Multilevel-control polyradical biomass-gasification energy regeneration system

A renewable energy and free radical technology, applied in biofuels, energy input, special forms of dry distillation, etc., can solve the problems of low reforming efficiency of syngas, difficult control of pyrolysis reactions, and pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

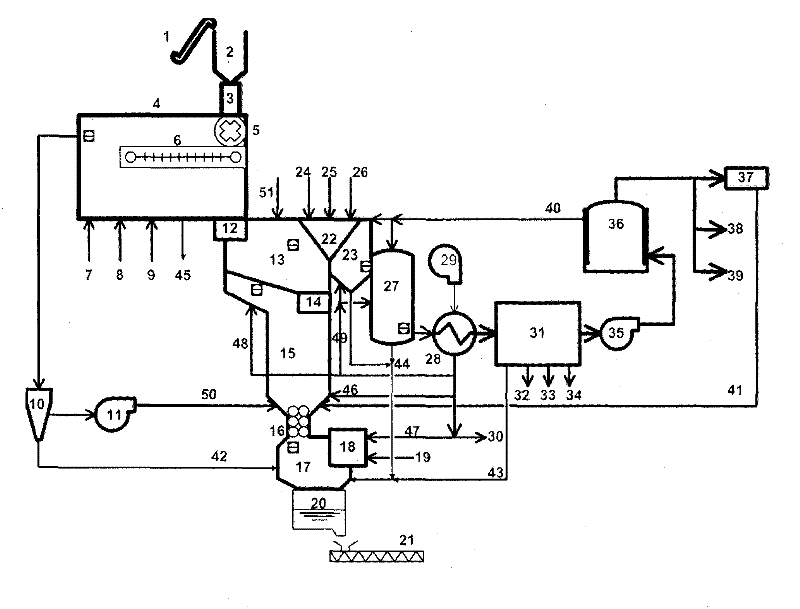

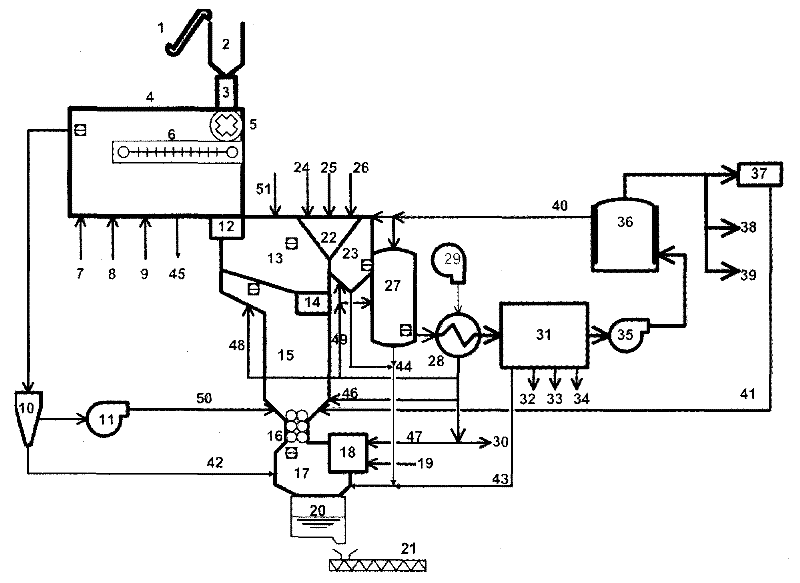

[0053] The multi-stage controlled free radical biomass gasification renewable energy system can convert a wide range of biomass and carbonaceous raw materials, including energy crops, agricultural and forestry by-products and wastes, organic wastes, industrial and hazardous wastes, etc., into high-grade energy.

[0054] For solid materials with common characteristics, such as firewood, straw or municipal solid waste, the normal process sends the solid materials directly to the pretreatment device 4, and after being processed by the pretreatment device 4, enters the pyrolysis gasification unit 13 to complete pyrolysis and gasification , the residual carbon is completely gasified in the carbon conversion unit 15, the ash enters the melting unit 17 and is completely melted into a molten slurry, passes through the pressurized quencher 20, and is finally discharged in the form of solidified slag. The generated gas passes through the melting unit 17, the carbon conversion unit 15, the ...

Embodiment 2

[0057] This example comes from a 5MW biomass gasification power generation system, the feed amount is ~100 tons / day, and air is used as the working gas. The material source composition is complex with a calorific value of 13 ~ 16MJ / kg and a humidity of 35% ~ 45%. The biomass raw material is gasified and purified, and supplied to seven 750kW gas-fired generator sets.

[0058] The material will complete the drying process in the fully enclosed pretreatment device 4 until the humidity of the material is less than 5%, and then sent to the pyrolysis gasification unit 13 . After the moisture evaporated in the drying process is sucked out, after being dedusted by the dust collector 10 , it enters the bottom of the carbon conversion unit 15 . The external heat source used in the drying process is mainly low-temperature waste heat generated in the downstream energy utilization process, including: steam heat source 7,150-180°C, indirectly heating materials; preheating low-temperature ai...

Embodiment 3

[0066] The present invention is equipped with an advanced gasification control system, for each sub-step process of gasification, each interconnected independent reaction unit: pretreatment, pyrolysis, carbon conversion, ash melting, accelerated reaction of polyfree radicals, synthesis gas reforming, waste heat utilization , finely controlled and integrated one by one to achieve optimization. For the complexity of biomass material characteristics, the control system can automatically optimize operating parameters according to material characteristics and actual working conditions. Simultaneous operation also includes a gasification process simulator, which has a huge database of tens of thousands of various types of raw materials and related chemical reactions. The simulator's unique performance, predictive capabilities are used in conjunction with the control system. Higher-level, finer-grained, and more comprehensive control can be achieved.

[0067] The main gasification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com