High-temperature-resistant epoxy resin-based neutron and gamma-ray shielding composite material and preparation method thereof

An epoxy resin and composite material technology, applied in shielding, nuclear engineering, reactors, etc., can solve the problems of poor dimensional stability, poor heat resistance and flame retardancy of polyethylene-based shielding composite materials, and large coefficient of linear expansion. Excellent dimensional stability, easy construction, wide range of adjustable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

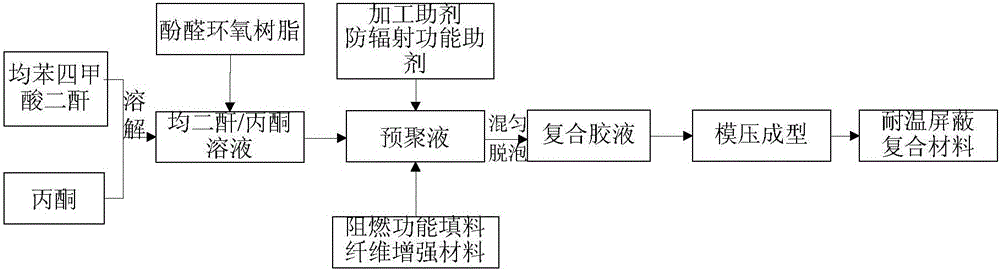

[0068] This example provides a method for preparing a high temperature resistant phenolic epoxy resin based neutron and gamma ray shielding composite material, the process flow chart is as follows figure 1 shown, from figure 1 It can be seen that the preparation method comprises the following specific steps;

[0069] (1) The shielding composite material is prepared by parts by weight from the following components (as shown in Table 1):

[0070] Table 1

[0071] raw material name parts by mass manufacturer Novolak epoxy resin F44 80 copies Jinan Yisheng Resin Co., Ltd. Pyromellitic dianhydride 20 copies Langfang Beide Trading Co., Ltd. acetone 60 copies Beijing Chemical Plant boron carbide 33 copies Ning'an Bohai Boron Carbide Co., Ltd. Tungsten powder 140 copies Beijing Youxinglian Nonferrous Metals Co., Ltd. magnesium hydroxide 100 copies Weifang Haililong Magnesium Industry Co., Ltd. glass fiber 40 c...

Embodiment 2

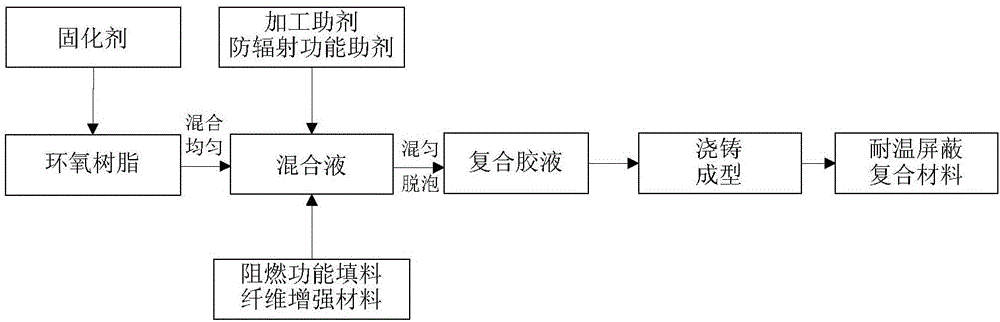

[0076] This example provides a method for preparing a high-temperature-resistant bisphenol A epoxy resin-based neutron and gamma-ray shielding composite material, and its process flow chart is as follows figure 2 shown, from figure 2 It can be seen that the preparation method comprises the following steps;

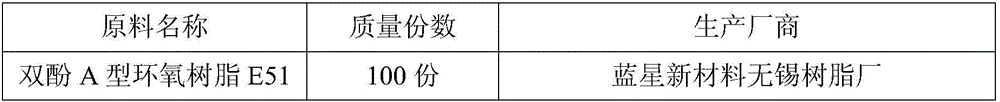

[0077] (1) The shielding composite material is prepared by parts by weight from the following components (as shown in Table 2):

[0078] Table 2

[0079]

[0080]

[0081] (2) First slowly add polyamide 650 into bisphenol A epoxy resin E51, stir evenly to obtain a mixed solution. Add benzyl glycidyl ether, phenol, amino-terminated liquid nitrile rubber, boron oxide, tungsten powder, magnesium hydroxide, and glass fiber in sequence to the mixture, stir evenly, and vacuum defoam to obtain a composite glue;

[0082] (3) Cast the above composite glue into a mold, keep it warm at 80°C for 2 hours, and vacuum <0.03MPa, after curing and molding, cool to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com