Method for recovering solids in paper-making coating waste water

A paint wastewater and recovery method technology, applied in papermaking, textiles and papermaking, chemical instruments and methods, etc., can solve problems such as inconvenient operation and cleaning, difficult transportation, easy clogging, etc., to improve grinding efficiency, improve dispersibility, The effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

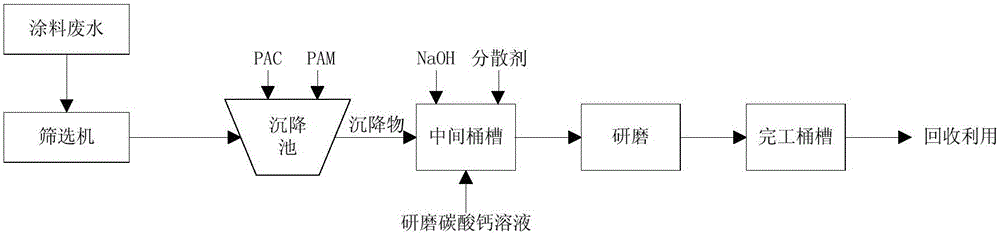

Method used

Image

Examples

Embodiment 1 to Embodiment 3

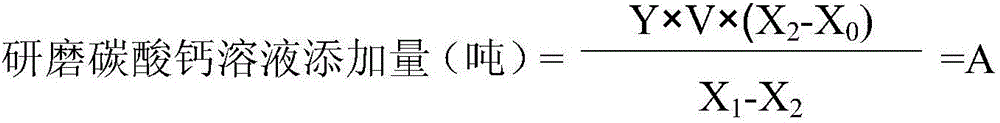

[0041] In the process of step S3, the solid content that settles down is collected and sent to the intermediate barrel tank that is provided with agitator again, the solid content of the solid content that settles down among the example 1 to embodiment 3 is respectively 21.9%, 28.8% and 34.01% , the stirring speed is 2000r / min, and NaOH, dispersant and ground calcium carbonate solution are sequentially added to the middle tank. After adding NaOH, the pH=8, the added amount of the dispersant is 400PPM, and the solid content of the newly added ground calcium carbonate solution is 75%.

[0042] The viscosity improvement result of embodiment 1 to embodiment 3 is as shown in table 2, and viscosity (unit is cPS) variation curve is as shown in figure 2 shown.

[0043] Table 2

[0044]

Embodiment 4 to Embodiment 6

[0046] In the process of step S3, the solid matter that settles down collects and sends into the intermediate vat that is provided with agitator again, the solid content of the solid matter that settles down among the example 4 to embodiment 6 is respectively 21.9%, 28.8% and 34.01% , the stirring speed is 3000r / min, and NaOH, dispersant and ground calcium carbonate solution are sequentially added to the middle tank. After adding NaOH, the pH=9.2, the added amount of the dispersant is 360PPM, and the solid content of the newly added ground calcium carbonate solution is 55%.

[0047] The improvement results of the viscosity (in cPS) of Examples 4 to 6 are shown in Table 3.

[0048] table 3

[0049]

[0050]

Embodiment 7 to Embodiment 9

[0052] In the process of step S3, the solid content that settles down is collected and then sent into the intermediate tank that is provided with agitator, and the solid content of the solid content that settles down among the example 7 to embodiment 9 is respectively 21.9%, 28.8% and 34.01% , the stirring speed is 5000r / min, and NaOH, dispersant and ground calcium carbonate solution are sequentially added to the middle tank. After adding NaOH, the pH=10, the added amount of the dispersant is 480PPM, and the solid content of the newly added ground calcium carbonate solution is 99%.

[0053] The improvement results of the viscosity (in cPS) of Examples 7 to 9 are shown in Table 4.

[0054] Table 4

[0055]

[0056]

[0057] From Tables 2 to 4 and figure 2 It can be seen that the present invention increases the treatment of the middle tank of step S3 before step S4 grinding, adjusts the addition ratio of NaOH and dispersant, reduces the viscosity, and realizes reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com