Drag reducing agent for fracturing fluid and preparation method thereof, fracturing fluid suitable for shale gas fracturing

A technology of drag reducing agent and fracturing fluid, applied in the field of oil field fracturing, can solve the problems of large formation damage, high residue amount, high cost of foam fracturing fluid, construction safety, etc., to reduce pollution, reduce waste, and sand-carrying performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolving 0.7-1.3 parts by weight of acrylamide and 0.7-1.5 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid in 1 part by weight of deionized water to prepare an aqueous phase;

[0025] Add 0.1:-0.3 parts by weight of perfluoroacrylate, 0.1-0.3 parts by weight of Tween 80 and 0.1-0.3 parts by weight of OP-10 to 1 part by weight of white oil to form an oil phase;

[0026] Proportioning 1 part by weight of the above-mentioned water phase with 0.3-0.8 parts by weight of the oil phase, and fully mixing to form a stable water-in-oil inverse emulsion base liquid;

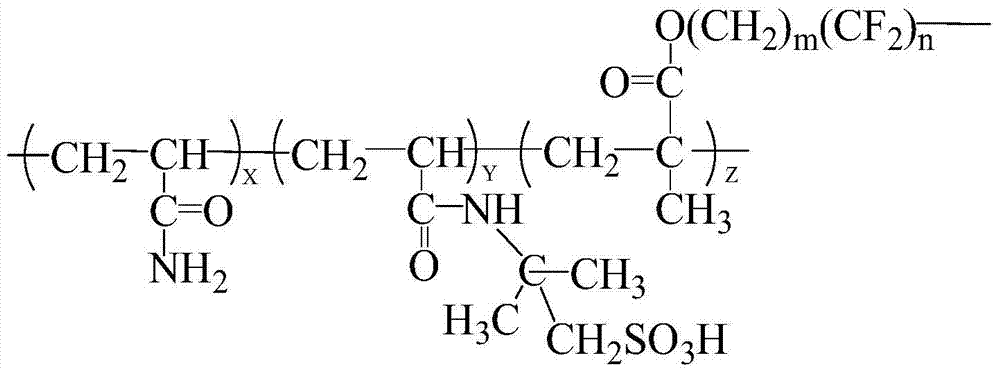

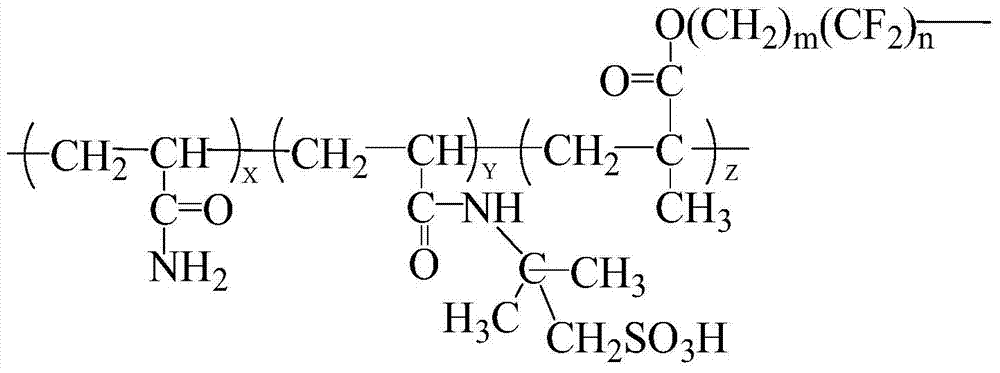

[0027] Utilize the initiator to carry out catalytic initiation, and finally synthesize the drag reducing agent with the following molecular formula:

[0028]

[0029] In the above formula, X, Y, and Z are integers, m is an integer of 3-6, and n is an integer of 2-4.

[0030] Wherein the initiator is ammonium persulfate.

[0031] The drag reducing agent of the embodiment of the present invention ha...

Embodiment 2

[0033] The fracturing fluid suitable for shale gas fracturing, the weight percentage of each component is as follows: 0.1% drag reducing agent, 0.3% drainage aid (ADB-1), 0.5% clay stabilizer (AND-1 ) and 0.05% fungicide (ADS-1). The drag reducing agent is the drag reducing agent of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com