Softening treatment device used before enamelling copper enamelled wires

A softening, enameled wire technology, applied in electrical components, circuits, and conductor/cable insulation, etc., to achieve the effect of temperature averaging, meeting the requirements of use, and softening evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

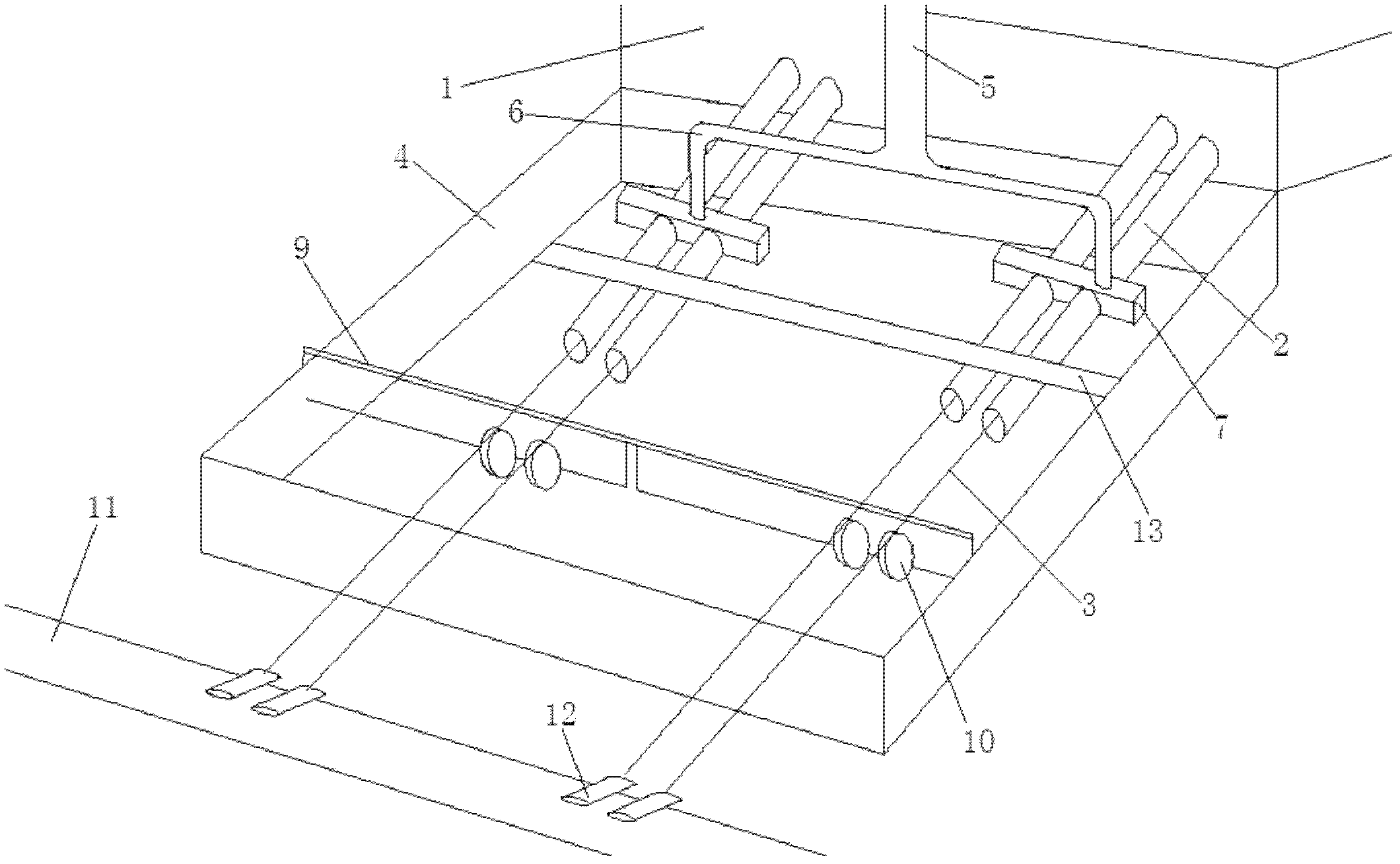

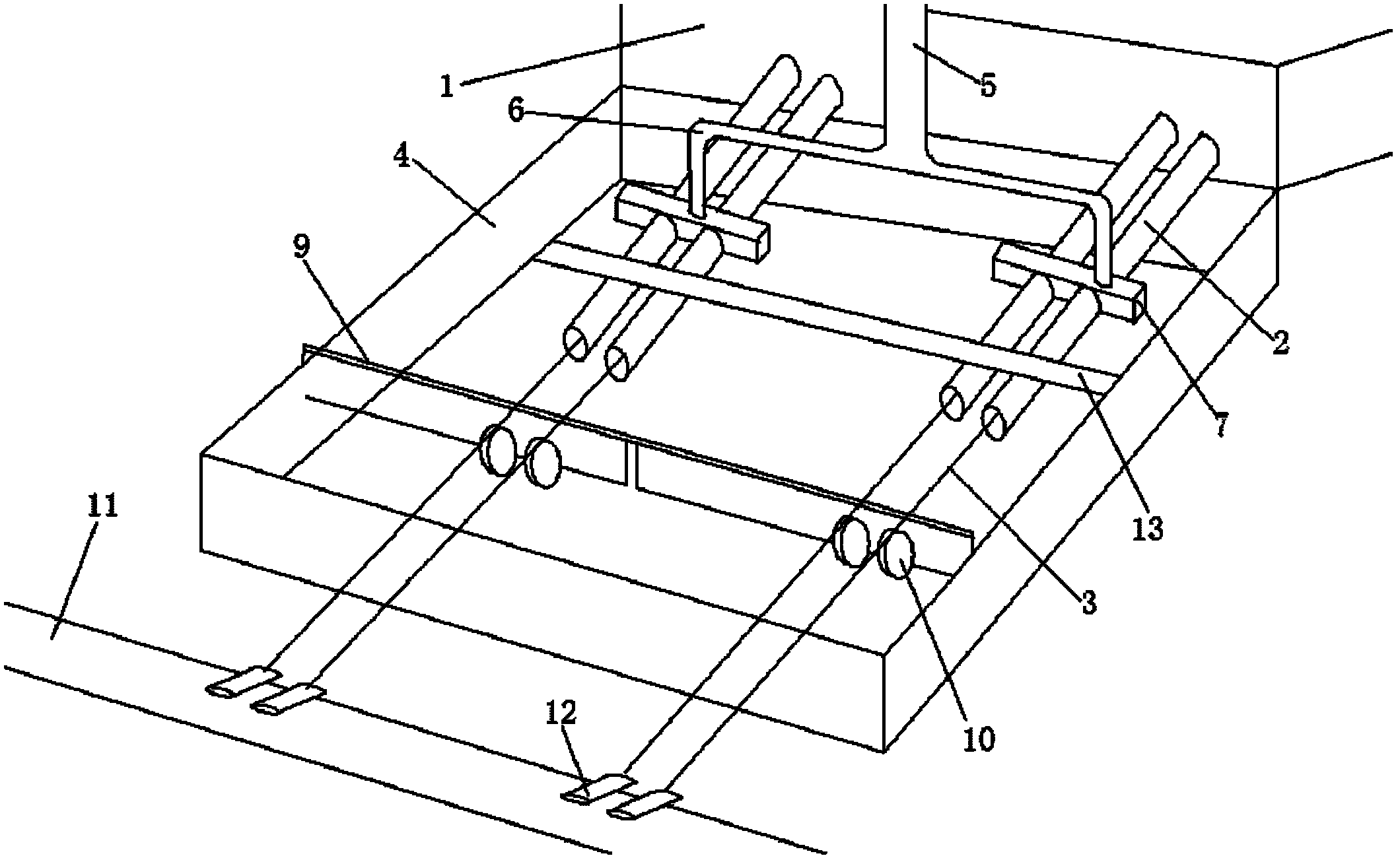

[0012] see figure 1 , a softening treatment device for copper enamelled wire before painting, comprising an annealing chamber 1, the wire inlet end of the annealing chamber is provided with a wire inlet hole, the copper wire enters the annealing chamber 1 from the wire inlet hole, and the wire outlet end of the annealing chamber is provided with a plurality of Conduit 2, copper wire 3 passes through in the conduit, and described conduit 2 is inclined downward, and the front of described conduit 2 is provided with water tank 4, and the top of described water tank 4 has steam pipe 5, and described steam pipe 5 is connected with a plurality of branch pipes 6, and the end of each branch pipe 6 is connected with a casing 7, and each wire conduit 2 is connected with the casing 7 in front of each branch pipe respectively, and the lower end of the wire conduit 2 extends into the In the water tank 4, it plays a role of water seal, so that the steam enters the annealing chamber 1; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com