Waste gas-fuel reforming and recycling natural gas engine system and control method

An engine system and recirculation technology, which is applied to combustion engines, internal combustion piston engines, charging systems, etc., can solve problems such as increased CO and HC emissions, increased cycle fluctuations, and unstable combustion, to reduce the combustion temperature in the cylinder , reduce volume, widen the effect of lean burn limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

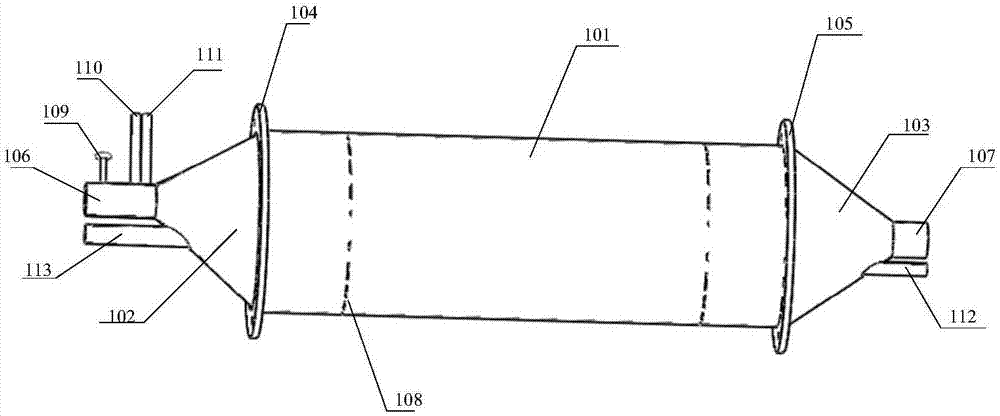

[0044] Such as figure 1 , figure 2 The exhaust gas-fuel reforming recirculation natural gas engine system shown includes an engine 200, a fuel supply device 203 provided in the engine 200 to supply fuel to the engine 200, a gas tank 201 supplied to the fuel supply device 203, a reformer 100 and a central Cooler 206. combine image 3 As shown, the reformer 100 includes a cylindrical reaction shell 101, a hollow front cover 102 fixedly installed on the front end of the cylindrical reaction shell 101 through a front connecting flange 104, and a rear end of the cylindrical reaction shell 101 fixedly installed through a rear connecting flange 105. The hollow rear end cover 103, the intake pipe 106 installed in the air inlet 102a at the central position of the hollow front end cover 102, the waste gas exhaust pipe 107 installed at the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com