge is higher than that of incineration methods, waste of land resources andgeological pollution caused by landfill of papermaking sludge are reduced, a production process is clean, environmentally friendly and free of production, and the integrated production cost of heavy-duty package kraft linerboard is reduced.

Owner:DONGGUAN TAICHANG PAPER CO LTD

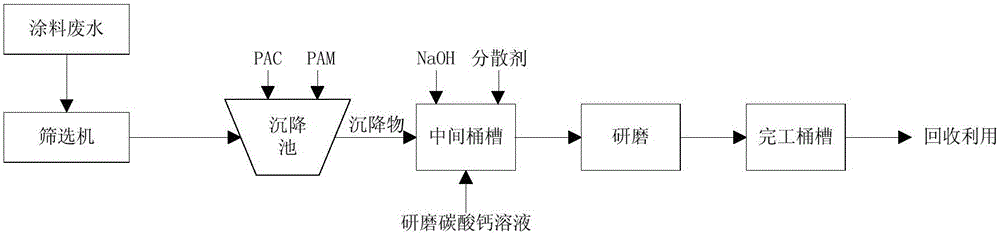

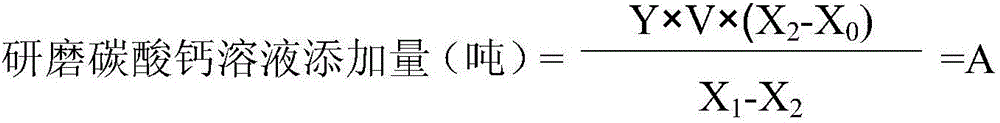

Method for recovering solids in paper-making coating waste water

ActiveCN106758464ALow viscositySolve easy blockagePulp liquor regenerationWaste product additionHigh concentrationDispersity

The invention provides a method for recovering solids in paper-making coating waste water. The method comprises the following steps: S1, removing the impurities in the coating waste water by using a screening machine, and sending the waste water without impurities into a sedimentation tank; S2, adding a flocculant into the coating waste water so as to enable the solids in the coating waste water to settle down to the bottom of the sedimentation tank; S3, collecting the settled solids, sending the collected solids into an intermediate barrel tank which is internally provided with a stirrer, and sequentially adding NaOH, a dispersing agent and a ground calcium carbonate solution into the intermediate barrel tank to obtain a total calcium carbonate solution, wherein the solid content of the ground calcium carbonate solution is higher than that of the settled solids; S4, grinding the total calcium carbonate solution, and recovering the ground total calcium carbonate solution. The method is used for effectively reducing the viscosity of a coating solution and increasing the dispersity and the grinding efficiency, and the solid content of the recovered coating solution reaches the high concentration suitable for a paper-making technology, so that the problem that a pipeline is easily blocked is solved, the investment for equipment is saved, and the process cost is greatly lowered.

Owner:HAINAN JINHAI PULP & PAPER

Treatment of solid containing material derived from effluent

InactiveUS20020079075A1Reducing and eliminating cost and environmental impactSimpler and cheapCalcium/strontium/barium carbonatesWaste product additionParticulatesSludge

A method of treating solid containing material derived from effluent or sludge from a plant for de-inking paper, the material containing calcium in the form of one or more insoluble calcium compounds, the method including the steps of treating the material with an acid to cause dissolution of the calcium thereby forming a calcium ion-containing solution in which insoluble solids are suspended, separating the solution from the insoluble solids and incinerating the separated solids. The solution containing calcium ions may be treated by adding one or more reagents to form a calcium compound precipitate, eg calcium carbonate. The particulate solids produced following the incineration step and following the precipitate formation may be employed as pigments or fillers in paper making or paper coating.

Owner:IMERYS MINERALS

Popular searches

Sedimentation separation Differential sedimentation Water/sewage treatment by flocculation/precipitation Lignin material coatings Protein coatings Pigment pastes Sludge treatment by de-watering/drying/thickening Water treatment compounds Specific water treatment objectives Waste water treatment from plant processing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com