Hydrogenation method for reducing condensation point of diesel

A diesel oil and freezing point technology, which is applied in hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of easy poisoning and deactivation of noble metal catalysts, complicated process flow, expensive catalysts, etc., and achieves the improvement of the yield of low freezing point diesel oil , High yield of diesel oil, good pour point depressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

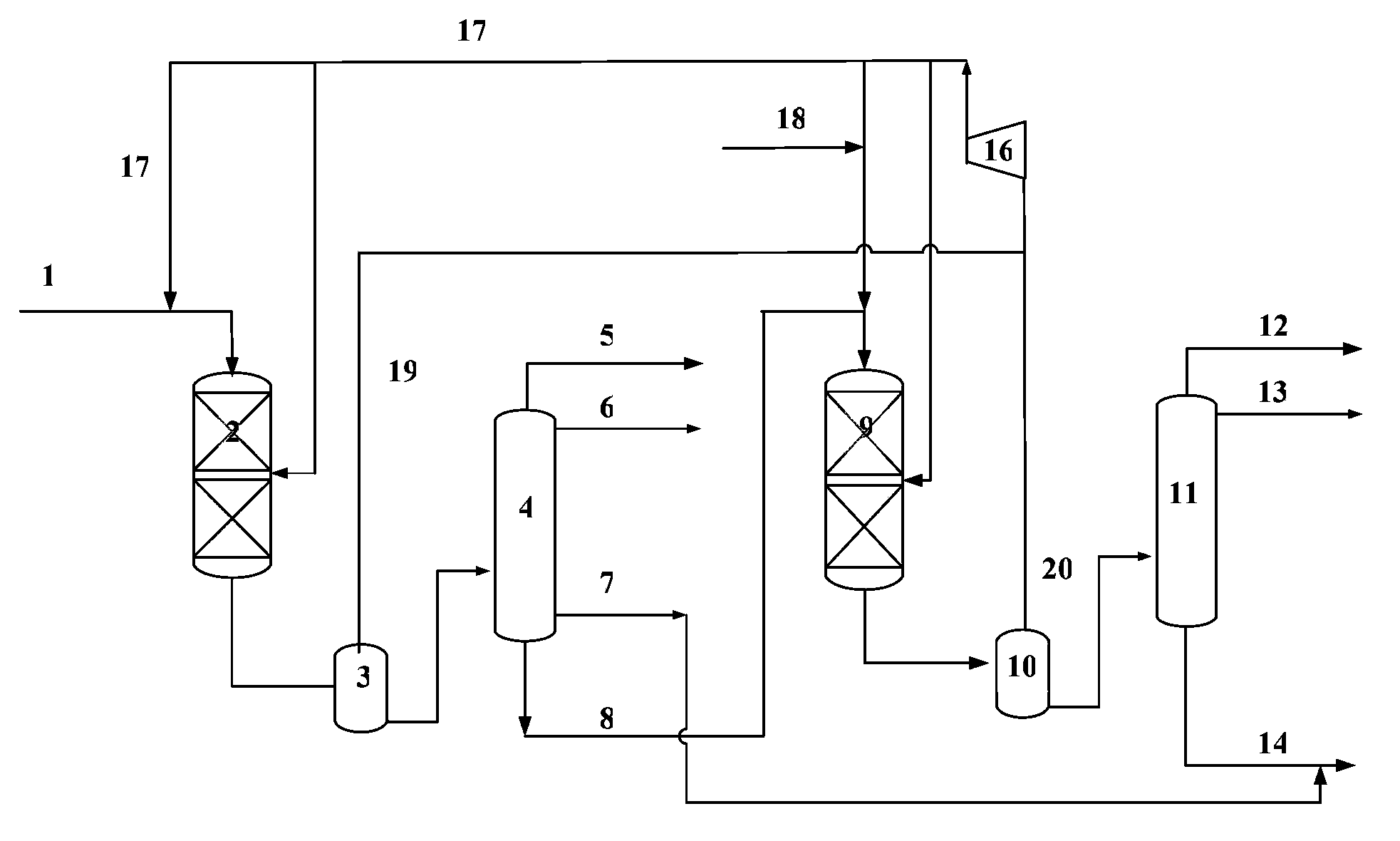

Method used

Image

Examples

Embodiment 1

[0060] Using a straight-run diesel oil A as raw material, the raw material A is firstly contacted with the hydrorefining catalyst RS-2000 in the first reaction zone for hydrorefining, and the effluent from the first reaction zone enters the first separation system and the first fractionation system for cutting Gas, naphtha fraction, low-condensing diesel fraction I and high-condensing-point heavy diesel fraction (distillation range 325-376°C), all high-condensing-point heavy diesel fractions enter the second hydrogenation reaction zone, The hydrogen reaction zone is in contact with the hydrogenation-modifying decondensation catalyst E to carry out the isomerization depreciation reaction; the effluent from the second reaction zone enters the second separation system and the second fractionation system to cut out gas, naphtha fraction and low-point-point diesel fraction II . The low-condensation diesel fraction I and the low-condensation diesel fraction II are mixed to obtain a ...

Embodiment 2

[0068] A catalytic diesel oil B is used as a raw material, and the pour point is depressed according to the method provided by the present invention. The distillation range of heavy diesel oil with high freezing point is 265~379℃. The hydrofinishing catalyst is a non-supported hydrofinishing catalyst F, and the loading volume ratio of the hydrofinishing catalyst and the hydromodifying pour point depressing catalyst E is 60:40. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 3.

[0069] It can be seen from the data in Table 3 that the freezing point of the diesel product decreased to -26°C, the cold filter point decreased to -16°C, the yield reached 91.4%, the cetane number increased to 51.2, and the sulfur content was greatly reduced.

Embodiment 3

[0071] Using a direct diesel oil C as a raw material, the pour point depressing is carried out according to the method provided by the present invention. The distillation range of heavy diesel oil with high freezing point is 315~371℃. The hydrofinishing catalyst is a non-supported hydrofinishing catalyst F, and the loading volume ratio of the hydrofinishing catalyst and the hydromodifying pour point depressing catalyst E is 70:30. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 3.

[0072] It can be seen from the data in Table 3 that the freezing point of the diesel product is reduced to -27°C, the cold filter point is reduced to -18°C, the yield reaches 95.1%, the cetane number increases to 53.5, and the sulfur content is greatly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com