Softening treatment method of columnar loofah sponge

A softening treatment, loofah technology, applied in fiber treatment, improved hand-feeling fibers, textiles and papermaking, etc., can solve the problems of small planting, inability to meet, destroying the spatial network structure, etc., to prevent yellowing, easy to soften , the effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

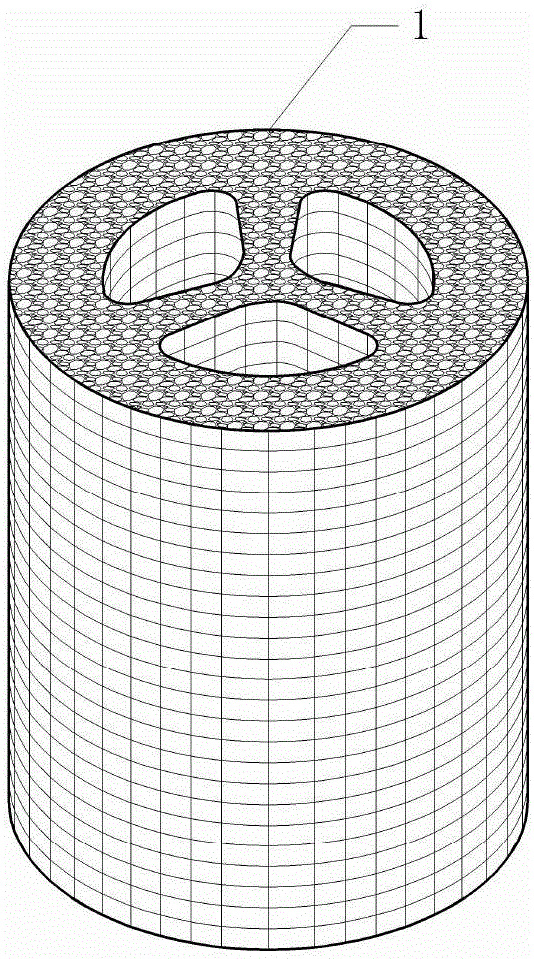

[0029] Example 1: Density at 30Kg / m 3 -45Kg / m 3 Softening treatment of columnar loofah

[0030] Step 1: After the loofah is washed and dried, cut off the two ends of the loofah with a woodworking table saw, and cut the middle part into a columnar loofah with a length of 3cm-5cm, with a height error of ±0.2cm, and remove the seeds.

[0031] Step 2: Screen out the columnar density at 30Kg / m by wind 3 -45Kg / m 3 The hard columnar loofah of the present invention is used as softening treatment raw material, and the columnar loofah of wind force screening is carried out random inspection by 1%.

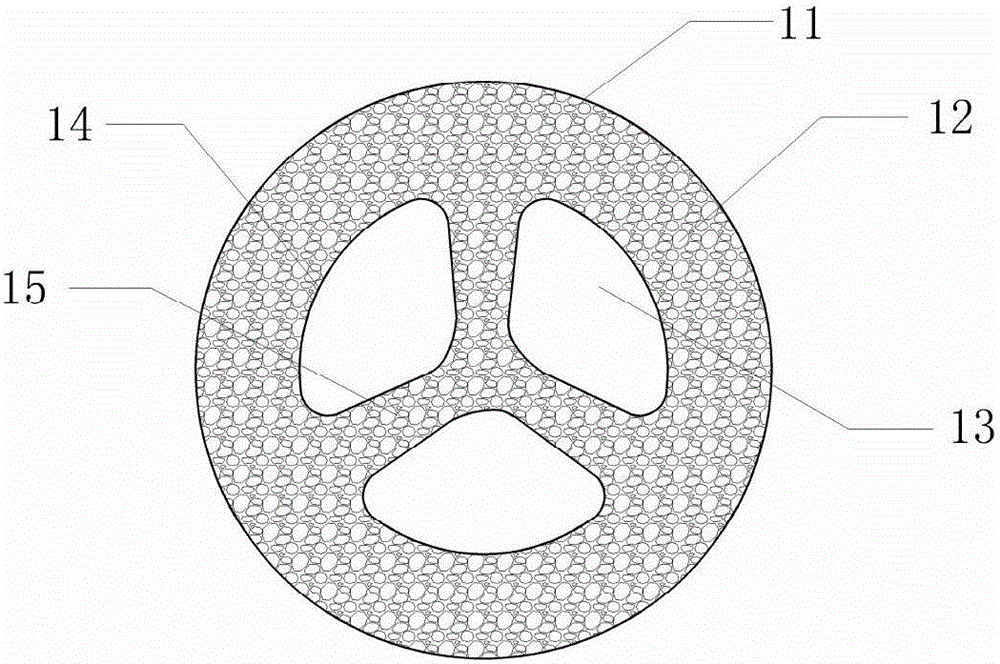

[0032] During sampling inspection, the method for density measurement is: first calculate the upper and lower cross-sectional areas S1 and S2 of the columnar loofah (both are the area except the middle hole, such as image 3 Shown), calculate the average and promptly obtain S average, columnar loofah volume V=S 均 *h 高 . Then weigh the mass m with an electronic balance, and obtain the ...

Embodiment 2

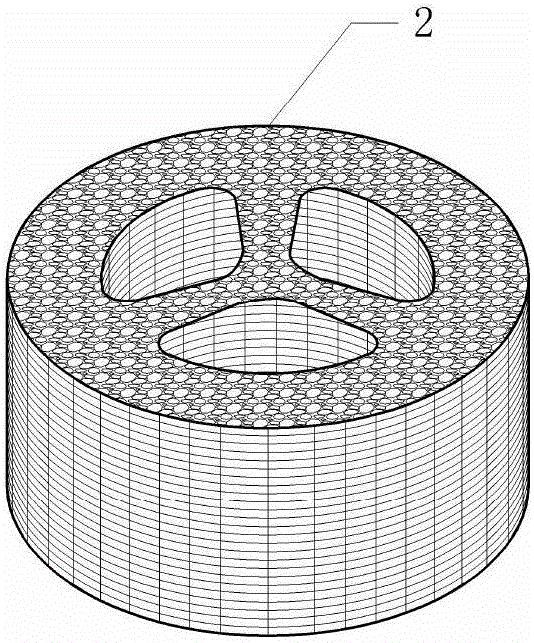

[0039] Embodiment 2: Density at 46Kg / m 3 -55Kg / m 3 Softening treatment of columnar loofah

[0040] Step 1: After the loofah is washed and dried, cut off the two ends of the loofah with a woodworking table saw, and cut the middle part into a columnar loofah with a length of 3cm-5cm, with a height error of ±0.2cm, and remove the seeds.

[0041] Step 2: Screen out the columnar density at 46Kg / m by wind 3 -55Kg / m 3 The hard columnar loofah of the present invention is used as softening treatment raw material, and the columnar loofah of wind force screening is carried out random inspection by 1%.

[0042] Sampling method is the same as embodiment 1

[0043] Step 3: Carry out hot-pressing compaction treatment on the columnar loofahs that have been sorted and inspected. The hot-pressing temperature is 70° C., the time is 3 minutes, and the compression amount is 60%.

[0044] Step 4: According to the required solution volume, prepare NaOH and H with a mass fraction of 7%. 2 o 2 ...

Embodiment 3

[0048] Embodiment 3: Density at 46Kg / m 3 -55Kg / m 3 The unsoftened treatment of columnar loofah

[0049] Step 1: Same as Example 2.

[0050] Step 2: Same as Example 2.

[0051] Step 3: The columnar loofah raw material is aged in a constant temperature and humidity environment, the temperature is 20±2°C, the humidity is 65±2%, and the aging time is 48 hours to obtain natural unsoftened columnar loofah. The unsoftened columnar loofah stress-strain curve is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com