Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Soften evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

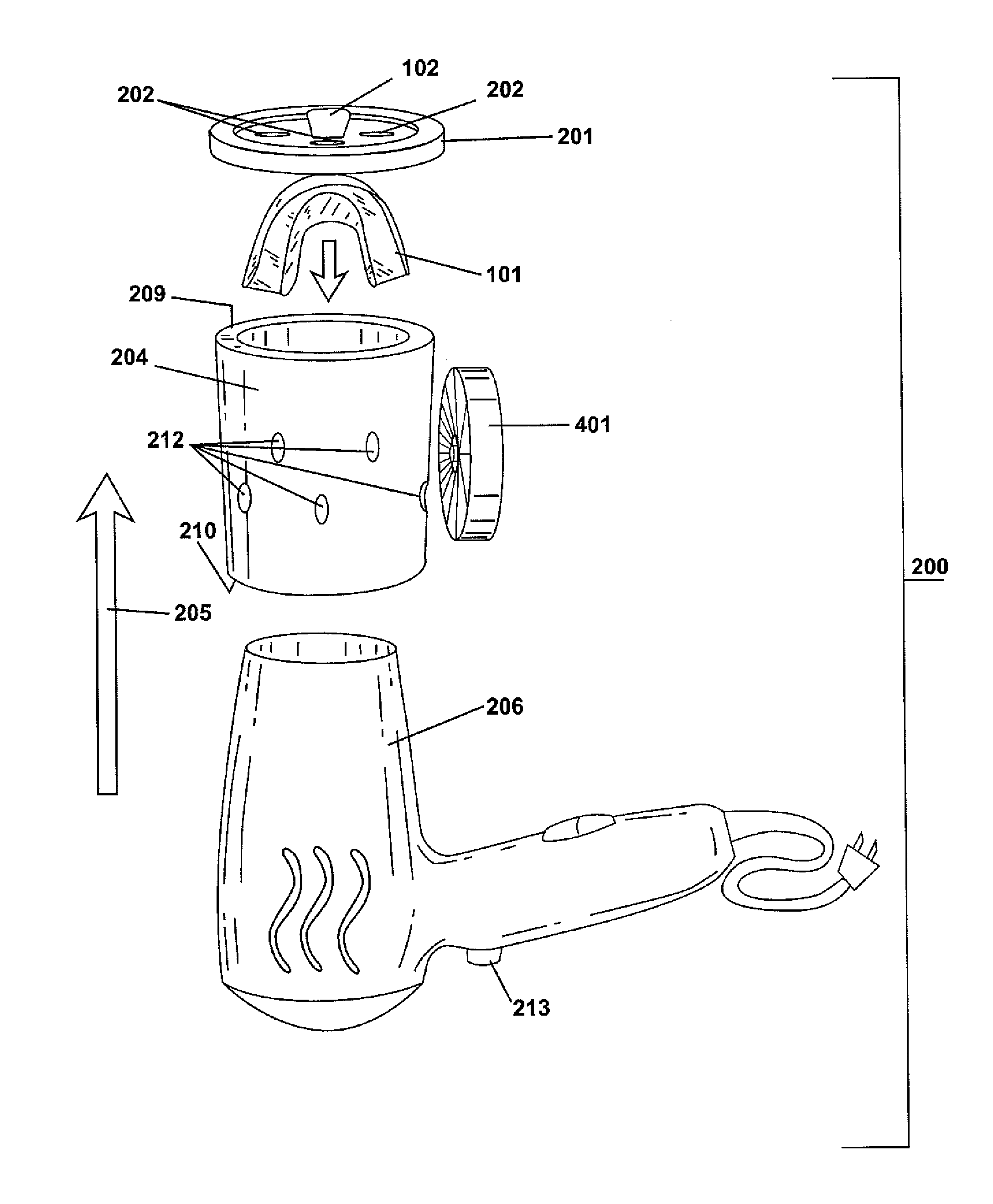

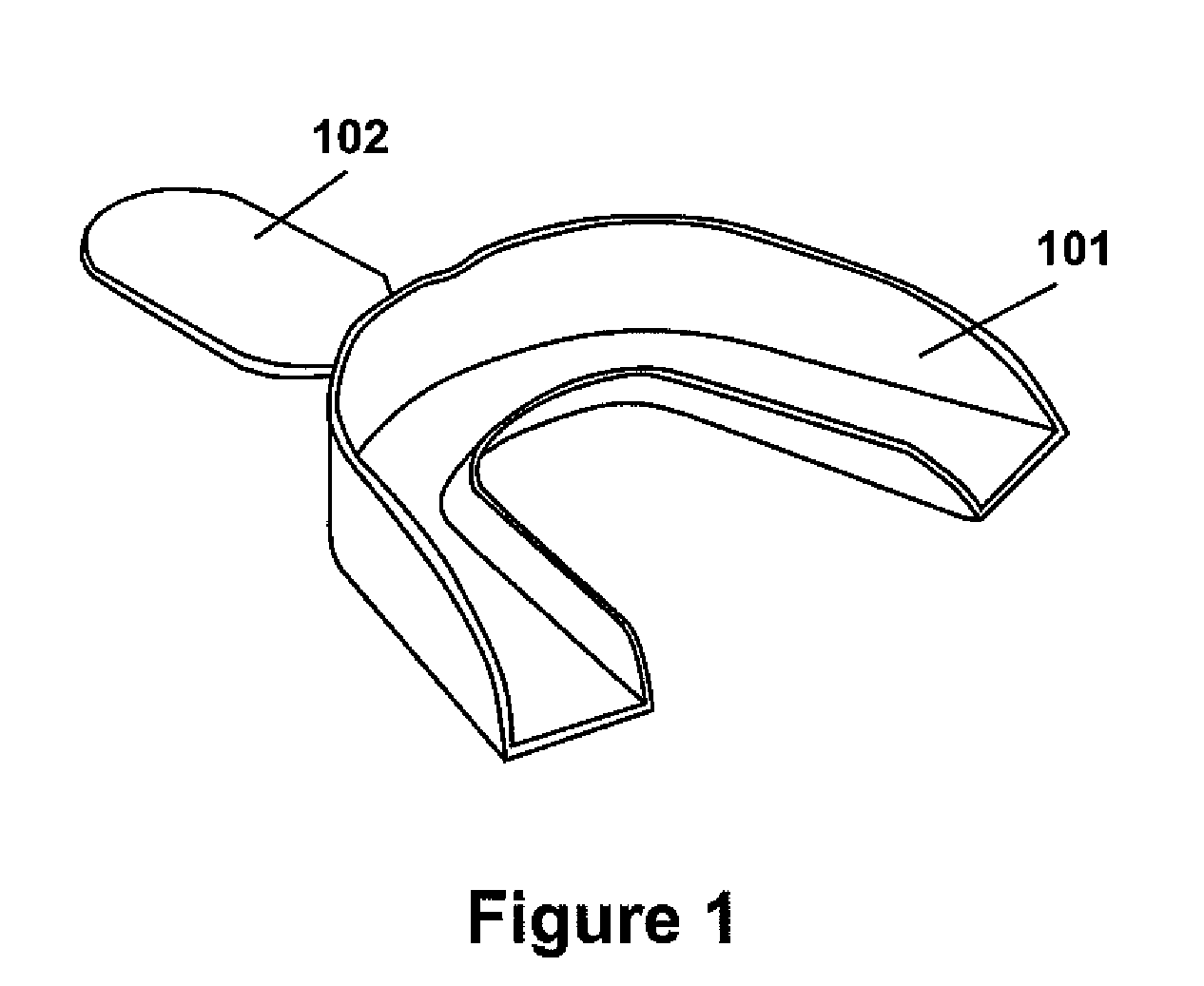

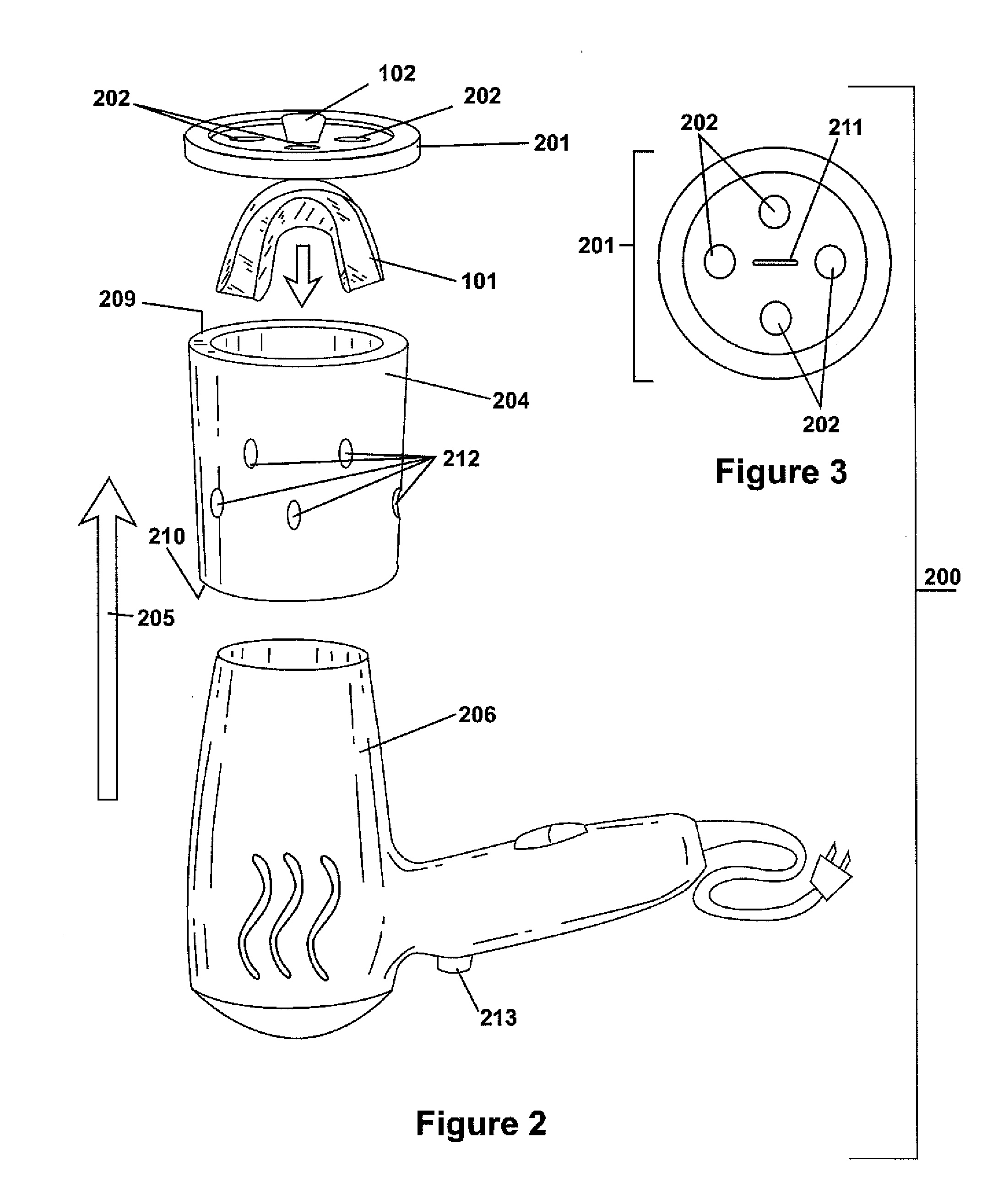

System and Process for Custom Molding Dental Trays

InactiveUS20080041400A1Heating evenly and efficientlyIncreasing turbulent air flowImpression capsTeeth fillingEngineeringDentistry

A system and method for custom molding dental trays is disclosed. The system includes a hot air source and heat chamber, wherein a thermoformable dental tray is placed within the heat chamber and heated to the appropriate temperature. The heat chamber may include air escape holes to allow for uniform heating. Furthermore, the heat chamber may incorporate a fan or other air removal device to improve uniform heating.

Owner:DARNELL DANIEL H

Chinese medicinal mouldproof willow rattan softening agent and its preparation method

The invention relates to a Chinese medicinal mouldproof willow rattan softening agent, which is made of the following raw materials by weight part: 5-7 of sodium bicarbonate, 15-18 of ethanol, 3-4 of sodium silicate, 3-4 of gluconic acid, 15-25 of radix isatidis, 10-12 of honeysuckle, 8-10 of acorus gramineus, 4-5 of povidone iodine, 3-4 of an assistant, and 100 of water. The Chinese medicinal mouldproof willow rattan softening agent adopts weak acid and weak base, which have small corrosion to a surface, and an even softening effect can be achieved. Ethanol and sodium silicate are employed, so that the stem surface can be smooth, and the weaving efficiency can be improved. By using radix isatidis and other Chinese herbal medicines and povidone iodine, mould and moths can be prevented.

Owner:FUNAN YONGXING ARTS & CRAFTS

Softener for thick salix integra and preparation method of softener

ActiveCN103659979AImprove toughnessSmoothReed/straw treatmentWood impregnation detailsEthylenediamineBetaine

A softener for thick salix integra is made from raw materials in parts by weight as follows: 5-7 parts of ethylenediamine, 4-5 parts of tartaric acid, 4-5 parts of coco-betaine, 1-2 parts of decyl polyglucoside, 4-5 parts of ammonium dihydrogen phosphate, 10-12 parts of dandelion, 4-6 parts of chrysanthemum, 10-12 parts of coptis chinensis, 3-4 parts of camphor tree bark, 6-8 parts of povidone iodine,3-4 parts of an assistant and 100 parts of water. According to the softener, the ethylenediamine, the tartaric acid and multiple surfactants are used, so that the softener is high in permeation speed, high in softening speed and even in softening; the salix integra is good in toughness and touches smooth, and the weaving efficiency can be improved; and Chinese herbal medicines such as the camphor tree bark and the like as well as the povidone iodine are used, so that salix integra is smooth in surface, mould-proof and free of worms. The softener is applicable to softening of the thicker salix integra.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

A mildew-resistant willow rattan softener and a preparing method thereof

InactiveCN104085007AReduce corrosionSoften evenlyWood treatment detailsWood impregnation detailsSodium bicarbonateHouttuynia

A mildew-resistant willow rattan softener is disclosed. The softener is prepared from following raw materials by weight in part: 12-15 of glycerol, 4-7 of sodium hexametaphosphate, 5-7 of sodium bicarbonate, 6-7 of sodium citrate, 3-4 of wild chrysanthemum flower, 5-7 of the tuber of stemona, 2-4 of cordate houttuynia, 4-5 of povidone-iodine, 3-4 of auxiliary agents and 100 of water. The softener adopts a weak acid and a weak base, and is low in surface corrosion, uniform in softening and good in toughness. By using the glycerol and the sodium hexametaphosphate, surfaces of rattans are smooth and the weaving efficiency is increased. By using the tuber of stemona and other Chinese herbal medicines, mildew and damage by worms can be prevented.

Owner:ANHUI HUAYU CRAFTS GRP

Softening agent for thin willow rattans and preparation method of softening agent

The invention discloses a softening agent for thin willow rattans. The softening agent is prepared from the following raw materials in parts by weight: 10-12 parts of bicarbonate, 2-3 parts of diphenyl ethyl compound phenol polyoxyethylene ether, 1-2 parts of oleic acid polyoxyethylene ester, 3-4 parts of radix aconiti sinensis, 2-3 parts of flos daturae, 4-5 parts of lavender, 6-8 parts of cassia twig, 5-7 parts of povidone iodine, 3-4 parts of auxiliaries and 100 parts of water. By the use of weak alkaline and a non-ionic surfactant, the softening agent for the thin willow rattans is uniform in softening, low in speed and suitable for softening of the thin willow rattans and cannot excessively corrosion the thin willow rattans; by the virtue of the traditional Chinese herbs such as the flos daturae and the lavender and the povidone-iodine, the softening agent can be prevented from being mildewed and damaged by worms and can disperse fragrance for a long time.

Owner:FUNAN YONGXING ARTS & CRAFTS

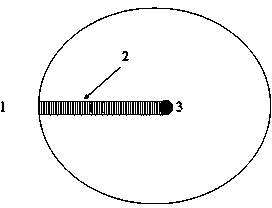

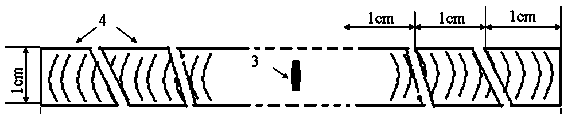

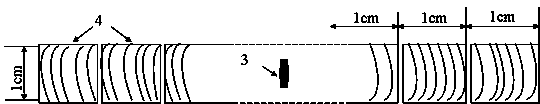

Making method of wood cross section year-by-year growth ring microscopic slices

InactiveCN103994906ASoften evenlyWon't breakPreparing sample for investigationTree rootEthylenediamine

The invention discloses a making method of wood cross section year-by-year growth ring microscopic slices, which comprises the following steps: wood sampling, to be more specific, a tree root part, a tree trunk part and a tree branch part of a tree are respectively sampled, and wood strips or wood blocks (2) are sampled from pith (3) to bark (1); wood softening, to be more specific, sampled wood strips or wood blocks of trees of the same specie are placed in a heatable closed glass container, an ethylenediamine solution with a concentration of 5%-30% is added until the wood strips or wood blocks are soaked, the closed glass container is heated to enable the temperature inside the closed glass container to be maintained at 25-60 DEG C, the sampled wood strips or wood blocks are sealed for soaking and softening treatment, wherein the hard and heavy wood is soaked for 1-4d, and the light and soft wood is soaked for 5-8d; and wood sheet production, to be more specific, the softened wood strips or wood blocks are sliced for making, from the pith to the bark, small cut pieces capable of covering more than two growth rings are obliquely cut and picked in an angle of 40-50 degree according to the marshalling sequence of the growth rings in every 1cm distance. The prepared slices are suitable for wood identification and tree species identification, also suitable for extraction of wood dissection data from year-by-year growth rings without loss or confusion of the growth rings.

Owner:HENAN UNIV OF SCI & TECH

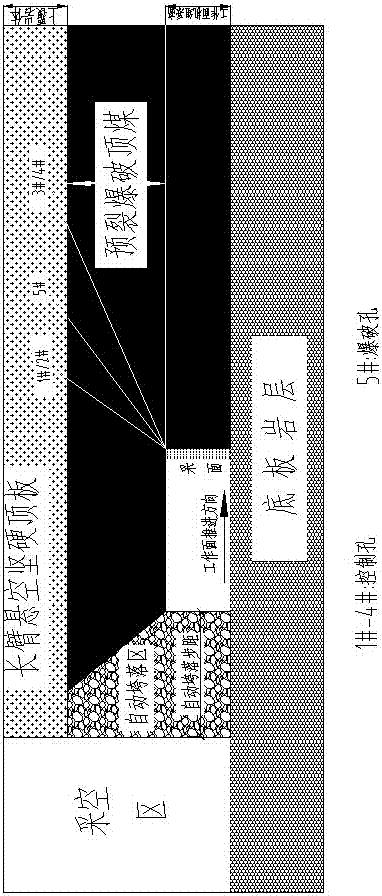

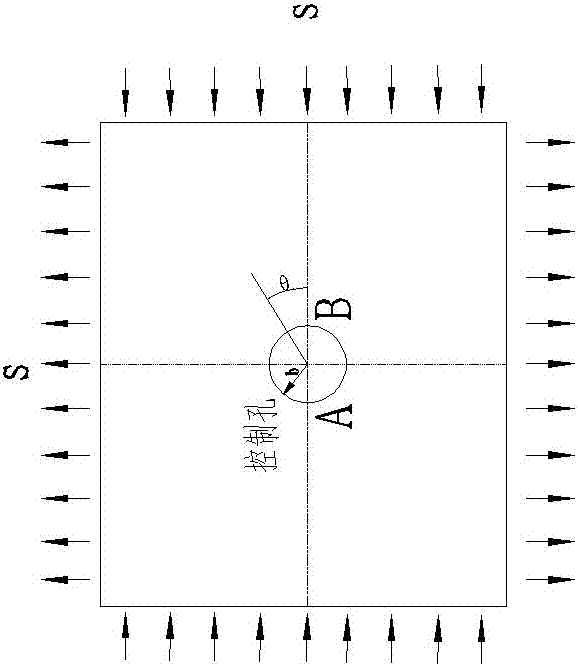

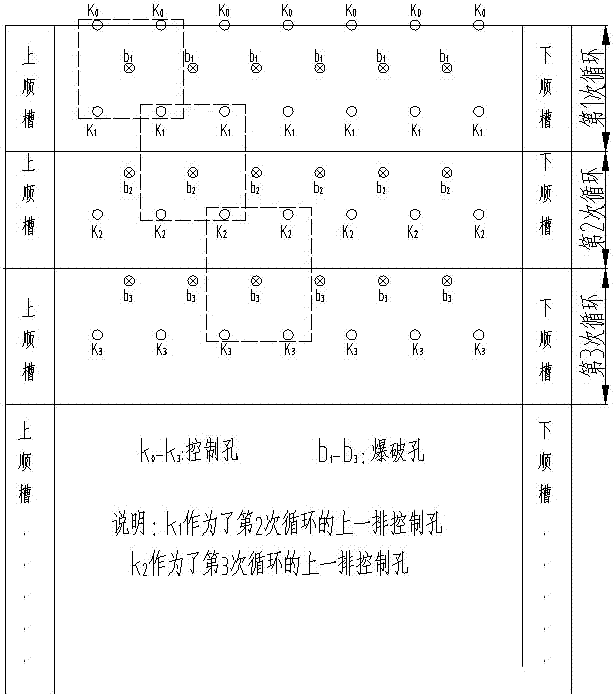

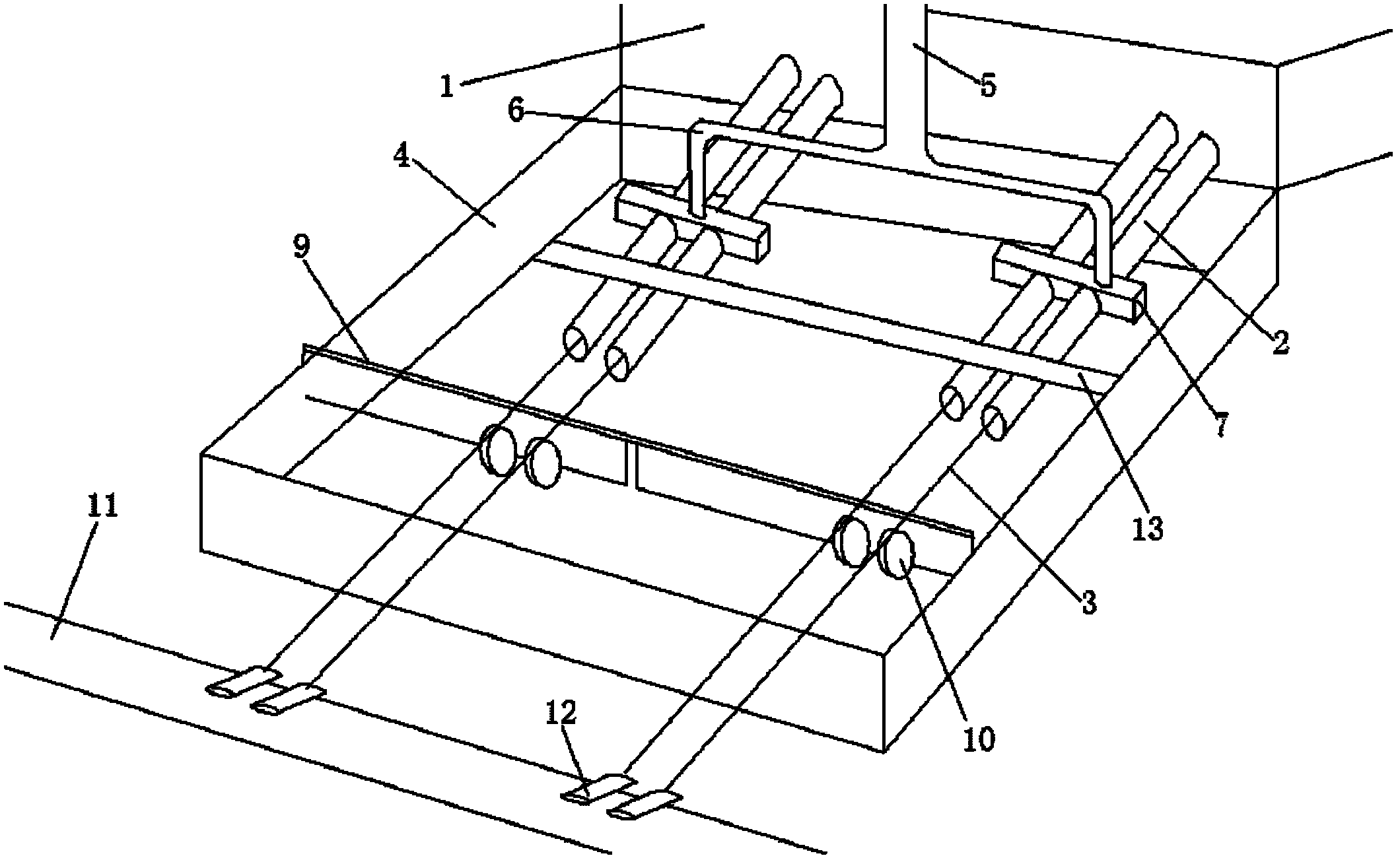

Porous control method for blasting softening of hard top plate and coal seam

InactiveCN107387085ASoften evenlySpread evenlyUnderground miningBlastingMiddle groupMechanical engineering

Disclosed is a porous control method for blasting softening of a hard top plate and a coal seam. The method comprises the following steps that a drilling arrangement scheme is determined according to the hard top plate and the coal seam at an underhole place to be blasted, that is to say, three groups of blast-holes are formed along the overall length of a working surface in an up-down parallel mode at equal intervals, wherein the uppermost group of blast-holes and the lowermost group of blast-holes are both rows of control hole groups, the middle group of blast-holes is a row of blasting hole groups, and each control hole group comprises several control holes which are formed along the overall length of the working surface in a parallel mode at equal intervals. Thus, according to the method, the overall blasting softening effects on the hard top plate and a coal body are good; by conducting blasting softening treatment on the hard coal rock mass covering at the front of the working surface in advance, the limit caving step of the top plate at the rear portion of the working surface is reduced, and puking, nicking and other accidents are prevented from occurring on a mined surface; the method has the advantages of being high in drilling hole utilization rate, low in engineering workload, high in blasting safety factor and the like and can be applied to softening and caving control of various hard top plates and coal bodies under coal mines.

Owner:HENAN POLYTECHNIC UNIV

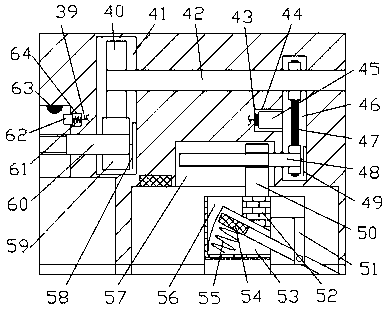

Traditional Chinese medicine material steam softening equipment

InactiveCN108836854AProblems that easily affect the loss of drug efficacyControl by conveniencePharmaceutical product form changeEngineeringTraditional Chinese medicine

The invention discloses traditional Chinese medicine material steam softening equipment. The traditional Chinese medicine material steam softening equipment comprises a machine body, wherein a separating plate is arranged in the machine body, the left side and the right side of the separating plate are fixedly connected with the left inner side wall and the right inner side wall of the machine body, ventilation holes are formed in the surface of the separating plate, and a regulating mechanism is arranged at the bottom of the separating plate; the regulating mechanism comprises a first rotating motor fixedly connected with the inner wall of the bottom of the machine body, a first bevel gear is fixedly connected to the output end of the first rotating motor, and second bevel gears are meshed with the left side and the right side of the first bevel gear; a reciprocating screw rod is fixedly connected to one of opposite sides of the two second bevel gears; one end away from the corresponding second bevel gear, of each reciprocating screw rod is rotatably connected with the side wall of the machine body through a corresponding first rolling bearing; and a first sliding block is arranged on the outer wall of each reciprocating screw rod in a sliding and sleeving manner. The traditional Chinese medicine material steam softening equipment disclosed by the invention is convenient to operate, the inflation quantity of steam can be conveniently controlled, and besides, uniform steam softening can be conveniently performed on traditional Chinese medicine materials.

Owner:广西奕琦科技有限公司

Waste rubber softening device for rubber production

InactiveCN108527704ASoften evenlyReduce lossPlastic recyclingMechanical material recoveryWaste rubberHeat losses

The invention relates to the technical field of rubber production, in particular to a waste rubber softening device for the rubber production. The waste rubber softening device comprises a feed pipe,a heating cavity and a flow-guiding pipe. Waste rubber is used as production raw materials, environment is protected, and energy is saved. The waste rubber is smashed by a smashing knife in the feed pipe, falls into the heating cavity, and is convenient to heat. An outer heating piece and an inner heating piece generate heat, and raw material particles falling into a grinding cavity fall on a grinding wheel; not only are heating and softening carried out, but also part of the raw material particles moves following the grinding wheel, and is in contact with the inner wall of a tank body to be heated and softened, so that uniform heating and softening of the rubber are realized. The softened rubber flows into the bottom of the heating cavity, is squeezed by the grinding wheel, and flows intothe flow-guiding pipe. The rotating shaft rotates to drive screw blades to rotate to stir the rubber so as to ensure the ductility. An insulating layer of the outer wall reduces heat loss to keep thetemperature.

Owner:ANHUI PROPELLENT HEAT TRANSFER TECH CO LTD

Softening treatment method of columnar loofah sponge

ActiveCN105803759AAvoid yellowingKeep shapeVegetable fibres from other vegetable matterGrip property fibresFiberSurface layer

The invention provides a softening treatment method of a columnar loofah sponge. The method comprises the following steps of: firstly, cutting the columnar loofah sponge with the size of 3cm-5cm and measuring the density; carrying out hot pressing and compression treatment on the cut columnar loofah sponge; then treating the columnar loofah sponge subjected to the hot pressing treatment with an alkali and hydrogen peroxide mixed solution, wherein an alkali is sodium hydroxide and the content of sodium hydroxide is 5%-10%, the content of hydrogen peroxide is 5%-10%, the temperature of the solution is 70-90 DEG C and the immersing time is 40min-1.5h; and finally, carrying out water washing and constant-temperature and constant-humidity treatment to finally obtain the softened columnar loofah sponge. By virtue of the method provided by the invention, the aim that fibers of an outer surface layer, an inner surface layer and a core layer of the columnar loofah sponge can be subjected to the softening treatment very well can be realized; meanwhile, the elasticity in the longitudinal direction of the columnar loofah sponge is relatively good, so that the aim of filling a mattress can be met very well; and meanwhile, the columnar loofah sponge subjected to the softening treatment of the method can meet the requirements of use comfort of the mattress, prevention of yellowing and the like very well.

Owner:ANHUI AGRICULTURAL UNIVERSITY

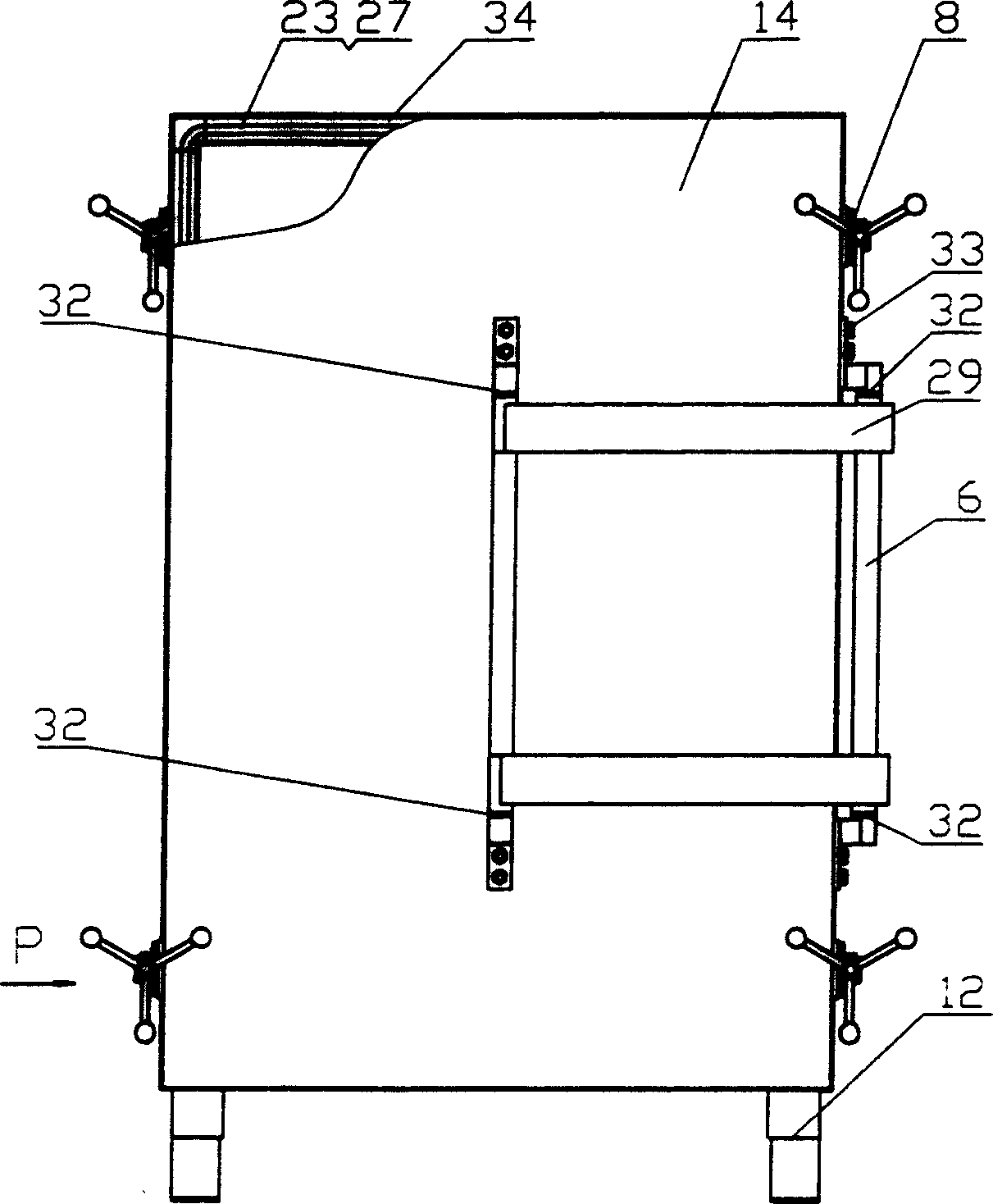

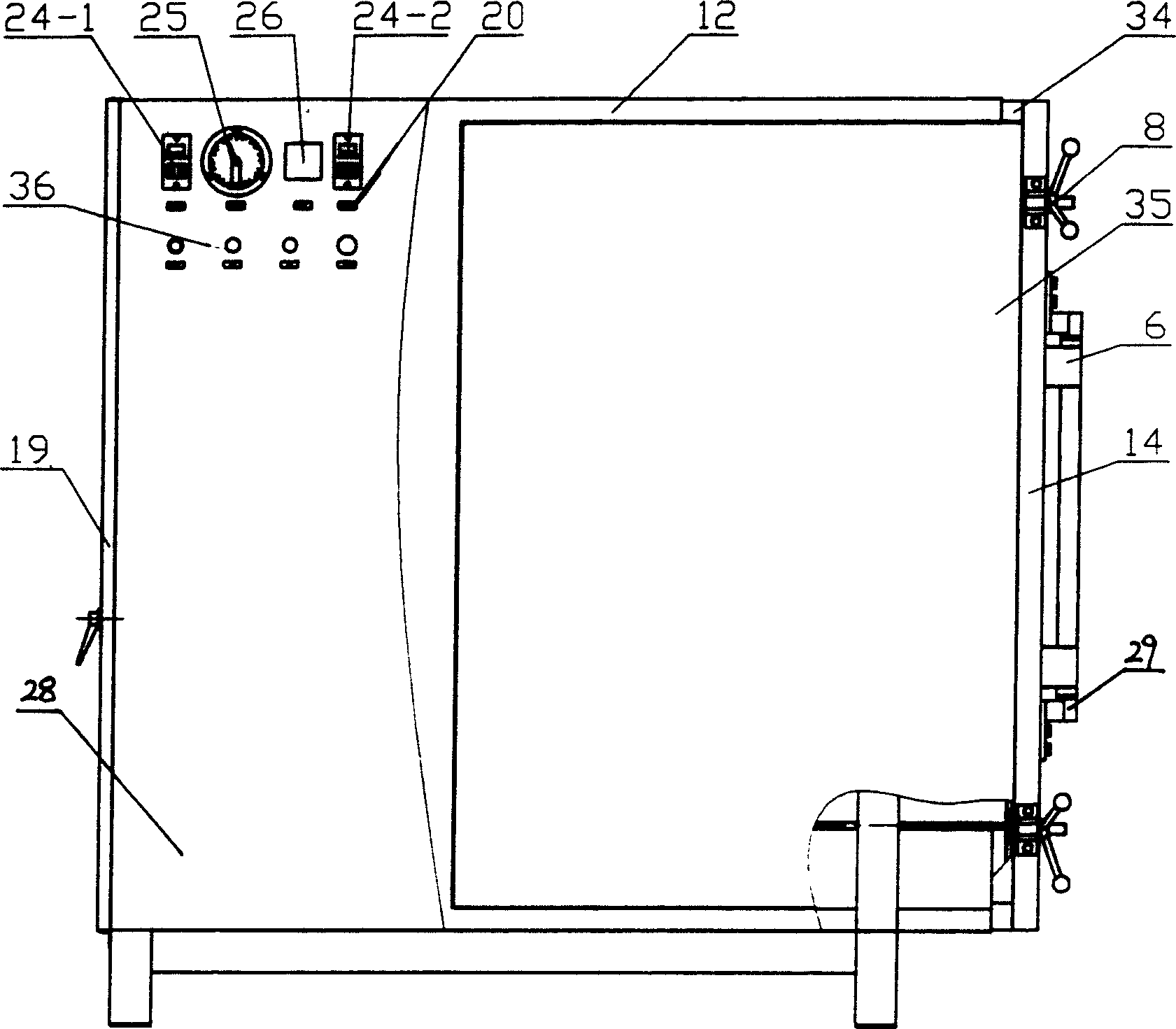

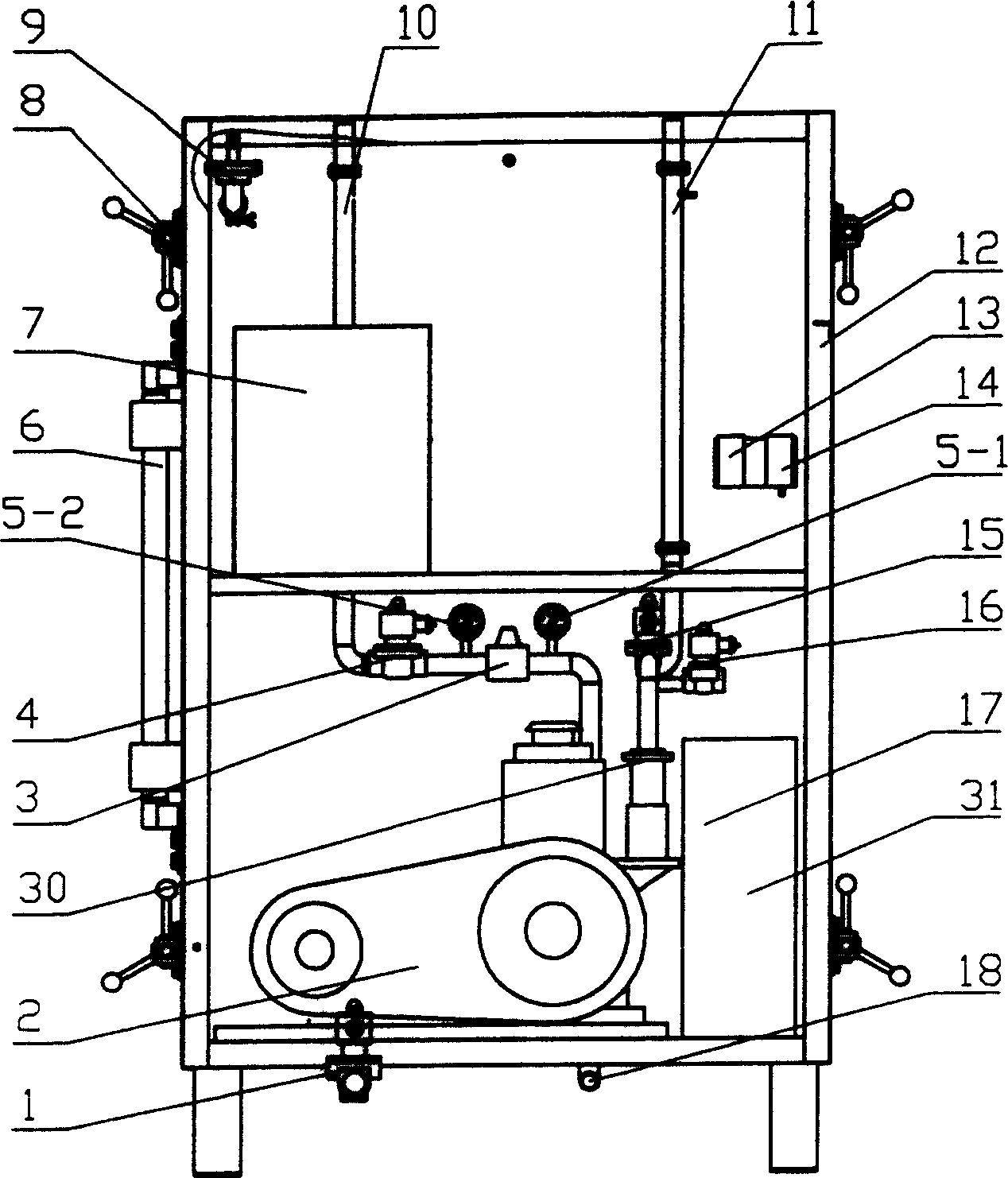

Gas phase replaceable demulcen machine

InactiveCN1561943AQuality improvementIncrease moisture contentPharmaceutical product form changeGas phaseElectrical control

A gas-phase displacement type wetting machine for softening the Chinese-medicinal materials and agricultural products in order to make post-treating easier is composed of case, gate mechanism, vacuumizing unit, electric controller, sealing unit including the sealing elastic ruber tube embedded in the slot on gate frame, and steam pipeline.

Owner:HANGZHOU HAISHAN PHARMA EQUIP

Softening treatment device used before enamelling copper enamelled wires

InactiveCN102637484AQuality assuranceIngenious structural improvementInsulating conductors/cablesMetallurgyCopper wire

The invention discloses a softening treatment device used before enamelling copper enamelled wires. The device comprises annealing chambers, wherein wire inlet holes are arranged at the wire inlet ends of the annealing chambers and copper wires enter the annealing chambers from the wire inlet holes. The device is characterized in that a plurality of parallel wire conduits are arranged at the wire outlet ends of the annealing chambers; the copper wires pass out of the wire conduits; the wire conduits incline downwards; a water tank is arranged in front of the wire conduits; a steam pipe is arranged above one end of the water tank; the lower ends of the wire conduits extend into the water tank; steam enters the annealing chambers; and the bare copper wires passing out of the wire conduits enter wire outlet pipes via wire wheels in the water tank. The device has the following advantages that the structure is improved ingeniously and simply, the high temperature steam is utilized to heat the passing bare copper wires and the temperature is uniform, so that the copper wires are softened uniformly and bubbles are greatly reduced after the copper wire surfaces are enamelled, thus ensuring the quality of the copper enamelled wires.

Owner:ANHUI LEESOV IND

A mothproof brightening willow rattan softener and a preparing method thereof

ActiveCN104085024AReduce corrosionImprove toughnessWood treatment detailsWood impregnation detailsSalvia miltiorrhizaArundina

A mothproof brightening willow rattan softener is disclosed. The softener is prepared from following raw materials by weight in part: 12-15 of sodium carbonate, 6-8 of glycerin, 1-2 of salicylic acid, 2-3 of sodium tetrathiocarbonate, 4-5 of ammonium triphosphate, 5-6 of povidone-iodine, 4-5 of eucalyptus robusta smith, 3-4 of common cnidium fruit, 4-5 of red sage root, 10-12 of zornia gibbosa, 10-12 of arundina graminifolia, 3-4 of auxiliary agents and 100 of water. The softener adopts the sodium tetrathiocarbonate, the sodium carbonate, and the like, and is low in surface corrosion and uniform in softening. Willow rattans are good in toughness and smooth in surface, thus increasing the weaving efficiency. By using the common cnidium fruit, the red sage root, and other Chinese herbal medicines and the povidone-iodine, mildew rattan surfaces are high in glossiness and in a sandalwood color, and damage by worms can be prevented.

Owner:安徽华利达家居用品有限公司

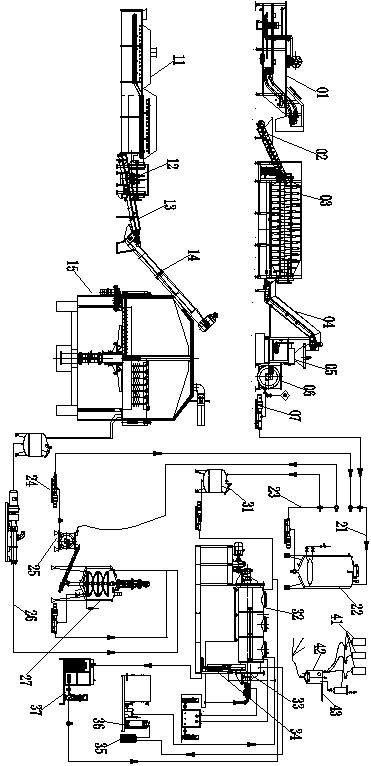

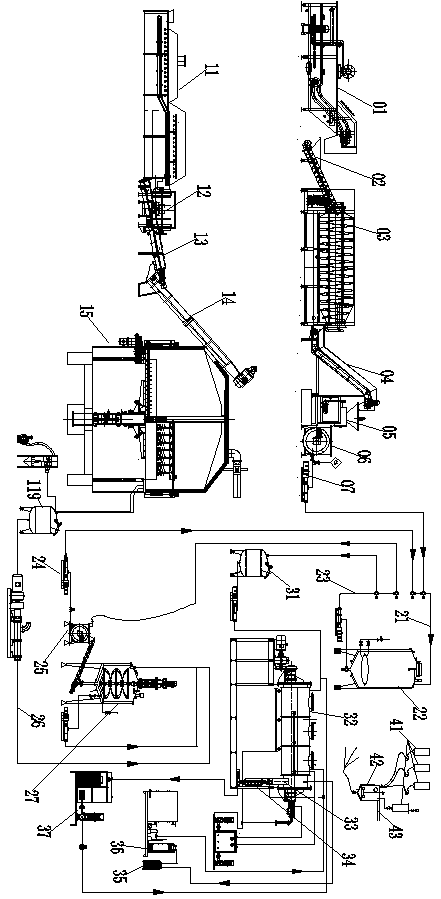

Method for production of Pixian bean paste

ActiveCN108208594AGuaranteed flavorGuaranteed qualityBioreactor/fermenter combinationsBiological substance pretreatmentsFlavorSteam cooking

The invention provides a method for production of Pixian bean paste, wherein the method includes the following steps: A, selecting dry chili pepper meeting standards, then cleaning with a cleaning machine, steam-cooking with a steam cooker, carrying out crushing treatment with a crusher, then inputting into a main fermenting tank by a chili pepper blank transport pump while stirring, and fermenting, to obtain a chili pepper blank; B, inputting broad bean halves into a rinsing steaming cooling device, rinsing and steaming, cooling, inoculating with a bacterial powder while cooling, transportingto a disc koji-making device while mixing, and koji-making the broad bean halves; and after the koji-making, inputting into a broad bean halves fermentation tank, and fermenting to obtain broad beanpaste halves; C, inputting the chili pepper blank obtained in the step A and the broad bean paste halves obtained in the step B into the main fermenting tank, and fermenting to obtain the Pixian beanpaste; and D, inputting the Pixian bean paste obtained in the step C into a drying discharging device, drying, and discharging to obtain the Pixian bean paste finished product. The method is mechanically operated in the whole process, the process control is more convenient and accurate, the flavor and quality of the Pixian bean paste are guaranteed, and at the same time, the truly feasible equipment base is provided for large-scale production and industry upgrading of the Pixian bean paste.

Owner:SICHUAN GAOFUJI FOOD

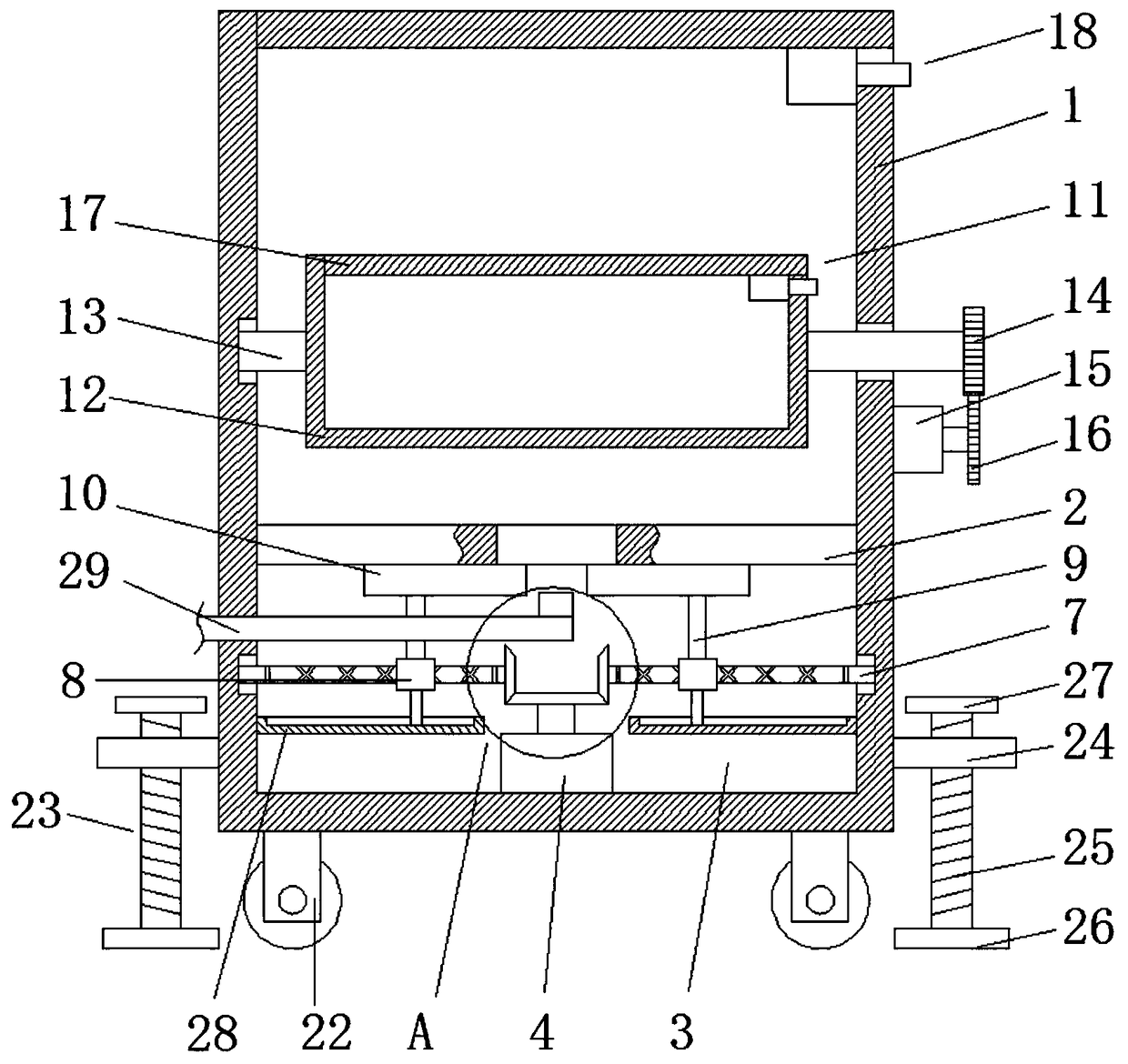

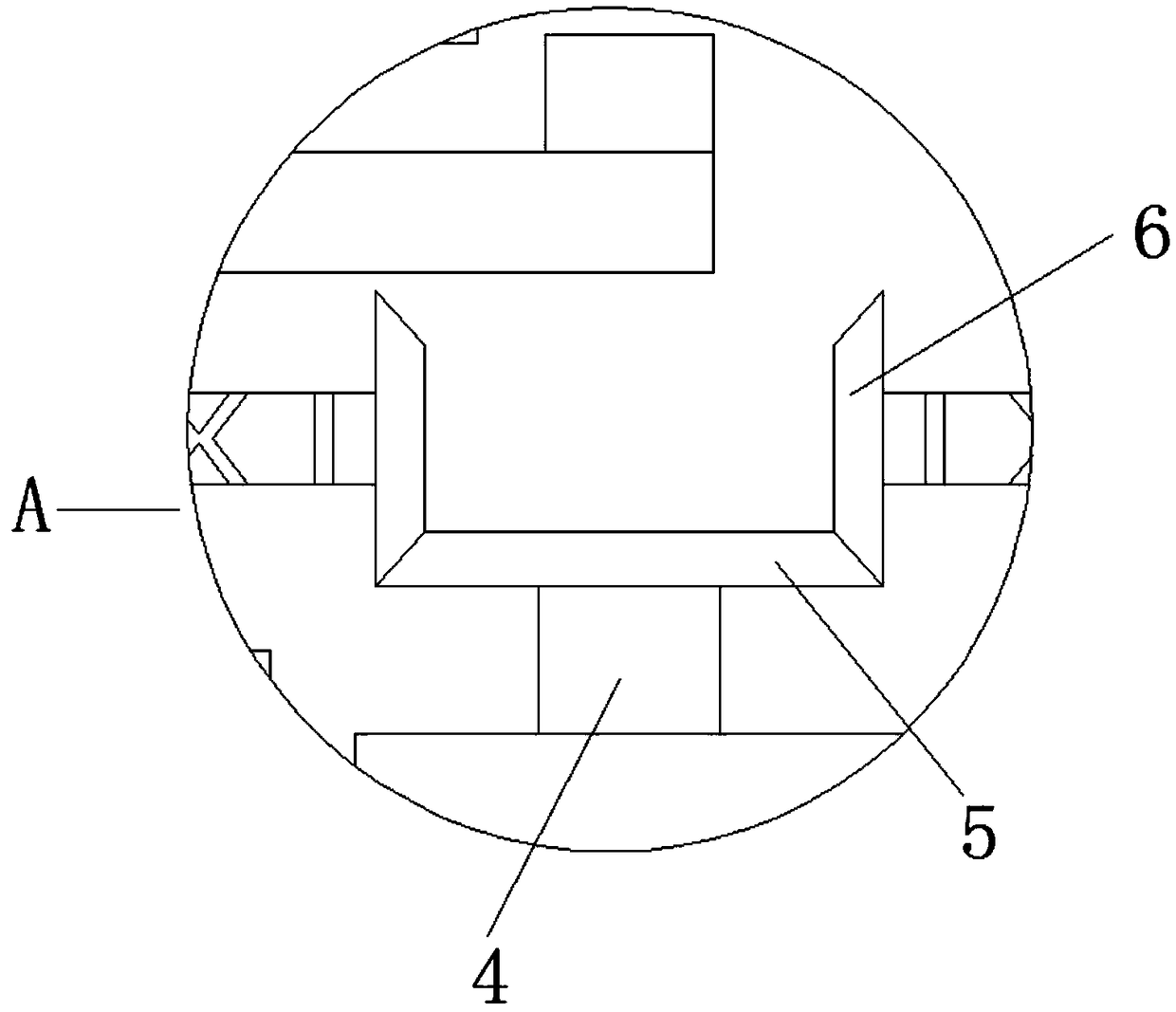

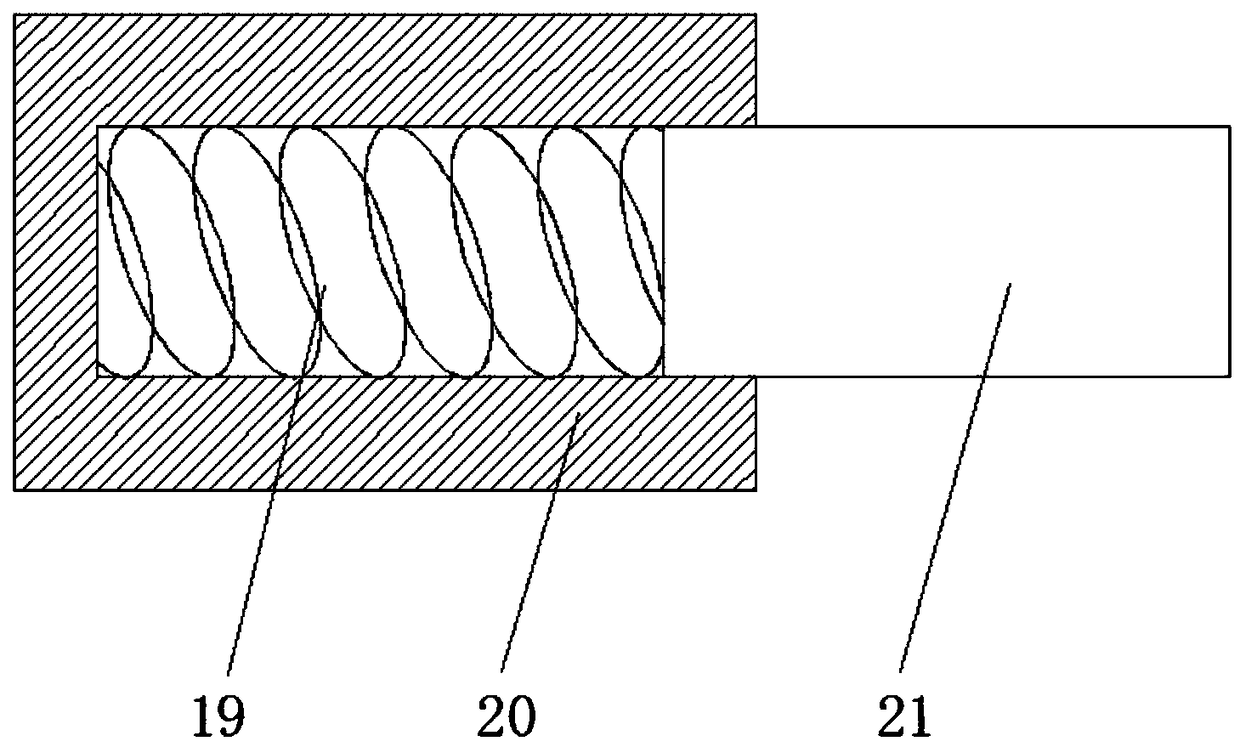

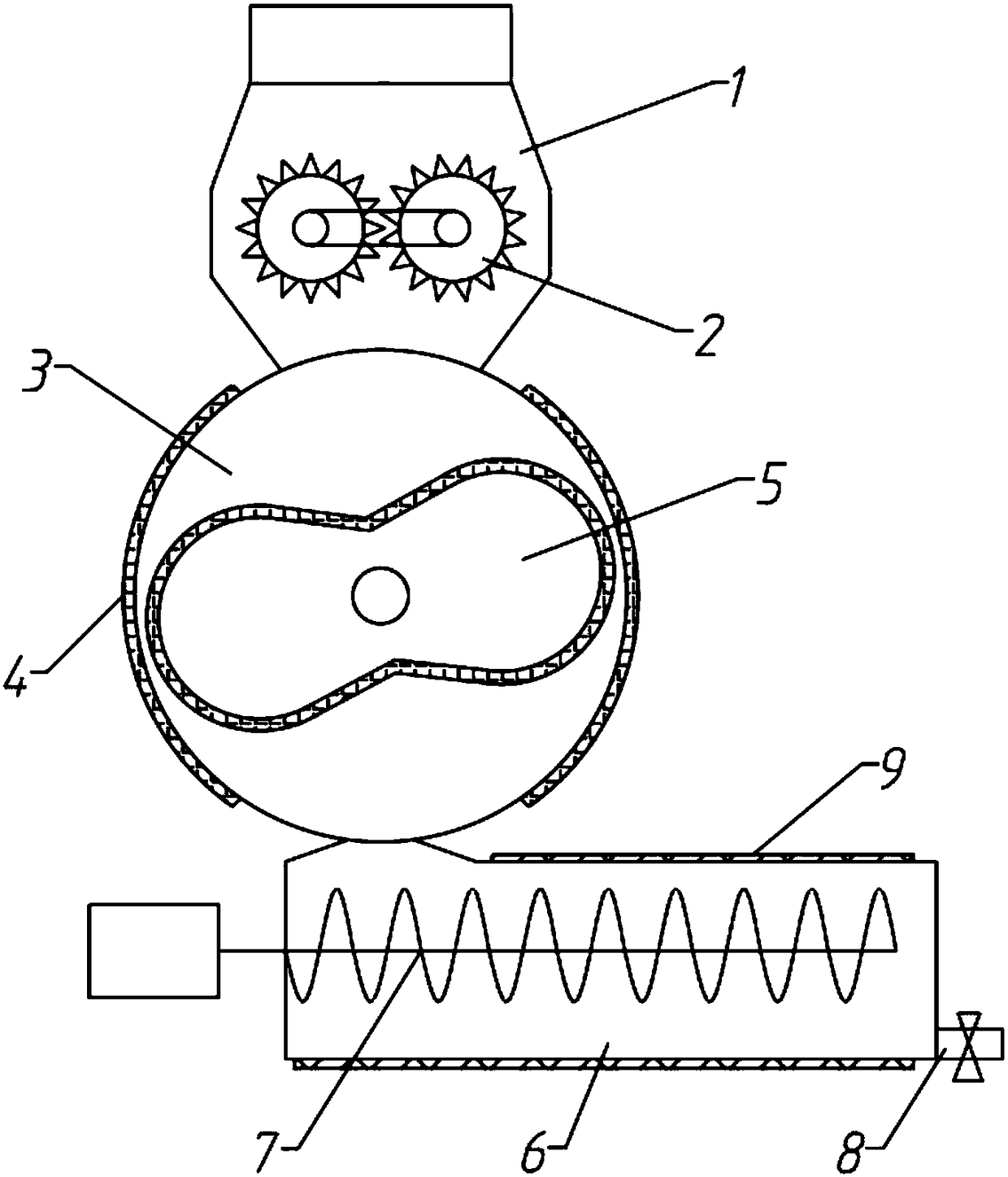

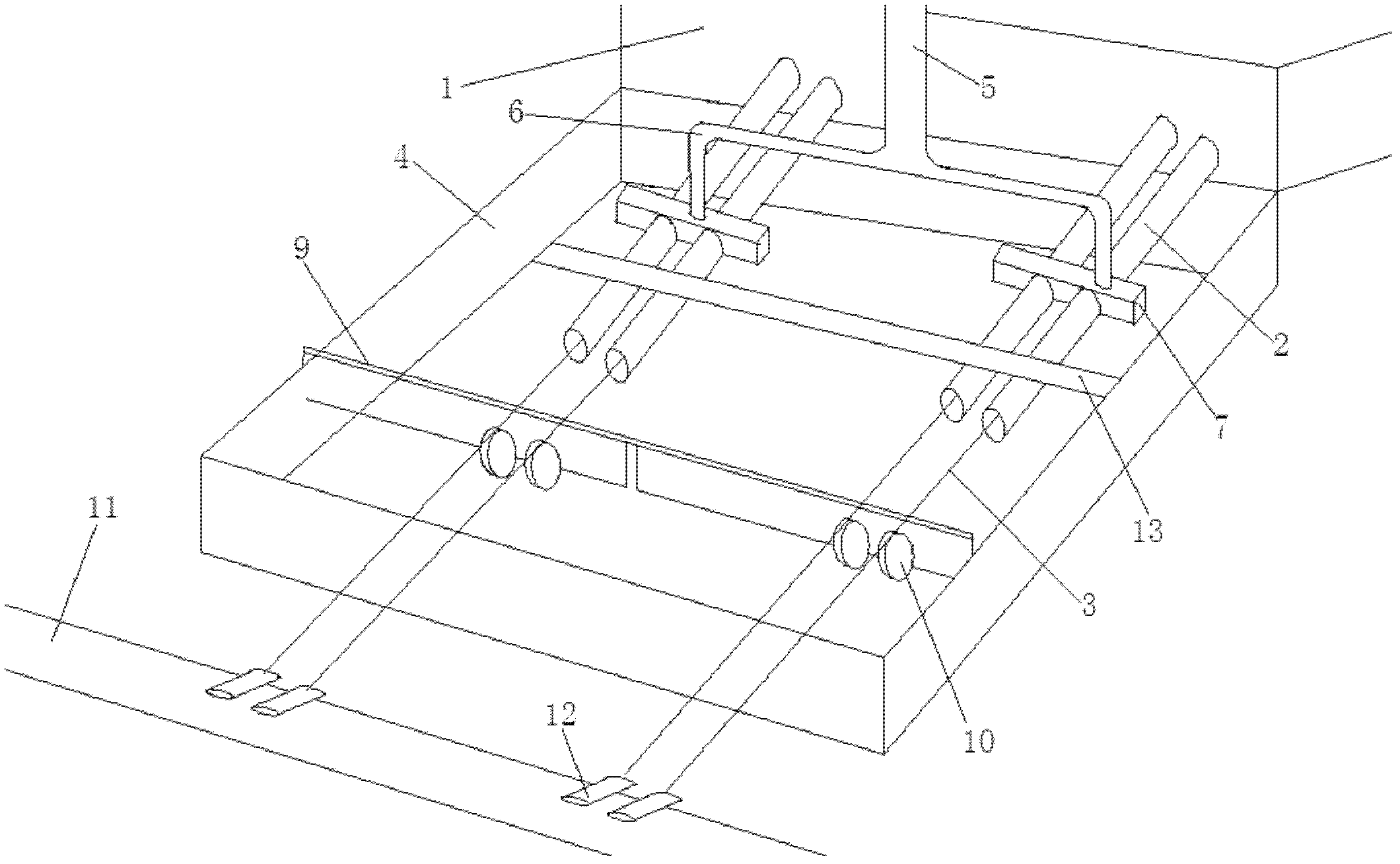

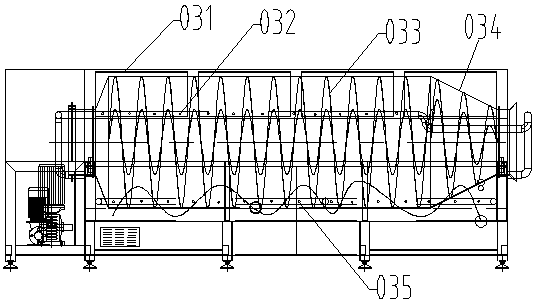

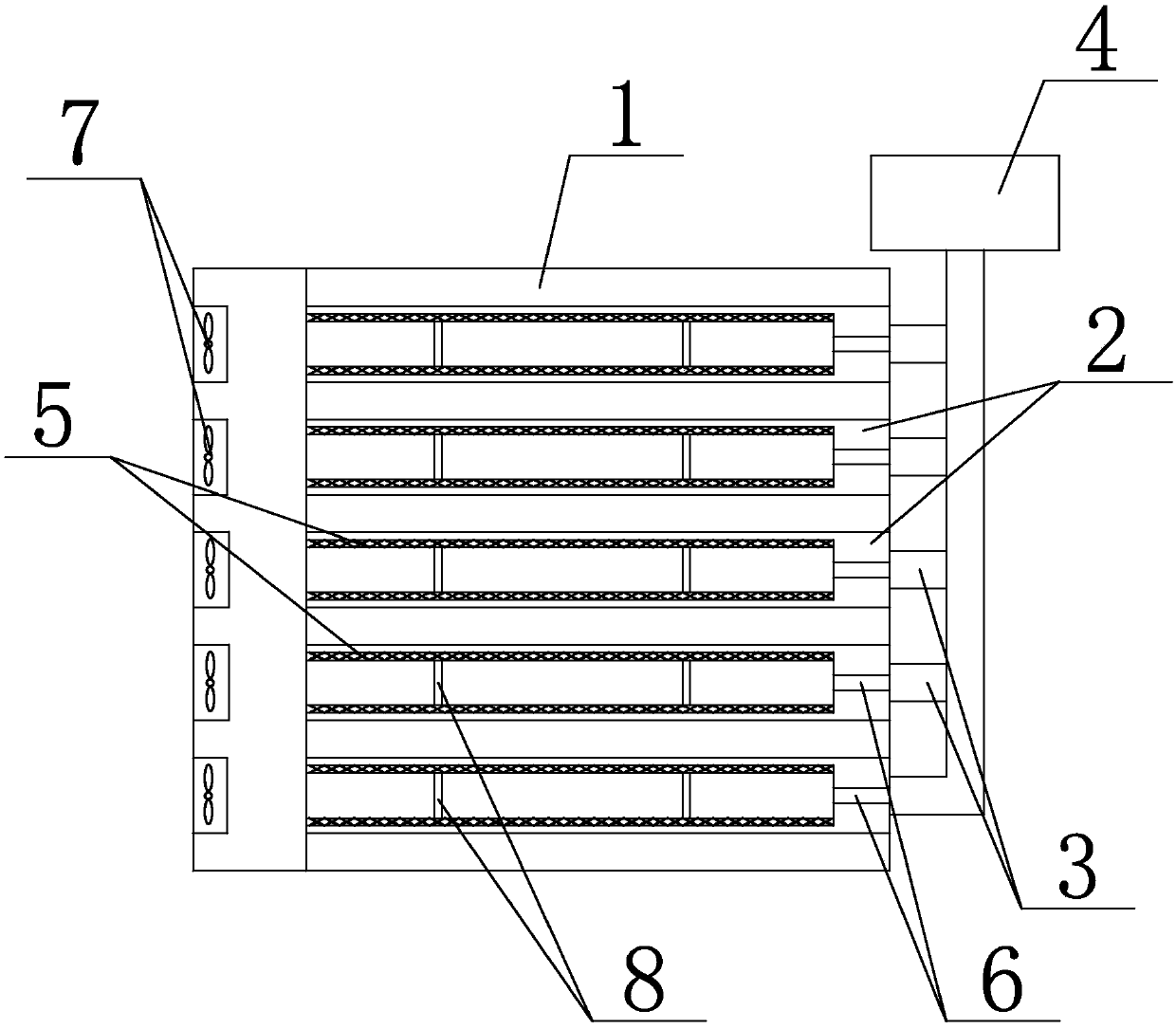

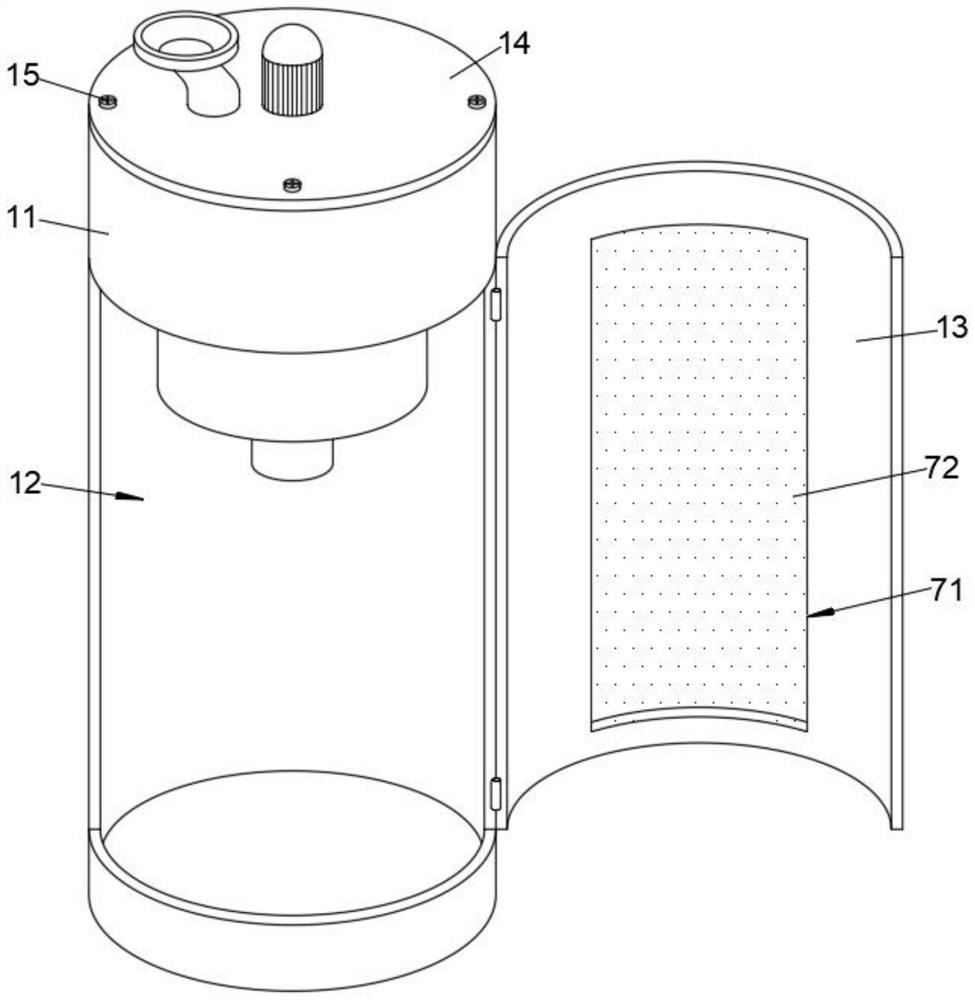

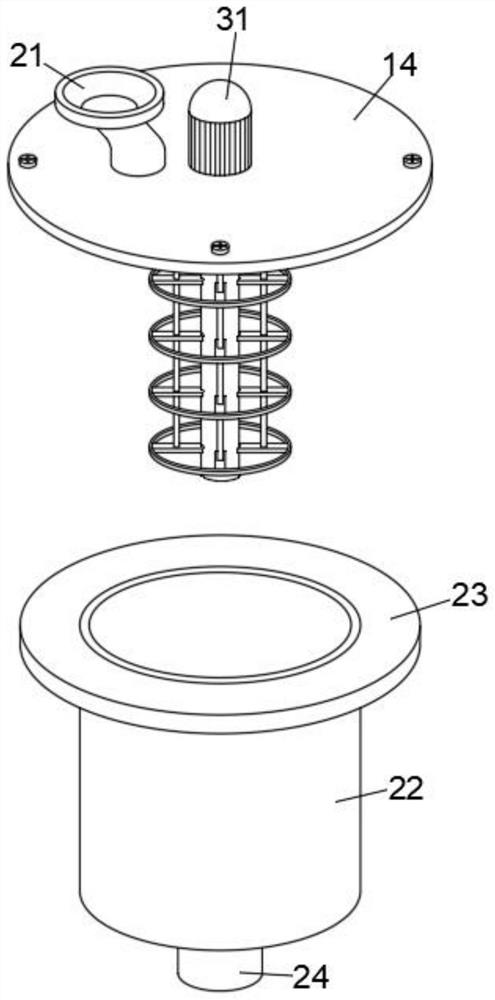

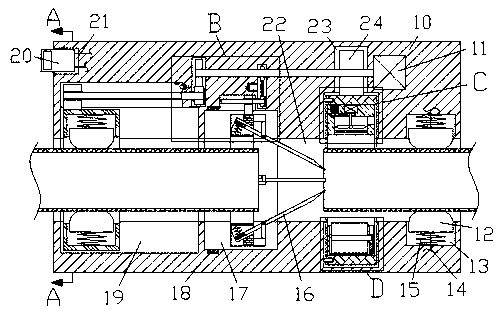

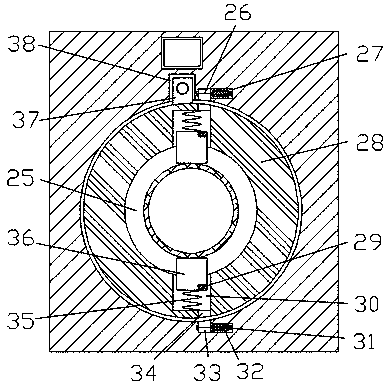

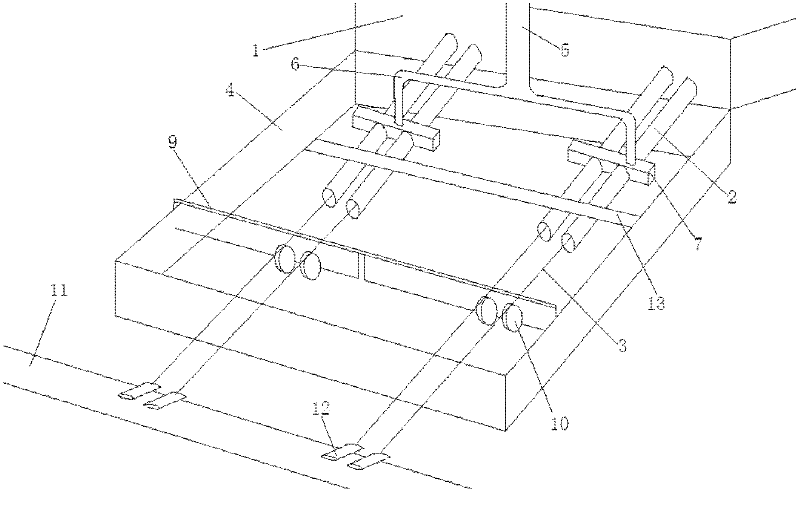

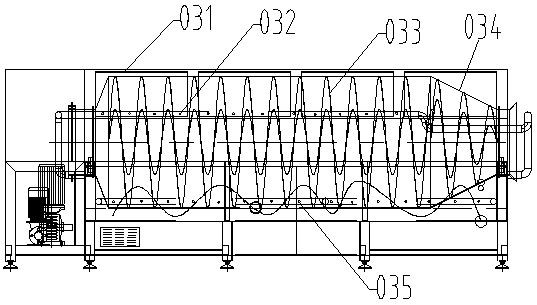

Medicine infiltrating machine for improving softening uniformity of medicinal materials

InactiveCN108030679AImprove the quality of moisturiserAvoid condensationPharmaceutical product form changeDomestic articlesTraditional medicineParallel arrangement

The invention discloses a medicine infiltrating machine for improving softening uniformity of medicinal materials. The medicine infiltrating machine comprises a medicine infiltrating tank which is internally provided with a plurality of medicine infiltrating pipes sequentially from top to bottom. One end of each medicine infiltrating pipe is positioned on the side wall of the medicine infiltratingtank and connected with an air inlet pipe in connection with a steam generator. Each medicine infiltrating is provided with a medicine mesh barrel, and one end, close to the corresponding air inlet pipe, of each medicine mesh barrel is connected with a rotating shaft vertically connected to the inner wall of the medicine infiltrating tank. Each rotating shaft is capable of driving the corresponding medicine mesh barrel to rotate axially under driving of a motor, and a plurality of blowing devices in one-to-one correspondence to the medicine mesh barrels are arranged on the inner wall of the medicine infiltrating tank and at one end, away from the rotating shafts, of the medicine mesh barrels. The medicine infiltrating machine has advantages that by the pipelines in parallel arrangement, complete contact between steam and traditional Chinese medicinal materials is guaranteed, and steam in horizontal movement avoids condensation of steam at the bottom of the medicinal materials, so thatinfiltrating quality of the traditional Chinese medicinal materials is improved.

Owner:SICHUAN ZHONGYONG PHARMA CO LTD

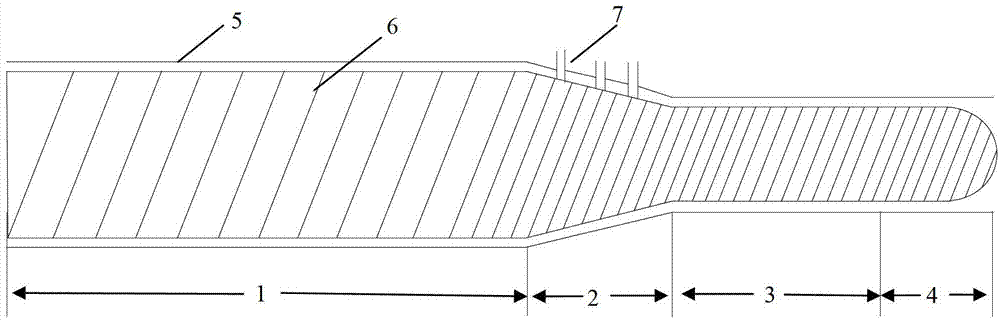

Method for spinning thermotropic liquid crystalline polyarylate by using reducing screw melt extruder

InactiveCN102732980ASave spaceSave resourcesSpinning head liquid feederArtificial thread manufacturing machinesLiquid crystallinePolymer science

The invention provides a method for spinning thermotropic liquid crystalline polyarylate by using a reducing screw melt extruder, and particularly relates to a method for spinning the thermotropic liquid crystalline polyarylate by using an integrated reducing screw melt extruder. According to the method for spinning the thermotropic liquid crystalline polyarylate by using the reducing screw melt extruder, the extruder is divided into a feed pre-crystallization drying area, a pre-melting air discharging area, a melting area and a compression metering area from front to back; barrels of the feed pre-crystallization drying area, the melting area and the compression metering area are cylindrical; the pre-melting air discharging area is conical; and the diameter of the barrel of the melting area is the same as that of the barrel of the compression metering area but is smaller than that of the feed pre-crystallization drying area. The temperature required by feed pre-crystallization drying is controlled to be 130 to 180 DEG C, and the temperature required by pre-melting air exhaust is controlled to be 3 to 10 DEG C less than the temperature required by melting raw materials. By the method, the raw materials are dried in the extrusion process, the pre-crystallization uniformity is high, the water in the raw materials can be fully removed, and large drying equipment is not needed.

Owner:DONGHUA UNIV

A flower-fragrance willow rattan softener and a preparing method thereof

ActiveCN104085006AReduce corrosionSoften evenlyWood treatment detailsWood impregnation detailsSodium bicarbonateGlycerol

A flower-fragrance willow rattan softener is disclosed. The softener is prepared from following raw materials by weight in part: 5-7 of sodium bicarbonate, 10-12 of glycerin, 5-7 of ascorbic acid, 3-4 of N,N-dimethyldecylamine-N-oxide, 5-7 of sodium hexametaphosphate, 4-5 of dahurian rhododendron leaf, 3-4 of Chinese holly, 2-3 of jasmine flower, 5-6 of clove, 6-7 of povidone-iodine, 3-4 of auxiliary agents and 100 of water. The softener adopts a weak acid, a weak base and a nonionic surfactant, and is low in surface corrosion, uniform in softening and good in toughness. By using the glycerol, surfaces of rattans are smooth and the weaving efficiency is increased. By using the jasmine flower, the clove, and other flowers and plants, a delicate fragrance is sent and mildew and damage by worms can be prevented.

Owner:安徽华柳家居用品有限公司

An anticorrosion willow rattan softener and a preparing method thereof

An anticorrosion willow rattan softener is disclosed. The softener is prepared from following raw materials by weight in part: 6-8 of sodium fluoride, 12-14 of ethanol, 3-4 of sodium dodecylbenzenesulfonate, 3-4 of petroleum sodium sulfonate, 5-6 of povidone-iodine, 3-4 of cineraria repanda, 5-6 of the root of Chinese pulsatilla, 3-4 of wormseed goosefoot, 10-12 of safflower, 5-8 of Chinese honeylocust spine, 3-4 of auxiliary agents and 100 of water. The softener adopts a weak acid and a weak base, and is low in surface corrosion, uniform in softening and good in toughness. By using glycerol and sodium hexametaphosphate, surfaces of rattans are smooth and the weaving efficiency is increased. By using the tuber of stemona, and other Chinese herbal medicines, mildew and damage by worms can be prevented.

Owner:ANHUI HUAYU CRAFTS GRP

Cocoon cooking method capable of increasing cohesion times of fresh cocoon raw silk

InactiveCN107245762AImprove mechanical propertiesEfficient removalSilk cocoons cleaning/classifyingGamma rayEngineering

The invention belongs to the technical field of silkworm cocoon cooking, and in particular relates to a cocoon cooking method for increasing the cohesion times of fresh cocoons and raw silk, including sorting fresh cocoons, soaking in rice washing water, gamma ray irradiation, soaking in a cocoon cooking machine, cooking and adjusting several process. Compared with the prior art, the invention has the following advantages: by soaking the silkworm cocoons with rice-washing water, the stains on the surface of the silkworm cocoons can be effectively removed, and the surface of the silkworm cocoons can also be adsorbed while having a cleaning effect, and gamma rays are irradiated under the condition of negative pressure. , the peptide bond in the amorphous region in the cocoon is broken, the orientation of the cocoon molecules is reduced, and the water molecules can quickly enter the sericin molecules; in the dipping stage I and dipping stage II respectively, the corresponding aqueous solution enters the The gap between the sericin molecules weakens the intermolecular force, realizes the uniform softening of sericin, and at the same time enhances the mechanical properties of the raw silk.

Owner:HEFEI JUFENG THROWING

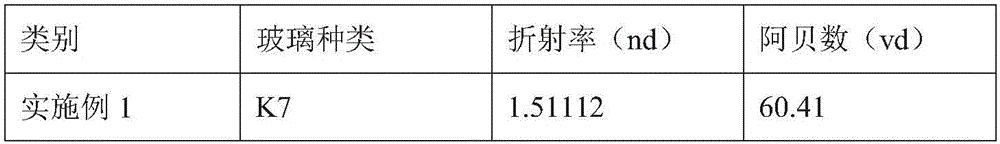

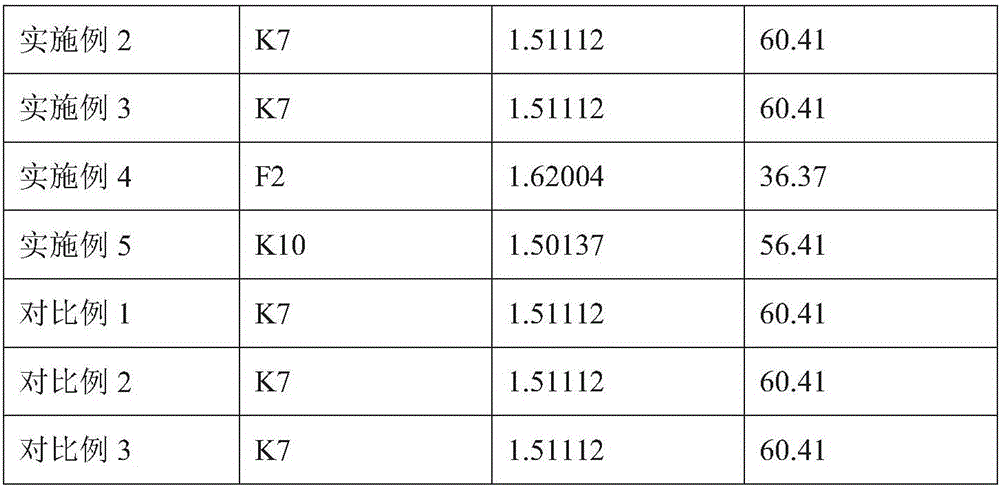

Glass re-shaping process

InactiveCN105837050ADoes not cause residueVolatile removalGlass pressing apparatusCoatingsThermal expansionForming processes

The invention belongs to the technical field of glass processing and particularly relates to a glass re-shaping process which includes the following steps: (1) coating the surface of a glass blank body with a coating; (2) arranging the coated glass blank body on a porcelain box, conveying the porcelain box into a heating zone in a softening furnace through a conveying apparatus, and performing zoned stepwise heating to soften the glass blank body; (3) performing die-press moulding to the softened glass blank body in a shaping mould; (4) after the die-press moulding, cooling and demoulding the glass, and removing the coating layer on the surface to obtain a performer of glass. The glass blank body is coated with the heat-resistant and -insulation coating, so that the problems of non-uniformity of glass body and generation of shrinkage grains in the glass, which are caused by non-uniform heating and heat-expansion and cold-contraction and the like factors, during the glass re-shaping process are avoided. Through the zoned stepwise heating method, the softening degree of the glass blank body can be controlled well, so that the glass blank body is easily to press and shape and qualified ratio of products is increased.

Owner:四川省洪雅维国光学有限公司

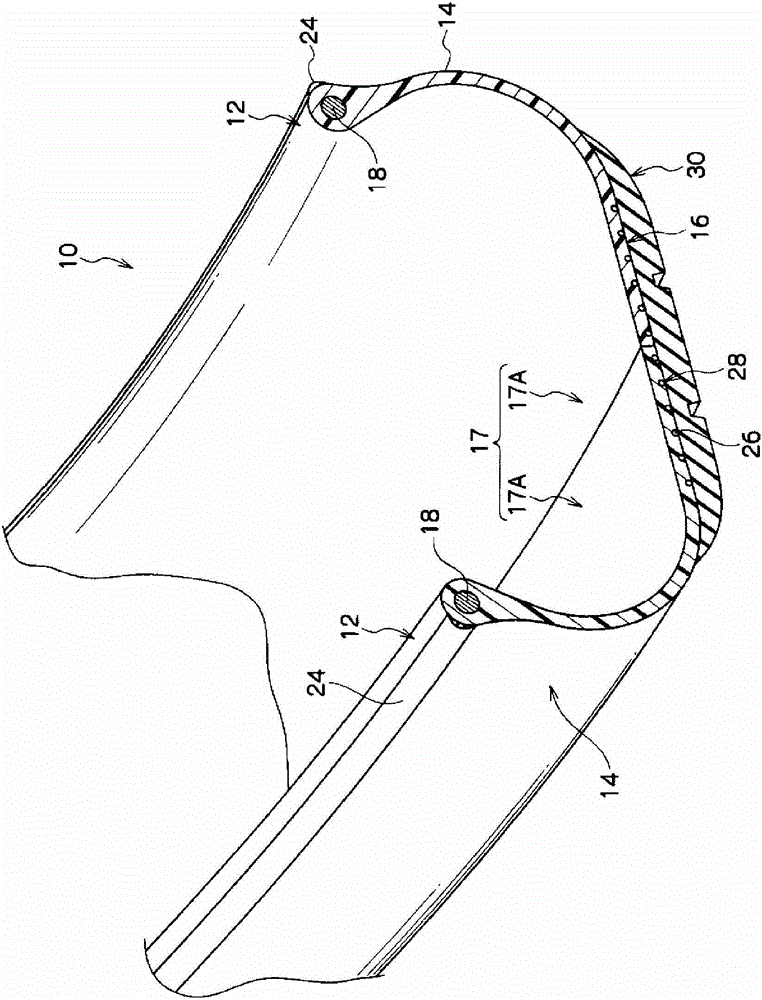

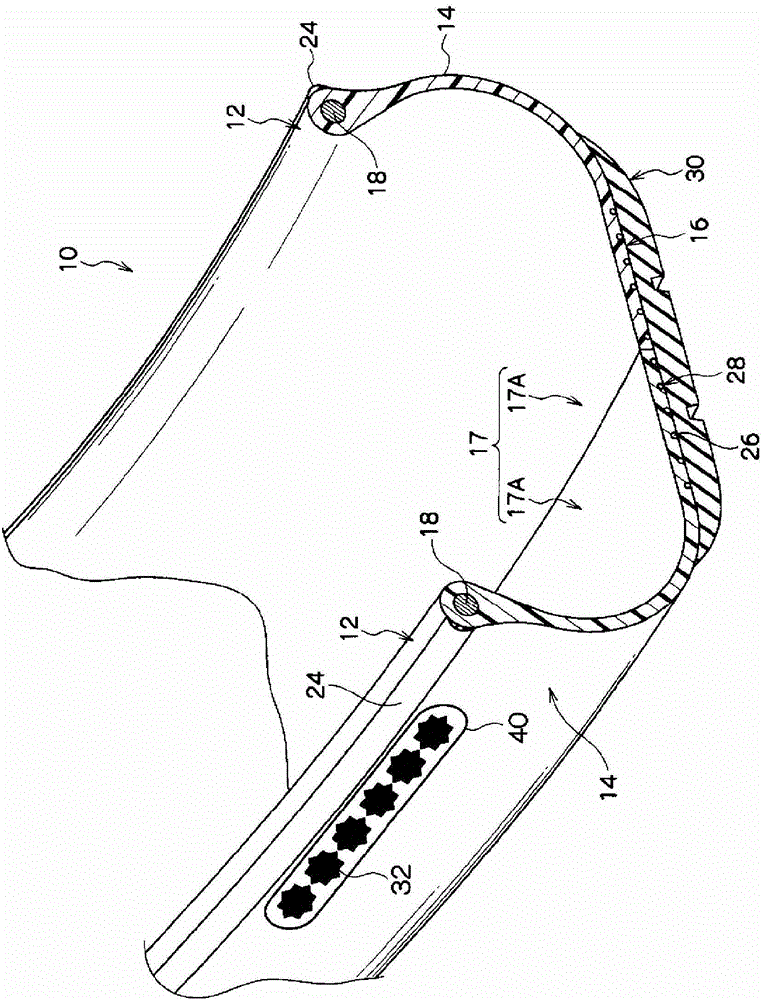

Tire and tire manufacturing method

ActiveCN103338946AEasy to manufactureEfficient manufacturingWithout cord reinforcementTyresPigmentColoring agents

To easily manufacture a tire the color of which does not fade due to traveling, a tire case (17) which is a tire (10) structural member is formed by injection molding using a colored first thermoplastic material which contains a pigment. A tire the color of which does not fade due to traveling can be easily manufactured.

Owner:BRIDGESTONE CORP

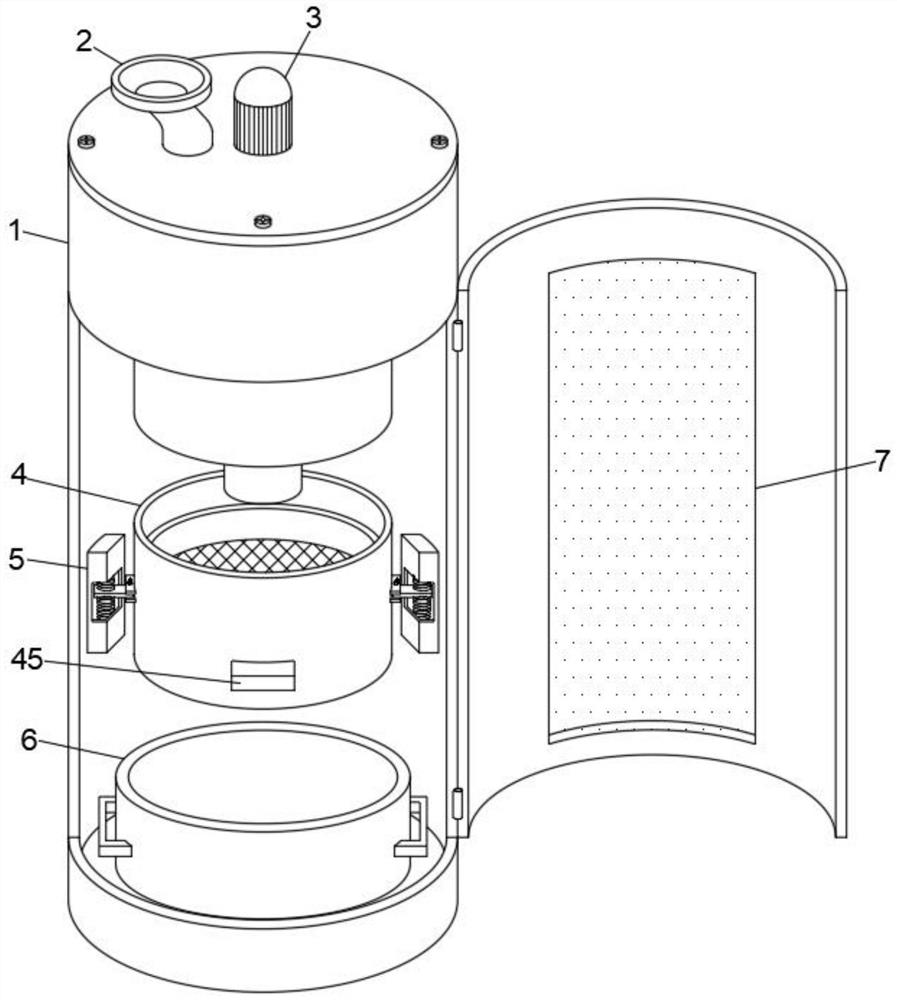

Purification and impurity removal device for brewing mead

InactiveCN112370852AEasy and quick passConducive to purification and removal of impuritiesRotary stirring mixersTransportation and packagingPhysical chemistryElectric machinery

The invention provides a purification and impurity removal device for brewing mead. The purification and impurity removal device for brewing mead comprises a purification box, a heating mechanism, a stirring mechanism, a filtering mechanism, a mounting mechanism, a bearing mechanism and an observation mechanism. Before honey is filtered, the honey is heated to be softened, the viscosity of the honey is reduced, and the fluidity of the honey is improved. Meanwhile, the honey is filtered twice, large impurities and small impurities are filtered out respectively, and the blockage situation can berelieved. In the honey filtering process, a vibrator drives a filter cartridge to vibrate quickly, so that honey passes through a first filter screen and a second filter screen quickly, the working efficiency is improved, and purification and impurity removal of the honey are facilitated. When the honey is heated in an electric heating barrel, a motor drives a stirring ring, a connecting rod anda stirring rod which are connected with a rotating shaft to rotate quickly to stir the honey, so that the honey is heated uniformly and softened quickly, the heating time of the honey is saved, and the working efficiency is improved.

Owner:云南中蜂蜂业有限公司

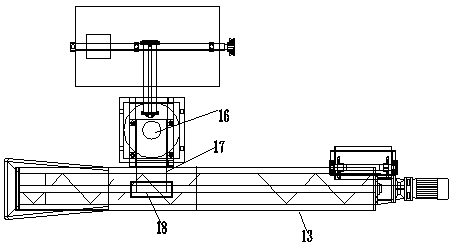

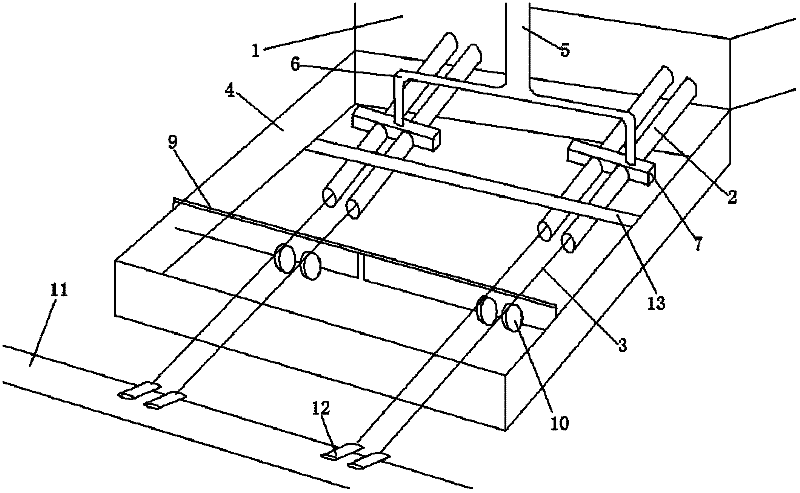

Non-joint automatic connecting device for PVC pipes

ActiveCN111497263APlay a guiding roleClosely connectedPipe connection arrangementsTubular articlesGear wheelManual handling

The invention discloses a non-joint automatic connecting device for PVC pipes. The device comprises a main body box, a left-right through PVC pipe through cavity is formed in the main body box, a clamping box sliding cavity communicates with the outer side of the PVC pipe through cavity, a guide ring moving cavity communicating with the PVC pipe through cavity inwards is formed in the right side of the clamping box sliding cavity, an annular gear cavity communicating with the PVC pipe through cavity inwards is formed in the right side of the guide ring moving cavity; the softening compaction box rotates to achieve automatic heating softening and guarantee even softening at the same time, the guide rod plays a role in guiding and assists a left PVC pipe in being inserted into a right softened PVC pipe, automatic inserting connection is achieved, after inserting is completed, the guide rod is automatically pulled out to prevent interference with pulling out of the PVC pipes, meanwhile, acompaction wheel extends out and rotates to compact the softened PVC pipe, so that the risk of scalding possibly caused by manual operation is avoided while tight connection of the softened PVC pipeis ensured.

Owner:安庆中凯信息技术咨询有限公司

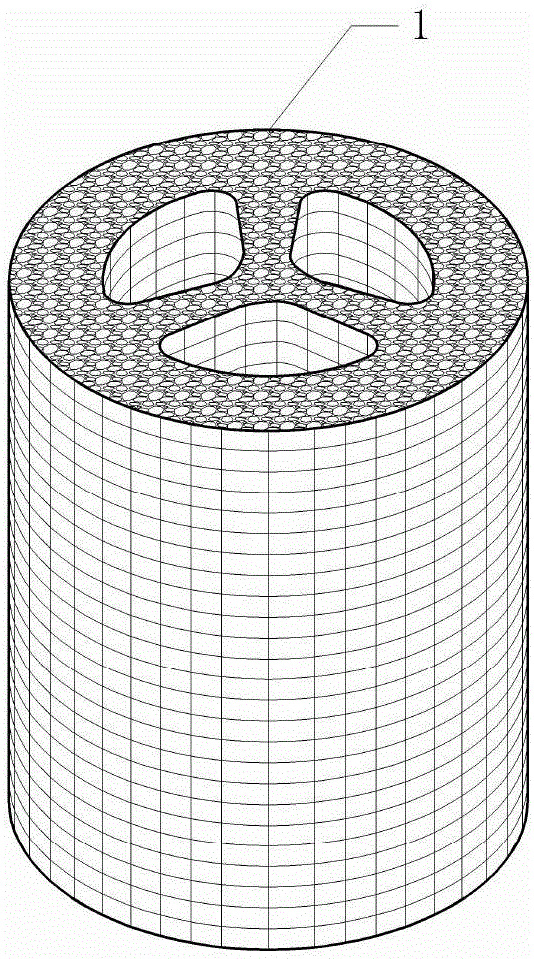

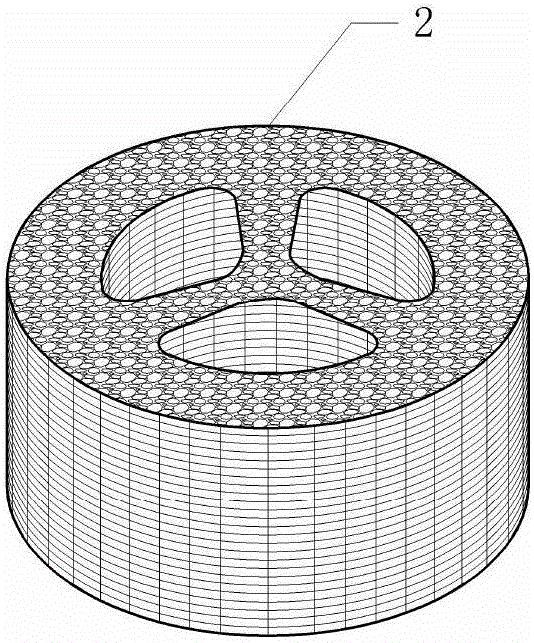

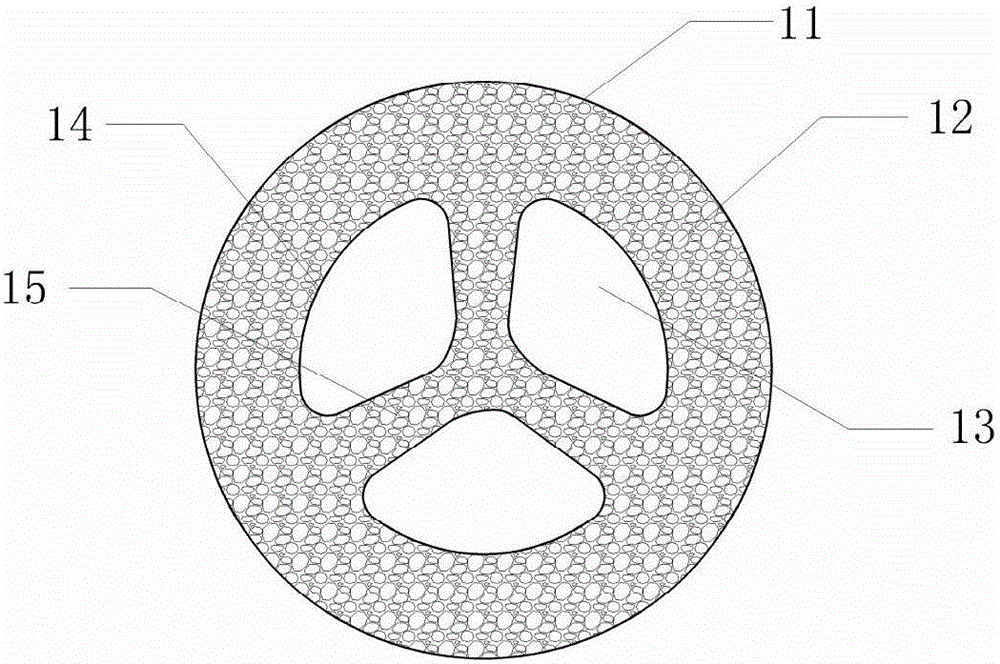

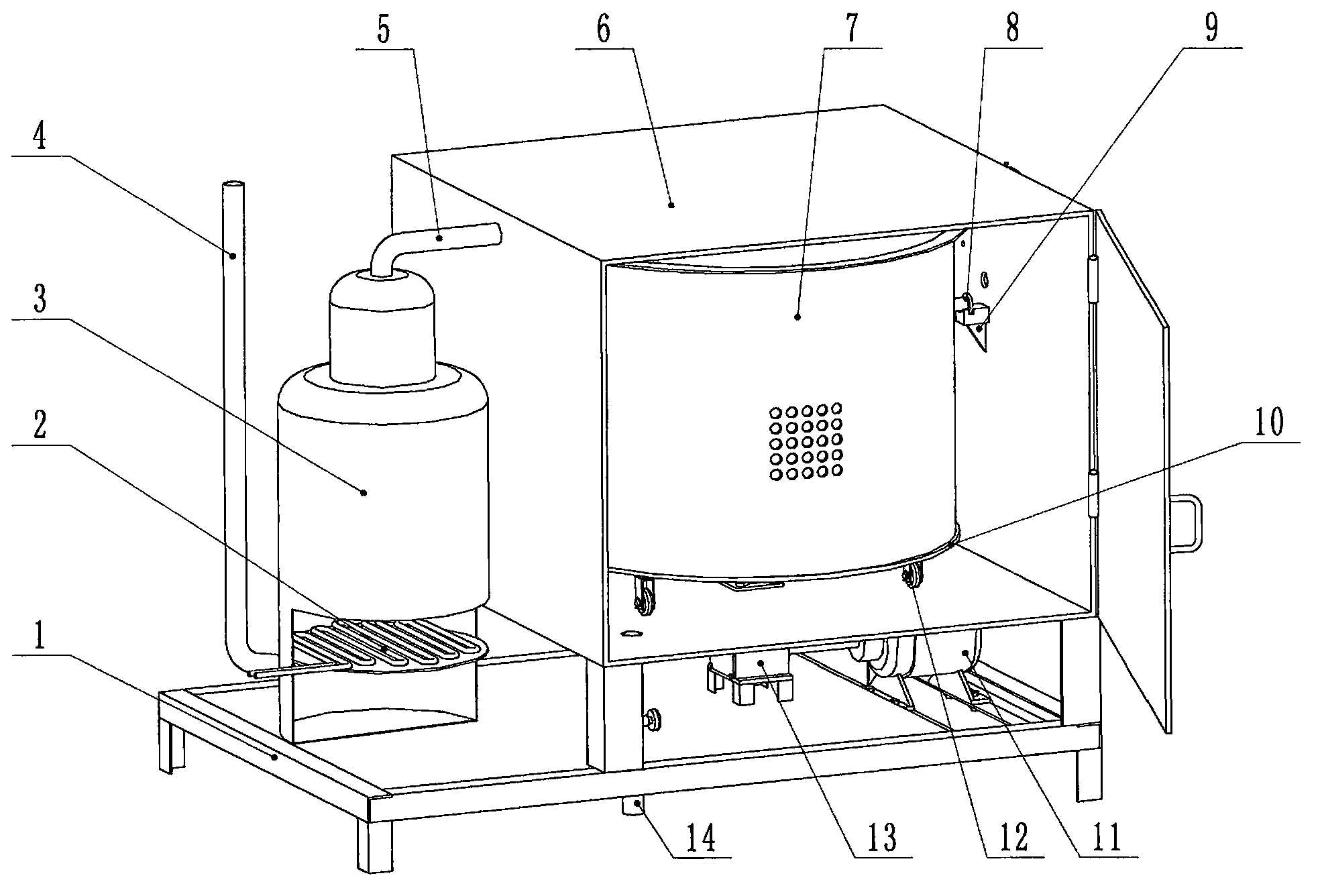

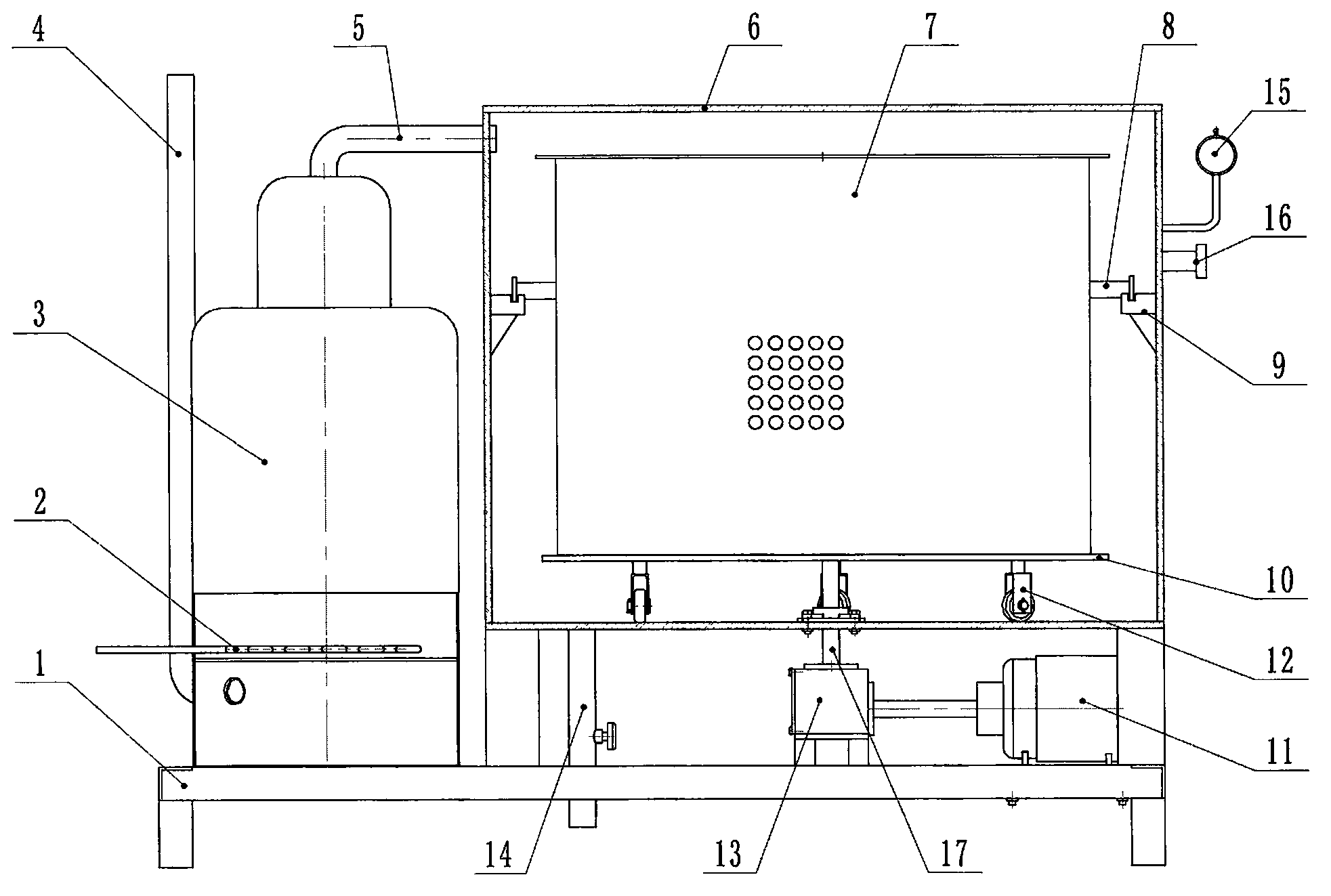

Coal-electricity dual-purpose machine for softening surface layer of traditional chinese medicinal materials through heating

InactiveCN104117331AEasy loading and unloadingSoften evenlyChemical/physical/physico-chemical processesEngineeringExhaust pipe

The invention relates to a coal-electricity dual-purpose machine for softening the surface layer of traditional chinese medicinal materials through heating. The machine comprises a frame, an electric heating tube, a dual-purpose steam oven, a smoke exhaust pipe, a steam guide pipe, a steam incubator, a medicine containing barrel, a hoisting shaft, spacing chuck plates, a rotation plate, a low-speed motor, universal wheels, a reduction gearbox, a water outlet pipe, a temperature controller, a safety valve and transmission shafts. The dual-purpose steam oven with the electric heating tube therein is mounted on the left side of the upper part of the frame; the spacing chuck plates are symmetrically arranged in the steam incubator, and are mounted on the right side at the upper part of the frame; the low-speed motor and the reduction gearbox are arranged on the frame below the steam incubator; the smoke exhaust pipe is arranged on one side of the dual-purpose steam oven; the water outlet pipe is arranged at the left-lower part of the steam incubator; the temperature controller and the safety valve are arranged on the outer wall on the left side of the steam incubator; the medicine containing barrel is mounted on the spacing chuck plates in the steam incubator through the hoisting shaft. The machine heats water by coal or electricity, then sends the water into the steam incubator by the steam guide pipe, the traditional chinese medicinal materials in the medicine containing barrel are rapidly heated and humidified by high temperature of steam; the medicinal material softening homogeneous degree can be improved by rotation of the medicine containing barrel driven by the rotation plate, the hoisting shaft is radially symmetrically arranged on the medicine containing barrel, so that the medicine containing barrel is convenient to assemble and disassemble, and the use convenience is enhanced. The machine has a reasonable structure, is high in reliability, good in softening efficiency and small in medicine damage, and lays a good foundation for the follow-up medicine peeling process.

Owner:李晓雄

Preparation method of chromium-free pickled leather

ActiveCN110129489ASoften bare hideBare skin softLeather manufacturingPre-tanning chemical treatmentFiberChromium free

The invention relates to a preparation method of chromium-free pickled leather, which can uniformly expand and be loosened properly, is beneficial to permeation and combination of tannins and dyes, and ensures that finished leather is soft and flat and fine in grain surface. Specifically, the following procedures are sequentially carried out: fur soaking, fleshing, pre-degreasing, enzyme depilating, alkali soaking, leather peeling, dealkalizing, degreasing and softening, pickling and pickled leather production, wherein the alkali soaking comprises the following steps: putting depilated leatherinto a rotary drum, controlling the liquid ratio to be 1.2-1.5, adding 0.2-0.5% of a penetrant and 0.5-0.8% of sodium hydrogen sulfide, and carrying out low-speed rotary drum treatment for 10-15 minutes; then, stopping operation of the drum and supplying water to adjust the pH value to be 7-8, sequentially adding 0.8%-1.0% of xonotlite fiber particles, 1.5%-3.0% of slaked lime and 0.8%-1.0% of alkaline leaching enzyme, performing low-speed rotary drum treatment at a low speed for 30-45 minutes, inspecting the leather, and washing the leather with water and discharging the leather from the drum after the expansion degree meets the requirement.

Owner:漳州香洲皮革有限公司

Softening enamelling device of copper enamelled wires

InactiveCN102637483AQuality assuranceIngenious structural improvementInsulating conductors/cablesMetallurgyCopper wire

The invention discloses a softening enamelling device of copper enamelled wires. The device comprises annealing chambers, wherein wire inlet holes are arranged at the wire inlet ends of the annealing chambers and copper wires enter the annealing chambers from the wire inlet holes. The device is characterized in that a plurality of parallel wire conduits are arranged at the wire outlet ends of the annealing chambers; the copper wires pass out of the wire conduits; the wire conduits incline downwards; a water tank is arranged in front of the wire conduits; a steam pipe is arranged above one end of the water tank; the lower ends of the wire conduits extend into the water tank; steam enters the annealing chambers; the bare copper wires passing out of the wire conduits enter wire outlet pipes via wire wheels in the water tank; enamelling and drying devices are arranged behind the annealing chambers; and the copper wires enter the enamelling and drying devices via the wire outlet pipes. The device has the following advantages that the structure is improved ingeniously and simply, the high temperature steam is utilized to heat the passing bare copper wires and the temperature is uniform, so that the copper wires are softened uniformly and bubbles are greatly reduced after the copper wire surfaces are enamelled, thus ensuring the quality of the copper enamelled wires.

Owner:ANHUI LEESOV IND

Method for producing frozen vegetable food material having soft texture

InactiveUS20110159147A1Easily and rapidlyAvoid damageTea extractionAnimal feeding stuffCyclic processCellulose

Provided is a method for producing a frozen soft vegetable food material which is suitable as a food for the aged, whose original shape is not damaged even in the circulation process, which has uniform softness even in the interior thereof and which can maintain its original shape.The method comprises steps of: (1) a step for freezing a vegetable food ingredient and then thawing the food ingredient to thus form a thawed food ingredient; (2) a step for immersing the thawed food ingredient in a dispersion containing a pectin-decomposition enzyme or a cellulose-decomposition enzyme under reduced pressure to form an enzyme-processed vegetable food ingredient; (3) a step for removing the enzyme-processed vegetable food ingredient from the enzyme-containing dispersion; (4) a step for subjecting the enzyme-processed vegetable food ingredient separated in the preceding step to a low temperature processing carried out at a temperature ranging from 0 to 10° C. for 8 to 24 hours to thus prepare a low temperature-processed vegetable food ingredient; (5) a step for heating the low temperature-processed vegetable food ingredient at a temperature and for a time sufficient to inactivate the foregoing pectin-decomposition enzyme or the cellulose-decomposition enzyme; and (6) a step for freezing the heat-treated vegetable food ingredient. Moreover, the thawing treatment in the foregoing step (1) may be carried out simultaneously with the enzyme-impregnation treatment carried out under reduced pressure in the subsequent step.

Owner:MISHIMA FOODS

Production method for bean paste

The invention provides a production method for bean paste, wherein the method includes the following steps: A, selecting dry chili pepper meeting standards, then successively cleaning with a cleaningmachine, steam-cooking with a steam cooker, injecting saline water and carrying out crushing treatment with a crusher, sending into a stirrer after crushing, then inputting into a main fermentation tank by a chili pepper blank transport pump while stirring, and fermenting, to obtain a chili pepper blank; B, inputting broad bean halves into a rinsing steaming cooling device, rinsing and steaming, cooling, and transporting to a disc koji-making device and koji-making while inoculating with a bacterial powder by a transporting inoculating device; and after koji-making, inputting into a broad beanhalves fermentation tank, and fermenting to obtain broad bean paste halves; and C, inputting the chili pepper blank obtained in the step A and the broad bean paste halves obtained in the step B intoa mixing tank, mixing evenly, inputting into the main fermentation tank by a feeding pump, and fermenting to obtain the Pixian bean paste. The method is mechanically operated in the whole process, theprocess control is more convenient and accurate, the flavor and quality of the Pixian bean paste are guaranteed, and at the same time, the truly feasible equipment base is provided for large-scale production and industry upgrading of the Pixian bean paste.

Owner:SICHUAN GAOFUJI FOOD

Soybean particle softening device for soybean oil production

PendingCN111763565ARealize secondary useIn line with the concept of environmental protectionFatty-oils/fats productionFood treatmentSoya beanPetroleum engineering

The invention discloses a soybean particle softening device for soybean oil production, and relates to the technical field of soybean processing. According to the invention, the problems as follows are overcome: in the prior art, soybeans are cleaned before being softened, most of water after cleaning is directly poured out, so that great waste is caused; and a steam softening roller for preparingsoybean oil cannot well and uniformly soften soybean particles, so that the softening effect of part of soybean particles is poor, and the soybean particles easily block a discharge port during discharging to influence the working efficiency. A scheme is provided as follows: the soybean particle softening device comprises an upper frame, a lower frame and a softening cylinder, the bottom of the upper frame is connected with the softening cylinder, the bottom of the softening cylinder is connected with the lower frame, a feed hole is formed in the top of the softening cylinder, and a dischargehole is formed in the bottom of the softening cylinder. According to the invention, integrated operation of soybean particle cleaning, softening and collecting is achieved, soybean softening is moreefficient, waste water can be reutilized, soybean softening is more uniform, and meanwhile the problem of blockage during discharging of soybeans can be prevented.

Owner:福建康宏股份有限公司

Softener for willow rattan and preparation method thereof

ActiveCN103692520BSoften evenlyFast solutionOther chemical processesWood treatment detailsPhenolOleic Acid Triglyceride

The invention discloses a softening agent for thin willow rattans. The softening agent is prepared from the following raw materials in parts by weight: 10-12 parts of bicarbonate, 2-3 parts of diphenyl ethyl compound phenol polyoxyethylene ether, 1-2 parts of oleic acid polyoxyethylene ester, 3-4 parts of radix aconiti sinensis, 2-3 parts of flos daturae, 4-5 parts of lavender, 6-8 parts of cassia twig, 5-7 parts of povidone iodine, 3-4 parts of auxiliaries and 100 parts of water. By the use of weak alkaline and a non-ionic surfactant, the softening agent for the thin willow rattans is uniform in softening, low in speed and suitable for softening of the thin willow rattans and cannot excessively corrosion the thin willow rattans; by the virtue of the traditional Chinese herbs such as the flos daturae and the lavender and the povidone-iodine, the softening agent can be prevented from being mildewed and damaged by worms and can disperse fragrance for a long time.

Owner:FUNAN YONGXING ARTS & CRAFTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com