Composition comprising polyoxyalkylene-based polymer composition

A polyoxyalkylene and composition technology, which is applied in detergent compositions, organic cleaning compositions, detergent compounding agents, etc., can solve problems such as pipeline blockage, failure to obtain satisfactory results, etc., and achieves prevention of fiber yellowing, The effect of excellent lime soap dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

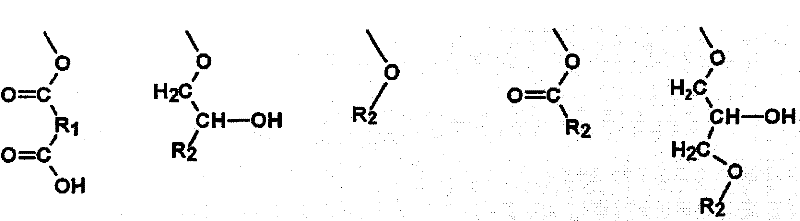

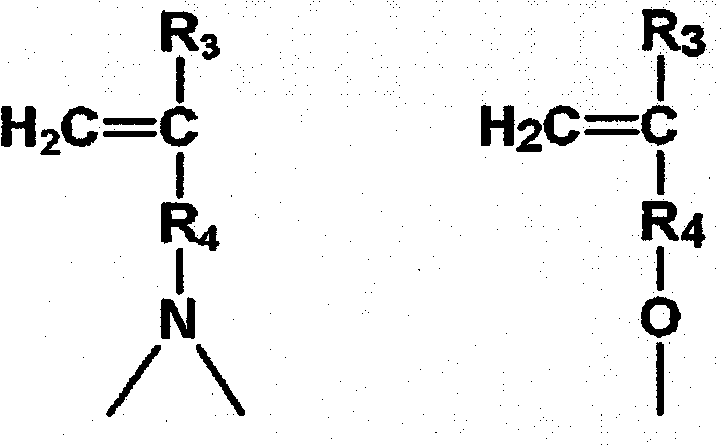

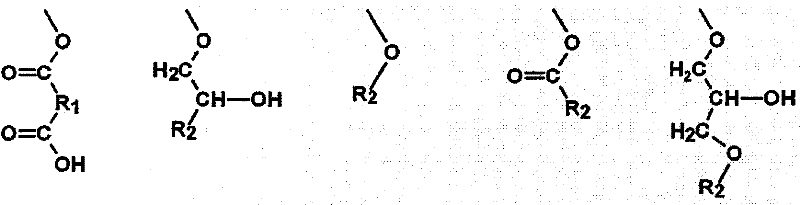

Method used

Image

Examples

Embodiment 1

[0193] Add 99.0 g of monomer 1 into a 500 mL capacity detachable glass flask equipped with a stirring device (stirring wing), then raise the temperature to 120° C. under stirring, inject nitrogen gas at the same time, and maintain the above conditions for 1 hour, And implement dehydration of the reaction system. Subsequently, the reflux condenser was connected, and the temperature was raised to 135° C.; then 11.0 g of 100% acrylic acid (hereinafter sometimes referred to as “AA”) and 527 μL (0.55 g, 5.0% by mass of AA) were added from a separate nozzle Tert-butyl peroxybenzoate (hereinafter sometimes referred to as "PBZ") as a polymerization initiator. The dropwise addition time of solution is set, and PBZ is 210 minutes, and AA is 210 minutes, starts to add dropwise 20 minutes after beginning to add PBZ. Also, the dropping rate of each solution was made constant, and the addition of each solution was continuously performed. After the addition of AA was completed, the above r...

Embodiment 2

[0196] Add 99.7g of monomer 1 into a detachable glass flask with a capacity of 500mL and equipped with a stirring device (stirring wing); then raise the temperature to 120°C under stirring, inject nitrogen gas at the same time, and maintain the above conditions for 1 hour, And realize the dehydration of the reaction system. Subsequently, a reflux condenser was connected, and the temperature was raised to 135° C.; then 17.6 g of 100% AA and 844 μL (0.88 g, 5.0% by mass of AA) of PBZ as a polymerization initiator were added from a separate nozzle. The dropwise addition time of solution is set, and PBZ is 210 minutes, and AA is 210 minutes, starts to add dropwise 20 minutes after beginning to add PBZ. Also, the dropping rate of each solution was made constant, and the addition of each solution was continuously performed. After the addition of AA was completed, the above reaction solution was maintained at a temperature of 135° C. for 70 minutes (aging) to terminate the polymeriz...

Embodiment 3

[0201] Add 99.0 g of monomer 2 into a detachable glass flask with a capacity of 500 mL and equipped with a stirring device (stirring wing); then raise the temperature to 120° C. under stirring, inject nitrogen gas at the same time, and maintain the above conditions for 1 hour, And implement dehydration of the reaction system. Subsequently, a reflux condenser was connected, and the temperature was raised to 135° C.; then 11.0 g of 100% AA and 527 μL (0.55 g, 5.0% by mass of AA) of PBZ as a polymerization initiator were added from a separate nozzle. The dropwise addition time of solution is set, and PBZ is 210 minutes, and AA is 210 minutes, starts to add dropwise 20 minutes after beginning to add PBZ. In addition, the dropping rate of each solution was made constant, and the addition of each solution was continuously performed. After the addition of AA was completed, the above reaction solution was maintained at a temperature of 135° C. for 70 minutes (aging) to terminate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com