Tire and tire manufacturing method

A manufacturing method and tire technology, applied in the direction of tire tread/tread pattern, pneumatic tire, special tire, etc., can solve problems such as limited rubber recycling and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] first exemplary embodiment

[0085] Next, a first exemplary embodiment of a tire according to the present invention will be described with reference to the drawings.

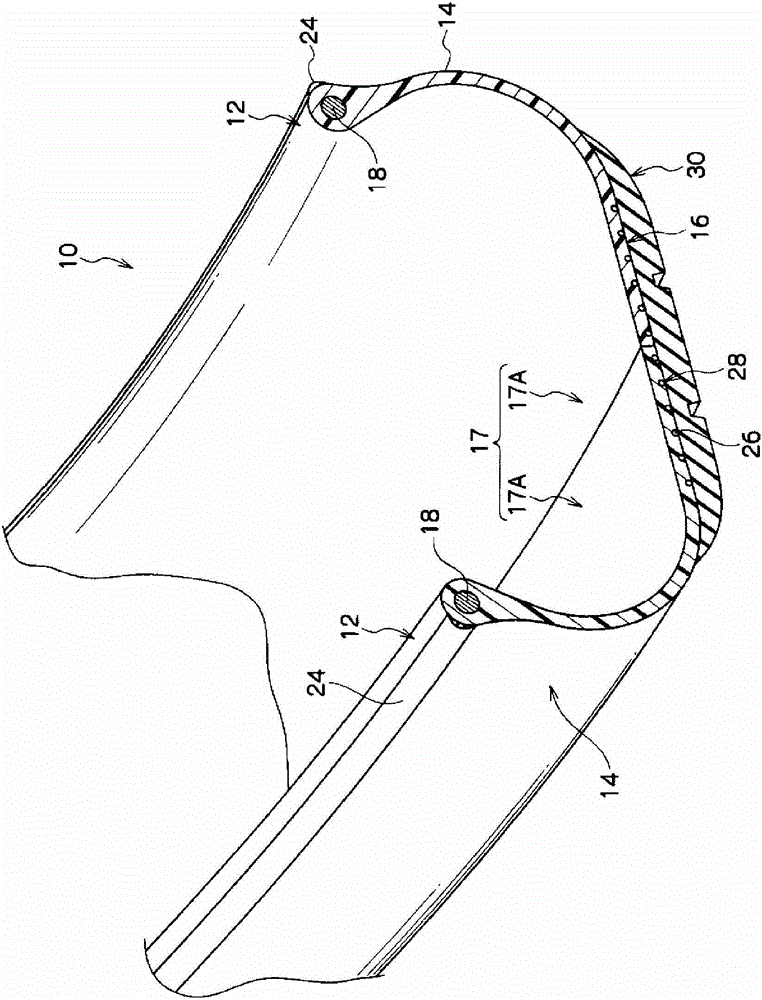

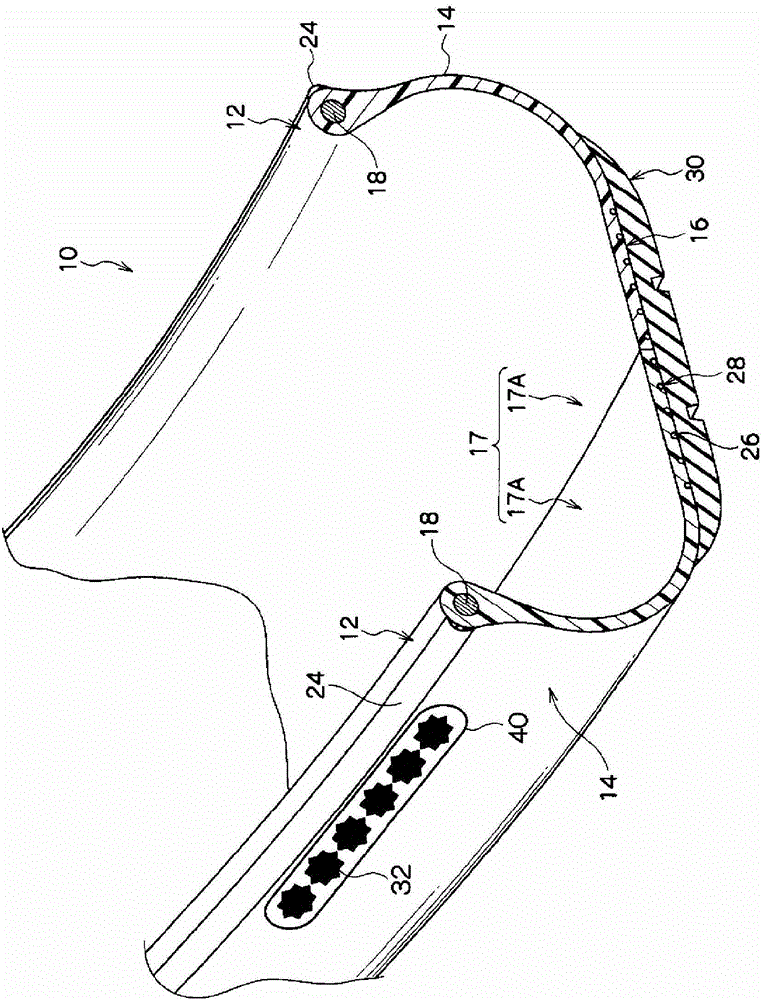

[0086] like Figure 1A and Figure 1B As shown, the tire 10 of the present exemplary embodiment has a cross-sectional shape similar to a conventional pneumatic tire made of conventional rubber for vehicles.

[0087] The tire 10 is provided with a tire case (tire frame member) 17 including a pair of bead portions 12 , a sidewall portion 14 , and a crown portion 16 . Contact, the sidewall portion 14 extends from the bead portion 12 to the radially outer side of the tire, and the crown portion 16 connects the radially outer end of the sidewall portion 14 on one side with the radially outer end of the sidewall portion 14 on the other side. The outboard ends are connected together.

[0088] The tire casing 17 of the present exemplary embodiment is formed of a first thermoplastic material.

[0089] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com