Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "High reforming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

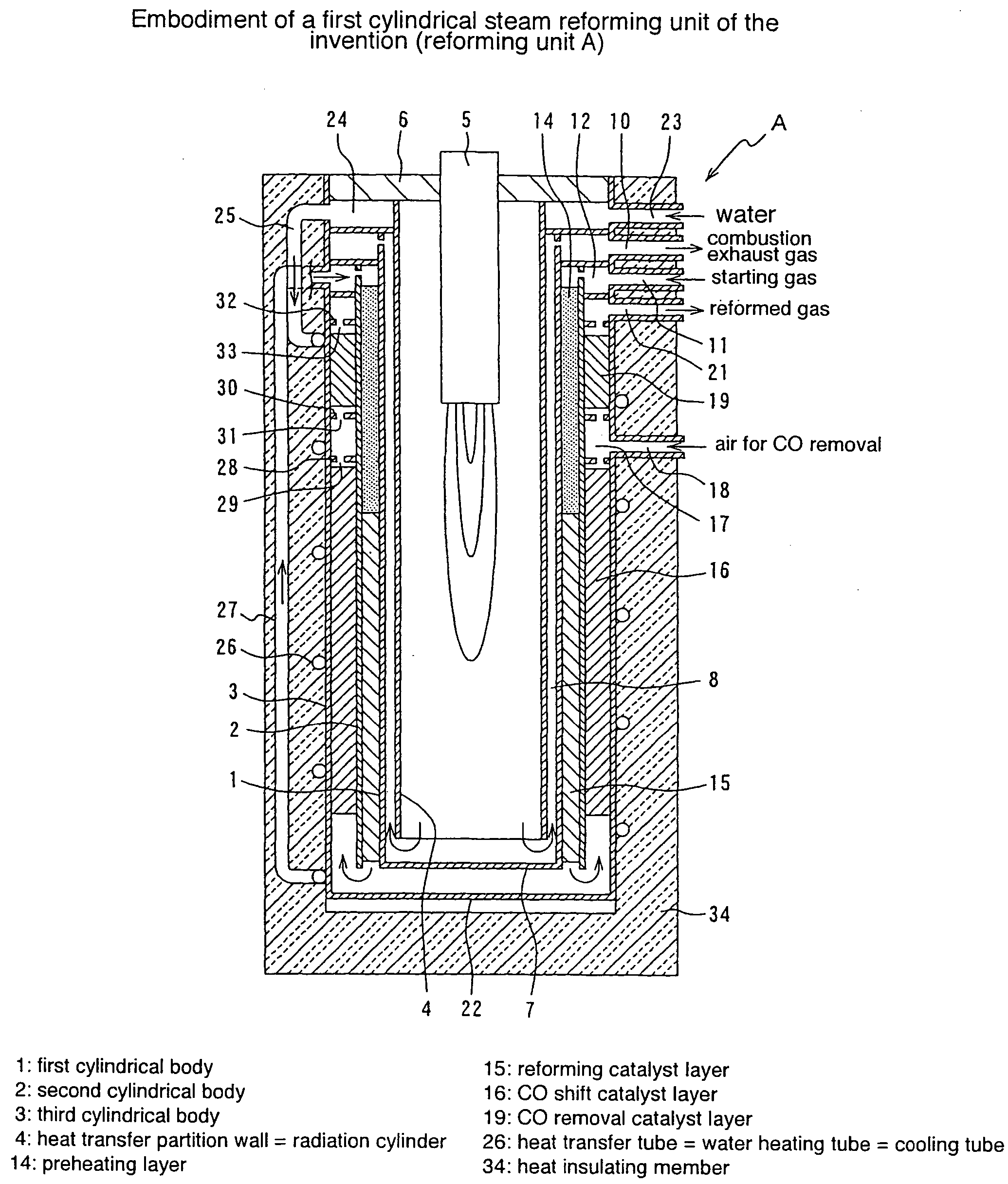

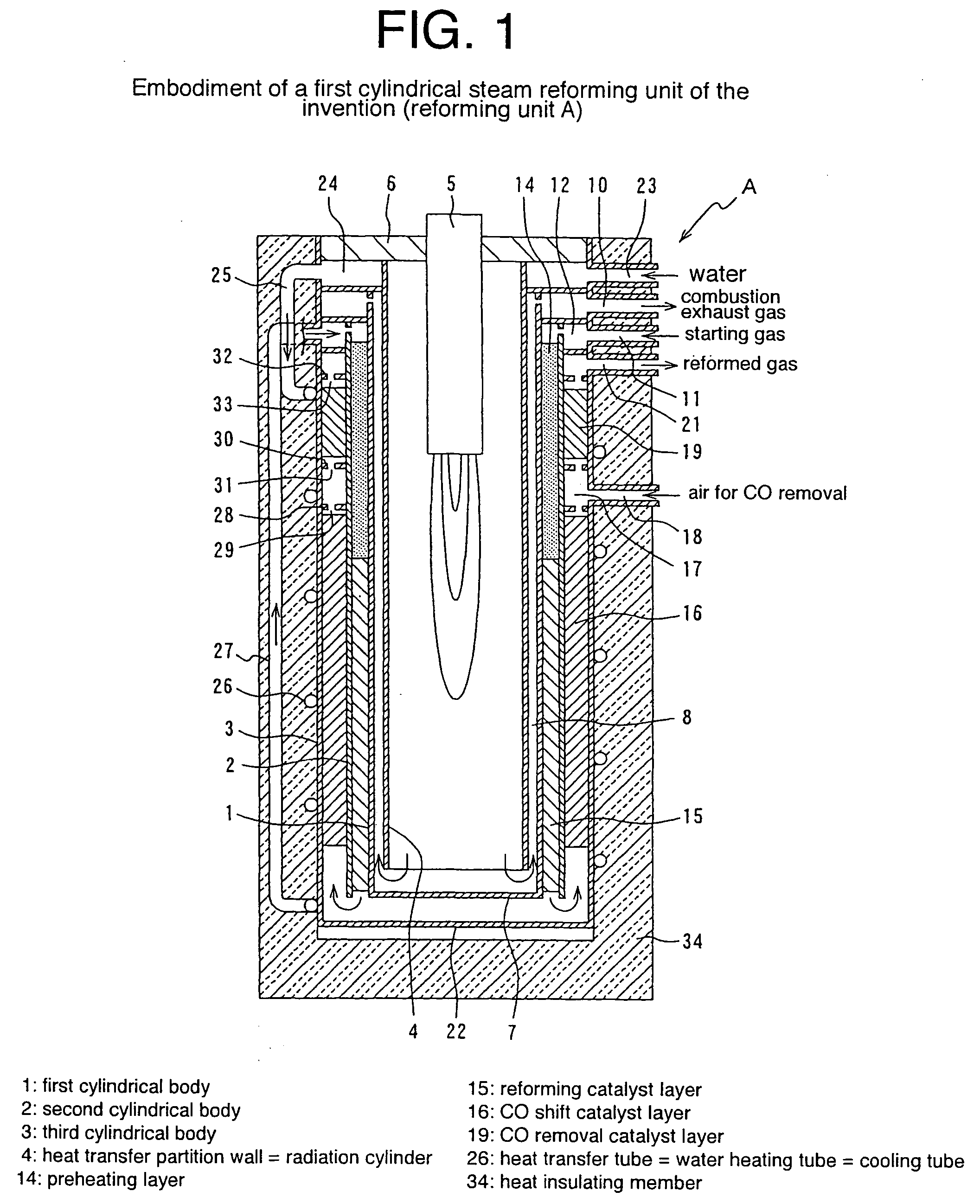

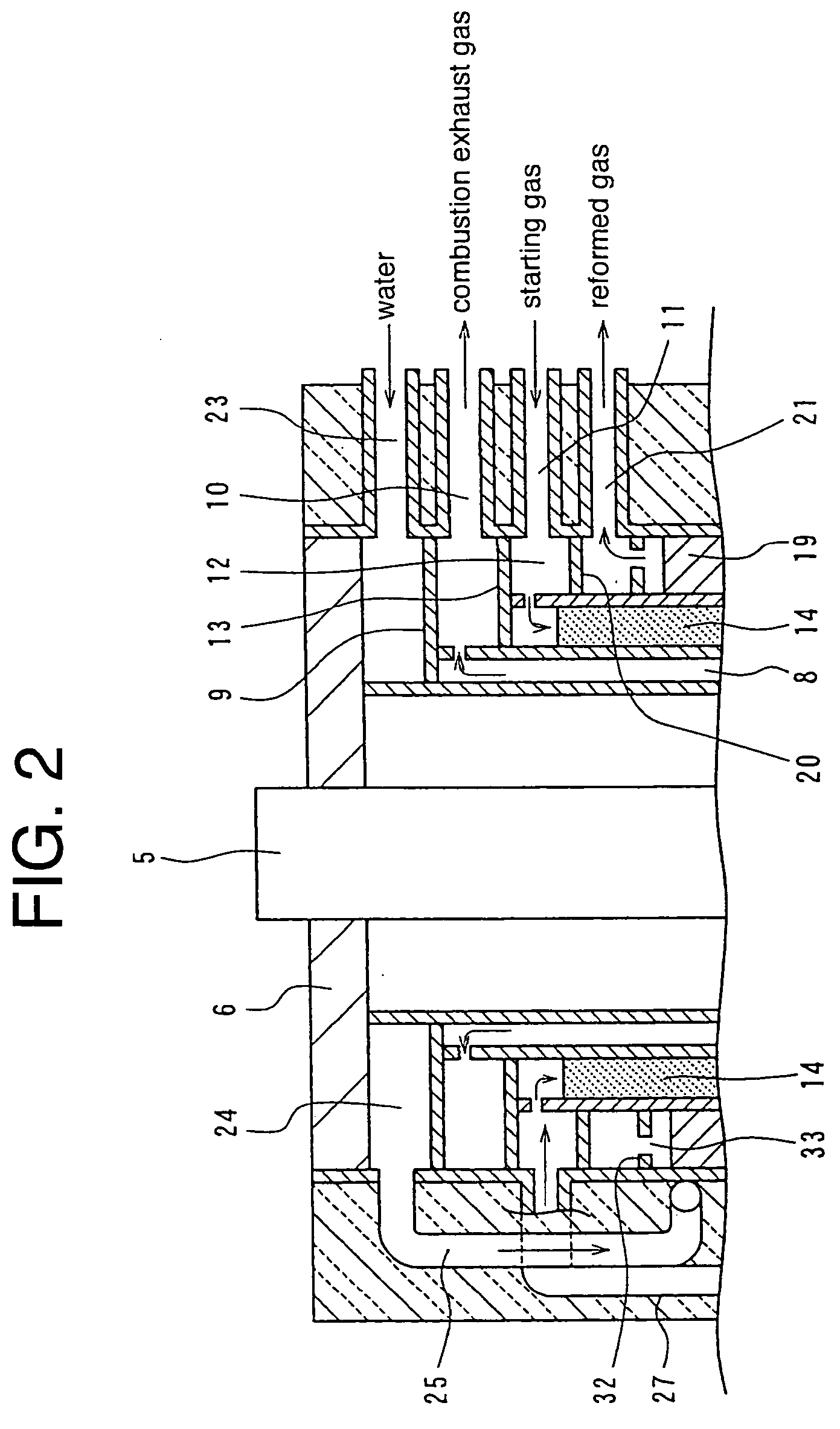

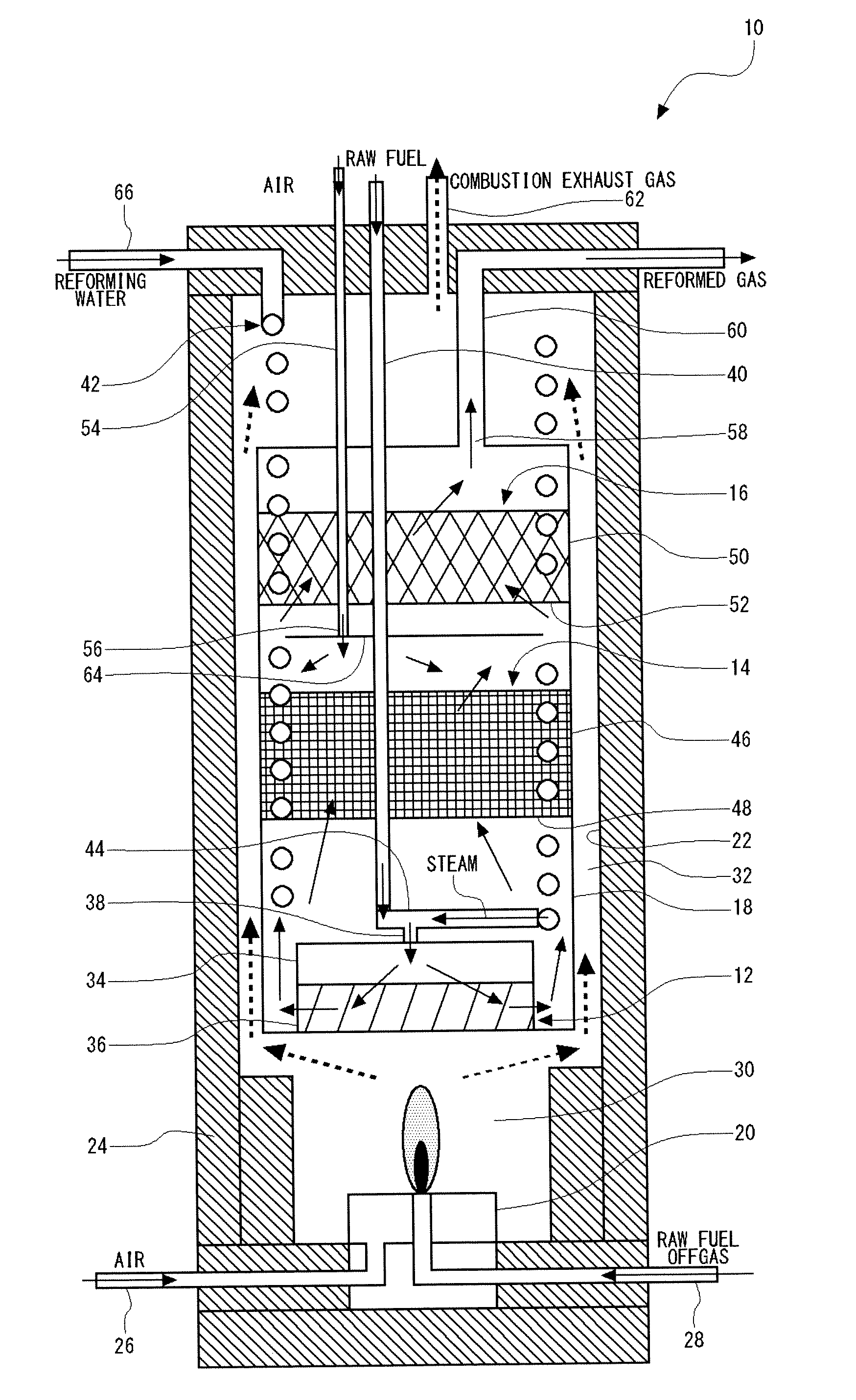

Cylindrical water vapor reforming unit

InactiveUS20040144029A1Small sizePass smoothlyHydrogen/synthetic gas productionChemical/physical/physico-chemical processesSteam reformingInsulation layer

A cylindrical steam reforming unit comprising a plurality of cylindrical bodies consisting of a first cylindrical body, a second cylindrical body and a third cylindrical body of successively increasing diameters disposed in a concentric spaced relation, a radiation cylinder disposed within and concentrically with the first cylindrical body, a burner disposed in the radial central portion of the radiation cylinder, and a reforming catalyst layer with a reforming catalyst filled in a gap between the first and second cylindrical bodies, wherein a CO shift catalyst layer and a CO removal catalyst layer are disposed in a gap between the second and third cylindrical bodies, the CO shift catalyst layer being formed in a gap with the direction of flow reversed at one axial end of the reforming catalyst layer and through a heat recovery layer of predetermined length. According to this reforming unit, without internally disposing a heat insulation layer, a cooling mechanism or the like, the reforming catalyst layer, CO shift catalyst layer, and CO removal catalyst layer can be integrated, achieving various useful effects, including size and weight reductions and the shortening of startup time.

Owner:TOKYO GAS CO LTD

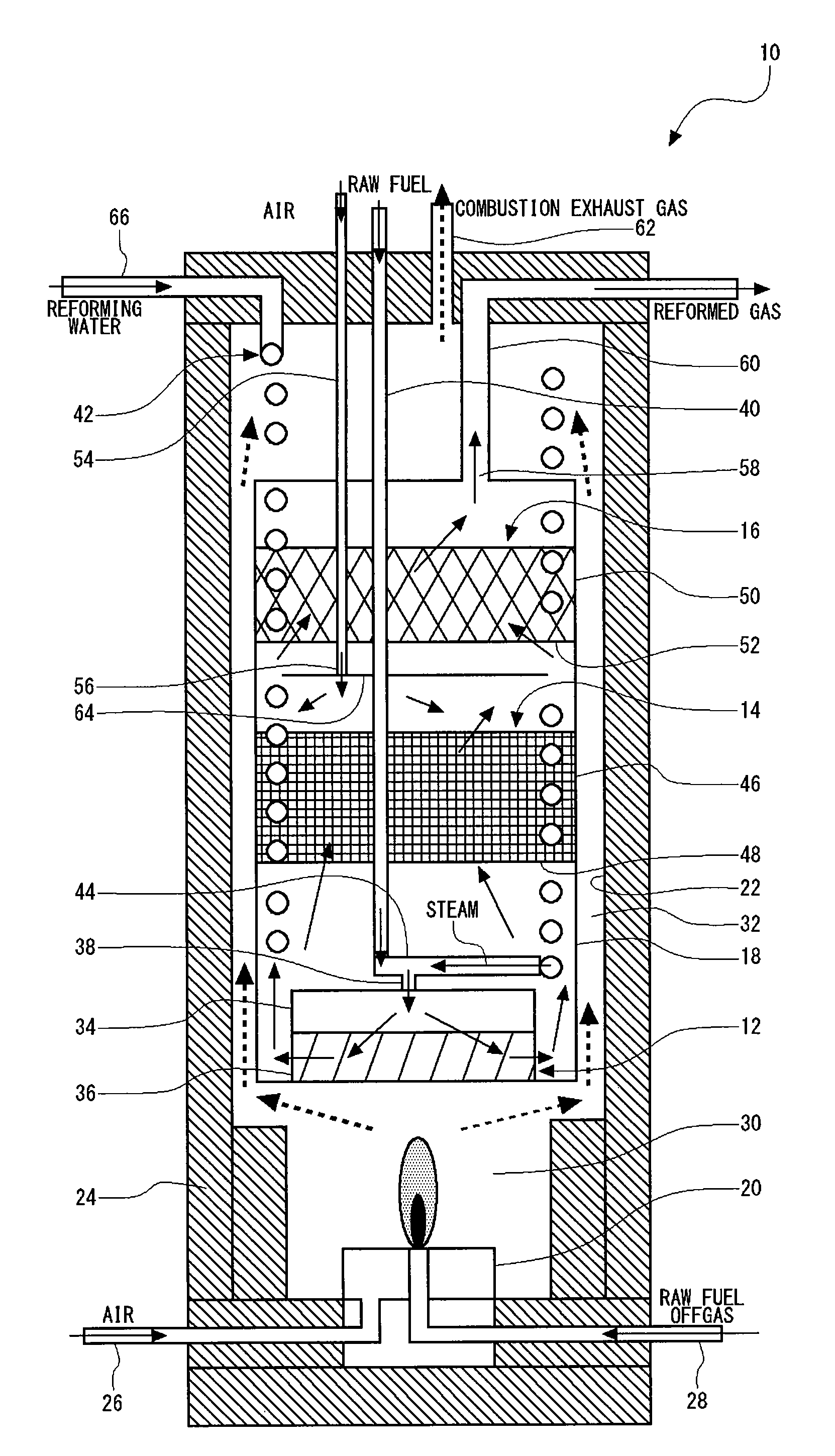

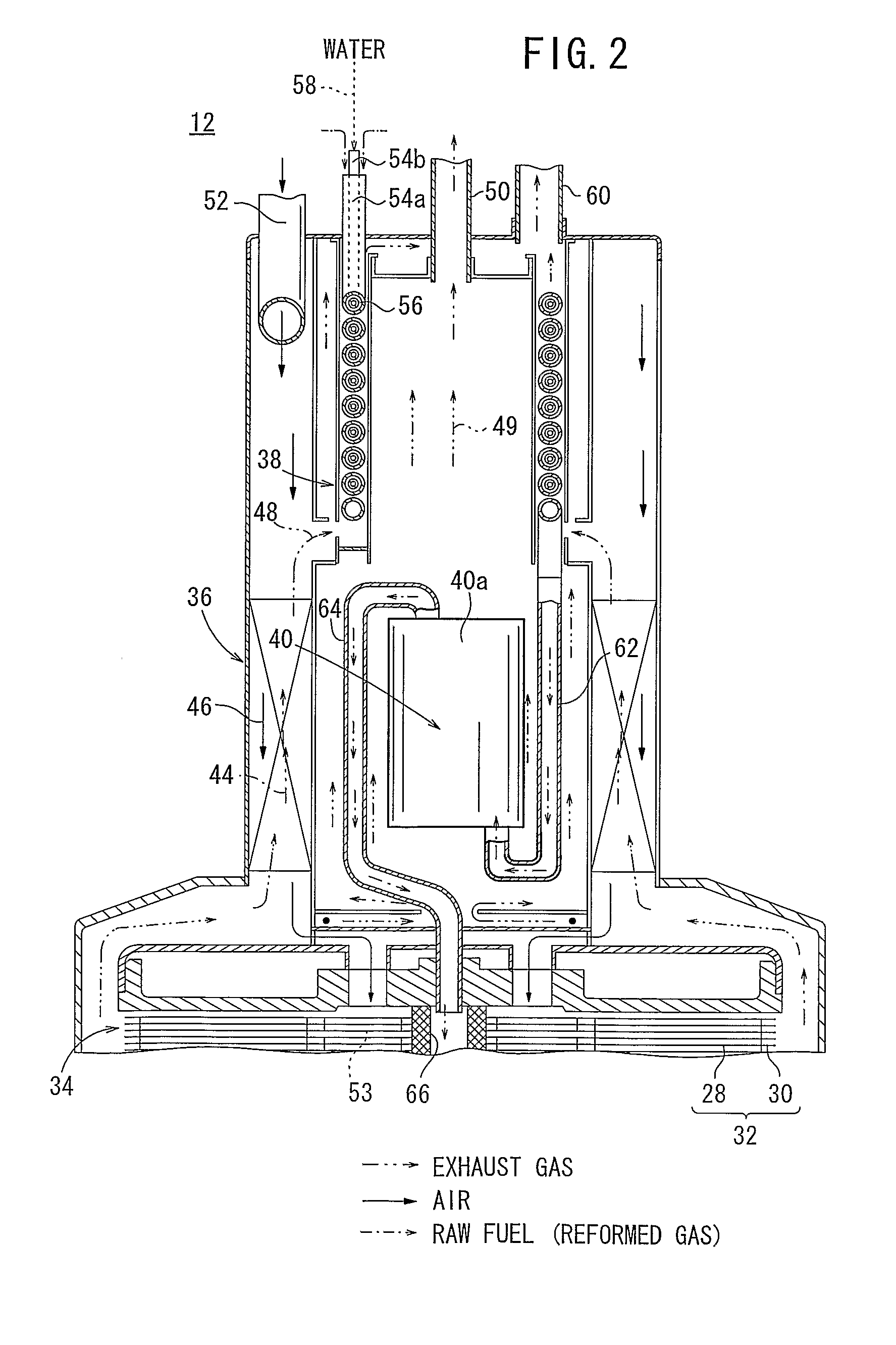

Reforming apparatus for fuel cell

InactiveUS20090087705A1Simple structureImprove thermal efficiencyHydrogenChemical industryHydrogenCombustion

In a reforming apparatus, for use in a fuel cell, for reforming a raw fuel into a hydrogen-rich reformed gas, a reformer generates the reformed gas from the raw fuel. A shift reactor reduces carbon monoxide contained in the reformed gas through a shift reaction. A selective oxidation unit reduces the carbon monoxide contained in the reformed gas that has passed through the shift reactor by performing selective oxidation on the carbon monoxide. A reforming reaction tube houses linearly the reformer, the shift reactor and the selective oxidation unit in this order. A combustion means produces combustion exhaust gas by combusting the raw fuel. An outer casing is placed around the reforming reaction tube, and the outer casing has a larger diameter than that of the reforming reaction tube. A heated flow passage through which the combustion exhaust gas passes to heat the reforming reaction tube is formed between the reforming reaction tube and the outer casing.

Owner:NIPPON OIL CORP

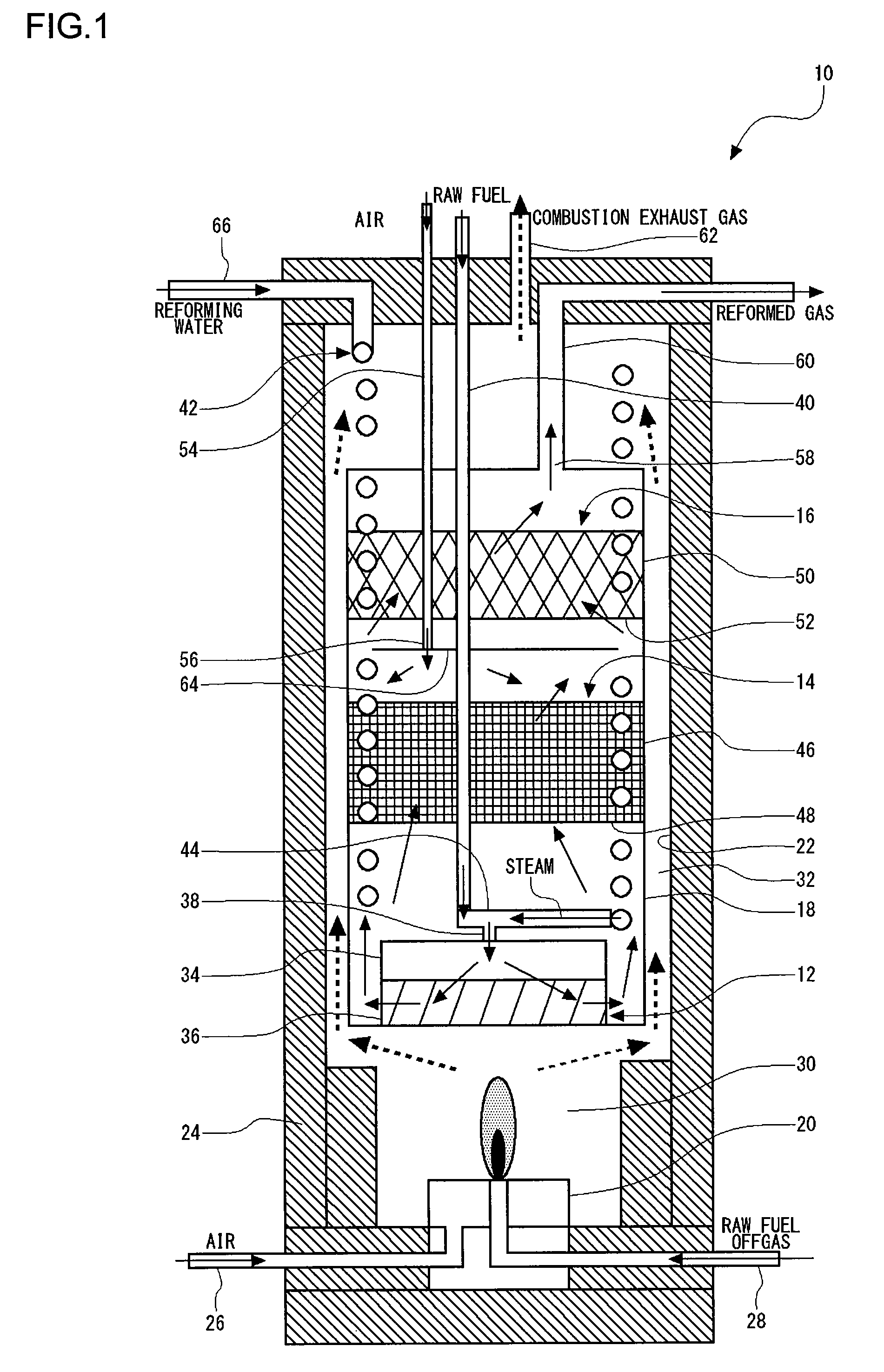

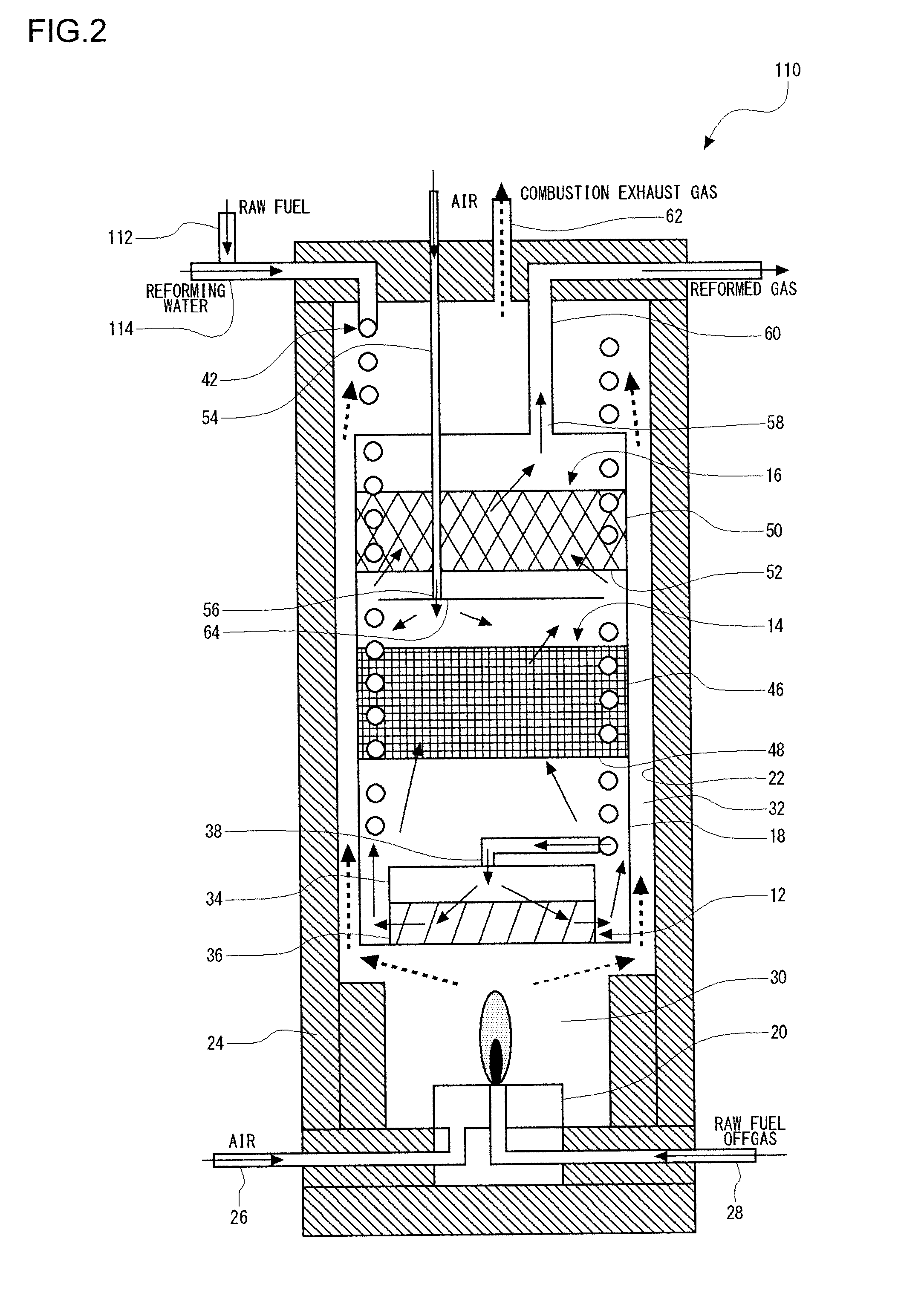

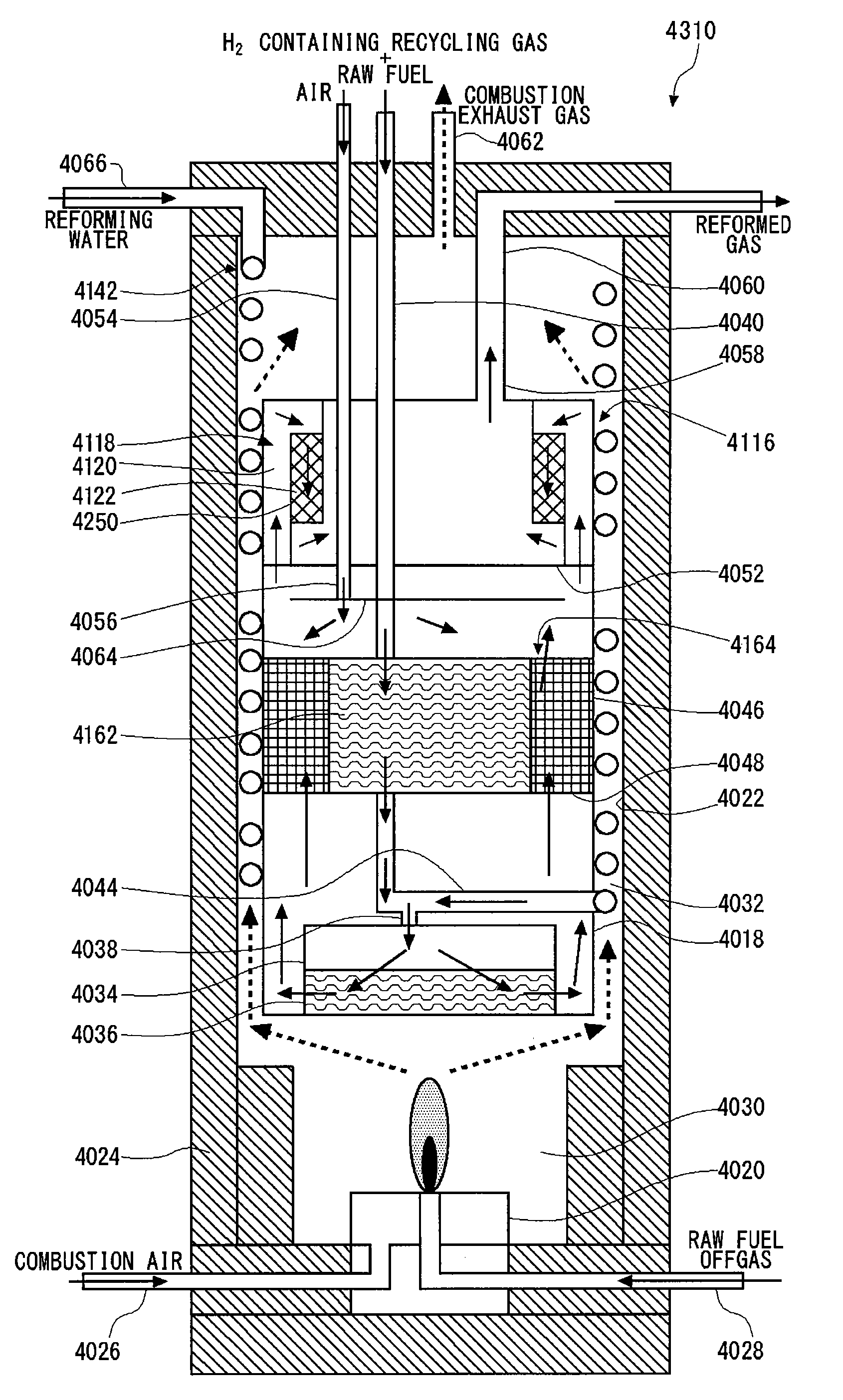

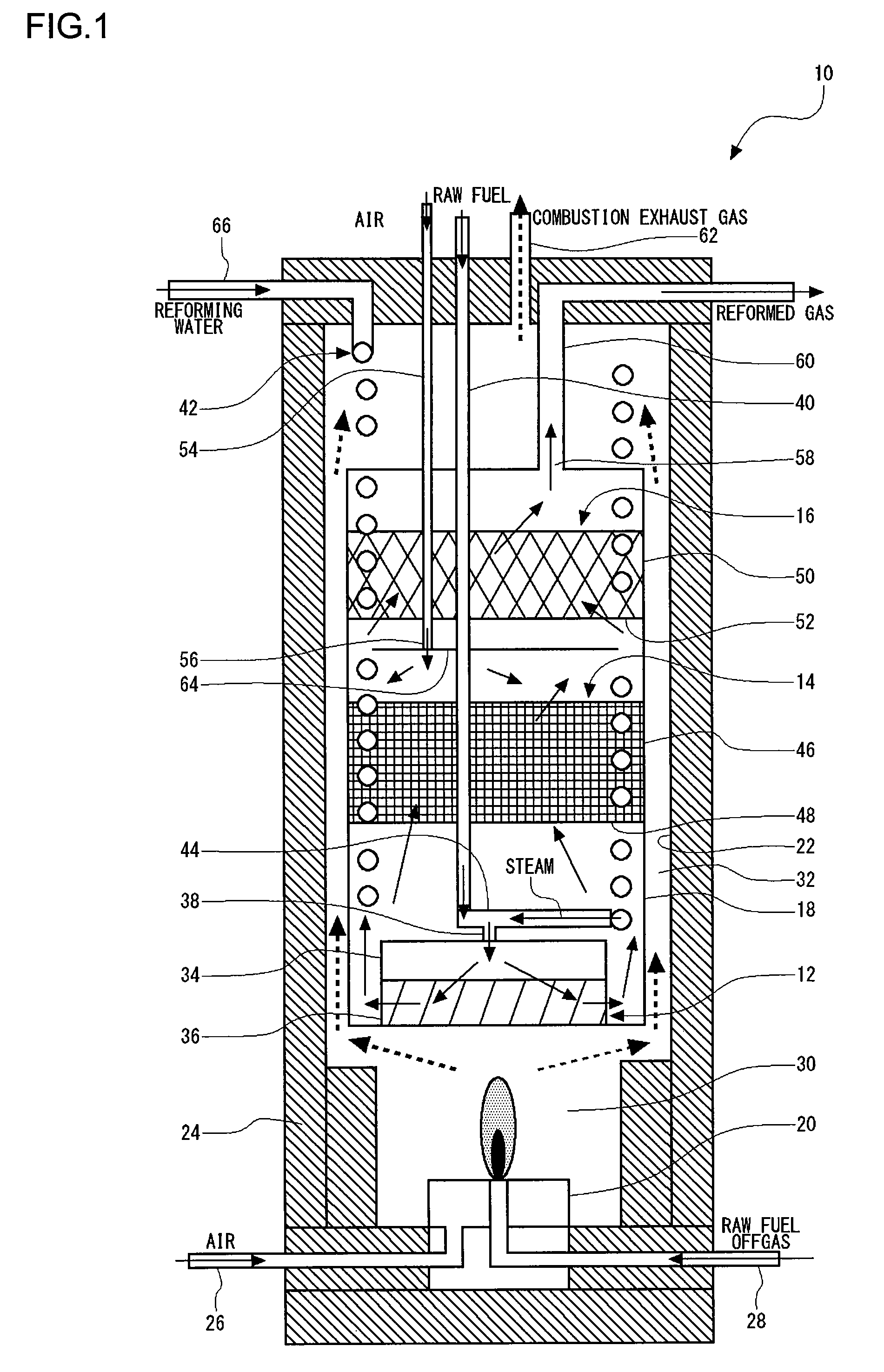

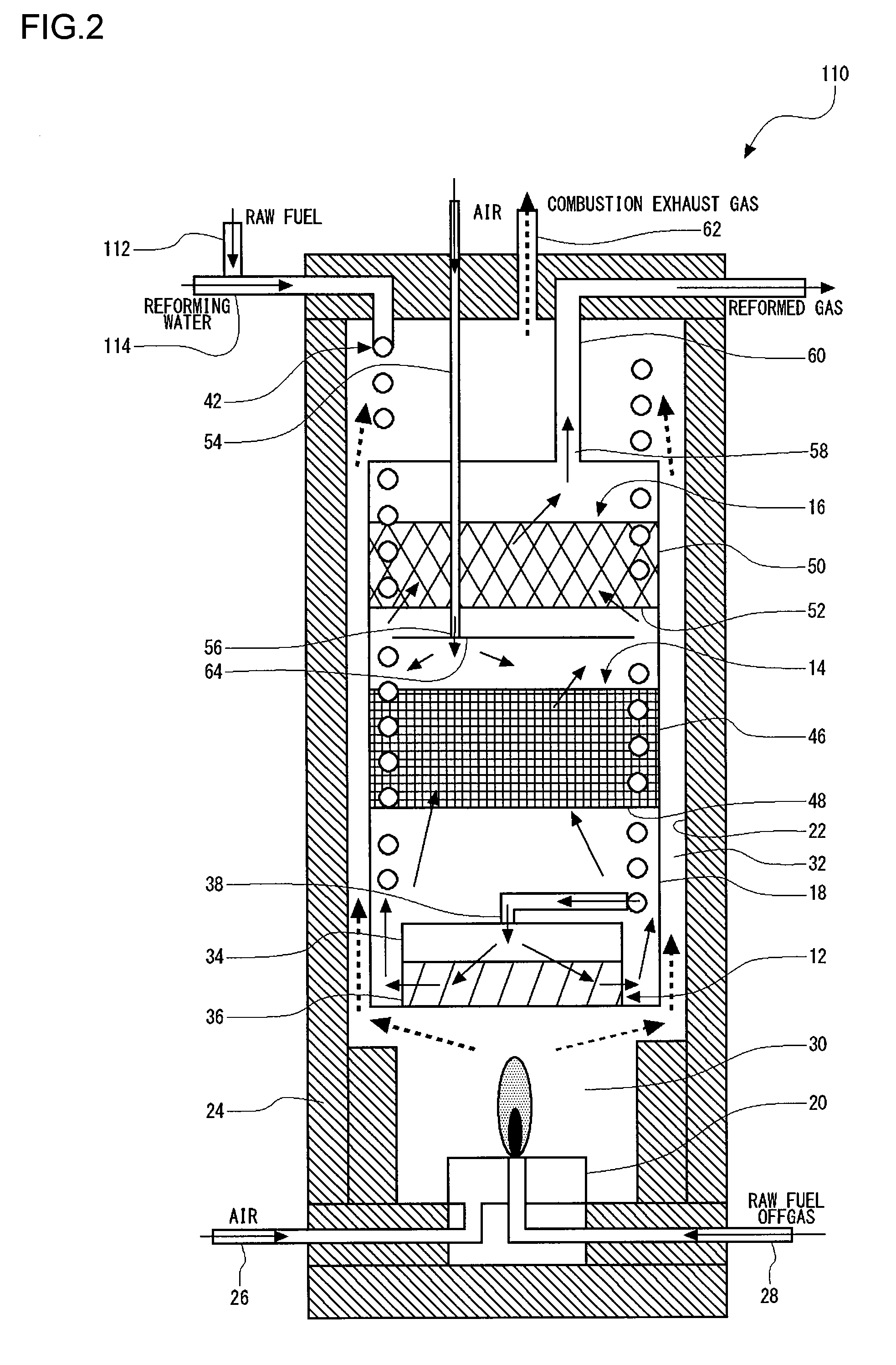

Reformer

ActiveUS20110165483A1Simple structureSmall sizeHydrogenGaseous chemical processesEngineeringWaste management

A reformer includes a reforming chamber having a raw fuel passage through which a raw fuel flows, the reforming chamber being filled with or carrying a reforming catalyst, a supply chamber disposed upstream of the reforming chamber, for uniformly supplying the raw fuel to the raw fuel passage, and a discharge chamber disposed downstream of the reforming chamber, for uniformly discharging the raw fuel from the raw fuel passage. The raw fuel passage has first and second reversers for reversing the direction in which the raw fuel flows. The raw fuel passage has a cross-sectional area which is smaller in a downstream portion thereof than in an upstream portion thereof.

Owner:HONDA MOTOR CO LTD

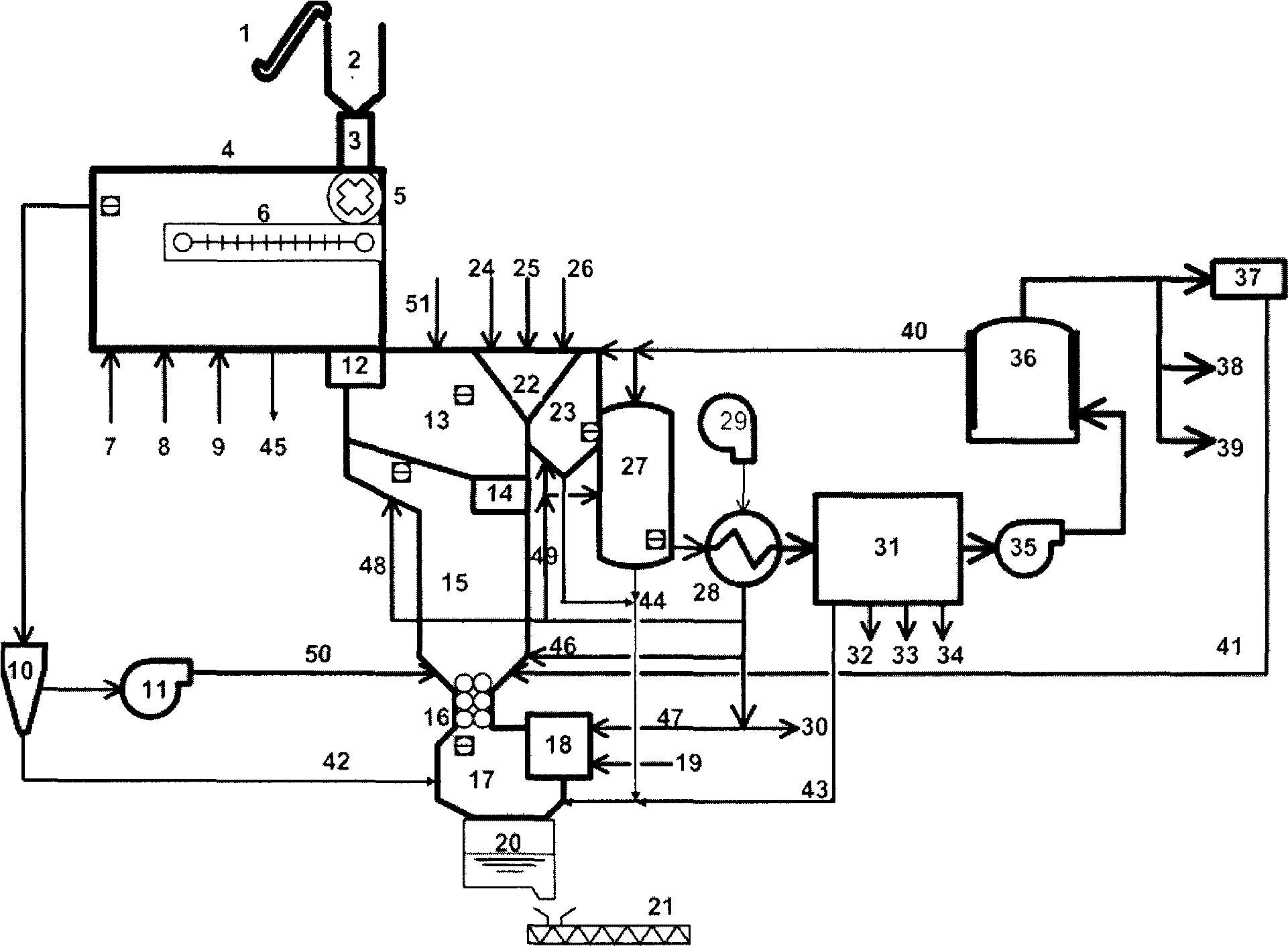

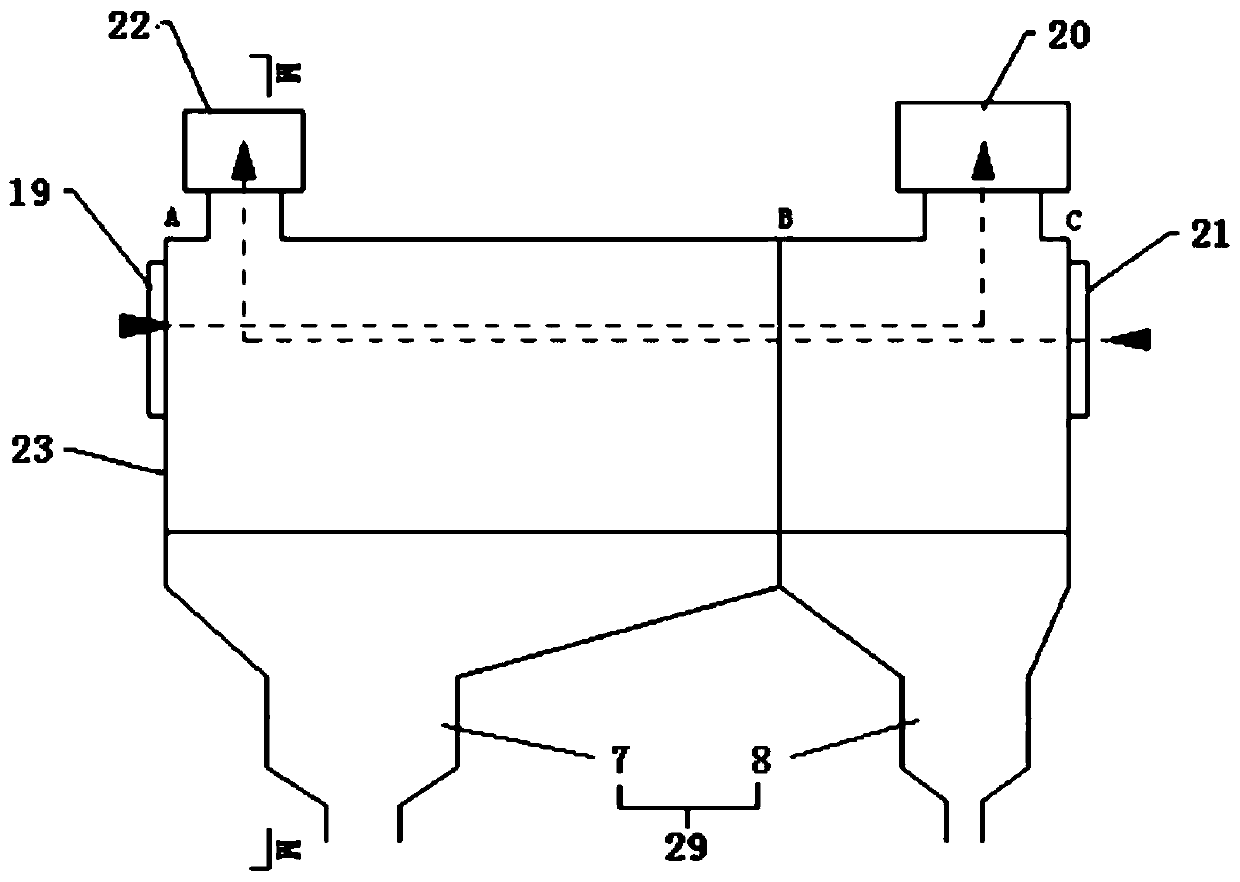

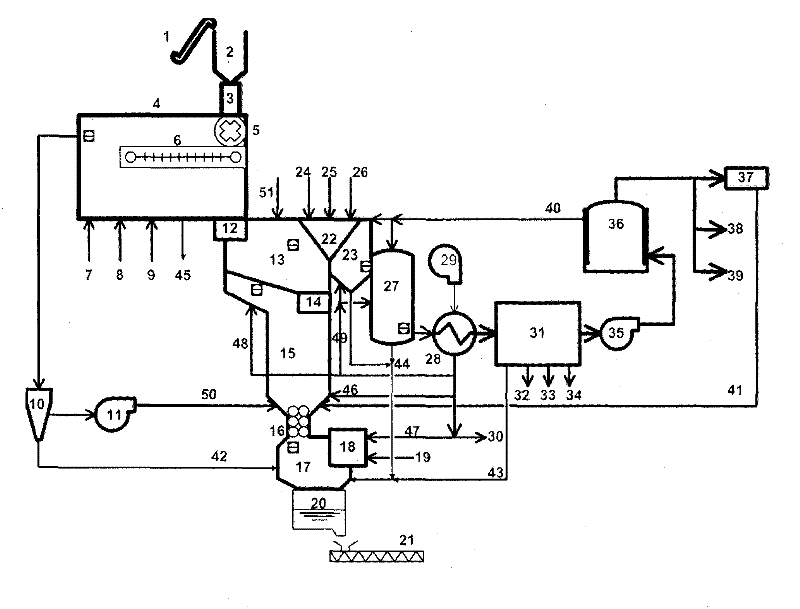

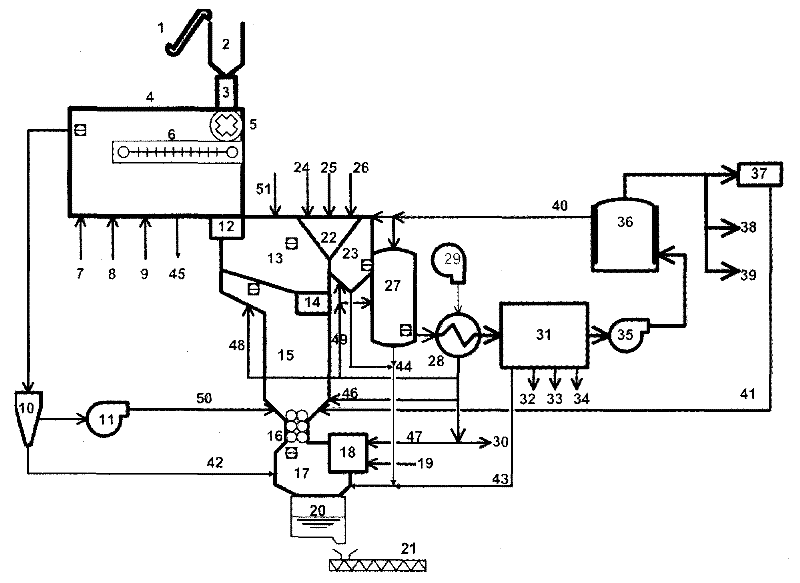

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604AImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas is in contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

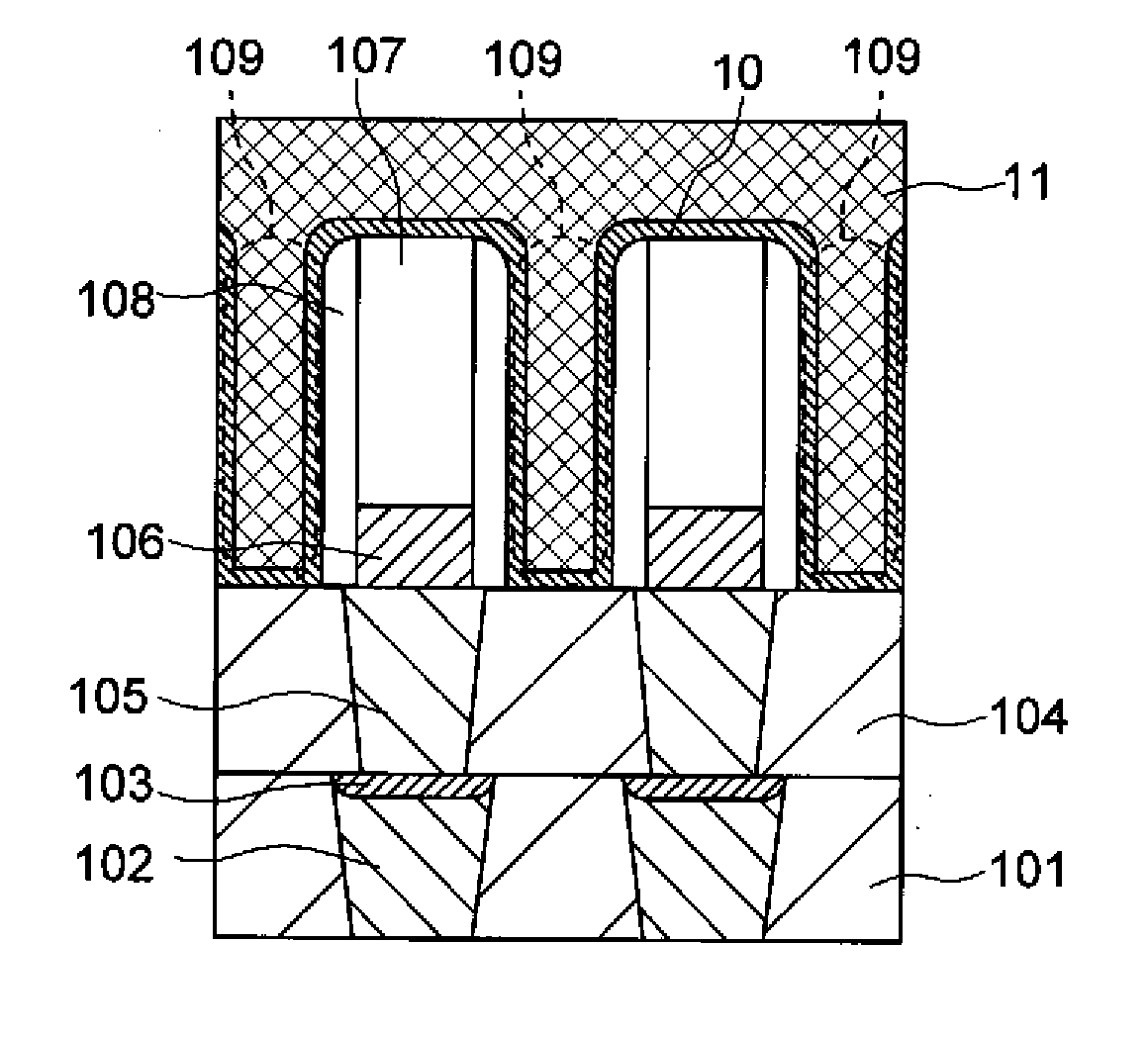

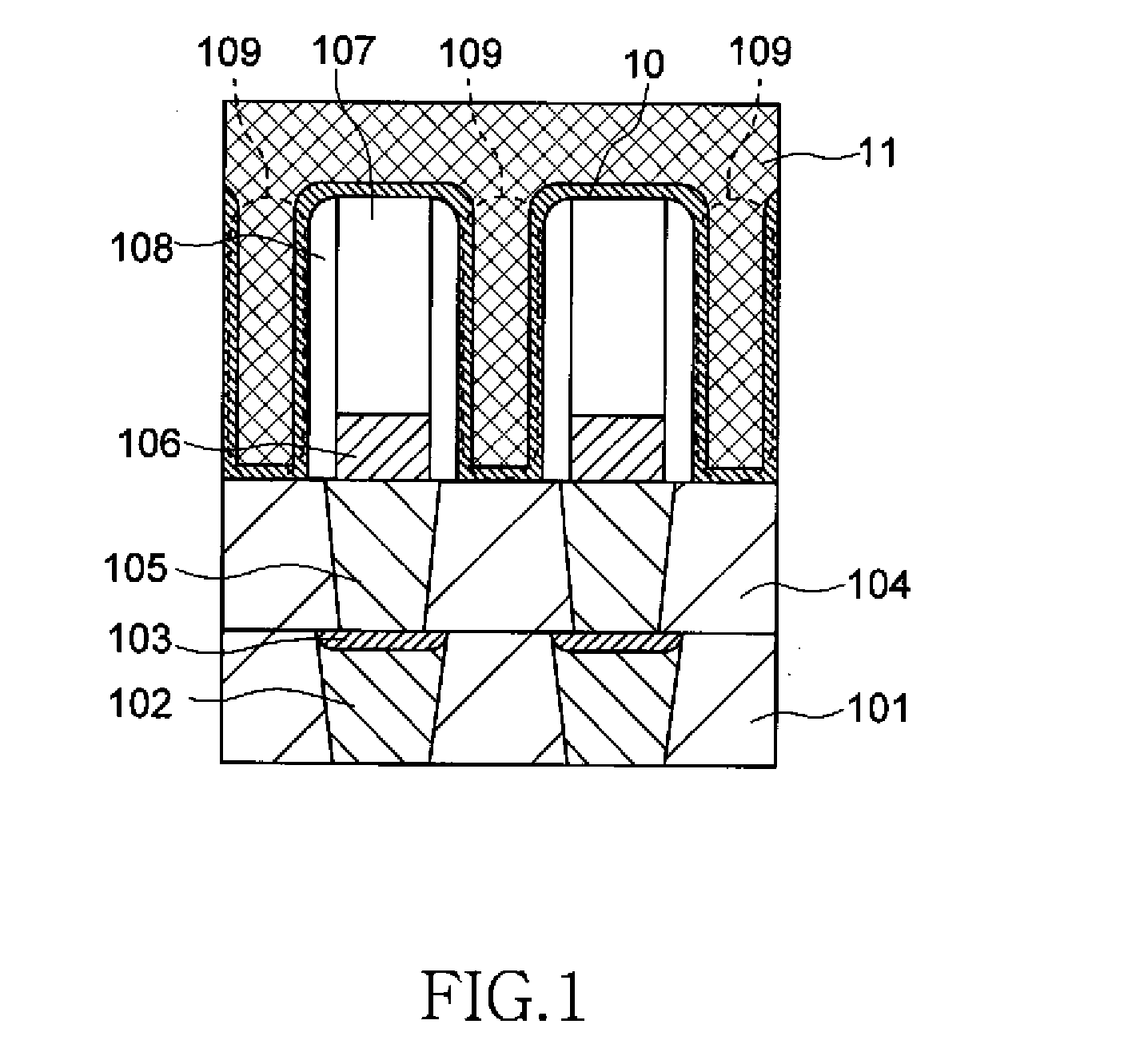

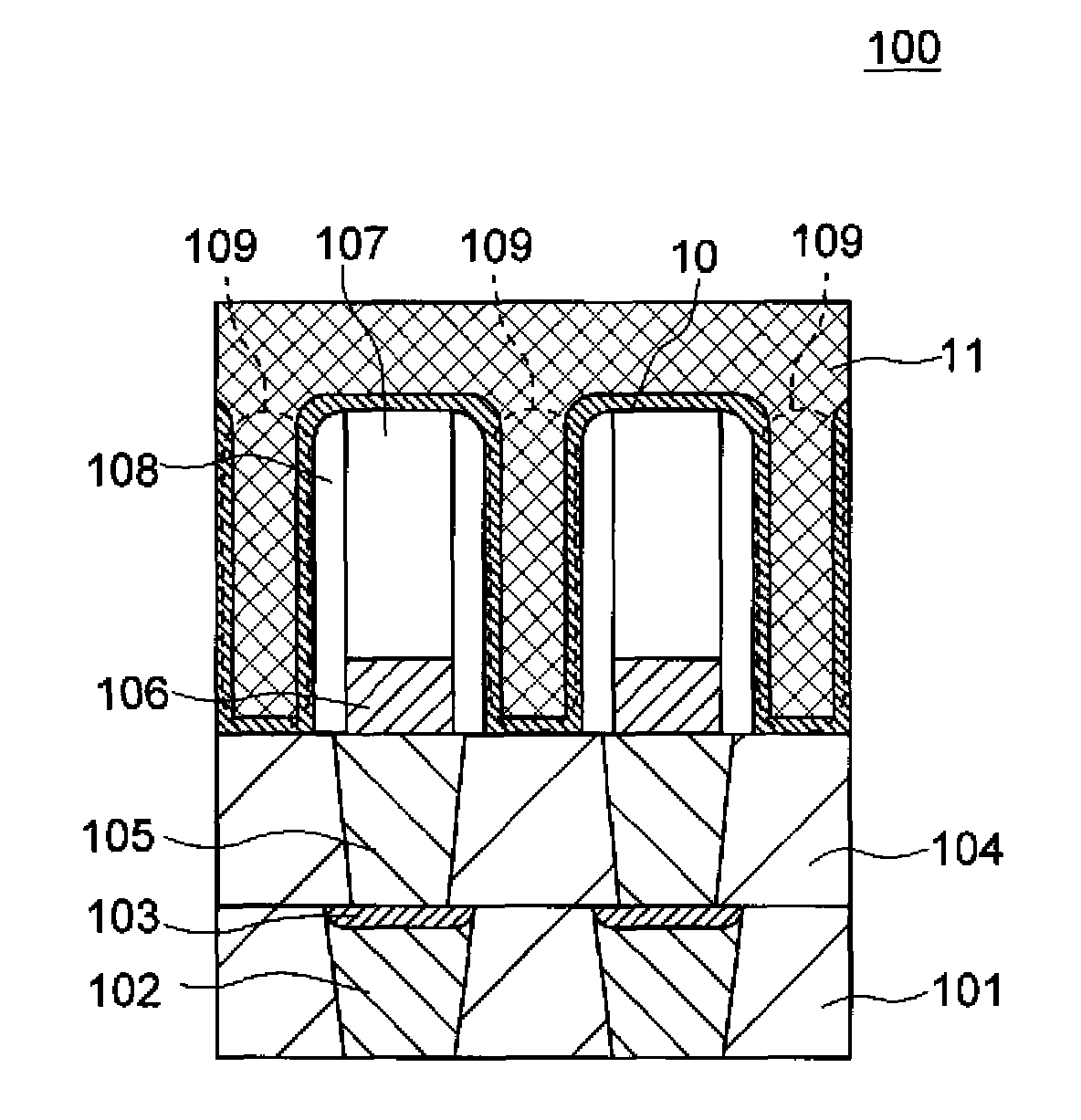

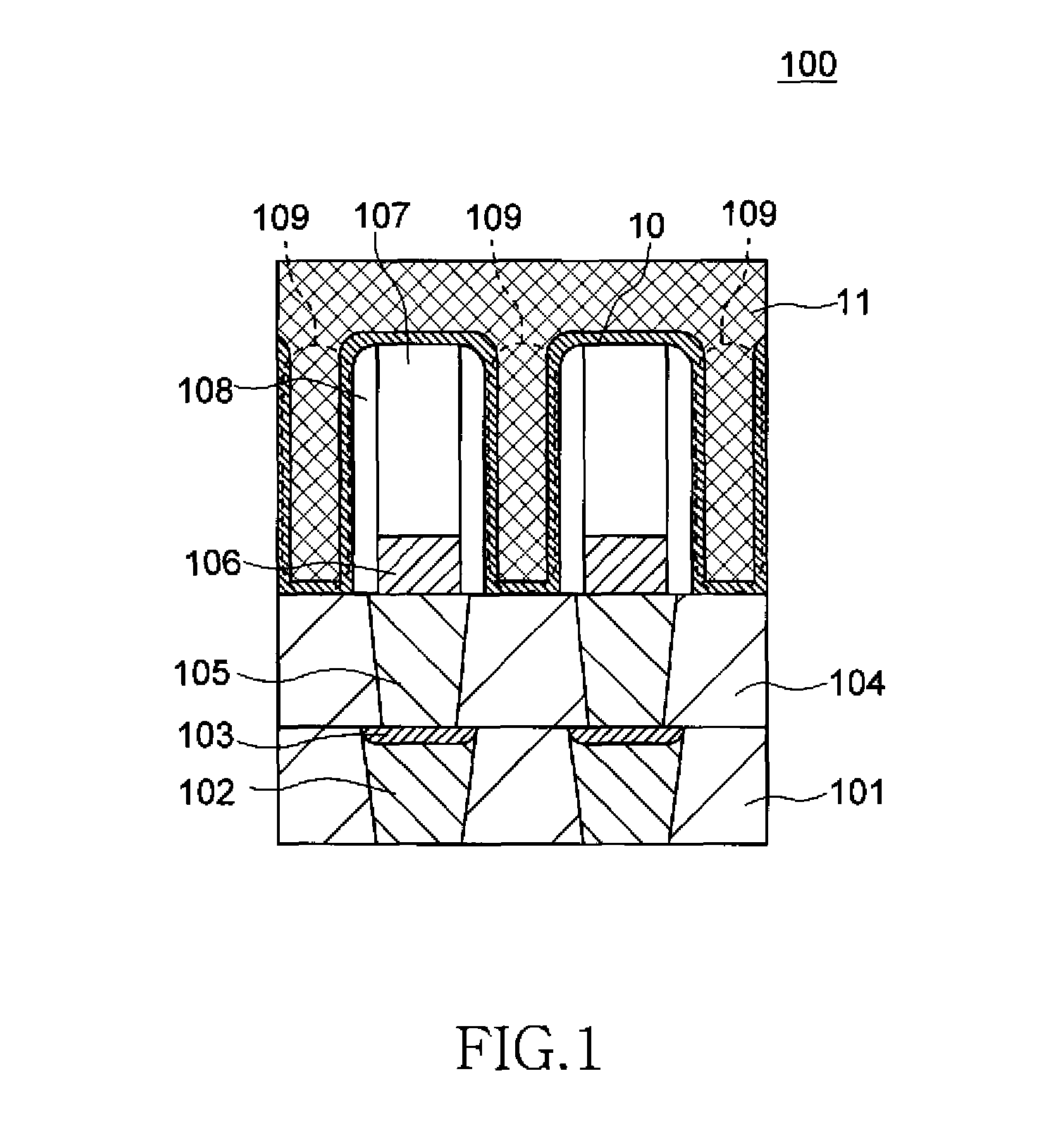

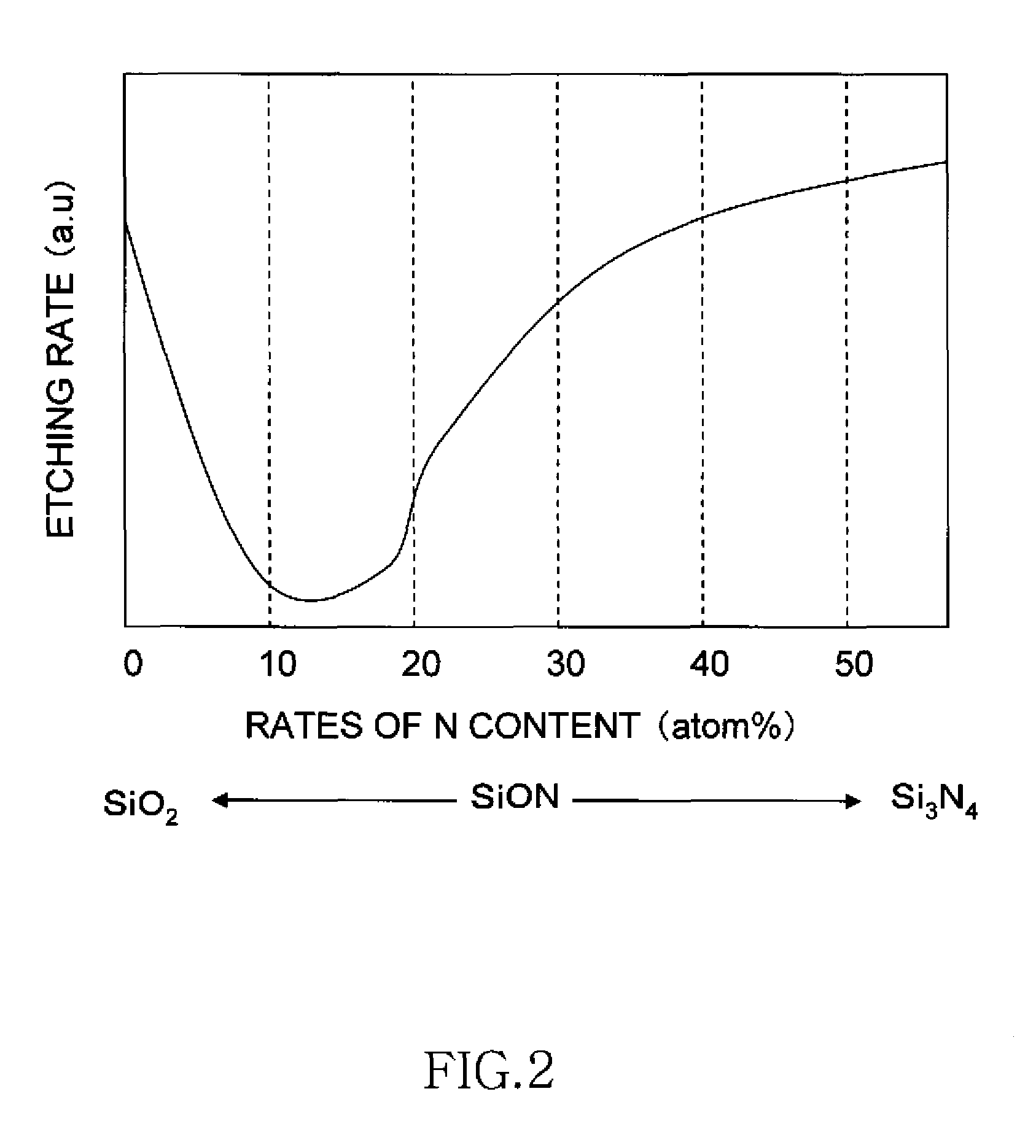

Semiconductor device and manufacturing method thereof

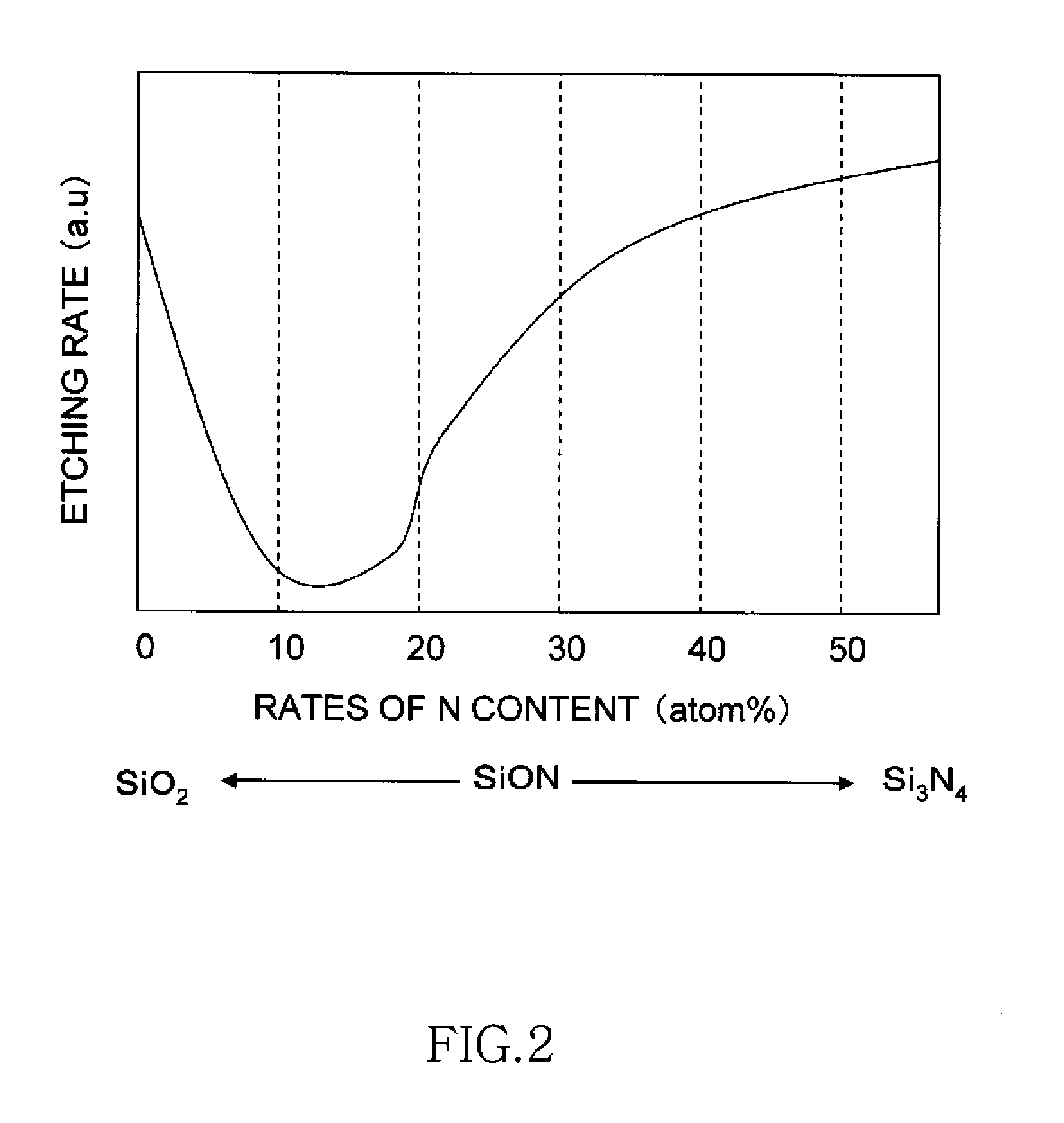

InactiveUS20100148301A1Inhibited DiffusionHigh reforming efficiencySolid-state devicesSemiconductor/solid-state device manufacturingBit lineNitrogen

A semiconductor device includes groove-like regions that are formed between two adjacent bit lines among a plurality of bit lines each having upper and side surfaces covered with a cap insulating film and a side-wall insulating film, respectively, a SiON film that contains more O (oxygen) than N (nitrogen) and continuously covers inner surfaces of the groove-like regions, and a silicon dioxide film formed by reforming polysilazane and filled in the groove-like regions with the SiON film interposed therebetween.

Owner:PS4 LUXCO SARL

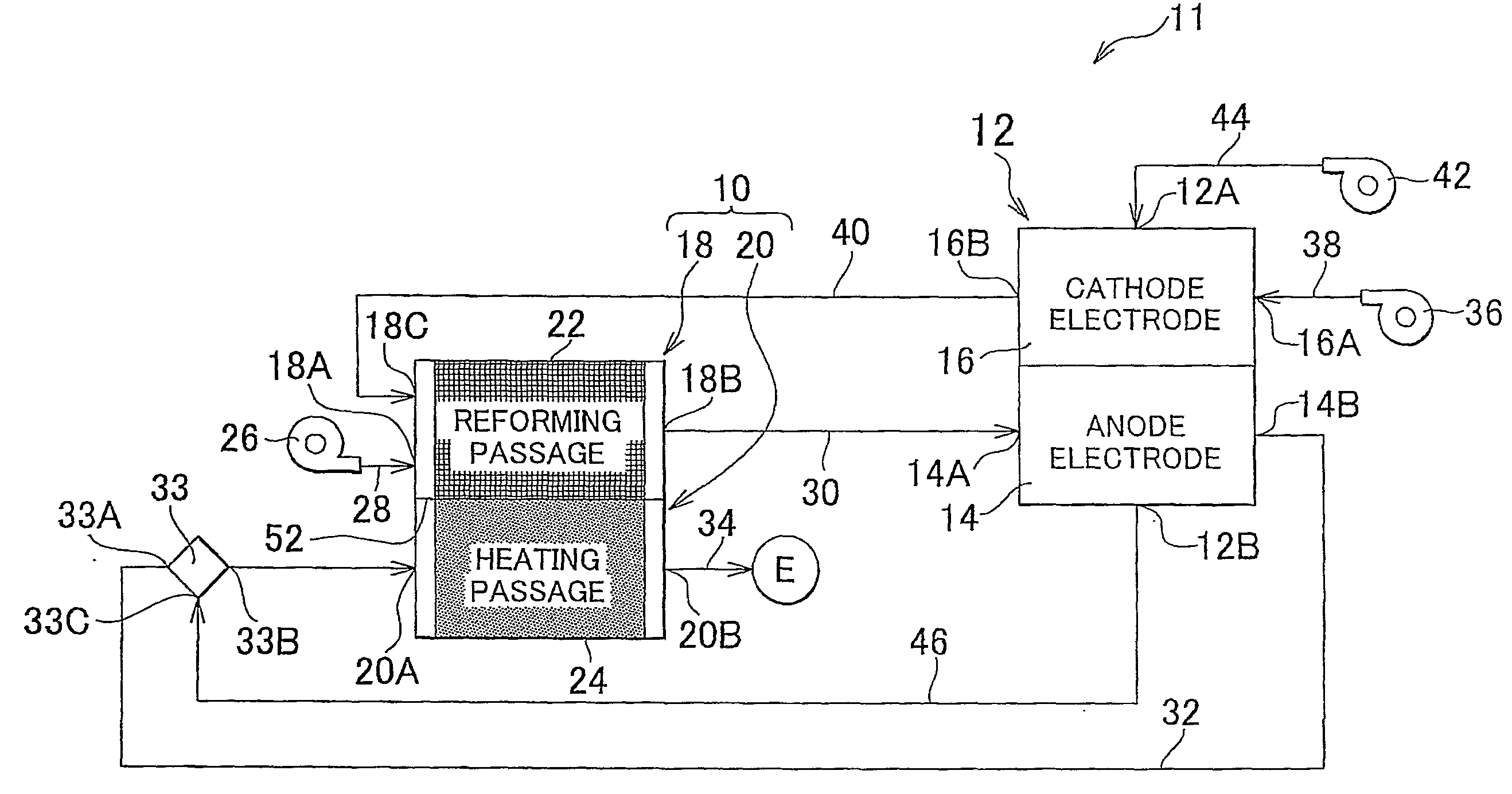

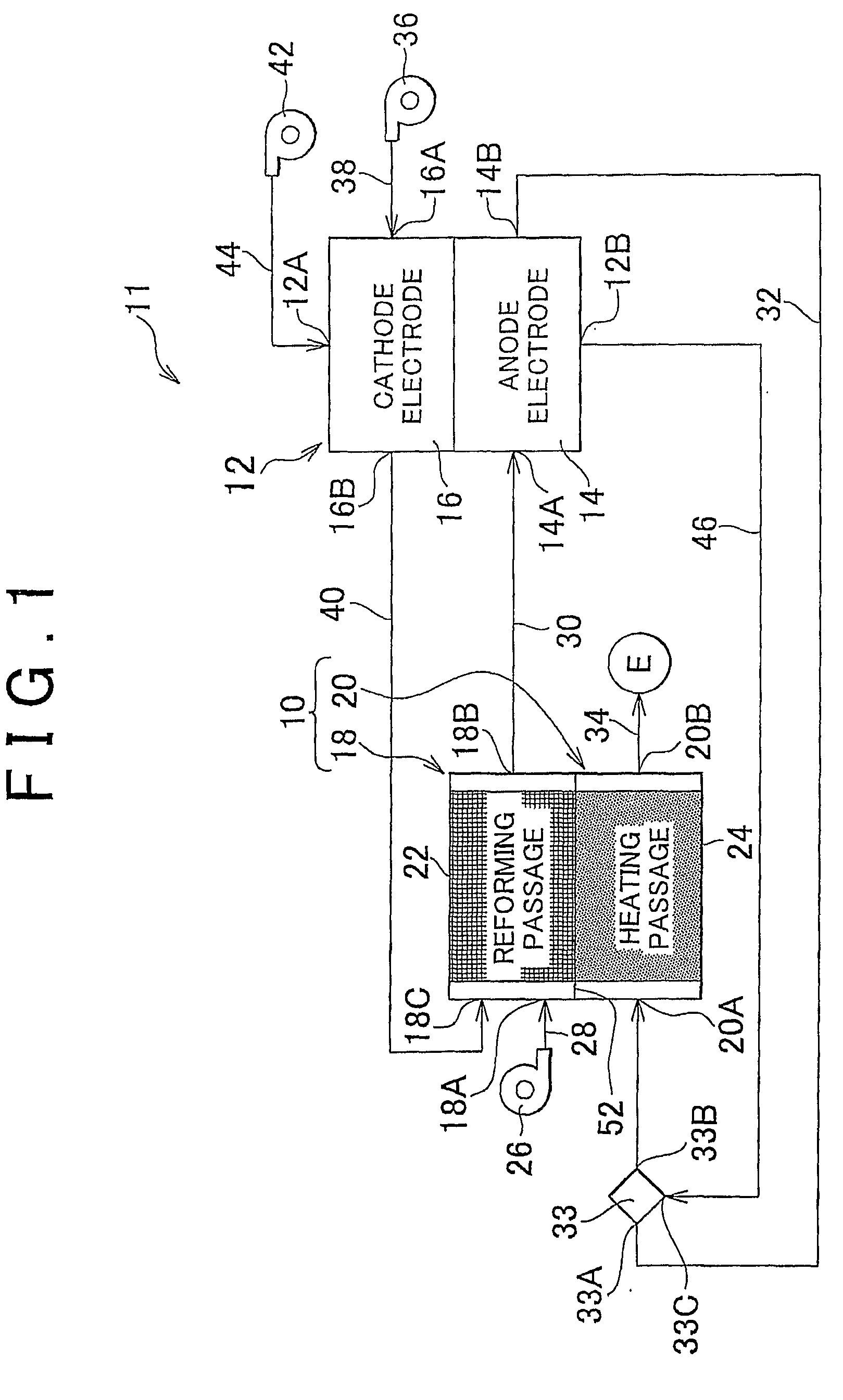

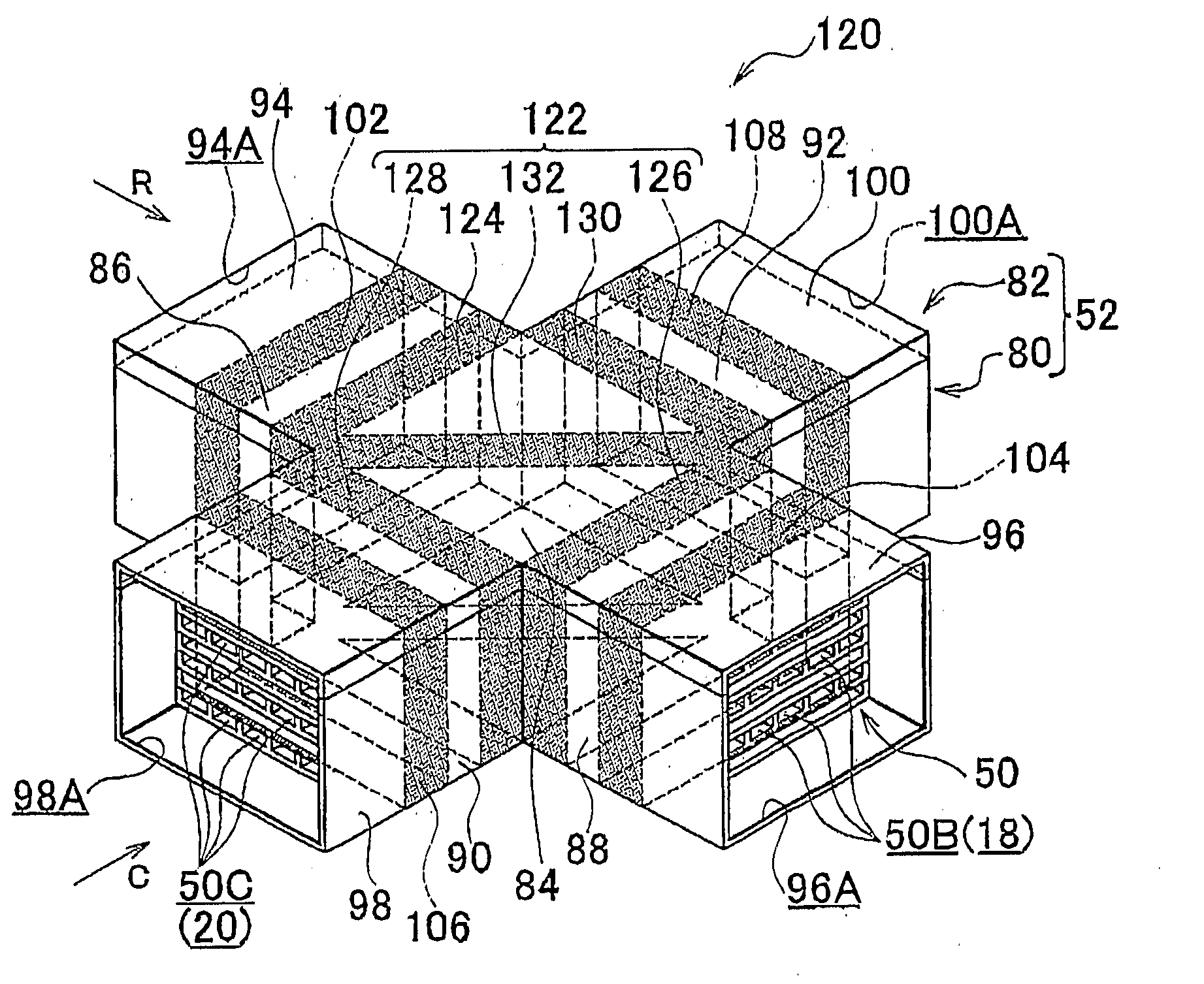

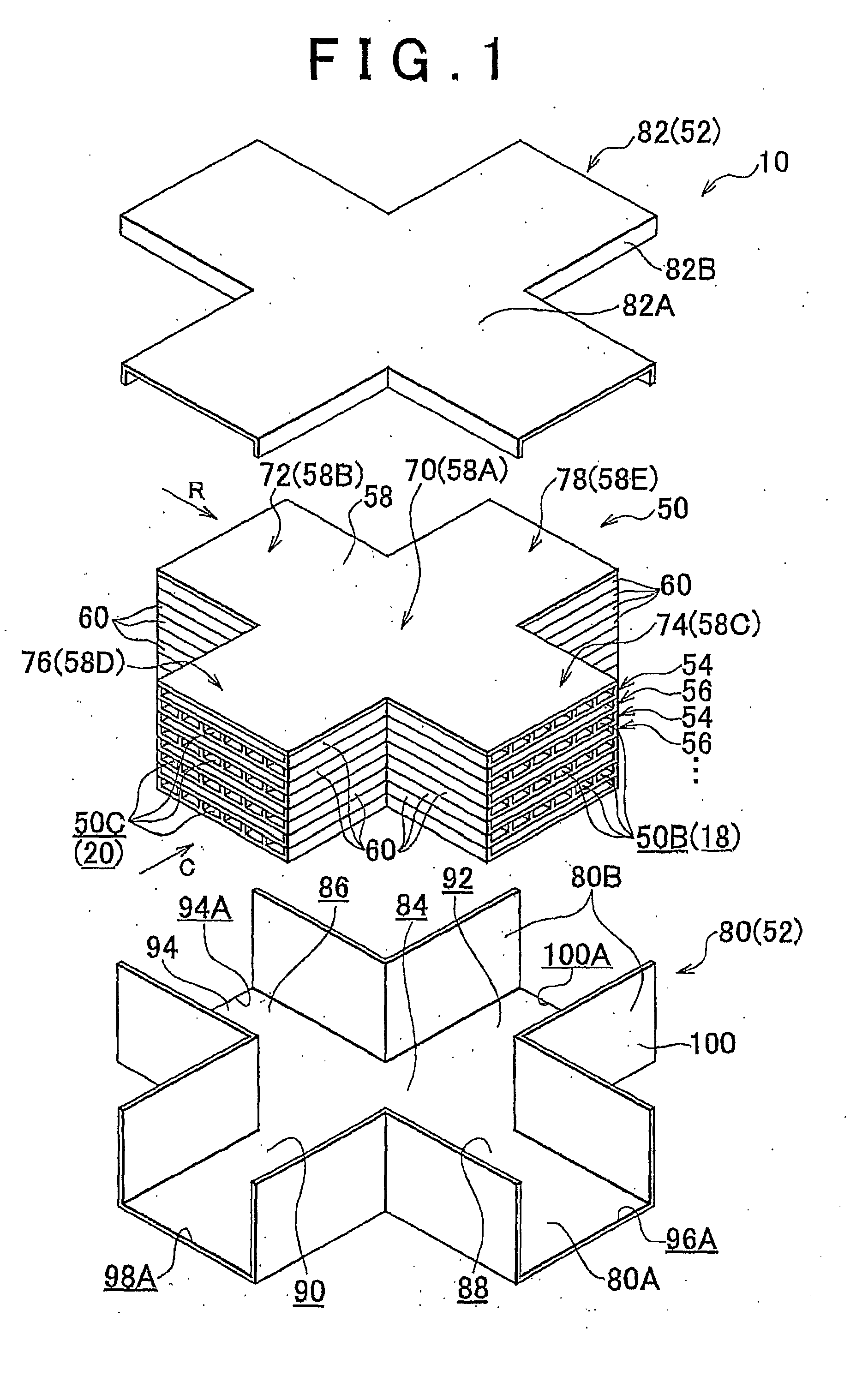

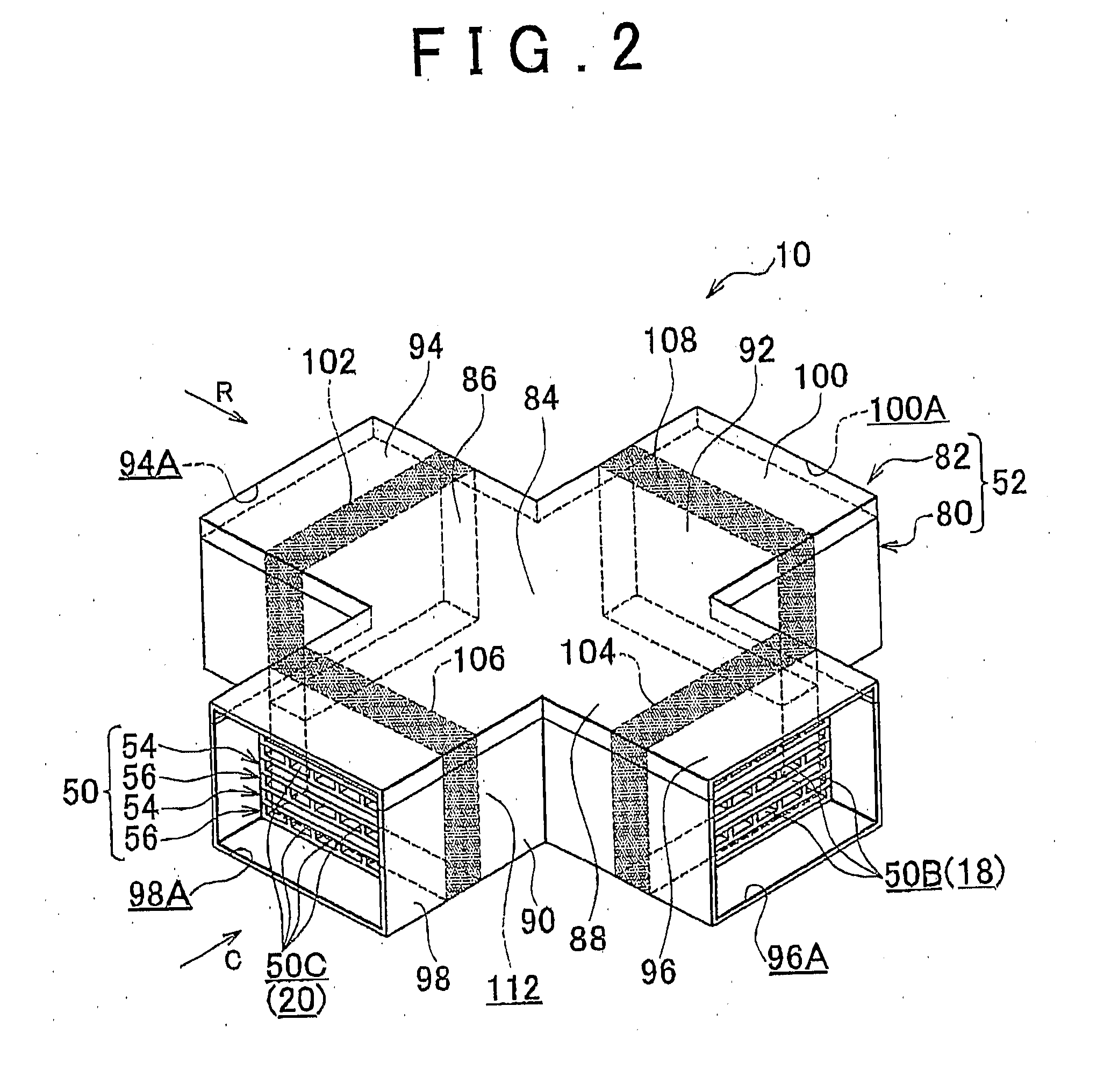

Heat exchange reformer unit and reformer system

InactiveUS20090064579A1High reforming efficiencyEfficient heatingHydrogenChemical industryHydrogenProcess engineering

In a heat exchange reformer unit, a reforming passage supporting reform catalyst for inducing reforming reactions and a combustion passage supporting oxidizing catalyst for combustion are disposed adjacent to each other with a plate portion interposed therebetween. Heat-exchanging passages of the reforming passage that produce reformate gas that contains hydrogen from supplied reformation material, and heat-exchanging passages of the combustion passage that supply heat, which is generated by catalytically burning supplied fuel, to the reforming passage constitute a parallel-flow heat exchanger. Reformation material guide passages for introducing reformation material into the heat-exchanging passages in a predetermined direction, and mixed gas guide passages for introducing fuel into the heat-exchanging passages in a direction intersecting the gas flow direction in the reformation material guide passages, are provided upstream of the heat-exchanging passages in a gas flow direction.

Owner:TOYOTA JIDOSHA KK

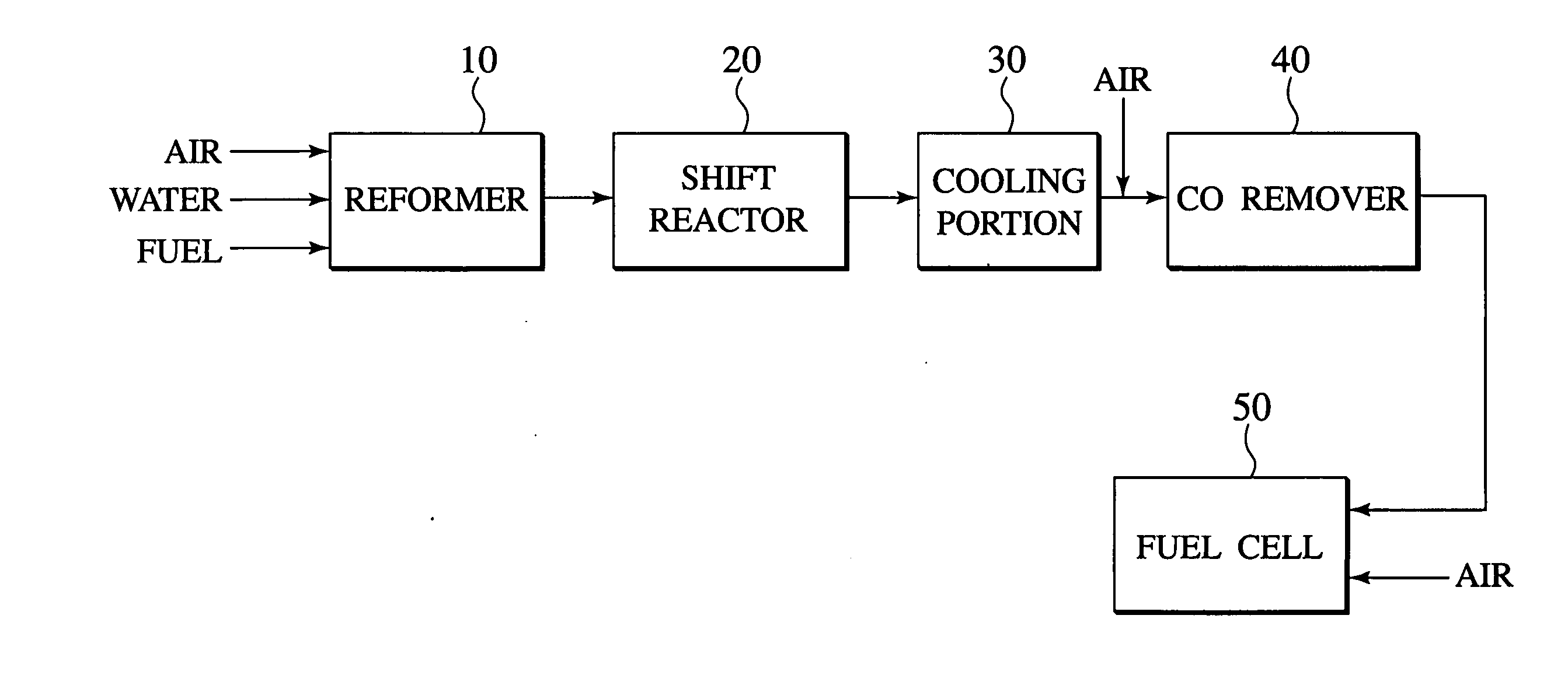

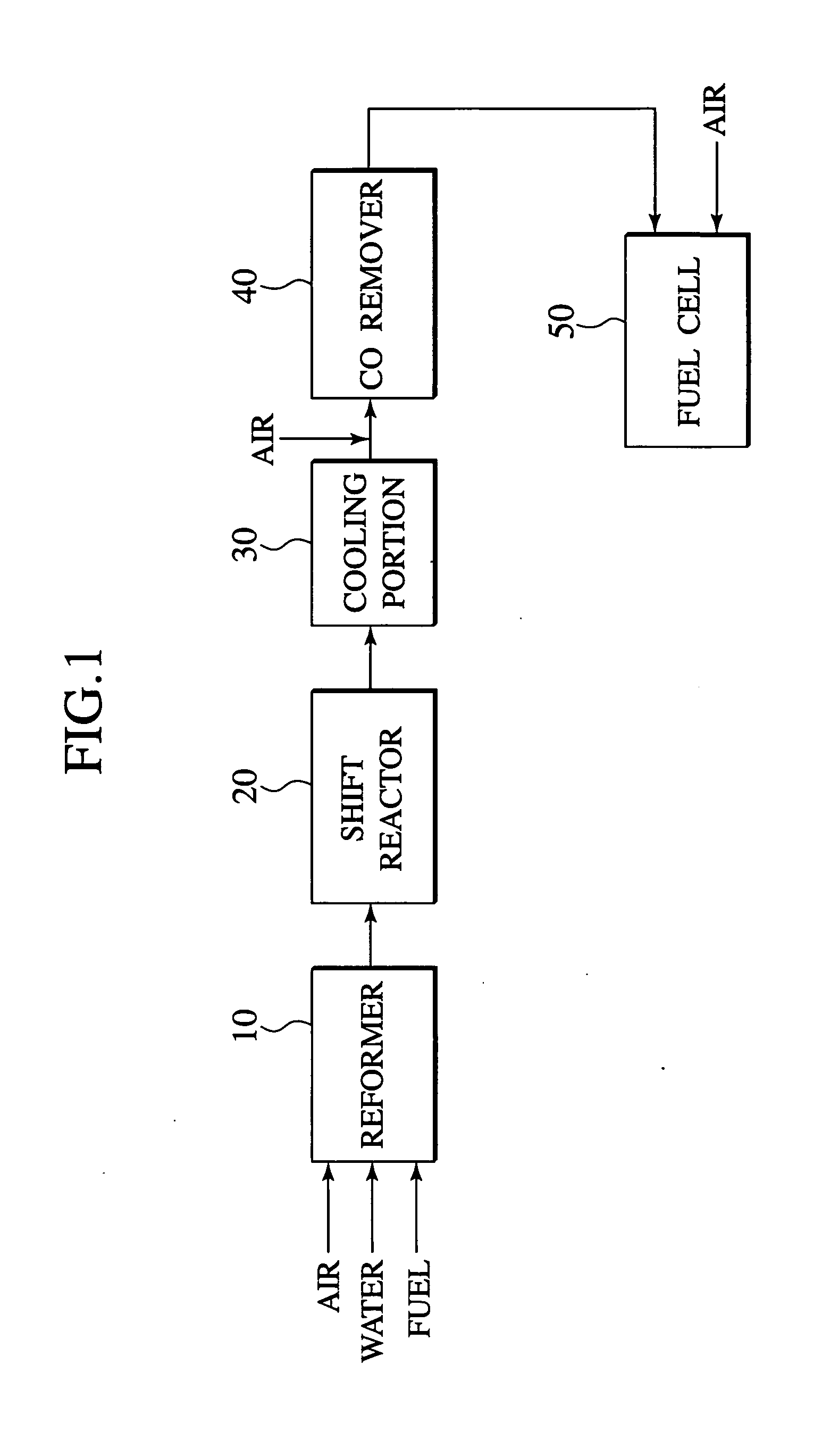

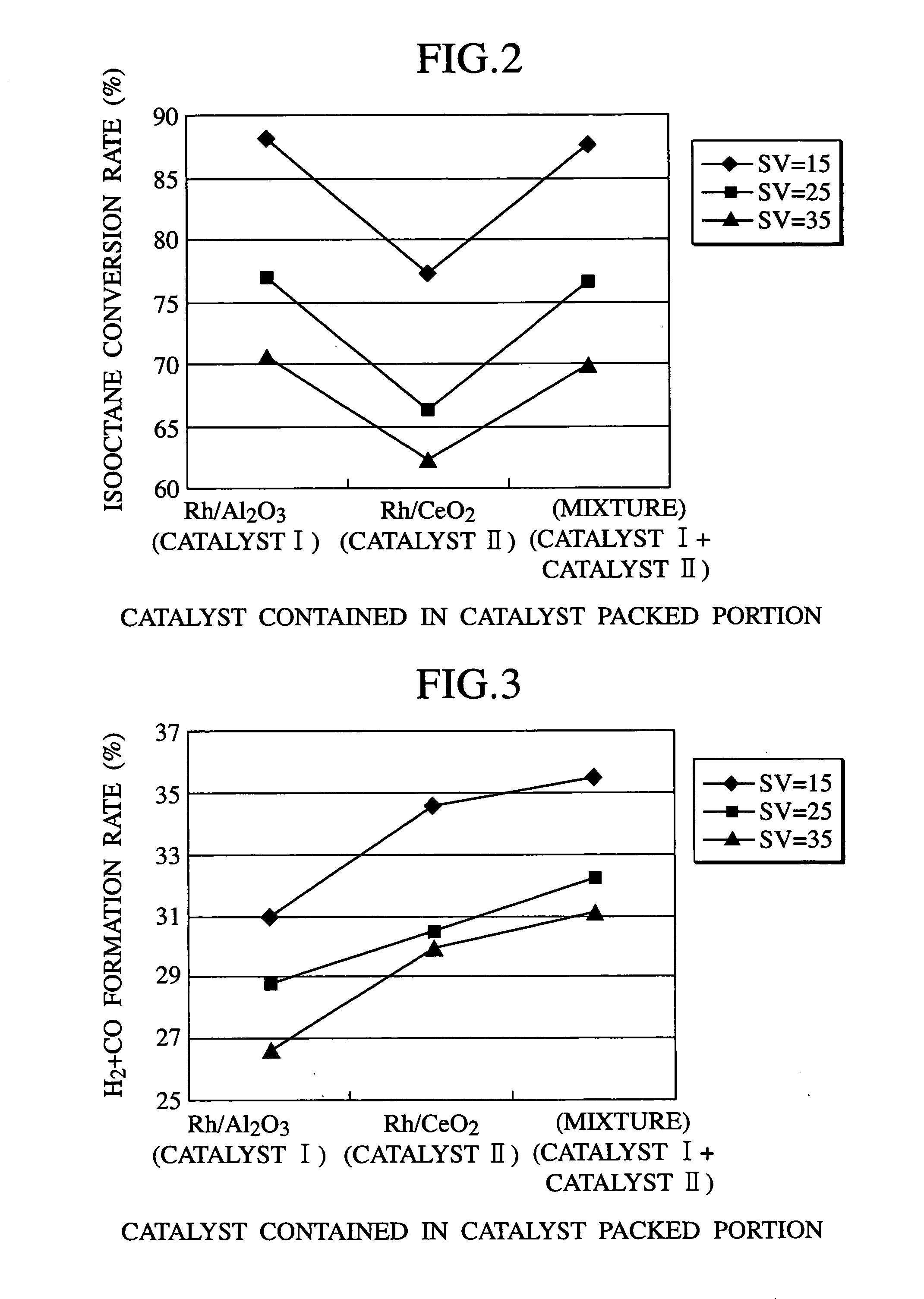

Fuel Reforming Apparatus And Fuel Cell System

InactiveUS20110223502A1Improving starting-up propertyImprove robustnessHydrogenFuel cell applicationsFuel cellsHydrogen

A fuel reforming apparatus includes a catalyst packed portion containing therein fuel reforming catalyst (I) having excellent hydrocarbon conversion rate and fuel reforming catalyst (II) having excellent H2+CO formation rate. Each of catalyst (I) and catalyst (II) especially preferably includes rhodium supported thereon. When the carrier for catalyst (I) is aluminum oxide and the carrier for catalyst (II) is cerium oxide, the hydrogen generation efficiency is excellent particularly even at start-up.

Owner:NISSAN MOTOR CO LTD

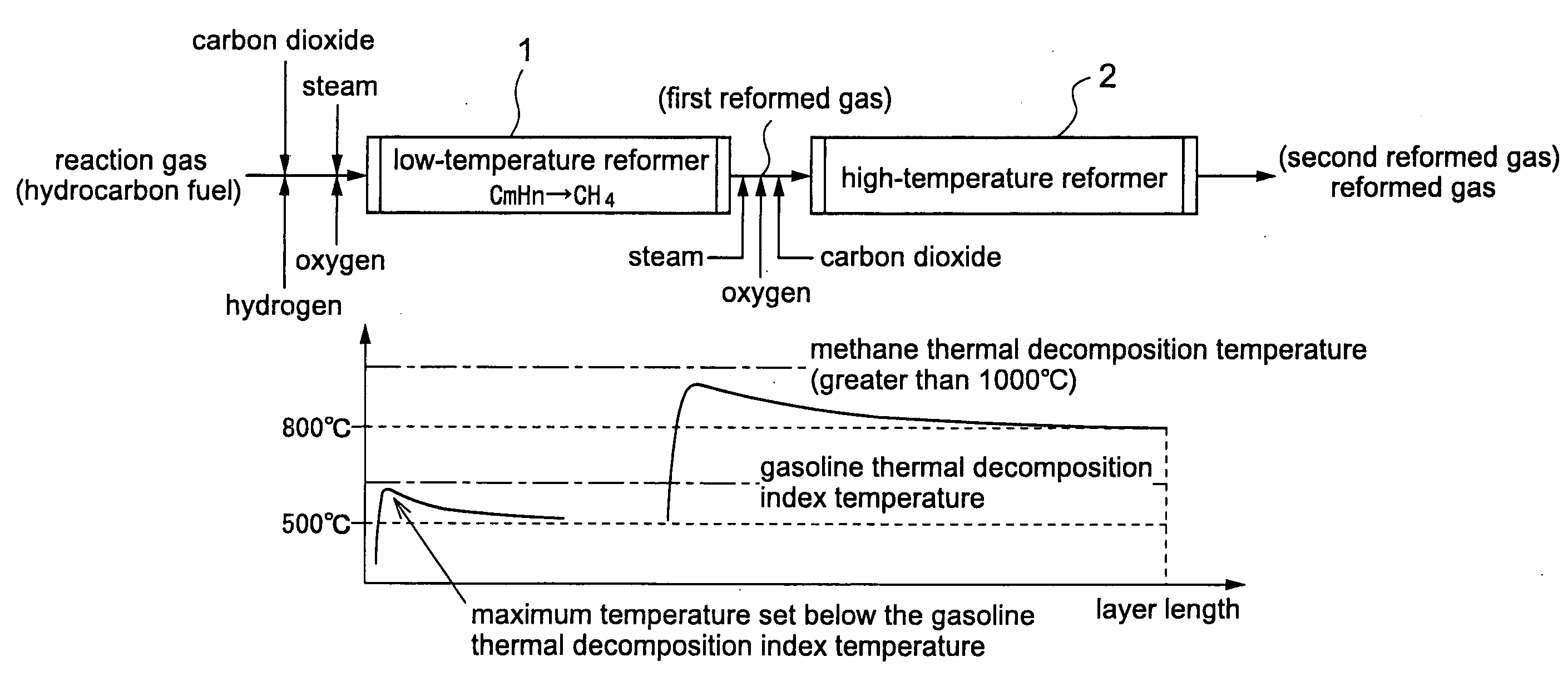

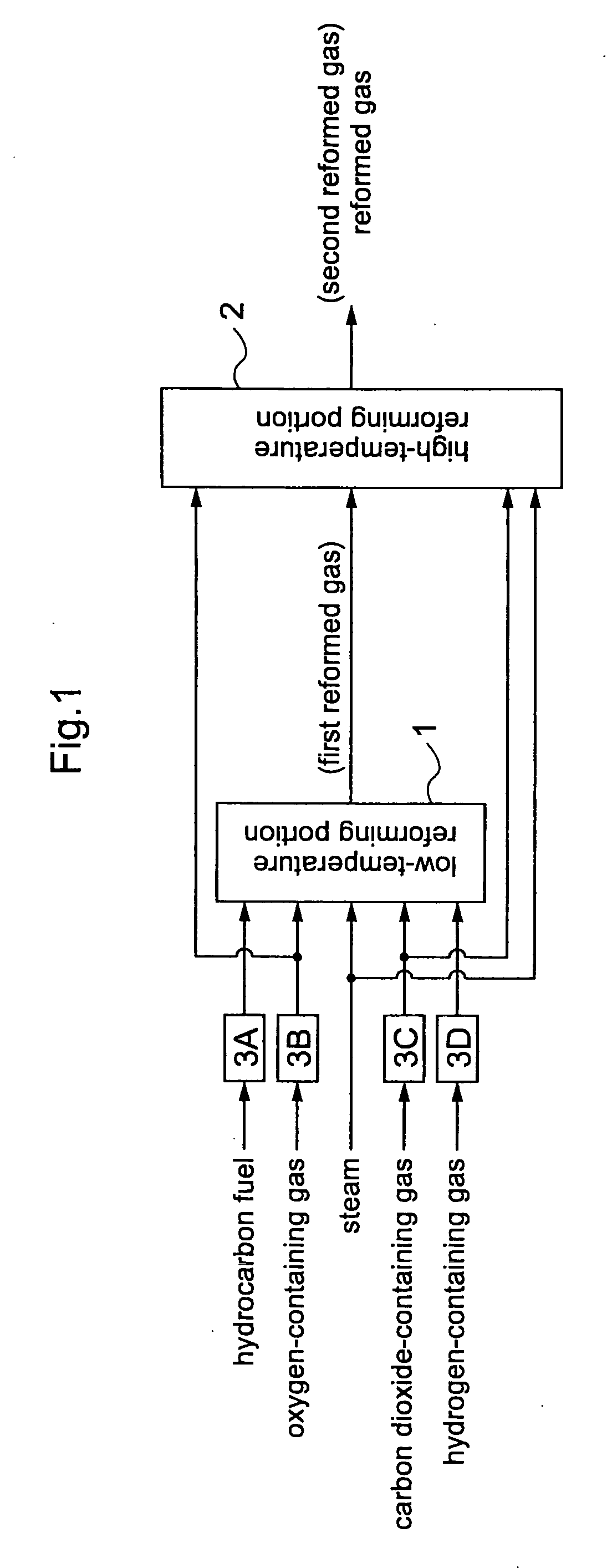

Reformed Gas Production Method and Reformed Gas Production Apparatus

InactiveUS20080263953A1Increase ratingsSuitable for useHydrogenFinal product manufactureHydrogenProduct gas

The invention provides a method for operating a reformed gas production apparatus with which it is possible to achieve a high reforming efficiency while preventing a drop in catalyst activity due to the deposition of carbon. The reformed gas production method uses a reforming catalyst to reform a fuel that contains a hydrocarbon having at least two carbon atoms to produce a reformed gas that includes methane, hydrogen, and carbon monoxide. With this method, a fluid that includes the fuel, at least one of steam and a carbon dioxide-containing gas, and an oxygen-containing gas, is supplied to a reforming reaction region, and with the thermal decomposition index temperature of the fuel, which is determined by the type and the concentration of the hydrocarbons having at least two carbon atoms that make up the fuel, serving as an upper limit temperature of the reforming reaction region, the fluid is brought into contact with the reforming catalyst to produce the reformed gas.

Owner:OSAKA GAS CO LTD

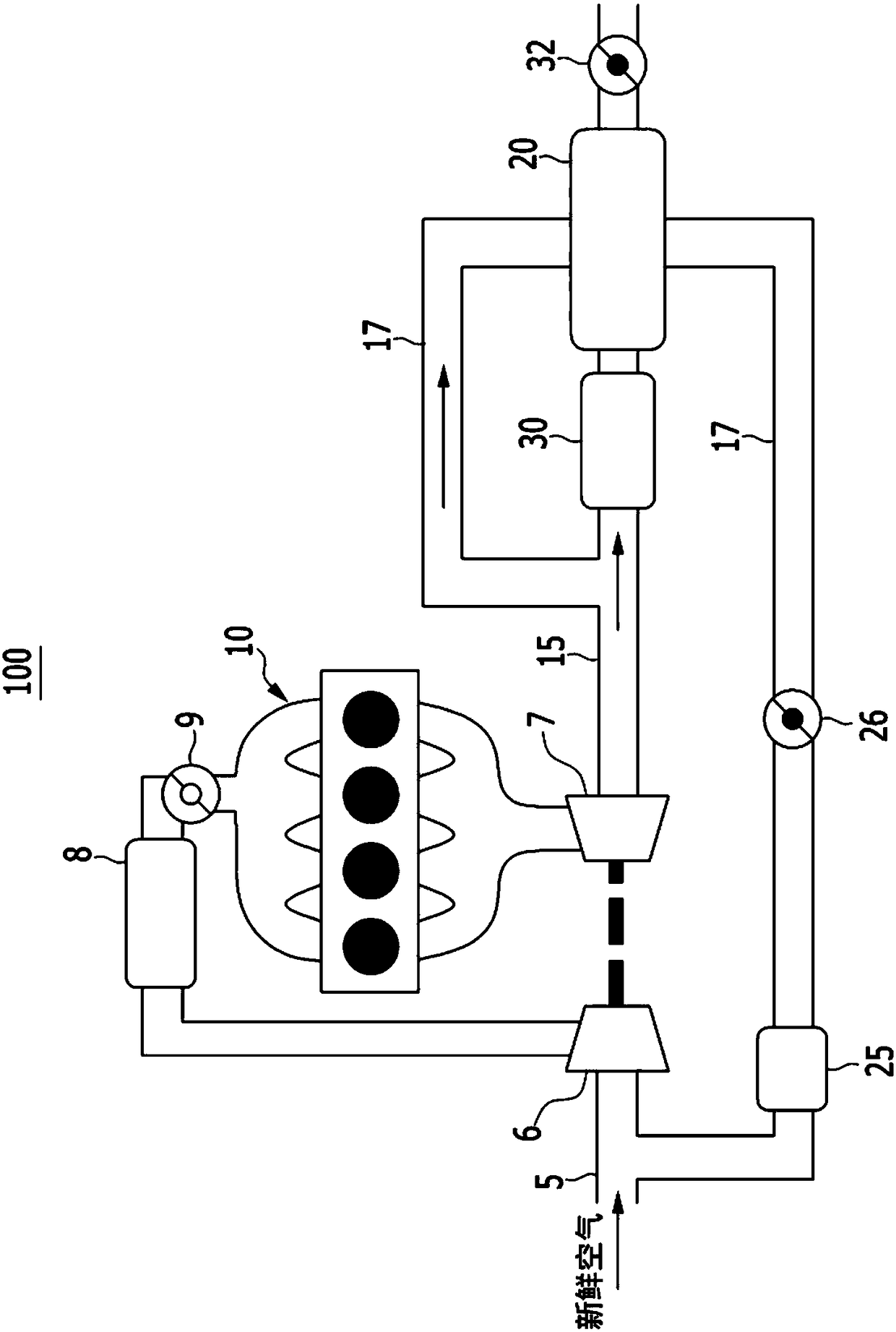

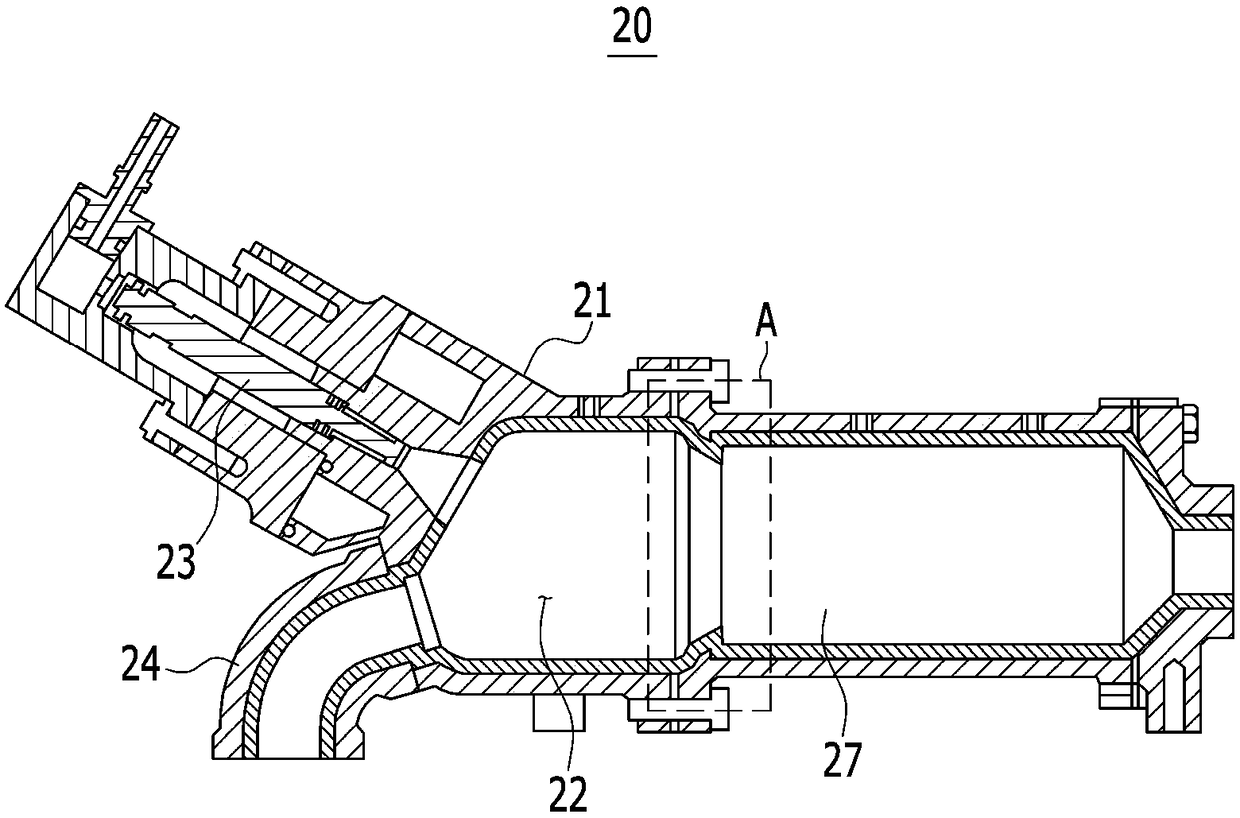

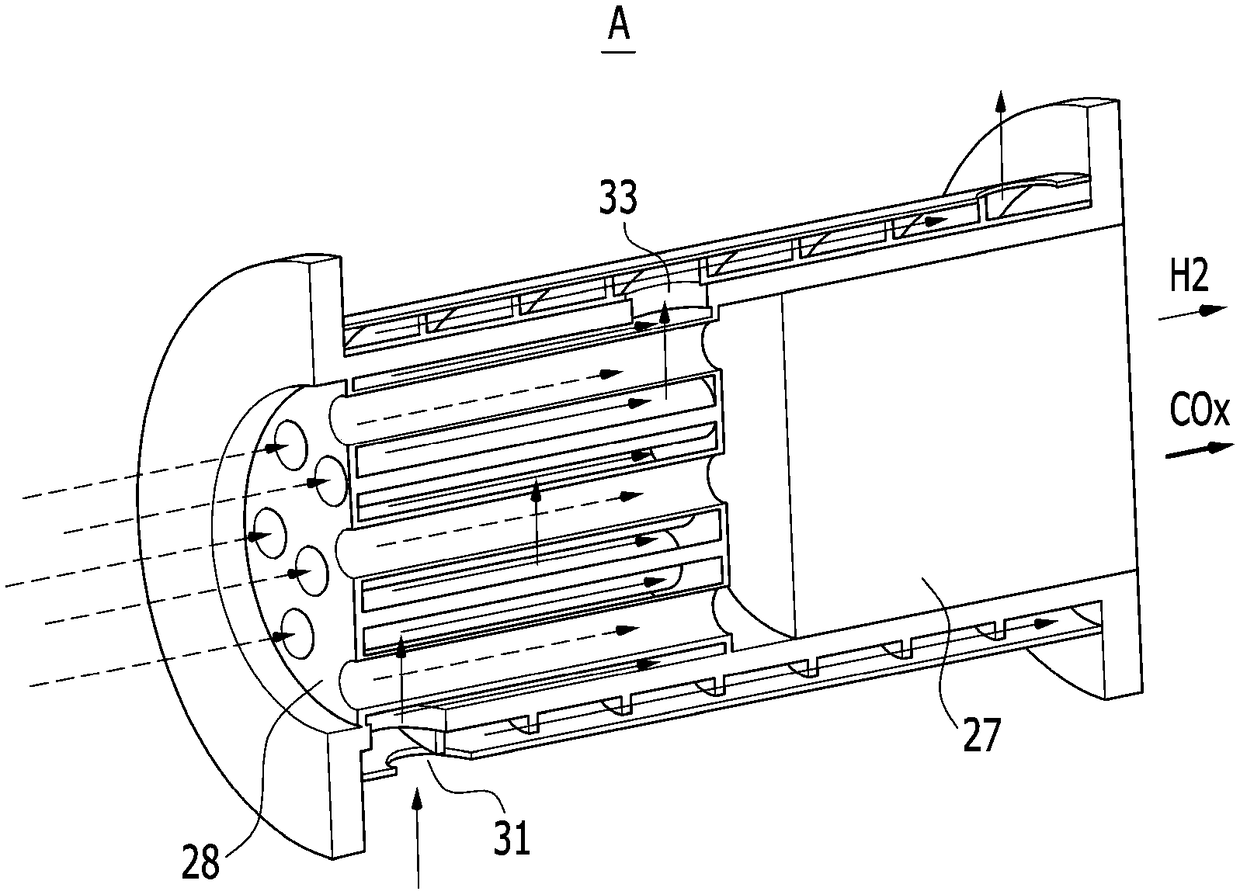

Waste gas-fuel reforming and recycling natural gas engine system and control method

ActiveCN107061053ARealize online preparationAvoid offeringInternal combustion piston enginesFuel supply apparatusWater vaporIntercooler

The invention discloses a waste gas-fuel reforming and recycling natural gas engine system and a control method. The waste gas-fuel reforming and recycling natural gas engine system comprises an engine, a fuel supply device, a gas tank used for supplying to the fuel supply device, a reformer and an intercooler. Engine fuel is directly subjected to a multiple reforming reaction with O2 and water vapor, so that reformed gas which is rich in H2 and CO is generated, and H2 production efficiency is high; online production of hydrogen is achieved, an extra fuel storage device or an extra hydrogen storage tank does not need to be provided, the safety is improved, and the size of the whole system is reduced; two pass tubes are adopted, so that the heat transfer coefficient is increased, and the reforming efficiency is improved accordingly; the reformed gas contains a large quantity of H2, the in-cylinder combustion speed is increased, and the lean burning extreme is widened; the oxygen concentration in a gas inlet pipe can be decreased through circulating waste gas, the specific heat capacity of working media is improved, and the in-cylinder combustion temperature is decreased; and by combining the reformed gas with the circulating waste gas, stable low-temperature lean burning of the natural gas engine can be achieved, and meanwhile, the HC concentration, the CO concentration and the NOx concentration can be decreased.

Owner:WUHAN UNIV OF TECH

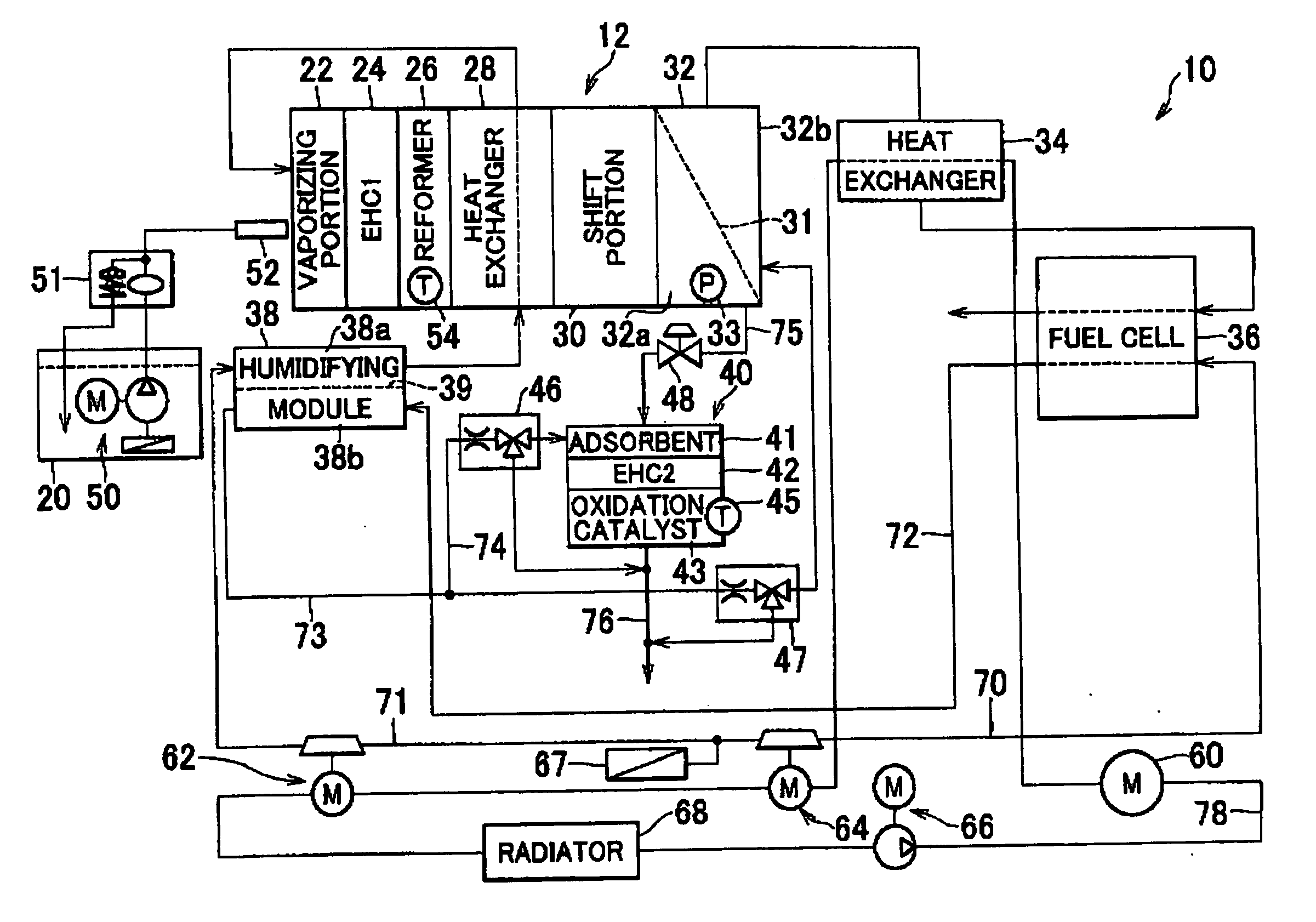

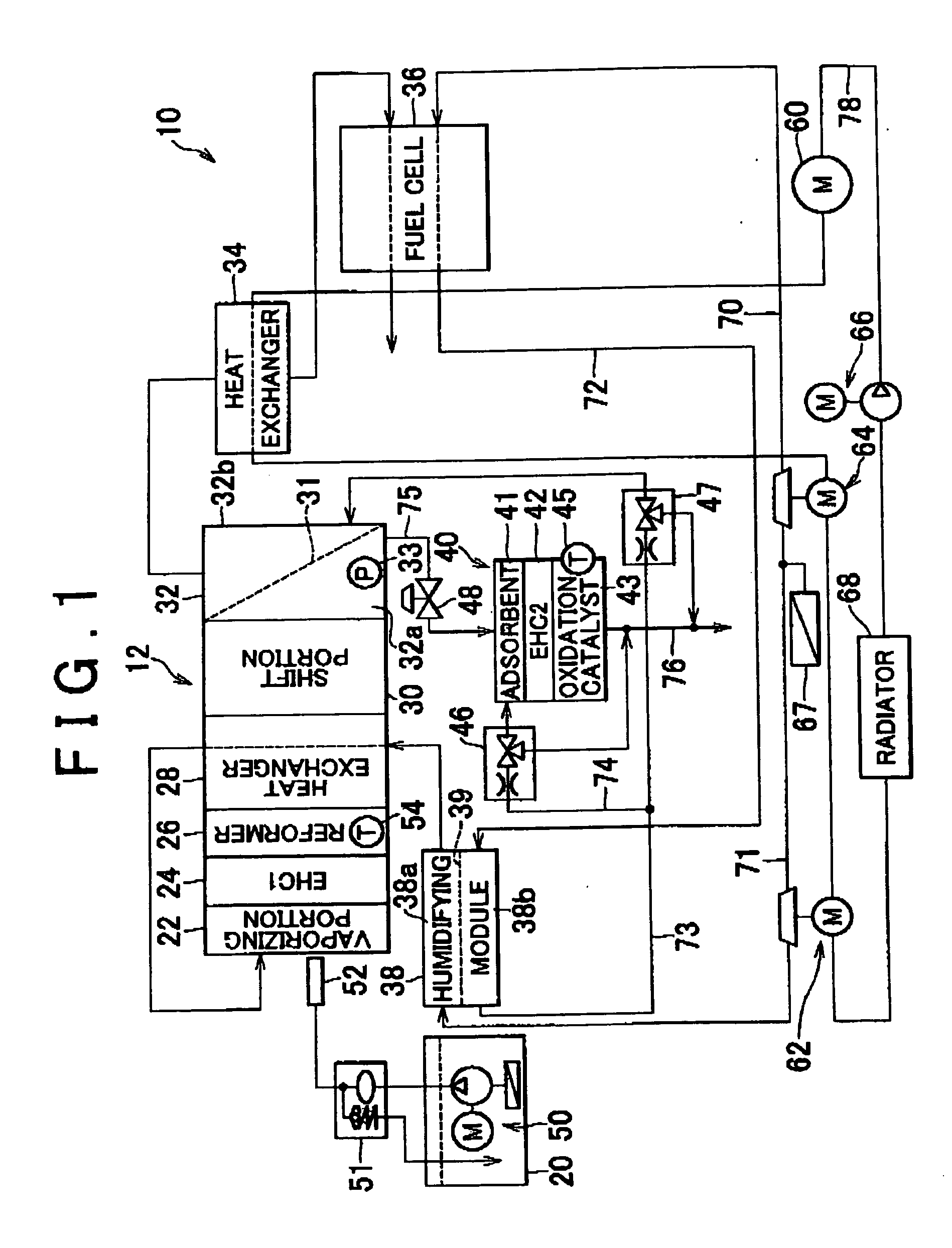

Fuel reforming apparatus and fuel cell system

InactiveUS20040226218A1Easy to evaporateStable stateThermal non-catalytic crackingProcess control/regulationFuel cellsGasoline

A fuel reforming apparatus includes a premixed fuel tank. In the premixed fuel tank, premixed fuel which is formed by emulsifying gasoline and water that are mixed with each other at a predetermined ratio, using a emulsifier. The premixed fuel is sprayed into a vaporizing portion through a nozzle. Heat can be supplied to the vaporizing portion by the reformer in which oxidation reaction proceeds, a first heating portion, and air supplied to the vaporizing portion through a heat exchanger. The premixed fuel sprayed into the vaporizing portion is vaporized immediately by the thus supplied heat, and is supplied to the reformer. In addition, air which has been humidified in a humidifying module cam be supplied to the vaporizing portion.

Owner:TOYOTA JIDOSHA KK

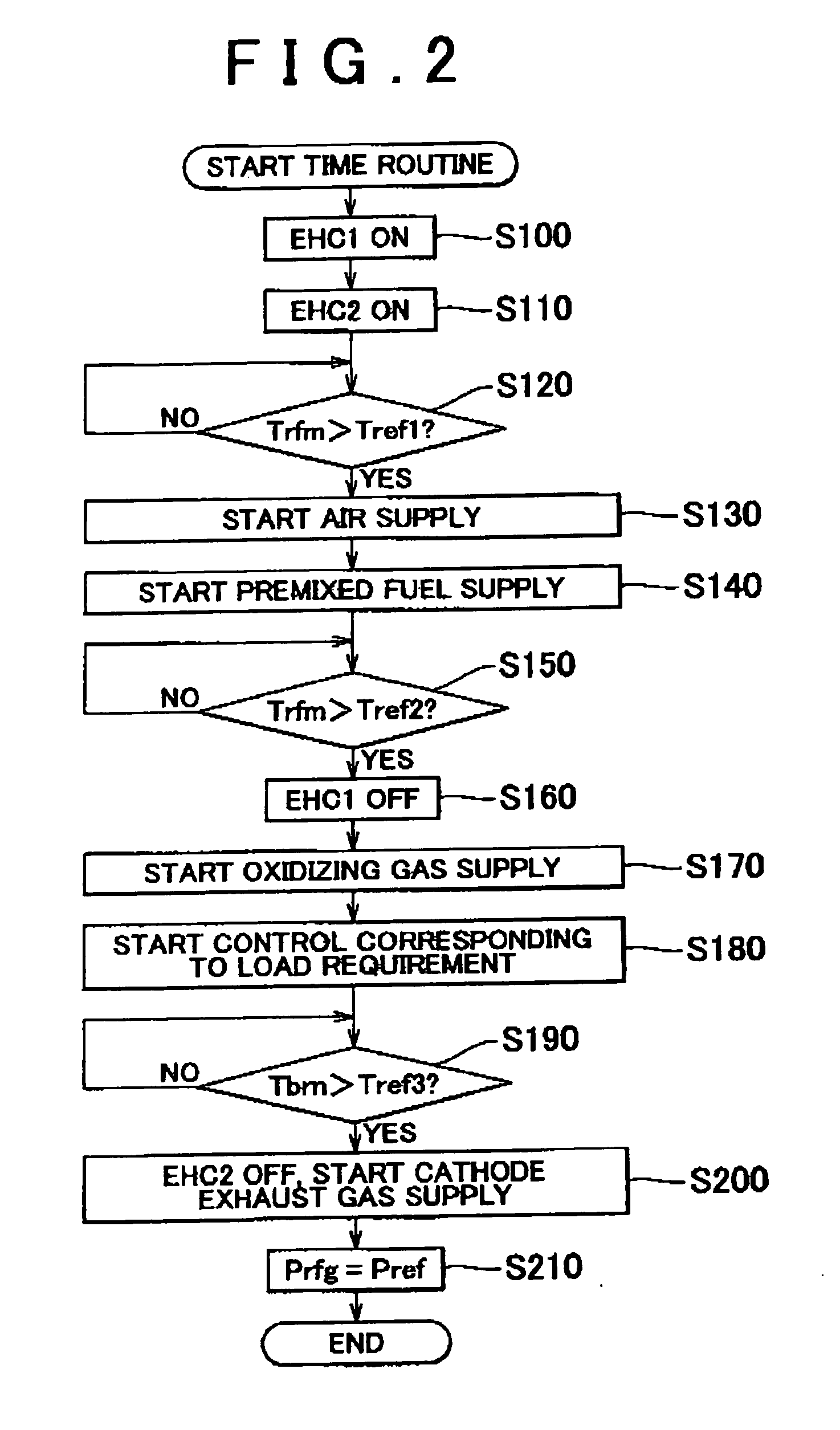

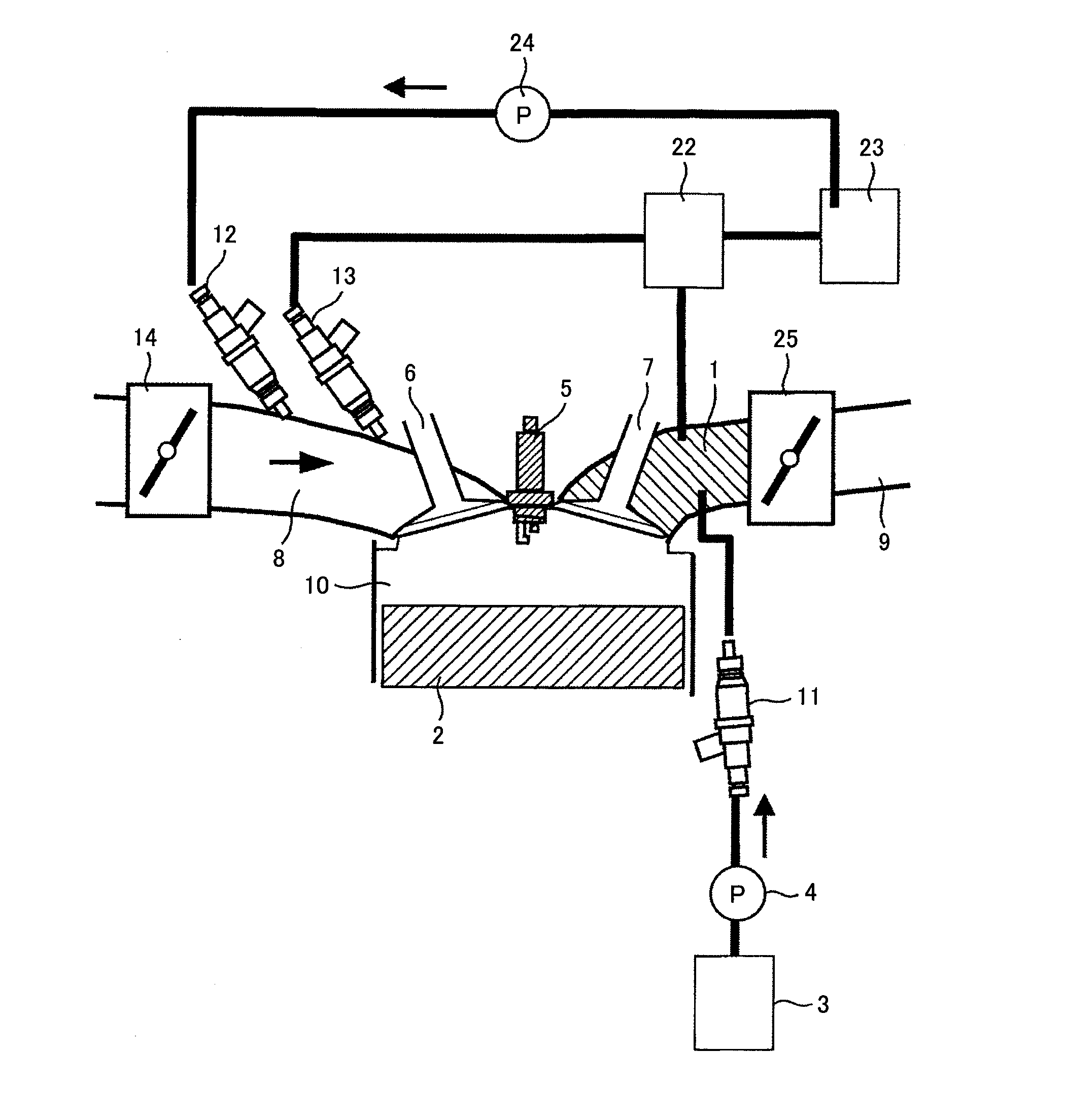

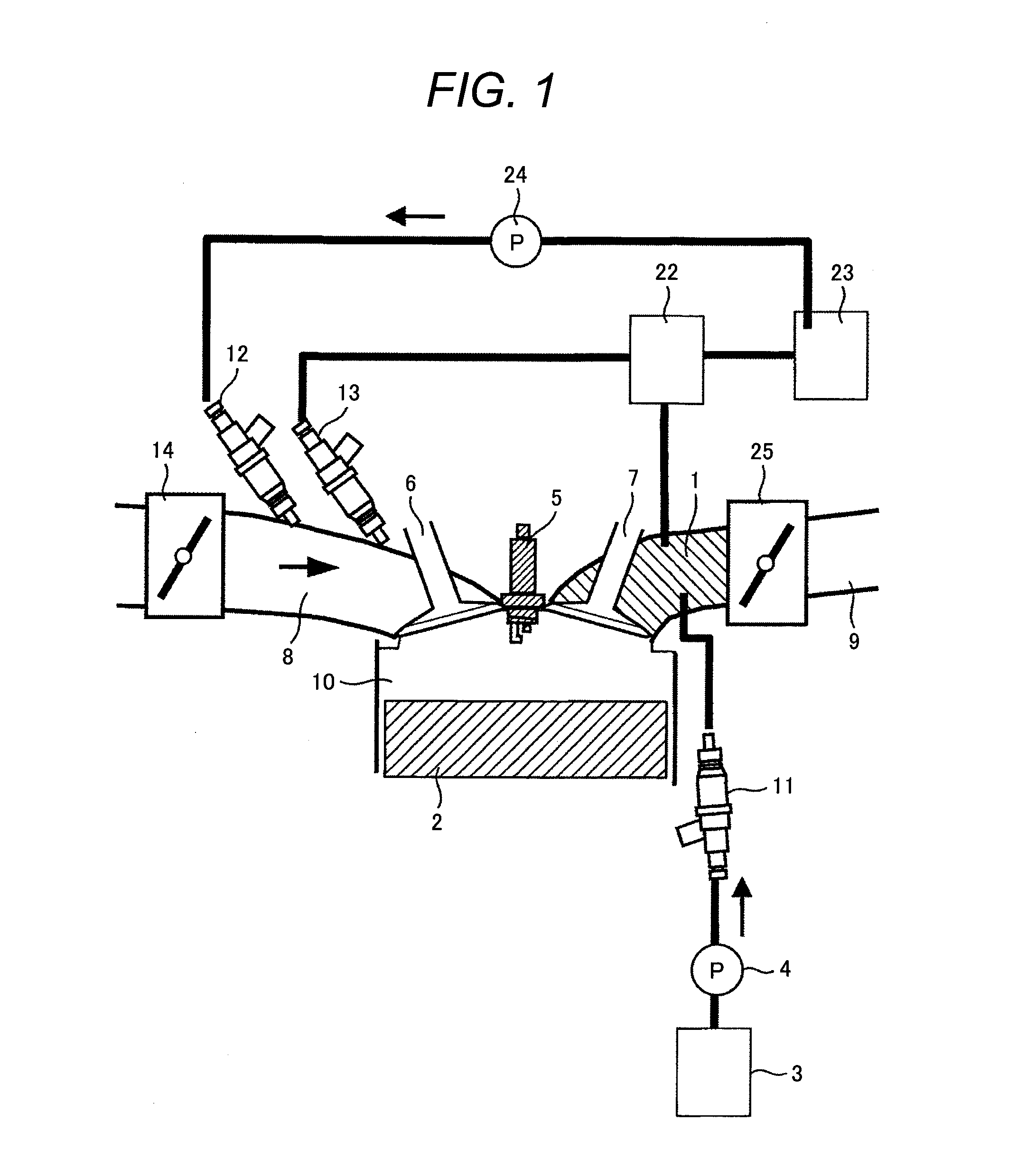

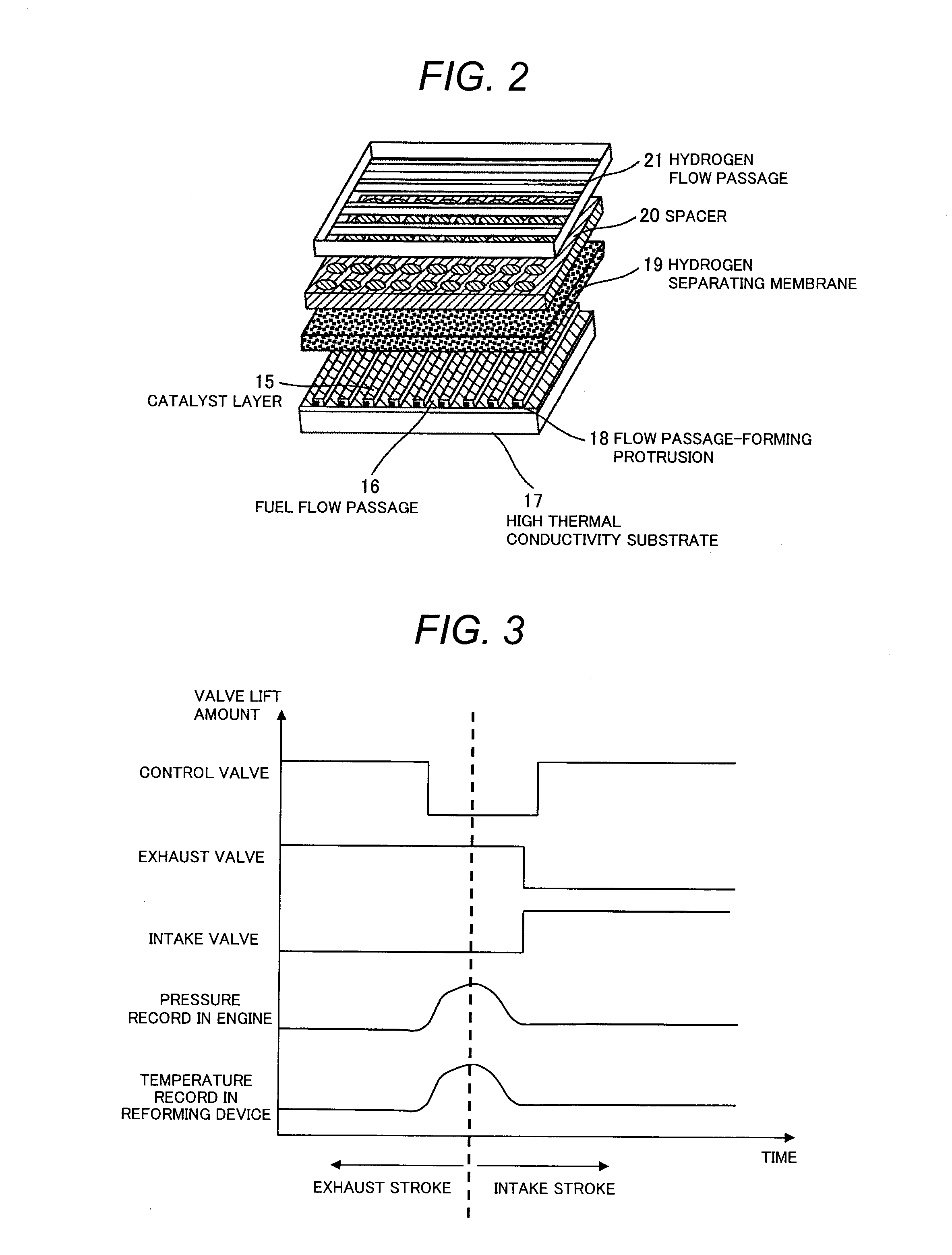

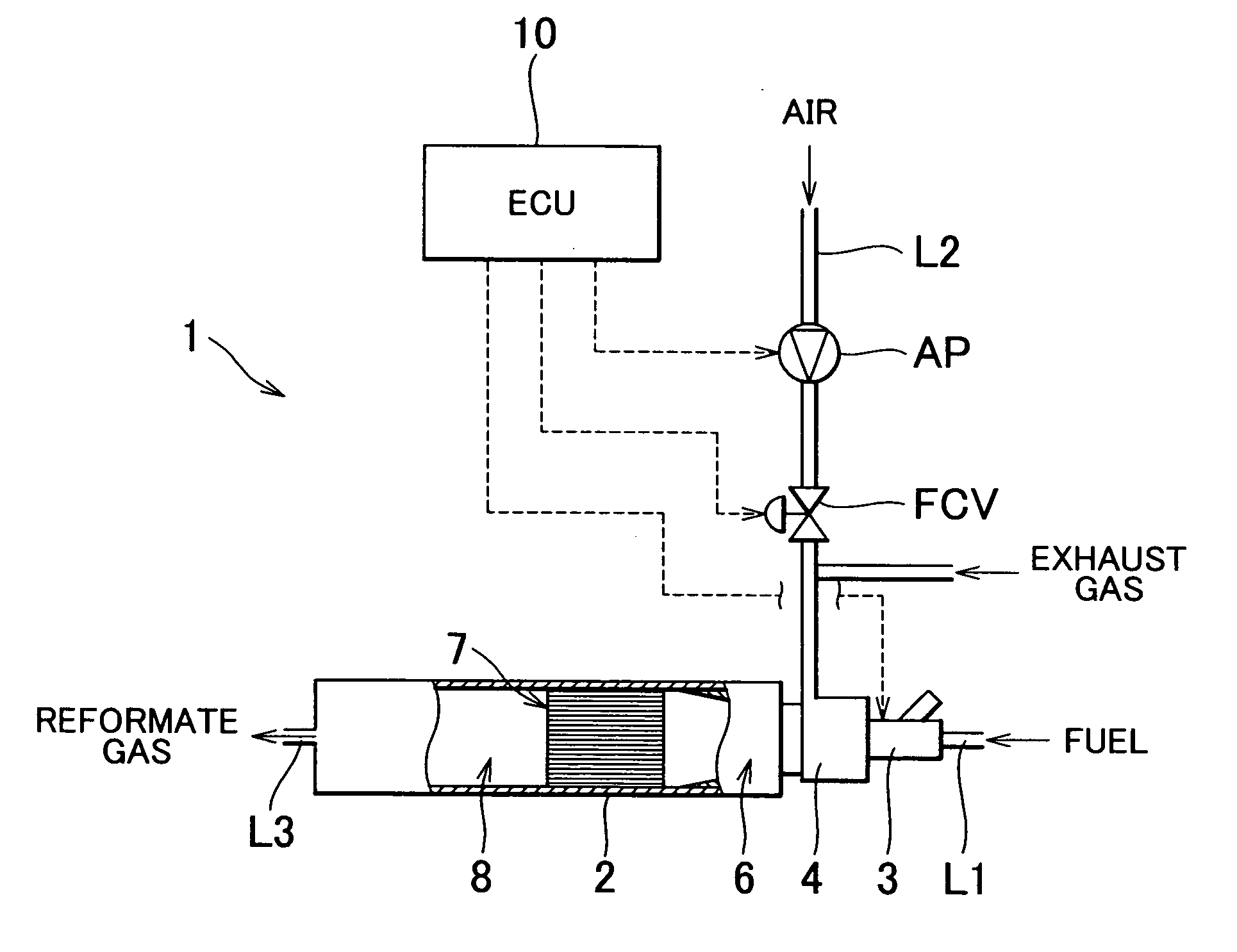

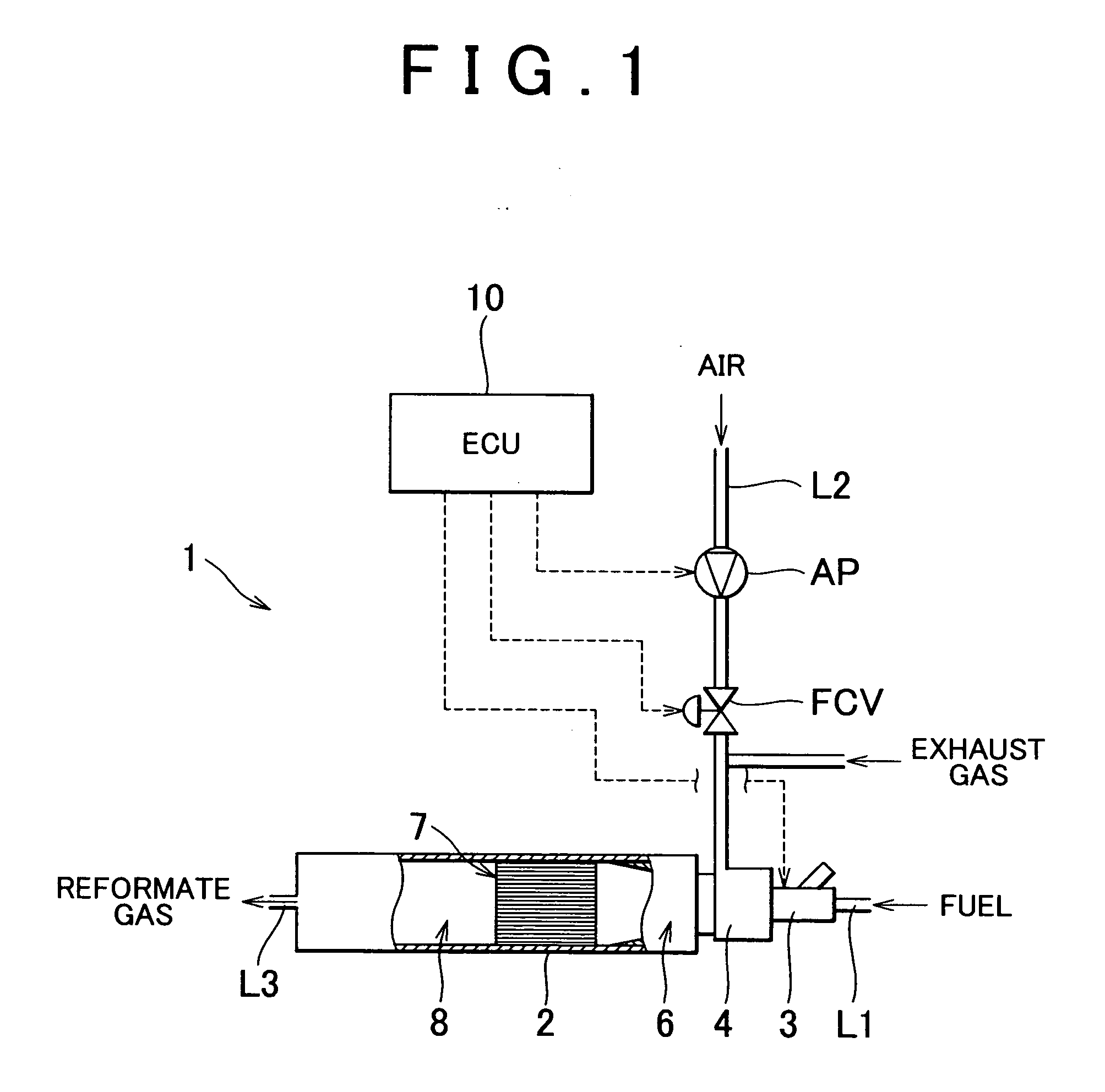

Engine System with Reformer

InactiveUS20120110984A1High reforming efficiencySmall sizeHydrogenNon-fuel substance addition to fuelExhaust fumesControl valves

In an engine system with a reformer being installed in an exhaust pipe to reform a fuel, a control valve for controlling a flow rate of exhaust gas is provided downstream from an installed position of the reformer in the exhaust pipe. In the engine system with the reformer, since a part of the exhaust gas can be trapped in a space between the reformer and an engine chamber by closing the control valve during an exhaust stroke, the reforming efficiency of the reformer can be heightened.

Owner:HITACHI LTD

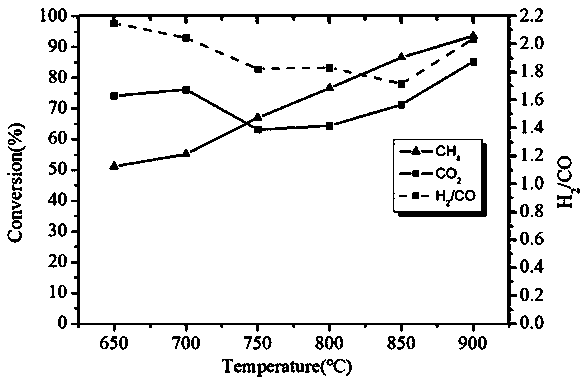

Process for reducing iron and generating carbon nanotubes by reforming methane and carbon dioxide

ActiveCN111333029AGuaranteed purityHigh reforming efficiencyHydrogenCarbon nanotubesCarbon depositNanotube

The invention discloses a process for reducing iron and generating carbon nanotubes by reforming methane and carbon dioxide, and belongs to the technical field of processes of iron catalytic methane and carbon dioxide reforming and iron reducing through synthesis gas. A purpose of the invention is to provide a process for reducing iron ore and generating carbon nanotubes by reforming methane and carbon dioxide. According to the invention, pure methane and carbon dioxide are directly used for reforming so as to ensure the purity of reactants, and synthesis gas of carbon monoxide and hydrogen isobtained after reforming, so that the reforming efficiency is improved; synthesis gas mainly comprises carbon monoxide and hydrogen and can be used for reducing iron ore, and the obtained carbon dioxide enters a reforming reaction process to be utilized; And in the reforming process, a large amount of deposited carbon is generated inevitably, and the deposited carbon can be changed into carbon nanotubes under certain conditions, so that the byproduct of carbon dioxide is the carbon nanotubes, and the product carbon nano tube with strong economic benefit enables the resource to be utilized reasonably.

Owner:TAIYUAN UNIV OF TECH

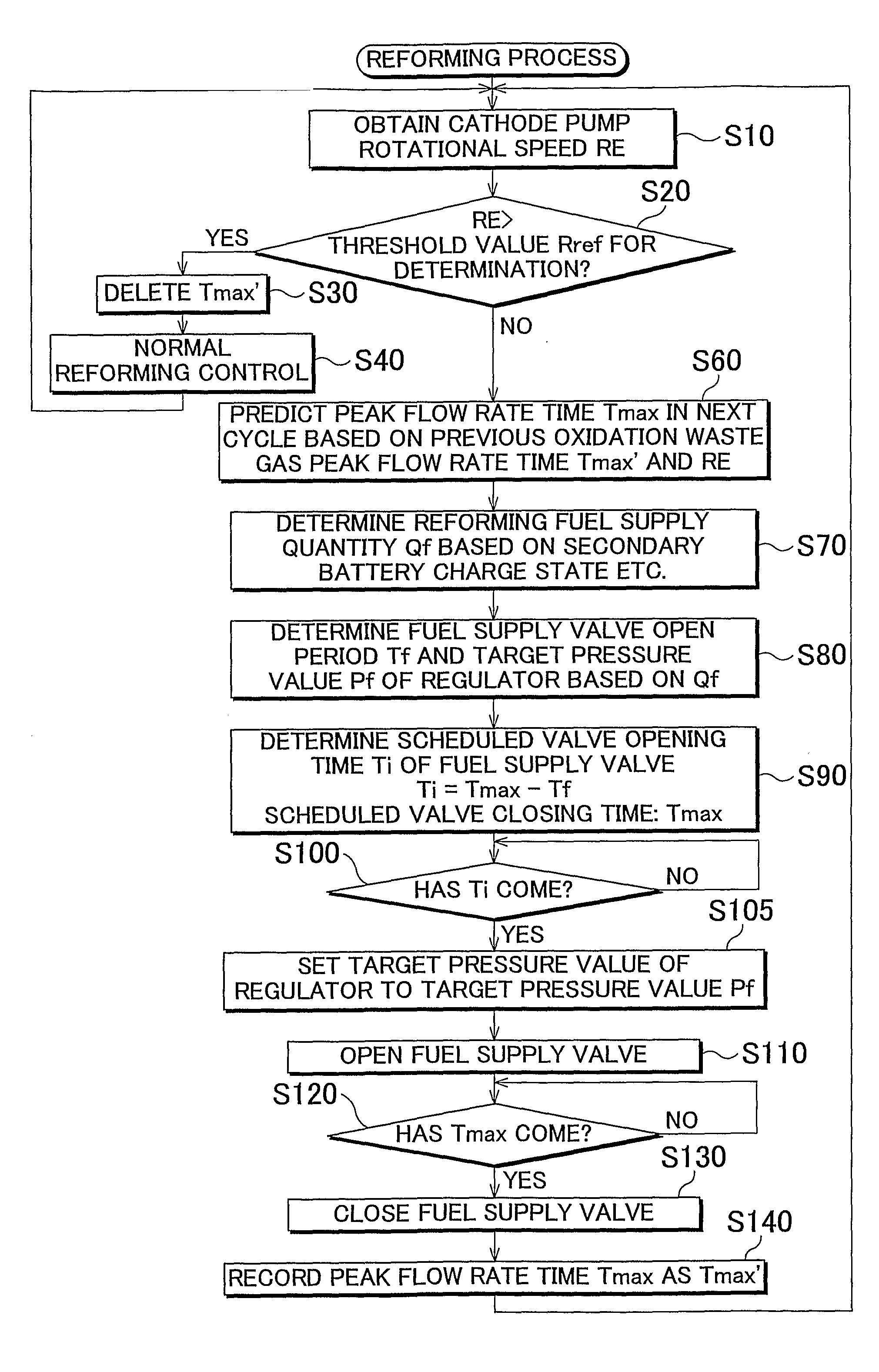

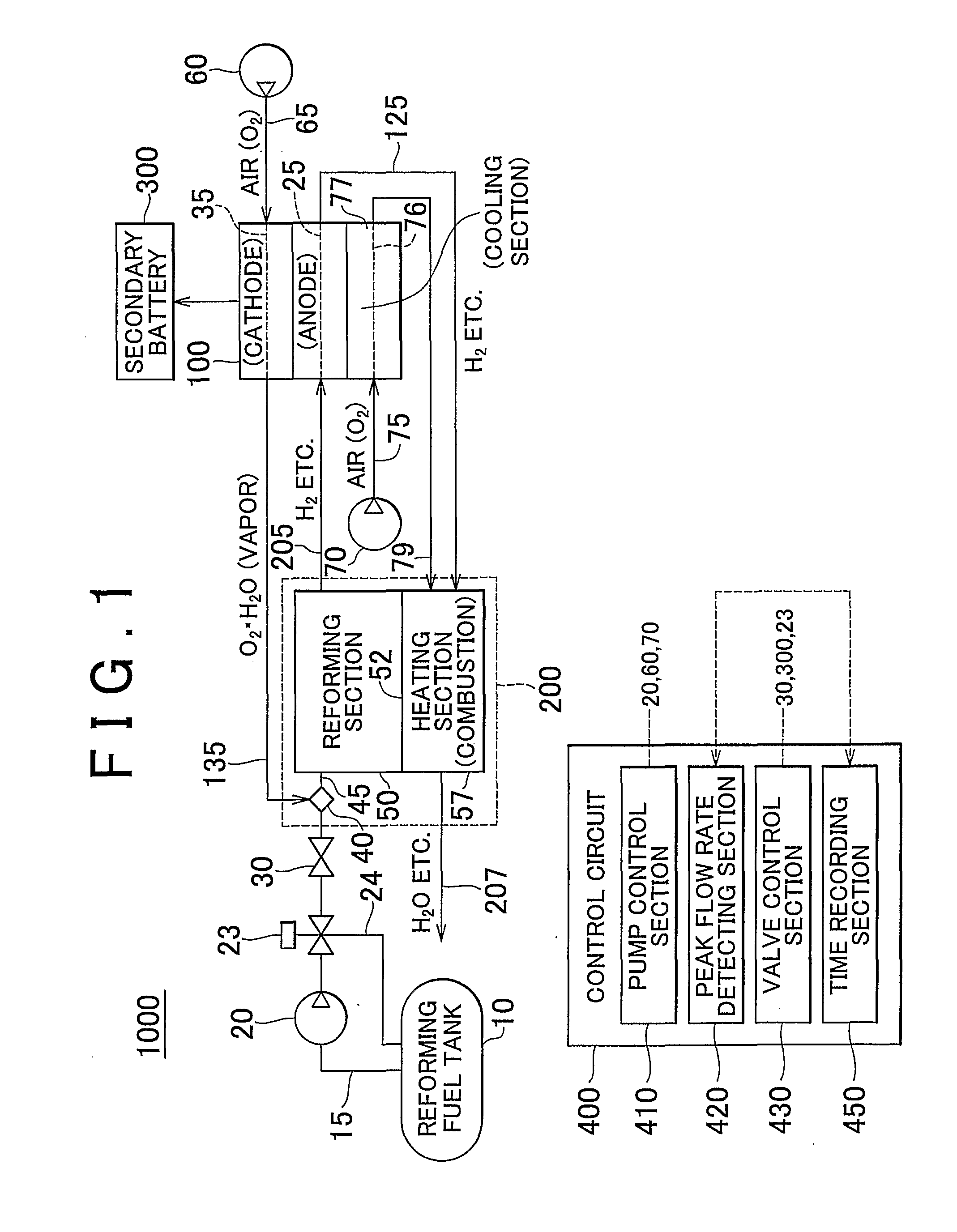

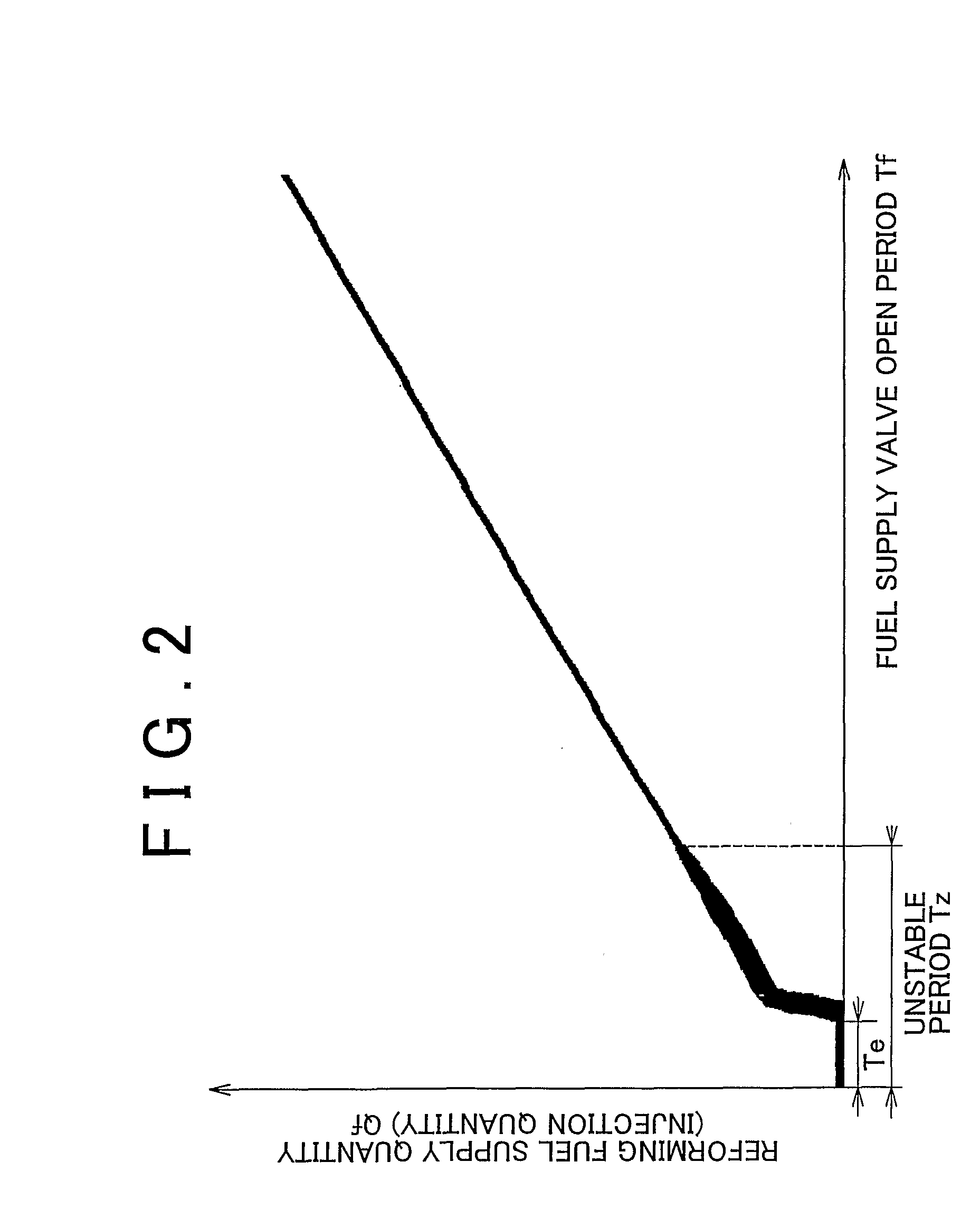

Reforming system and reforming method

InactiveUS20090263684A1Decrease concentrationImprove efficiencyHydrogenChemical industryFuel supplyProcess engineering

A reforming system including: a mixing section that mixes a reforming fuel and a reforming raw material other than the reforming fuel to produce a mixed gas; a reforming section that generates hydrogen from the mixed gas; a reforming fuel supply flow path; a reforming raw material supply flow path; a first supply device disposed in one flow path of the reforming fuel supply flow path and the reforming raw material flow path, that causes periodic fluctuation in a supply quantity of fluid flowing in the one flow path; a second supply device disposed in the other flow path of the reforming fuel supply flow path and the reforming raw material flow path; and a controller that controls the second supply device so that the second supply device supplies the fluid flowing in the other flow path in synchronization with the periodic fluctuation.

Owner:TOYOTA JIDOSHA KK

Polylactic acid resin composition and film

ActiveUS8512852B2High melting pointReduces fall of optical puritySynthetic resin layered productsThin material handlingShell moldingPack material

Provided is a polylactic acid resin composition useful as a molding material and a packaging material. The polylactic acid resin composition comprises a resin composition (l) comprising poly-L-lactic acid having an L-isomer content of 90-100 mol % as the main component and a resin composition (d) comprising poly-D-lactic acid having a D-isomer content of 90-100 mol % as the main component, the resin compositions (l) and (d) having been alternately stacked so that each layer has a thickness of 0.01-2.5 μm. The polylactic acid resin composition has specific thermal properties, can be used at high temperatures even after high-temperature melt molding, and can give molded polylactic acid articles having excellent suitability for various kinds of processing, such as printing, and having excellent transparency, etc. Also provided is a stretched polylactic acid resin film obtained by heating the polylactic acid resin composition to 280° C. or higher, subsequently cooling the composition, thereafter forming the polylactic acid resin composition into a film, and then stretching the film in at least one direction. This film can be used at high temperatures and has excellent suitability for various kinds of processing, excellent transparency, etc.

Owner:TOYOBO CO LTD

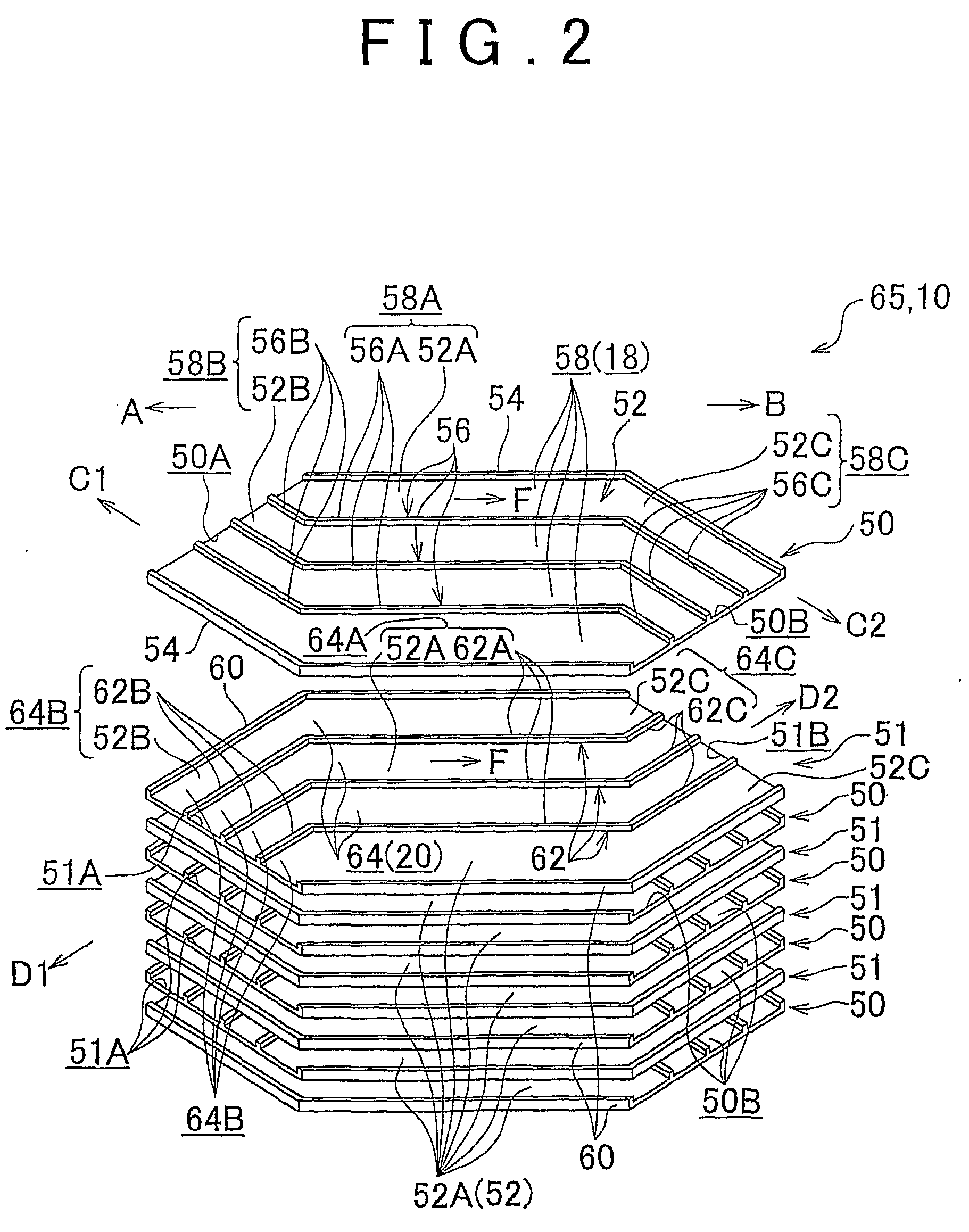

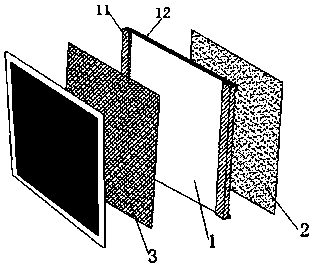

Heat exchanger, heat-exchange reformer, and methods of producing heat-exchanger and heat-exchange reformer

InactiveUS20090173481A1Improve the immunitySuppress heat lossHydrogenThermal insulationInsulation layerEngineering

A heat exchanger includes: a stacked core formed by stacking a plurality of unit plate members in each of which passage formation portions are formed independently of each other to extend from a heat-exchange passage formation portion along a plane; a case formed in accordance with the outer shape of the stacked core, and which houses the stacked core such that heat-exchange media flow into and flow out of the stacked core; and a join portion that serves as a sealing mechanism that supports the stacked core such that the stacked core does not contact the case, and that forms a heat-insulation layer between the case and the stacked core, wherein the heat-insulation layer is a closed space separated from the outside.

Owner:TOYOTA JIDOSHA KK

Semiconductor device and manufacturing method thereof

InactiveUS8154102B2Inhibited DiffusionHigh reforming efficiencySolid-state devicesSemiconductor/solid-state device manufacturingBit linePolysilazane

A semiconductor device includes groove-like regions that are formed between two adjacent bit lines among a plurality of bit lines each having upper and side surfaces covered with a cap insulating film and a side-wall insulating film, respectively, a SiON film that contains more O (oxygen) than N (nitrogen) and continuously covers inner surfaces of the groove-like regions, and a silicon dioxide film formed by reforming polysilazane and filled in the groove-like regions with the SiON film interposed therebetween.

Owner:PS4 LUXCO SARL

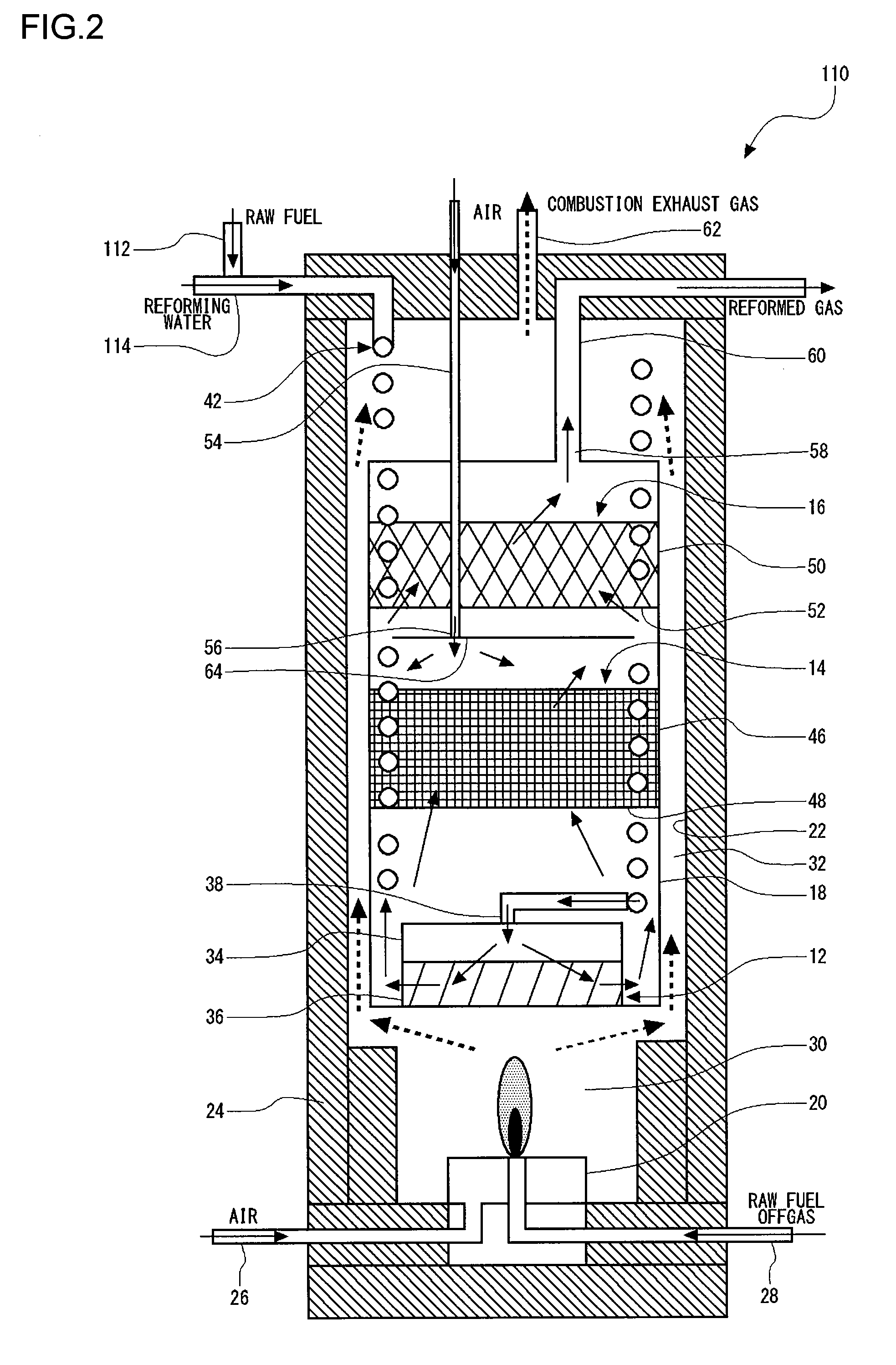

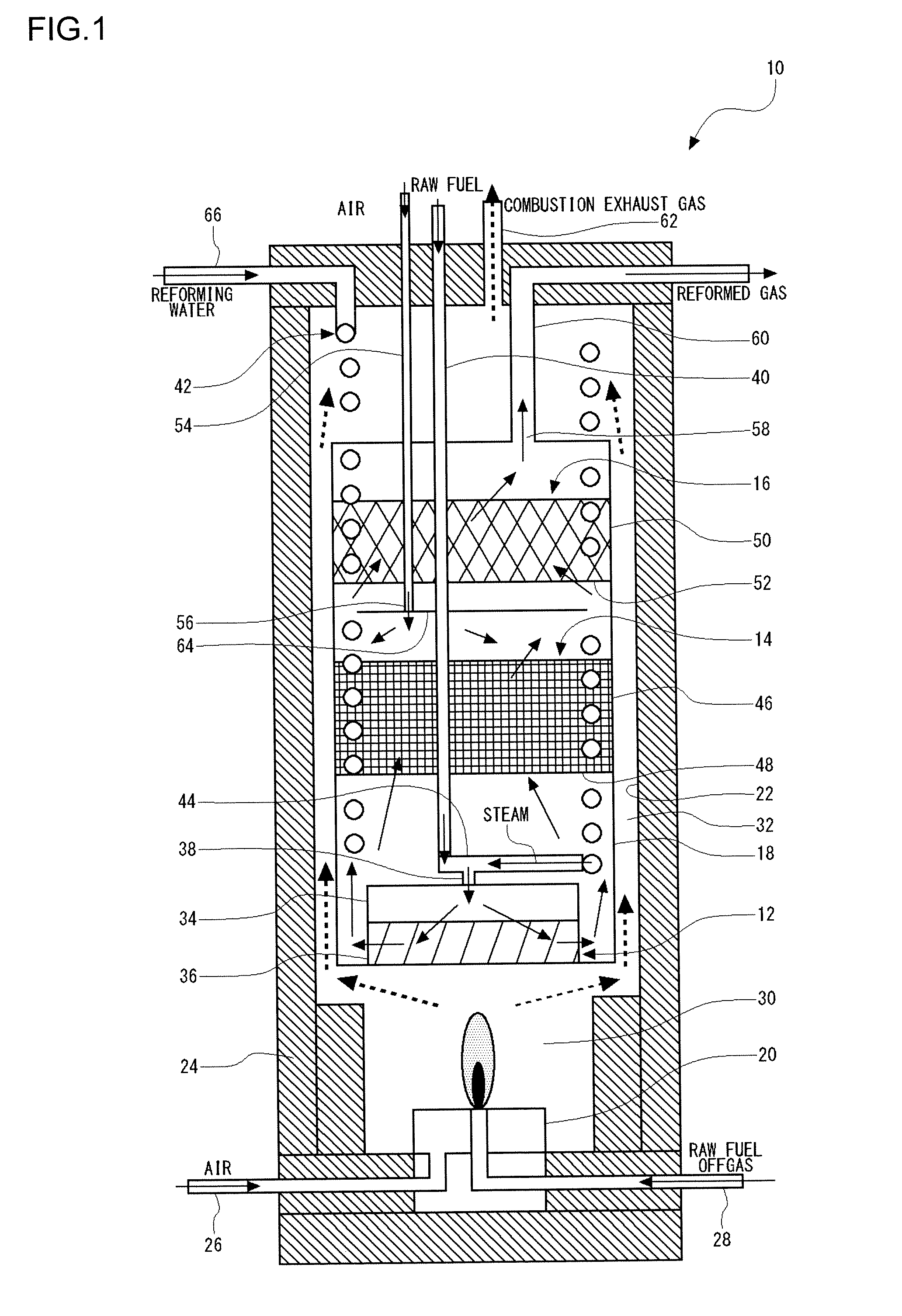

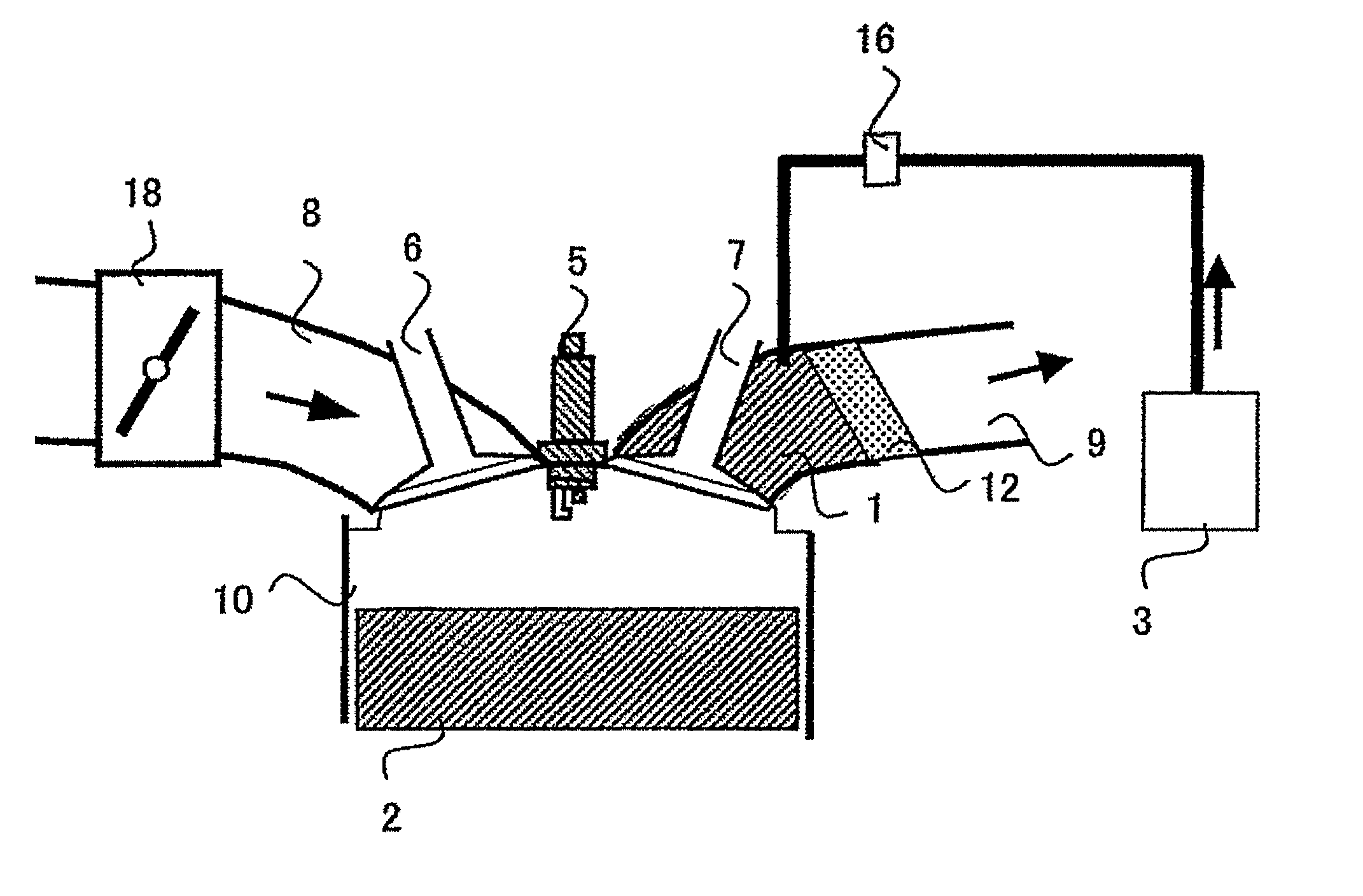

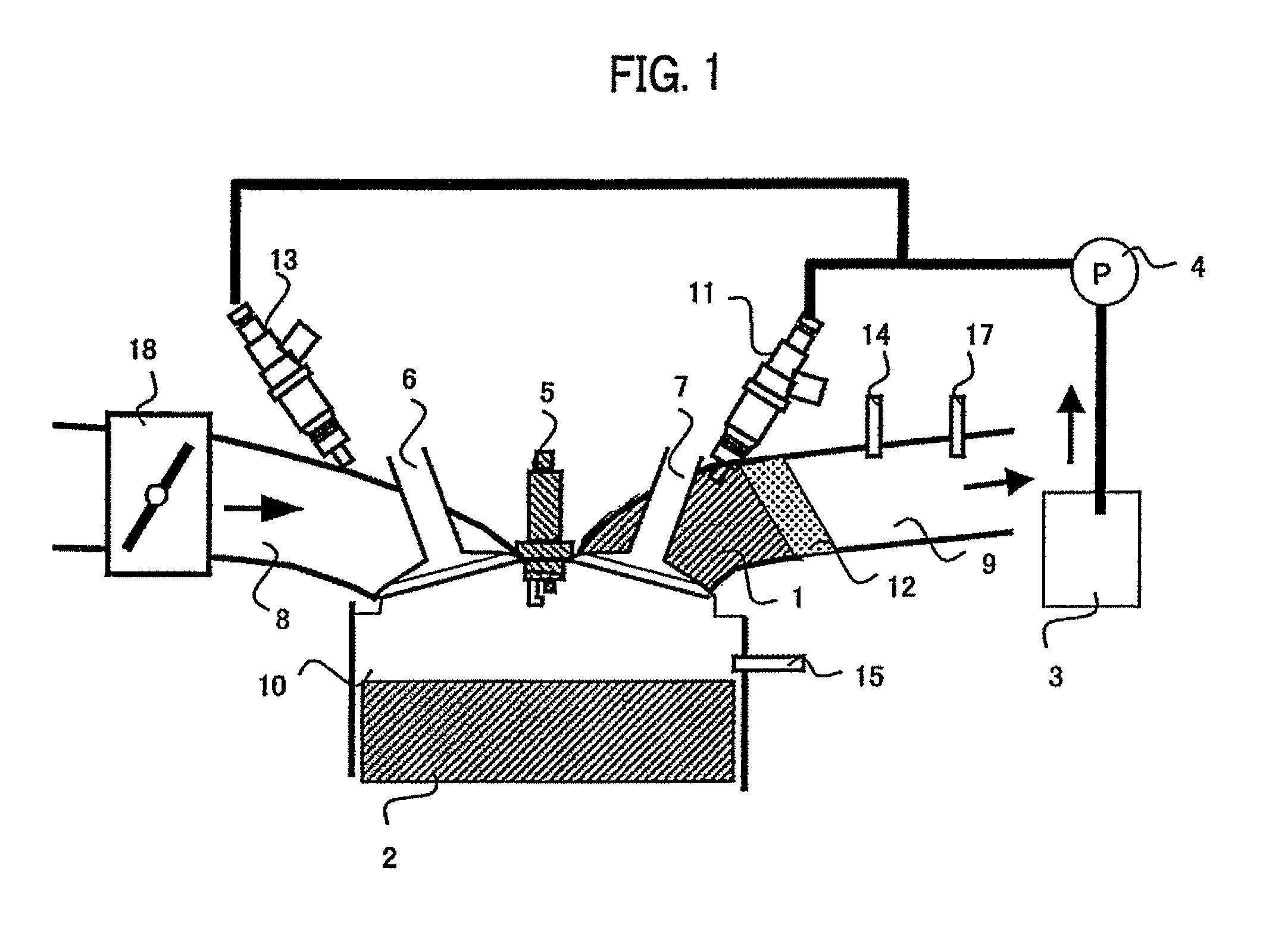

Reforming apparatus for fuel cell

InactiveUS20120237839A1Simple structureImprove thermal efficiencyHydrogenChemical industryHydrogenFuel cells

In a reforming apparatus, for use in a fuel cell, for reforming a raw fuel into a hydrogen-rich reformed gas, a reformer generates the reformed gas from the raw fuel. A shift reactor reduces carbon monoxide contained in the reformed gas through a shift reaction. A selective oxidation unit reduces the carbon monoxide contained in the reformed gas that has passed through the shift reactor by performing selective oxidation on the carbon monoxide. A reforming reaction tube houses linearly the reformer, the shift reactor and the selective oxidation unit in this order.

Owner:JX NIPPON OIL & ENERGY CORP

Reforming apparatus for fuel cell

InactiveUS8178062B2Simple structureImprove thermal efficiencyHydrogenChemical industryHydrogenFuel cells

In a reforming apparatus, for use in a fuel cell, for reforming a raw fuel into a hydrogen-rich reformed gas, a reformer generates the reformed gas from the raw fuel. A shift reactor reduces carbon monoxide contained in the reformed gas through a shift reaction. A selective oxidation unit reduces the carbon monoxide contained in the reformed gas that has passed through the shift reactor by performing selective oxidation on the carbon monoxide. A reforming reaction tube houses linearly the reformer, the shift reactor and the selective oxidation unit in this order. A combustion means produces combustion exhaust gas by combusting the raw fuel. An outer casing is placed around the reforming reaction tube, and the outer casing has a larger diameter than that of the reforming reaction tube. A heated flow passage through which the combustion exhaust gas passes to heat the reforming reaction tube is formed between the reforming reaction tube and the outer casing.

Owner:NIPPON OIL CORP

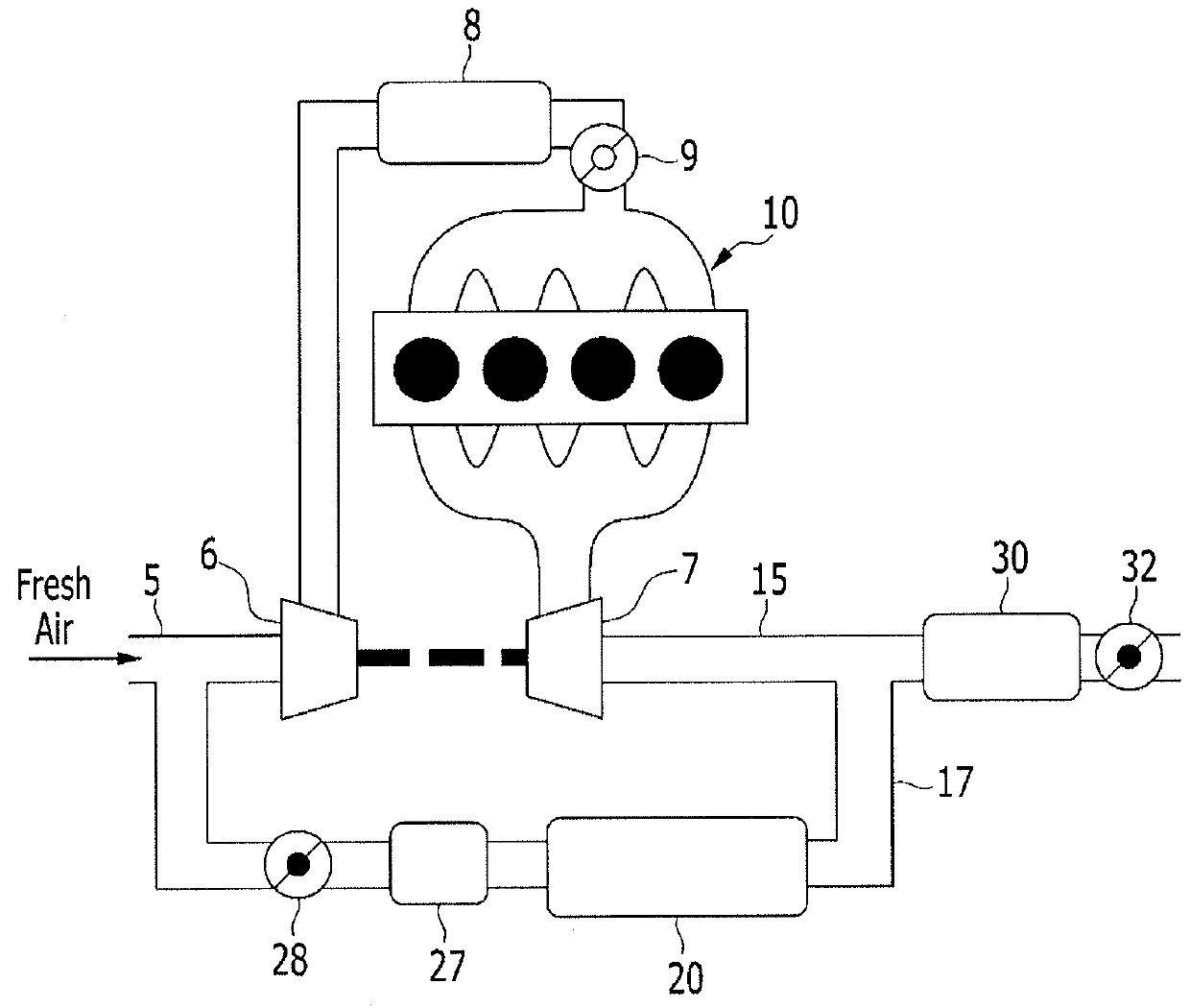

Reforming system

PendingCN108457774APromote generationHigh reforming efficiencyExhaust apparatusCombustion-air/fuel-air treatmentExhaust valveNitrogen oxides

The invention discloses a fuel reforming system. The fuel reforming system includes: an engine combusting reformed gas to generate mechanical power; an intake line connected to the engine to supply the reformed gas and air to the engine; an exhaust line connected to the engine to circulate the exhaust gas discharged from the engine; a fuel reformer provided at an exhaust gas recirculation (EGR) line diverging from the exhaust line; and a catalyst disposed at the exhaust line and purifying nitrogen oxide included in the exhaust gas at a front end of the fuel reformer. In particular, the fuel reformer mixes the fuel with the EGR gas which is a part of the exhaust gas and passes through the EGR line, and reforms the fuel mixed in the EGR gas.

Owner:HYUNDAI MOTOR CO LTD +1

Fuel reforming system and method of controlling flow rate of exhaust gas recirculation gas in a fuel reformer

ActiveUS20180163648A1Degree of opening is decreasedHigh degree of opennessElectrical controlInternal combustion piston enginesGas passingControl valves

A fuel reforming system may include an engine combusting reformed gas to generate mechanical power; an intake line connected to the engine to supply reformed gas and air to the engine; an exhaust line connected to the engine to circulate exhaust gas exhausted from the engine; a fuel reformer provided at an exhaust gas recirculation (EGR) line diverging from the exhaust line, mixing the EGR gas passing through the EGR line with the fuel and reforming the fuel mixed in the EGR gas; and an EGR flow controller determining a target opening degree of a flow rate control valve according to engine running condition, whether or not in a reforming running condition, required amount of EGR gas along to running condition, and controlling opening degree of the flow rate control valve on a basis of the target opening degree.

Owner:HYUNDAI MOTOR CO LTD +1

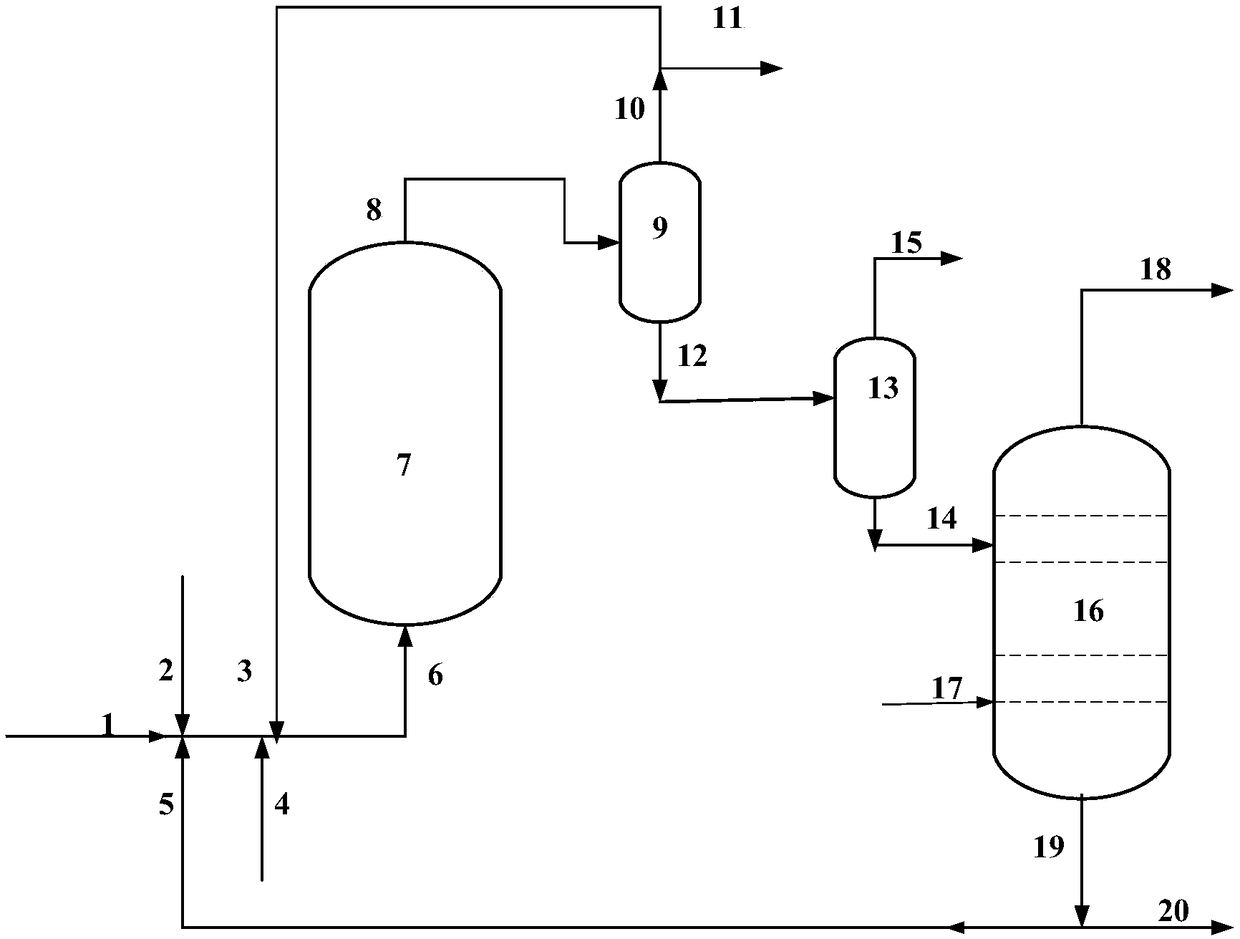

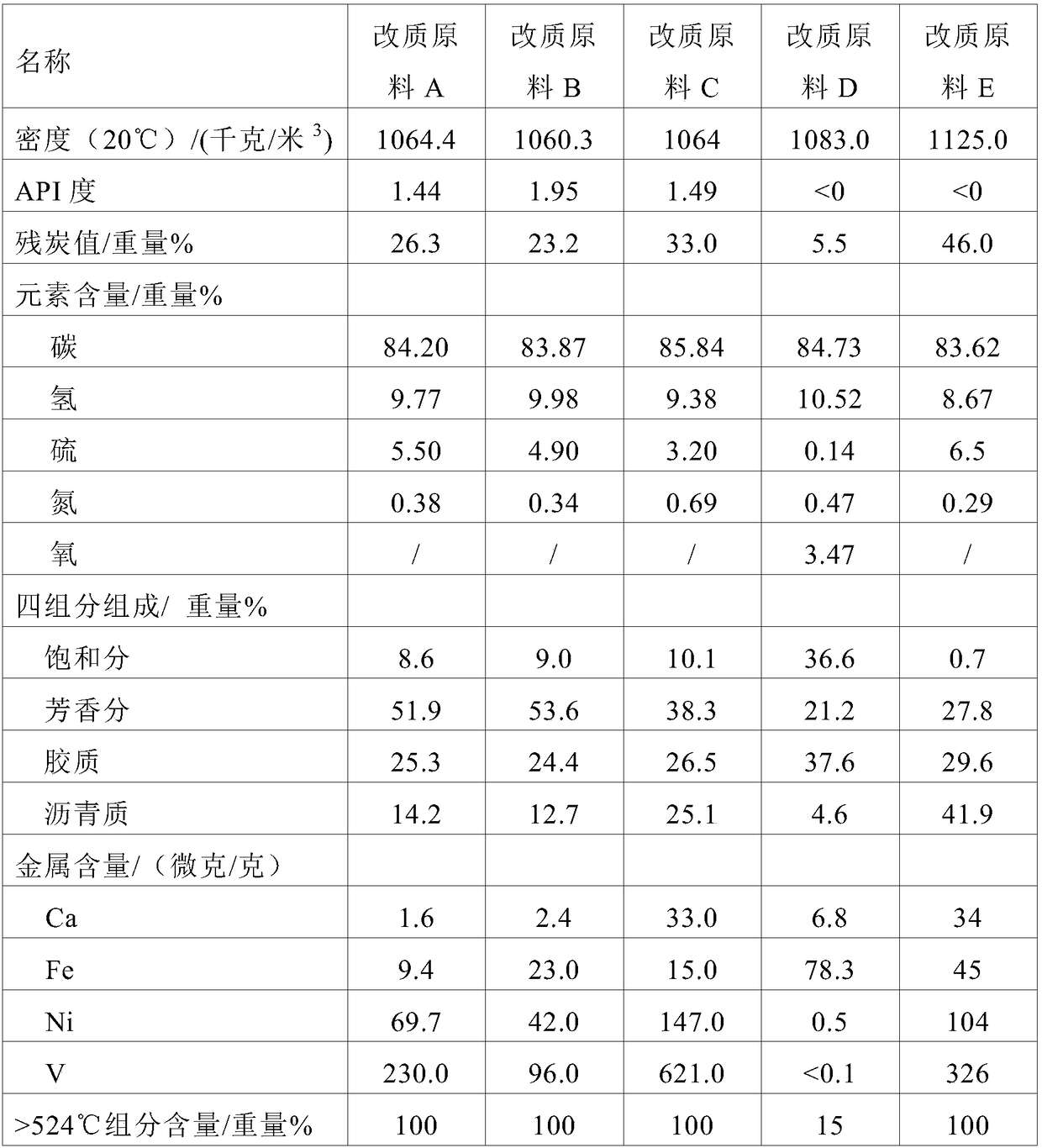

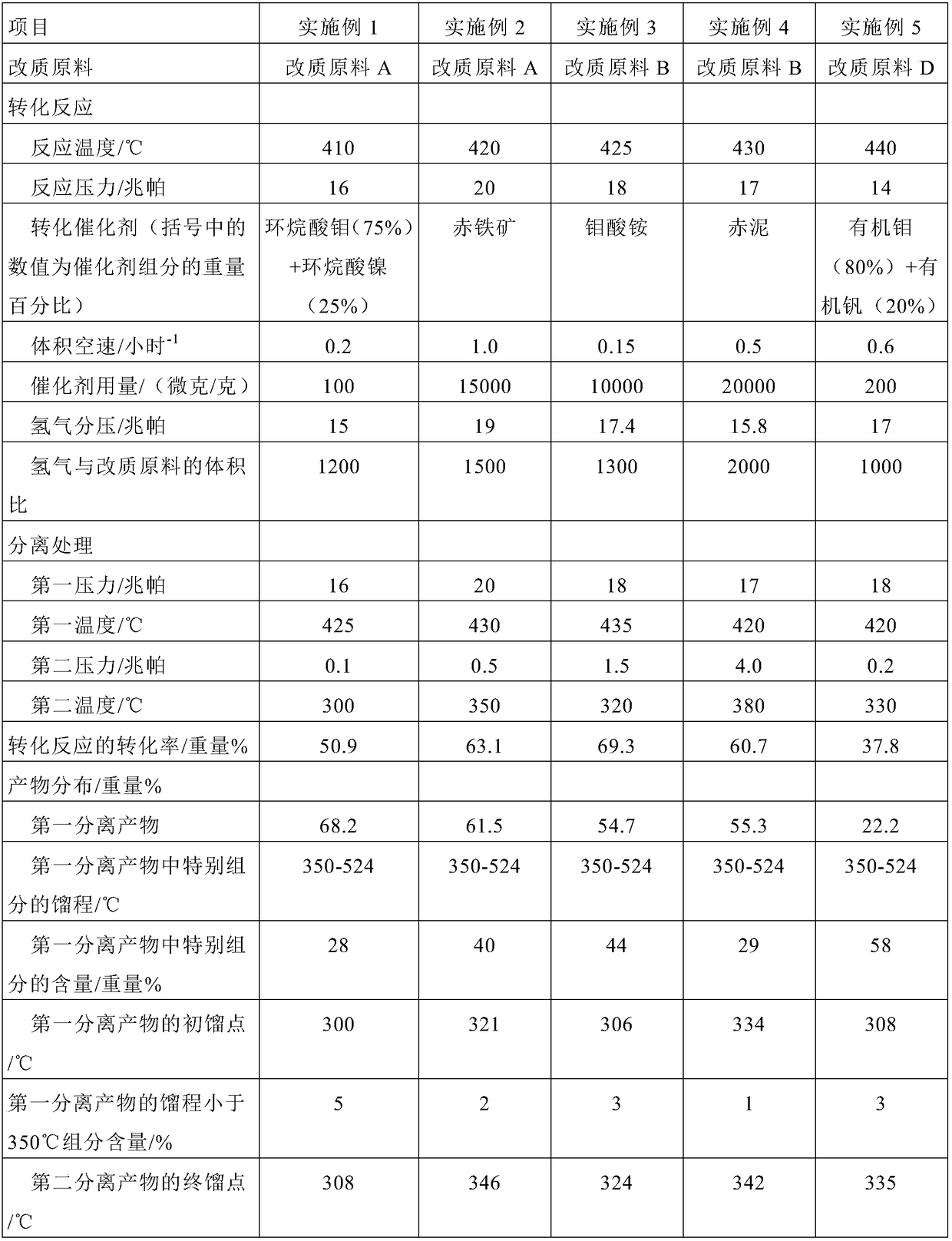

Method and system for modifying low-grade oil

ActiveCN109486518AHigh yieldReduce yieldWorking-up pitch/asphalt/bitumen by chemical meansTreatment with hydrotreatment processesSpin outLower grade

The invention relates to a method and system for modifying low-grade oil. The method includes: (1) subjecting low-grade oil as a modifying material to conversion reaction in a conversion reactor underhydrogen contact condition to obtain a conversion product; (2) separating the conversion product of step (1) to at least obtain a first separated product; (3) extracting and separating the first separated product of step (2) in an extraction separation unit to obtain modified soil and residue; (4) returning the residue of step (3) to step (1) for conversion reaction; alternatively, spinning out the residue of step (3); alternatively, returning the residue of step (3) to step (1) for conversion reaction, and spinning out the remainder of the residue. The method and system provided herein havethe advantage that long-term operation is maintained for the system at the premise that spun-out residue is as little as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

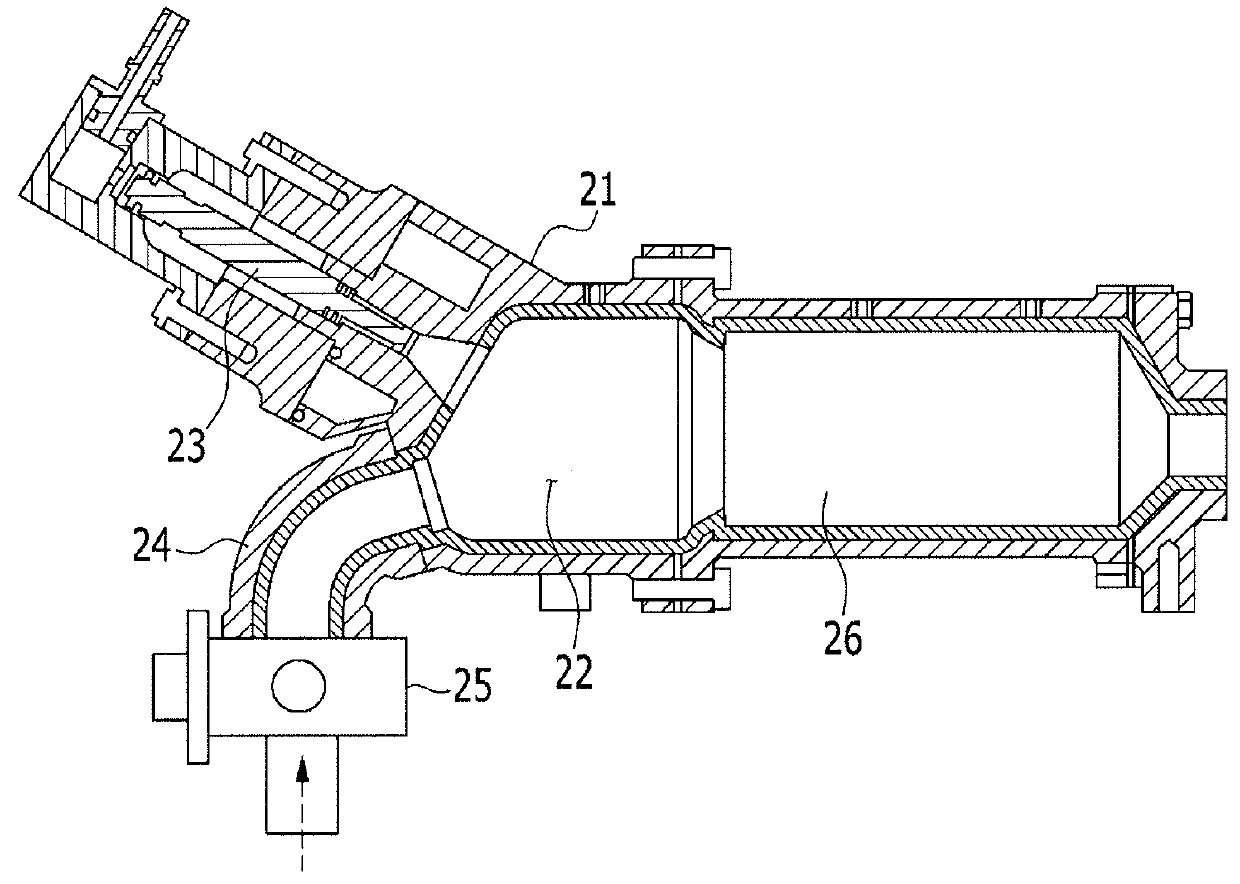

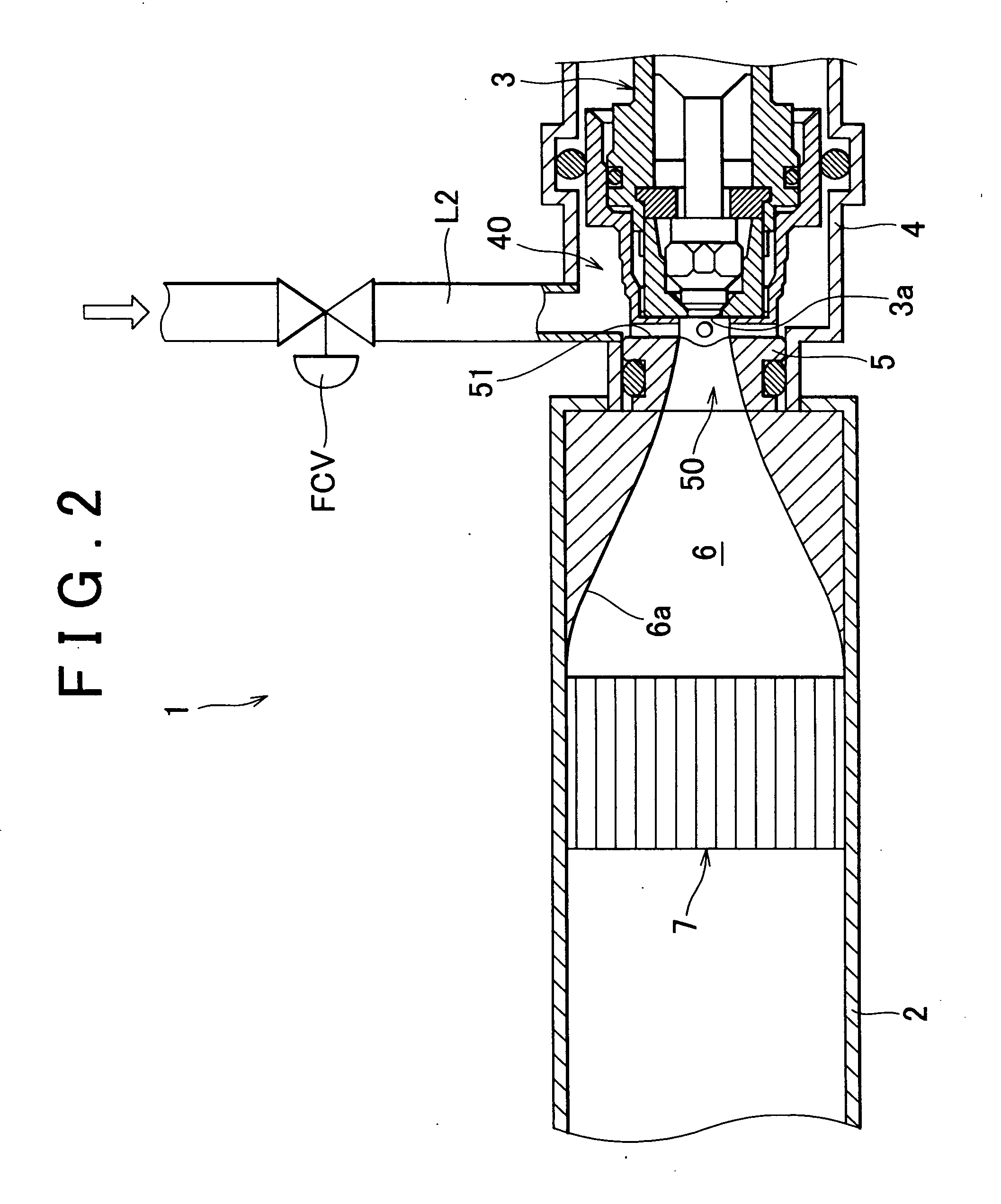

Fuel reforming apparatus

InactiveUS20050160671A1High reforming efficiencyProceed efficientlyHydrogenNon-fuel substance addition to fuelProcess engineeringOxygen

A fuel reforming apparatus for reforming a mixture of fuel and gas containing oxygen includes an air-fuel mixing chamber into which fuel and air are supplied in such a manner that the fuel and the air are mixed with each other; a reforming reaction chamber which is provided downstream of the air-fuel mixing chamber, and which includes a reforming catalyst for reforming the mixture; and a mixture flow chamber which is provided between the air-fuel mixing chamber and the reforming reaction chamber. The cross sectional area of an outlet of the air-fuel mixing chamber is smaller than the cross sectional area of an inlet of the reforming reaction chamber. An inner wall surface of the mixture flow chamber is formed such that the outlet of the air-fuel mixing chamber is smoothly continuous with the inlet of the reforming reaction chamber.

Owner:TOYOTA JIDOSHA KK

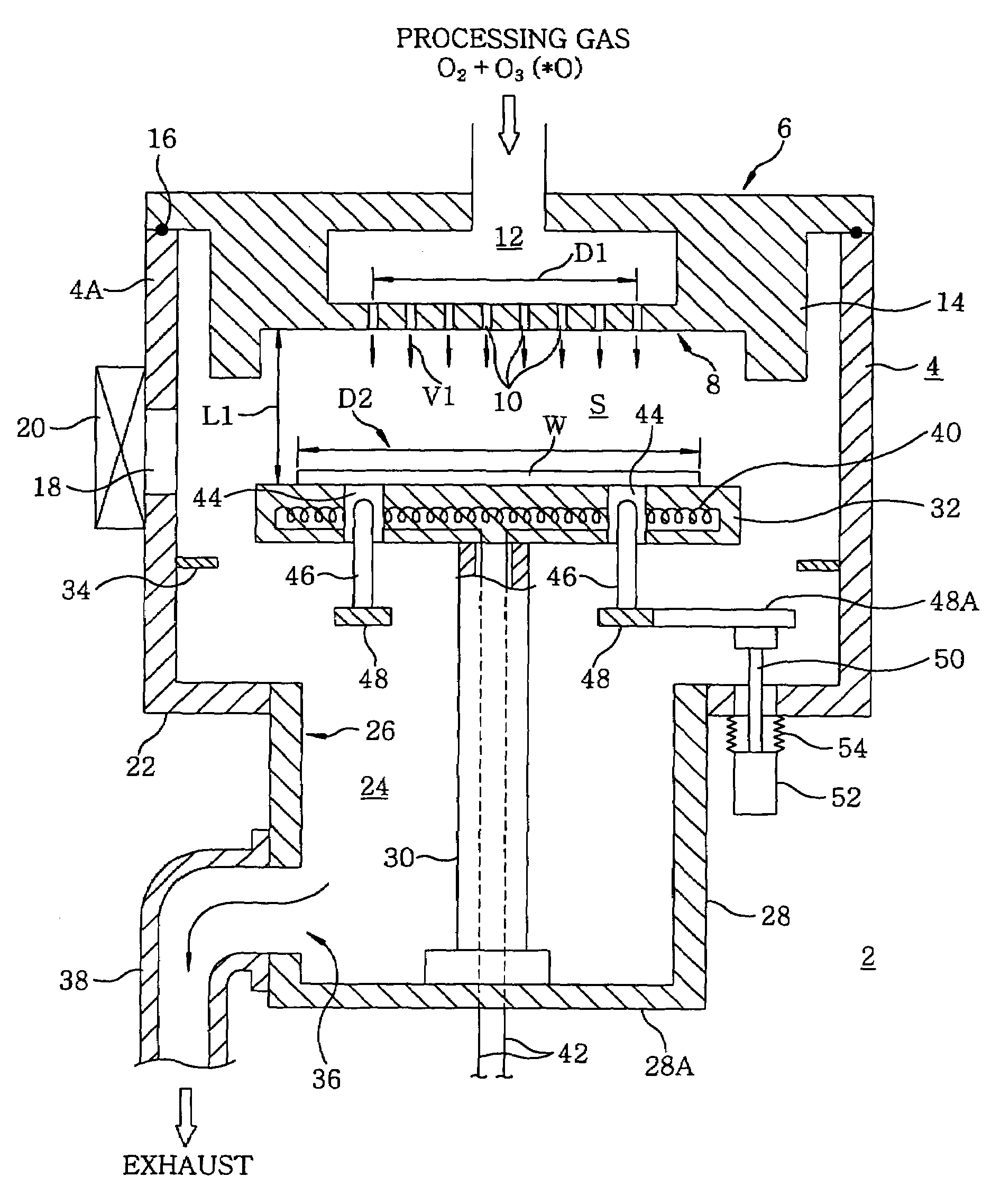

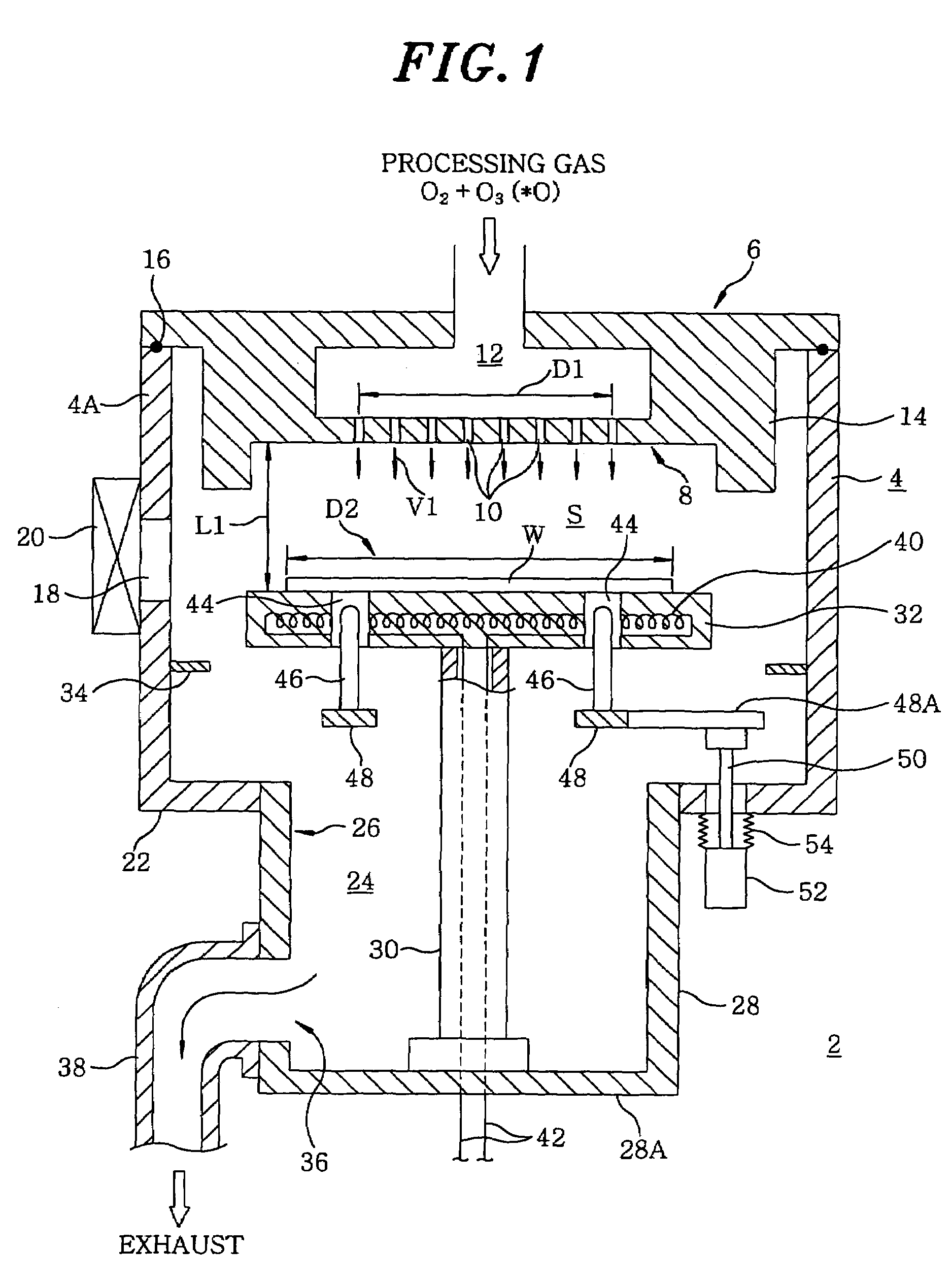

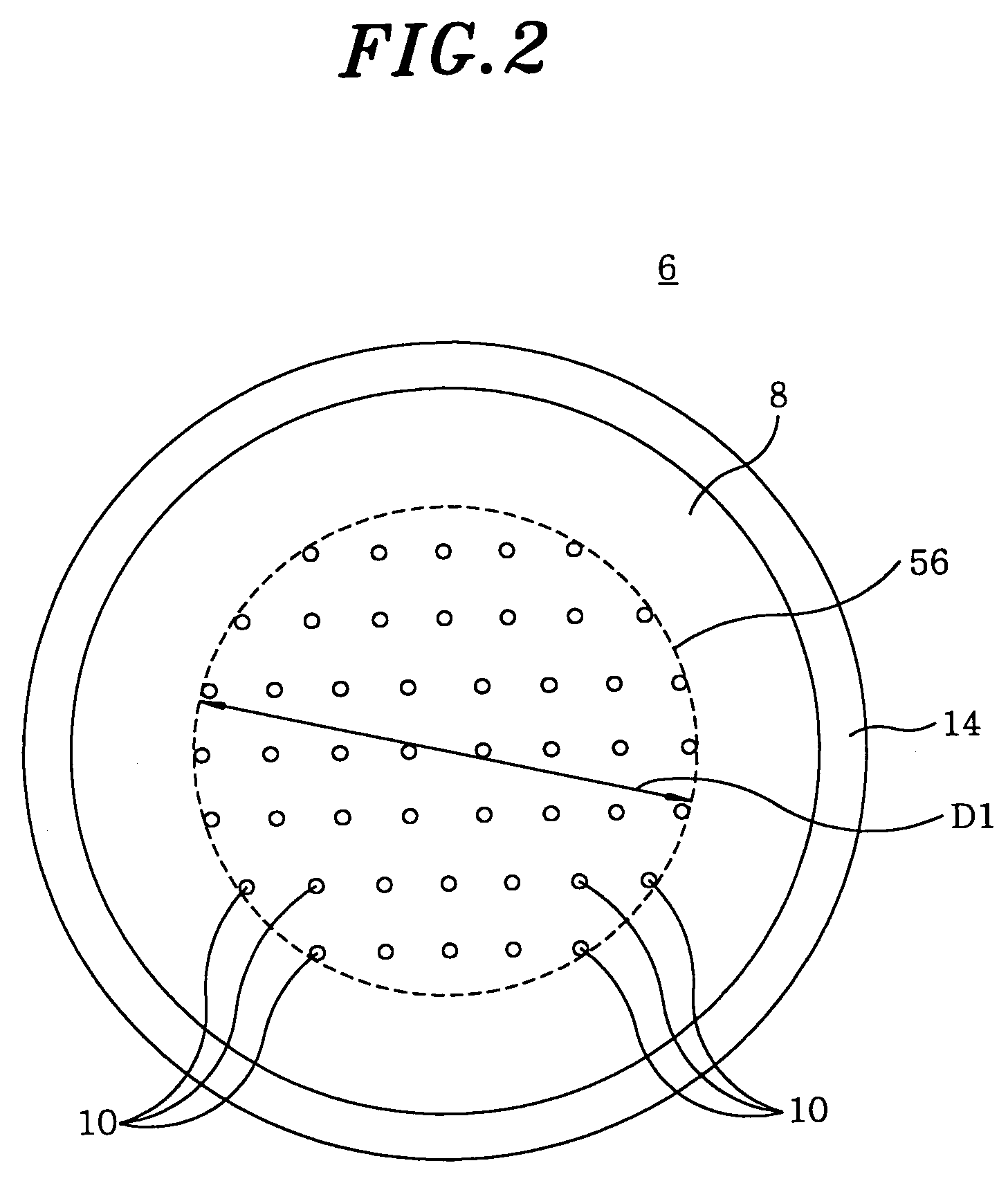

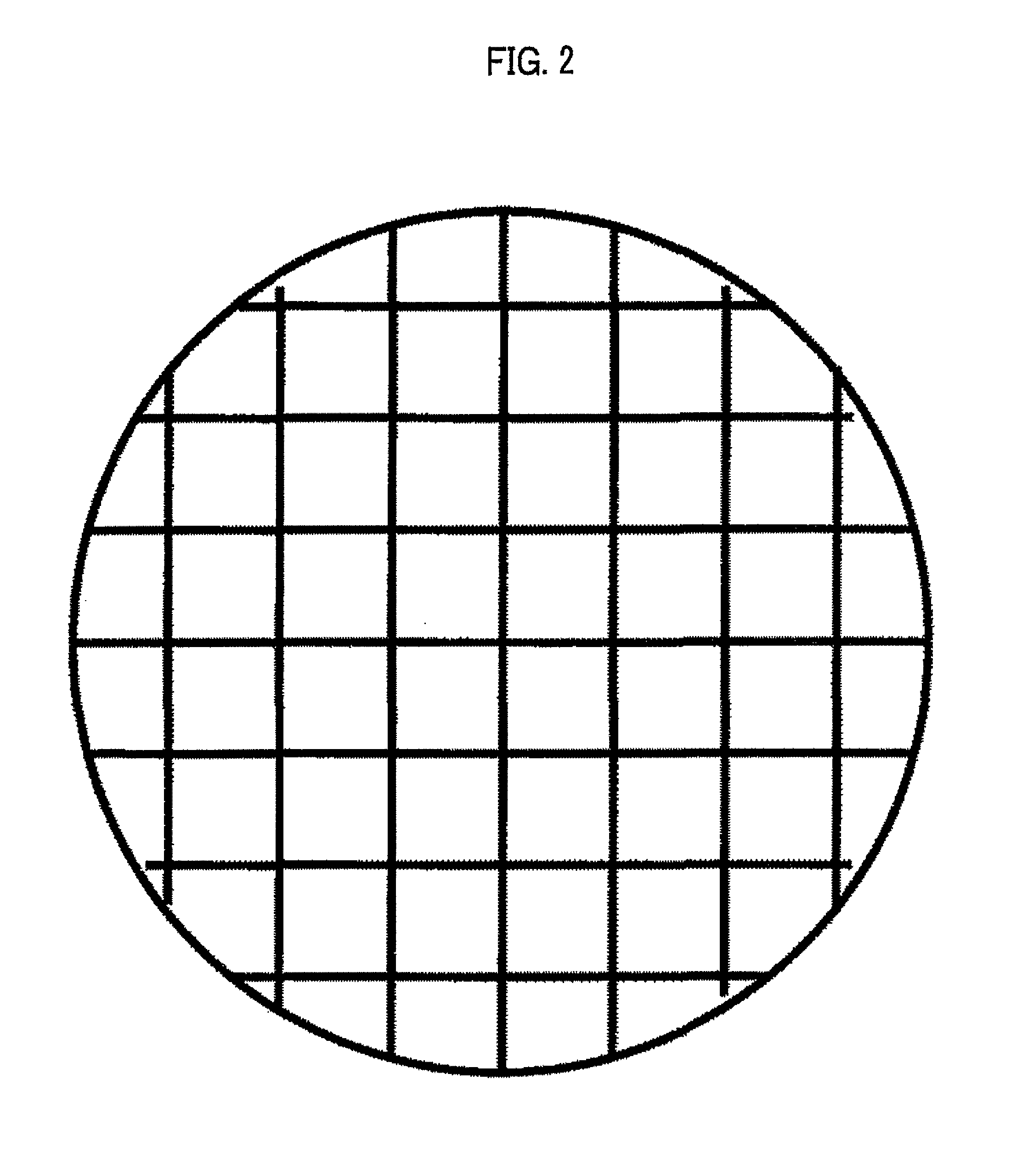

Processing device using shower head structure and processing method

InactiveUS7615251B2Improve throughputImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSquare Shape

A processing device, comprising a processing container, a shower head structure provided at the ceiling part of the processing container and having a plurality of gas jetting holes for jetting specified processing gas into the processing container formed in the gas jetting surface thereof facing the inside of the processing container, and a placing stand disposed in the processing container so as to face the shower head structure, wherein a head distance between the gas jetting surface and the placing stand and the blowing speed of gas from the gas jetting holes are set within the range surrounded by connecting, in a square shape with straight lines in a plane coordinate system having the head distance plotted on an abscissa and the gas jetting speed plotted on a coordinate, a point where the blowing speed of the gas from the gas jetting holes at the head distance of 15 mm is 32 m / sec, a point where the blowing speed of the gas from the gas jetting holes at the head distance of 15 mm is 67 m / sec, a point where the blowing speed of the gas from the gas jetting holes at the head distance of 77 mm is 40 m / sec, and a point where the blowing speed of the gas from the gas jetting holes at the head distance of 77 mm is 113 m / sec.

Owner:TOKYO ELECTRON LTD

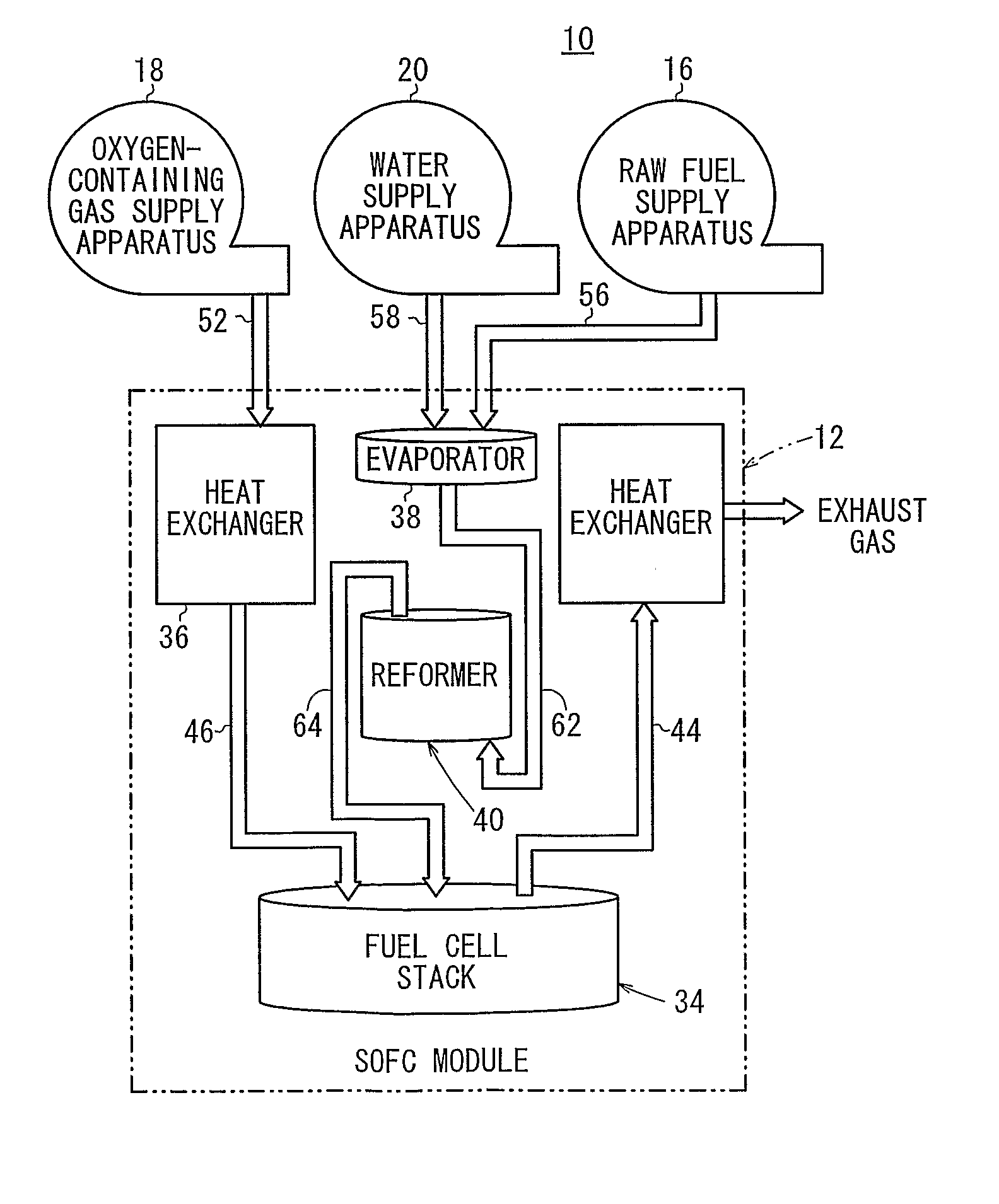

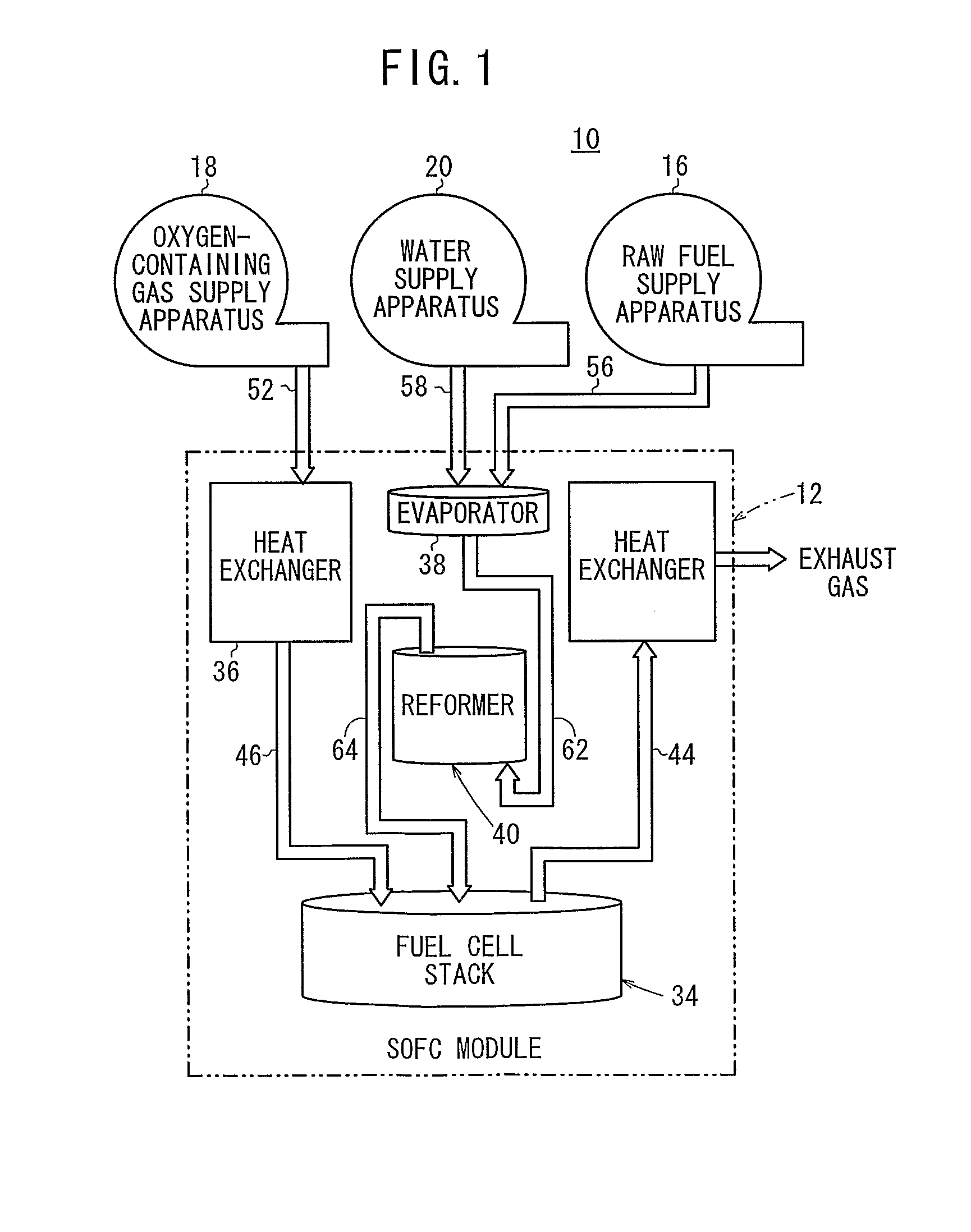

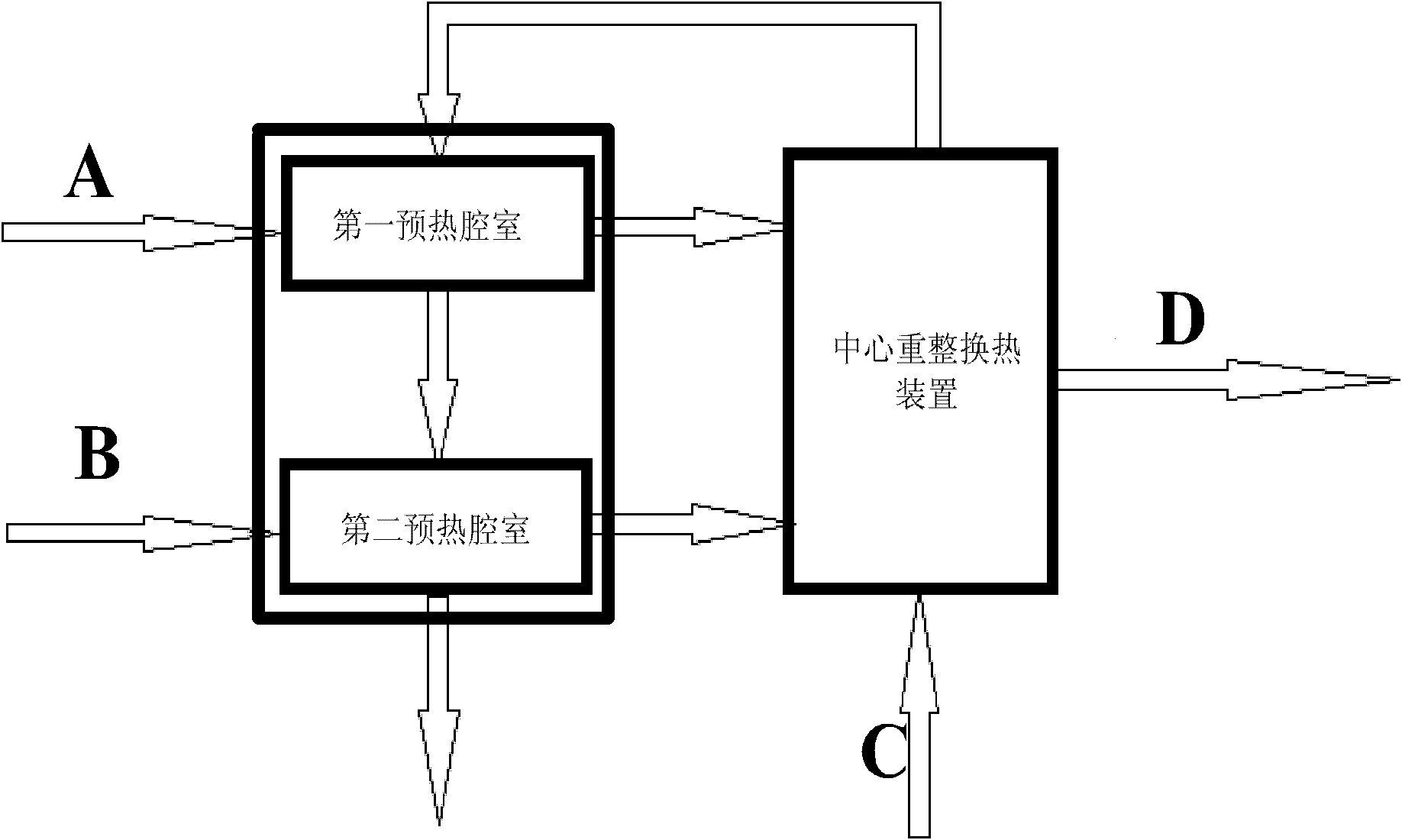

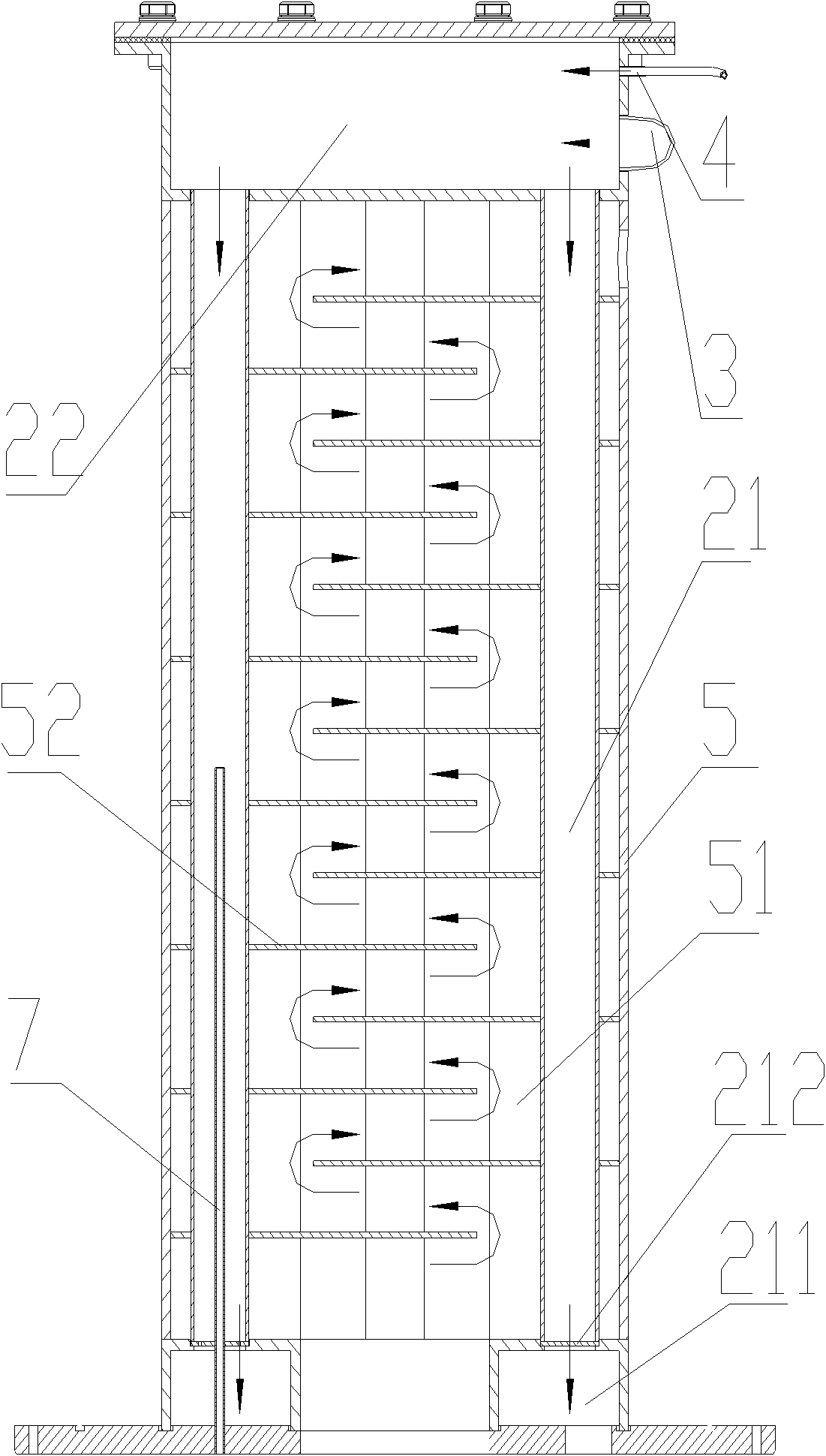

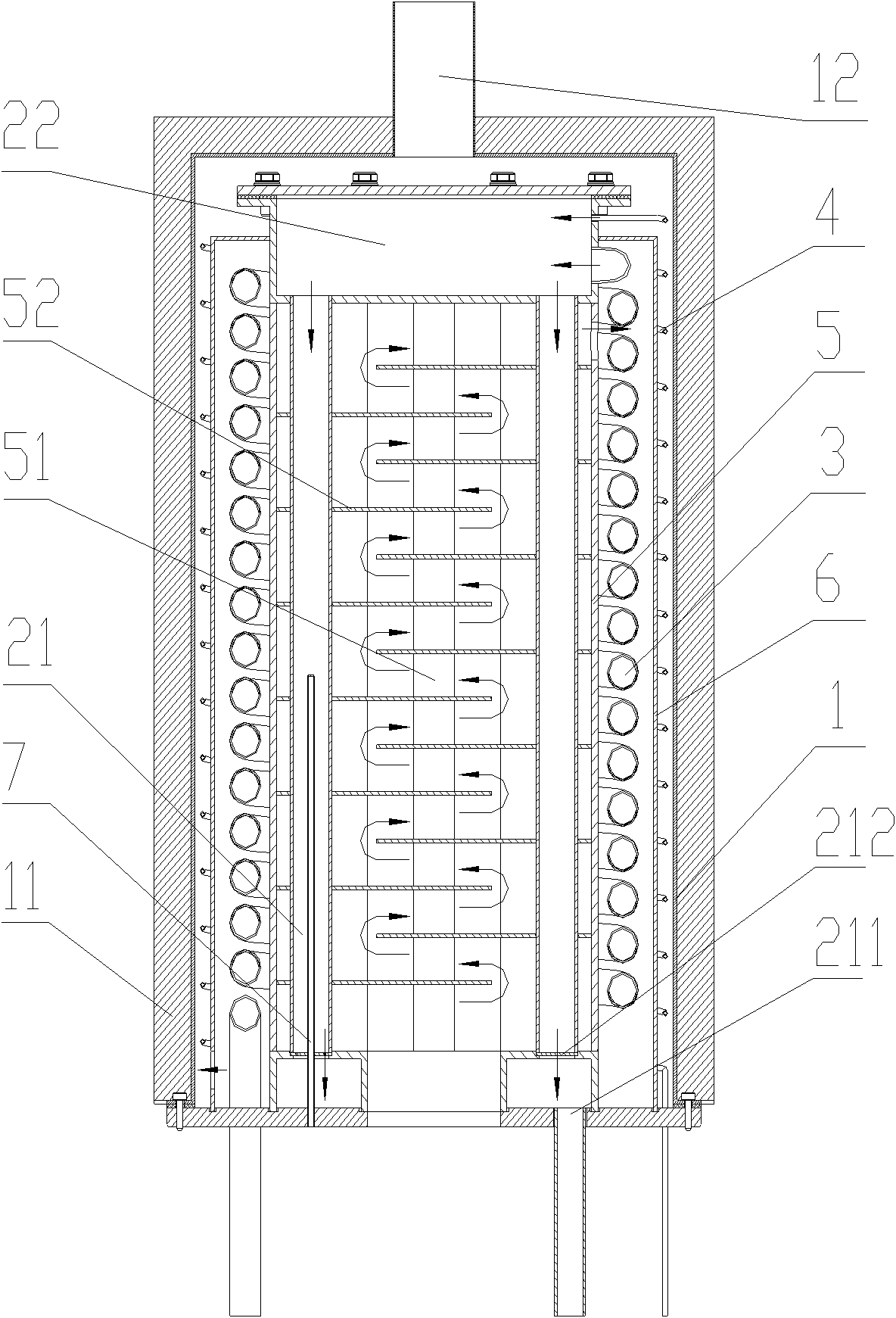

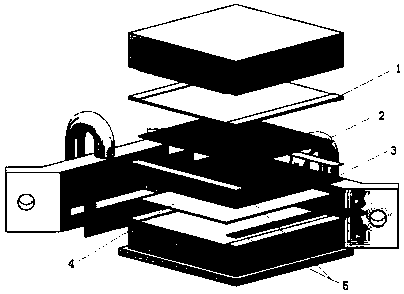

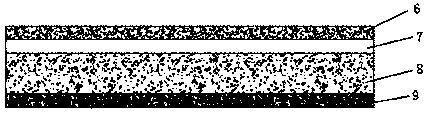

Solid oxide fuel cells power generating system and methane vapor reforming unit thereof

ActiveCN102723514AHigh reforming efficiencyTo achieve the purpose of warming upFuel cell heat exchangeSolid electrolyte fuel cellsProcess engineeringOxide

The invention discloses a methane vapor reforming unit, comprising a reforming heat exchange apparatus, a methane conveyer pipe and a vapor conveyer pipe, and a preheating chamber. The reforming heat-exchange apparatus comprises a reforming chamber and a high temperature channel. The methane conveyer pipe and the vapor conveyer pipe are communicated with the reforming chamber and pass through the preheating chamber. The high temperature channel passes through the reforming chamber. The methane vapor reforming unit also has a preheating chamber. The preheating chamber can preheat the methane and the vapor needed for the reforming, thereby shortening the time of heating the methane and the vapor in the reforming chamber and enabling the methane and the vapor in the methane vapor reforming unit to have relatively higher reforming efficiency.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

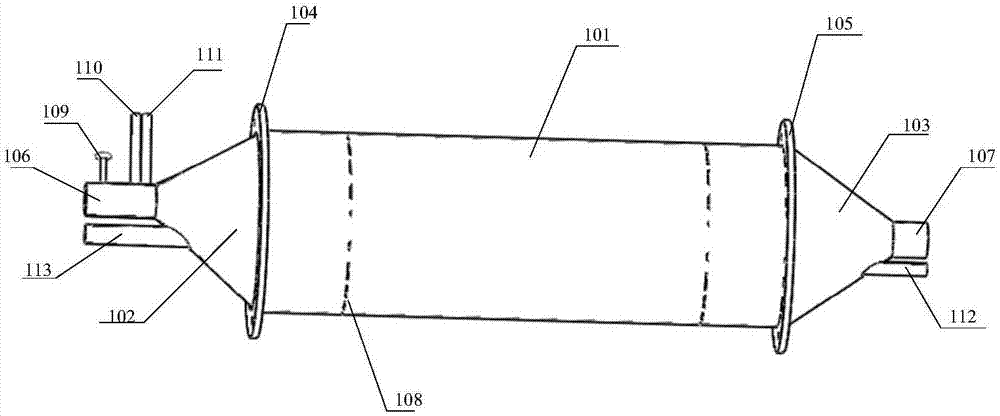

Oxidative Autothermal Reformer and Oxidative Autothermal Reforming Method Using the Same

InactiveUS20090158659A1Heat transfer area be enlargeQuickly transfer heatPhysical/chemical process catalystsCarburetting gasesChemistryAliphatic alcohol

This invention relates to an oxidative autothermal reformer (1) comprising a reforming layer (2) at least partially filled with a reforming catalyst for producing a reformed gas composed mainly of hydrogen through a reforming reaction by contacting a mixture of a hydrocarbon or an aliphatic alcohol and steam with the reforming catalyst; and an oxidative exothermic layer (3) at least partially filled with an oxidation catalyst for generating heat by oxidizing a part of the reformed gas, in which the reforming layer (2) is disposed at an upstream side of the oxidative exothermic layer (3); the reforming layer (2) and the oxidative exothermic layer (3) are in the form of a cylinder and have a triple circular tube structure formed by disposing an inner reforming layer (2A), an oxidative exothermic layer (3) and an outer reforming layer (2B) from the inside in a radical direction in this order; and at least a part of the reforming catalyst filled in the inner reforming layer (2A) and the outer reforming layer (2B) contains Ru metal.

Owner:JAPAN ENERGY CORP +1

Internal reforming solid oxide fuel cell stack

InactiveCN110600776AHigh reforming efficiencyReduce anode carbon deposition problemFuel cellsStructural unitAirflow

The invention particularly relates to an internal reforming solid oxide fuel cell stack. The fuel cell stack comprises a galvanic pile which is formed by stacking a plurality of structural units, an airflow buffer cavity which is located around the galvanic pile, and end plates which are located on the upper side and the lower side of the galvanic pile; each structural unit comprises a cathode airflow distribution plate, a connecting body, an anode airflow distribution plate and a single battery which are sequentially and tightly attached together; and a reforming catalytic material is impregnated on the anode airflow distribution plate. According to the invention, the reforming catalytic material is impregnated on the surface of the anode gas flow distribution plate, the steam and desulfurized natural gas are preheated and then directly introduced into the galvanic pile, the reforming reaction of the gas is completed before the gas enters the anode reaction area, the reforming catalytic material can accelerate the reforming efficiency, the problem of anode carbon deposition can be effectively reduced, and the whole system is simplified.

Owner:武汉华科福赛新能源有限责任公司

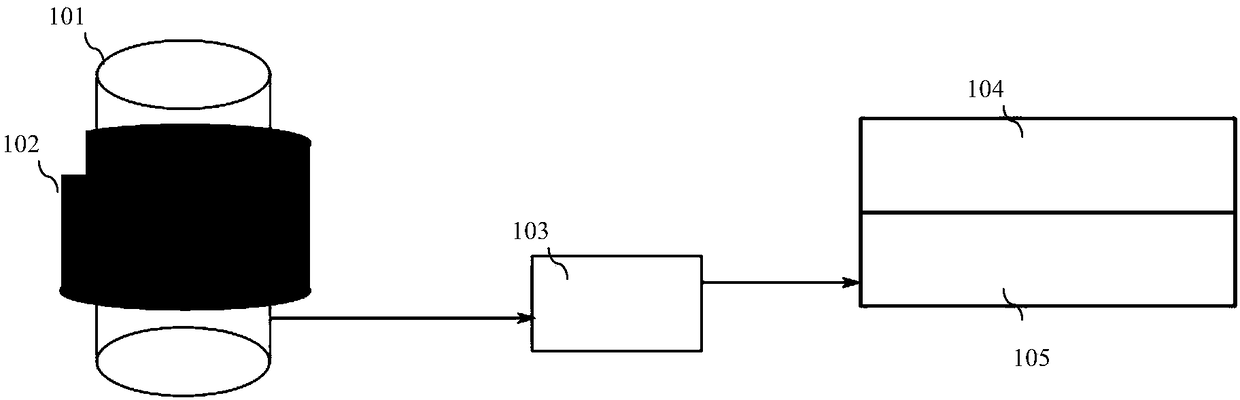

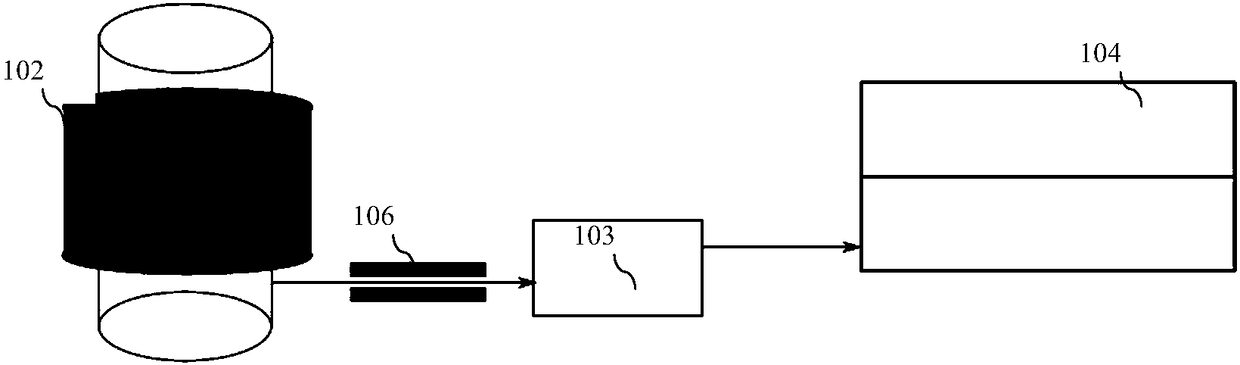

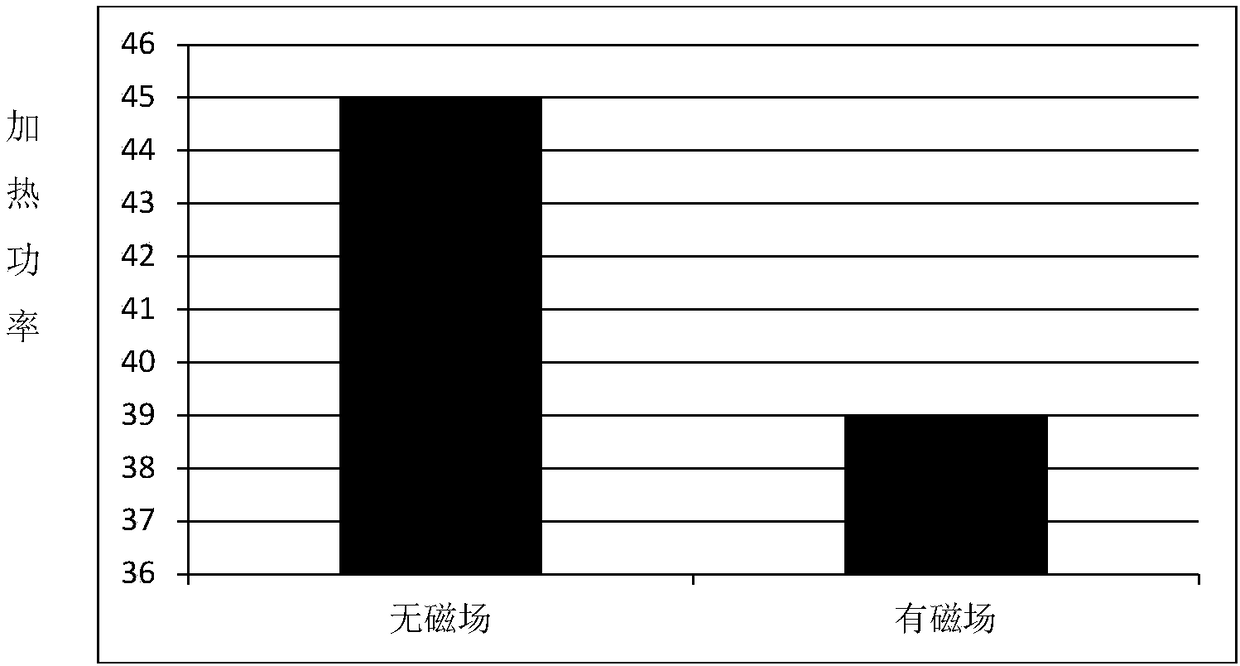

Fuel reforming reactor

ActiveCN108232253AChange intensityImprove reasonable distributionFuel cellsHydrogenNuclear engineering

A fuel reforming reactor comprises a fuel tank, a fuel vaporizing chamber and a fuel reforming chamber, wherein an outlet of the fuel tank is communicated with an inlet of the fuel vaporizing chamber;an outlet of the fuel vaporizing chamber is communicated with an inlet of the fuel reforming chamber; the fuel tank and / or the fuel vaporizing chamber are / is magnetic. Compared with the prior art, the fuel reforming reactor provided by the invention has the advantages as follows: through introduction of a magnetic material onto the fuel tank, the fuel vaporizing chamber and a connecting pipelineof the two, the strength of hydrogen bonds in fuel and water is changed, heat absorbed by the fuel and water in the vaporizing process is reduced, and reasonable distribution of the heat in the fuel reforming process is improved, and the reforming efficiency is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

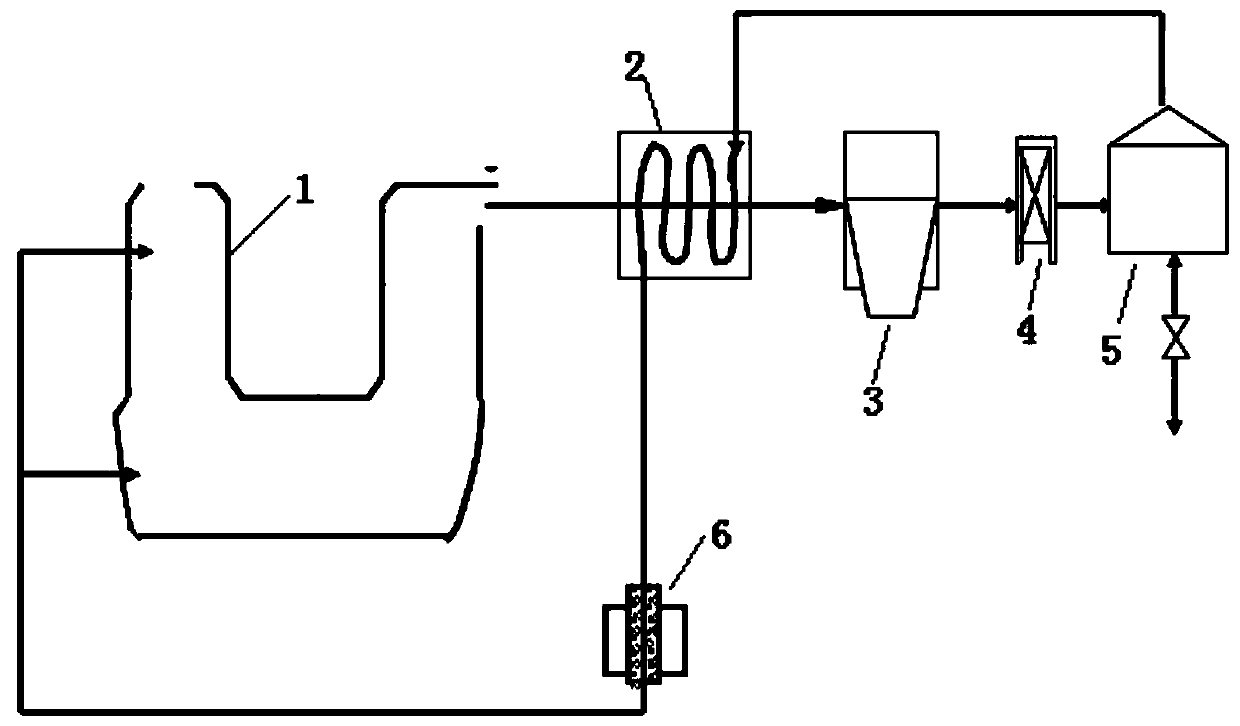

Flash circulation smelting system constructed based on high-temperature heat exchanger

PendingCN111519029ARealize heat exchangeStable jobIncreasing energy efficiencyCombustible gas purificationProcess engineeringHeat energy

The invention provides a flash circulation smelting system constructed based on a high-temperature heat exchanger. The flash circulation smelting system comprises a coal gas main pipeline, the coal gas main pipeline comprises flash metallurgical equipment, a hot-medium flow pass of the high-temperature heat exchanger, dust-removal desulfurization equipment, a fan, gas-storage and pressure-regulating equipment, a cold-medium flow pass of the high-temperature heat exchanger and coal gas reforming equipment which communicate in sequence through pipelines, and a reduced coal gas outlet of the coalgas reforming equipment is connected with a reduced gas inlet of the flash metallurgical equipment through a pipeline. The flash circulation smelting system constructed based on the high-temperatureheat exchanger is a closed-loop system, and net-zero emission of carbon dioxide is achieved; and meanwhile heat energy and chemical energy of high-temperature discharged smoke of the flash metallurgical equipment are recycled, and comprehensive energy consumption of the system is lowered.

Owner:TIANJIN FLASH IRONMAKING TECH CO LTD

Engine system with reformer

InactiveUS8596231B2Improve combustionIncrease heatHydrogenInternal combustion piston enginesCombustion chamberFuel supply

Disclosed is an engine system with a reformer, the engine system comprising a reformer and driving an engine using, as a fuel, a reformed fuel produced by reforming pre-reformed fuel with the reformer, in which the reformer is connected with both a pre-reformed fuel supply adjustment unit which adjusts the amount of the pre-reformed fuel supplied to the reformer and a reformed fuel supply adjustment unit which adjusts the amount of reformed fuel supplied to the engine, and the reformer is installed adjacent to the engine combustion chamber via the reformed fuel supply adjustment unit.

Owner:HITACHI LTD

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604BImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energThe invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises thy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controllede following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas isone by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas isin contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generatin contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearinion, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-savig pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.ng environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com